Professional Documents

Culture Documents

NSTP

Uploaded by

Paula BacaranOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NSTP

Uploaded by

Paula BacaranCopyright:

Available Formats

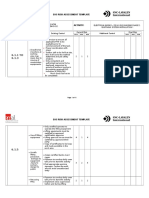

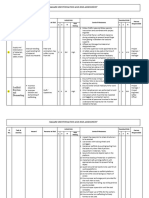

ACTIVITY 1:

Truckyard

SR# Job Hazards Existing Control L C R Control L C R

R R

1 Incomplete Receive Cargo Make clear

cargo information communication

information due with the personnel

to lack of in order to avoid

resource miscommunicatio

n

2 Defects in the Inspecting the Make an

truck or truck and inspection before

equipment equipment hipping out the

products to

determine the

faults

3 Unauthorized Securing work Must establish

personnel in area clear boundaries

work area and communicate

well with workers

4 Hazardous Inspecting cargo Conduct a

damaged hazards thorough

materials inspection for

each cargo to

secure safety

5 Collisions, or Operating loading Conduct a

trip overs equipment’s thorough

inspection for

each cargo to

secure safety

6 Serious injuries Lifting and Train the workers

such as positioning cargo how to lift properly

musculoskeletal to avoid any

injuries from accidents

improper lifting

7 Unsecured Securing cargo for Follow the

cargo could transit industry standard

lead to wrong security and make

shifting transits sure to double

check all the

cargo

8 Communicate Miscommunication Always make a

with the truck could lead to clear

drivers errors communication

with the truck

drivers

9 Manage traffic Disorganized Train personnels

within the traffic flow to manage traffic

truckyard properly rather

than bursting out

and causing

problems

10 Document and Inaccurate Keep a record in

make a record documentation order to

accurately modify

all the cargo and

be aware of the

whole process

Factory

SR# Job Existing L C R Control L C R

hazards control R R

1 Strains from Gather Provide

lifting heavy components proper training

components for lifting

techniques

2 Crush Assembling Provide

injuries from components training for

machinery workers to

avoid

accidents

3 Electric Use power Provide

shock tools proper training

on tool to

avoid

incidents with

the use of

power tools

4 Exposure to Handling Implement

chemical hazardous proper

materials materials storage of

materials to

avoid

accidents

5 Serious Inspect Provide a

injuries finished regular breaks

products to reduce

strain workers

6 Cuts from Package Must pack the

unpacked finished package well

well products to avoid cuts.

package Workers also

must wear

protective

gloves.

7 Incidents in Transporting Proper lifting

handling finished techniques

materials products must be

taught to the

workers to

avoid accident

8 Accidents or Operate Provide

tip-overs forklifts proper training

to establish

designated

traffic lanes

9 Fall or slip Clean work Maintain the

accidents area workplace

clean to avoid

accidents

10 Errors Document Keep a record

and make a in order to

record accurately

modify all the

cargo and be

aware of the

whole process

ACTIVITY 2

JOB SAFETY ANALYSIS: COOKING BREAKFAST – RICE AND HOTDOG MEAL

SEQUENCE OF TASKS POTENTIAL HAZARDS PREVENTIVE

MEASURES

1. Gathering falls and trips as a result of Make sure the surface is

Ingredients and messy or slick kitchen dry and clean, tidy the

utensils surfaces kitchen, and arrange the

ingredients and equipment

ahead of time.

2. Food preparation Cuts or injuries from knives Maintain sharp knives, use

and cutting and kitchen tools. appropriate cutting

techniques, and be mindful

of where your hands are

placed. To save counters

from being damaged, use

a cutting board.

3. Cooking rice on burns from steam and hot When handling hot

the stove surfaces. equipment, use pot holders

or oven mitts, stay a safe

distance away from steam,

and open lids carefully to

let out steam.

4. Frying hotdogs on Burns from splashing and When frying, employ a

the stove hot oil. splatter guard, exercise

caution around hot oil, and

use long-handled tools to

prevent reaching too close

to the hot surface.

5. Serving and burns from spills and hot When serving hot food,

plating meal dishes. wear oven mitts, let dishes

cool slightly before

handling, and take care

around hot surfaces when

plating.

You might also like

- 04.unloading of MaterialsDocument6 pages04.unloading of MaterialsKiran ChenchalaNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- Carefour RA-For Tile & Granite WorksDocument10 pagesCarefour RA-For Tile & Granite Worksfaizan khan100% (3)

- Lifting Operation BNQDocument2 pagesLifting Operation BNQsathiamurti100% (1)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- Carefour RA-For Block Works and Plastering WorksDocument17 pagesCarefour RA-For Block Works and Plastering Worksfaizan khanNo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Job Hazard Analysis For Filtration Job)Document3 pagesJob Hazard Analysis For Filtration Job)Chibuzor Samuel100% (1)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- 005 SWMS - Peb ErectionDocument12 pages005 SWMS - Peb Erectionsasi kumar100% (1)

- Maha VastuDocument42 pagesMaha VastuAayush K100% (1)

- Commercial Kitchen Hood Design Guide 1 031504Document21 pagesCommercial Kitchen Hood Design Guide 1 031504Edgie LiningNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Risk Assessment SD Sliding DoorDocument7 pagesRisk Assessment SD Sliding DoorDarius AdeNo ratings yet

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- Flushingchemical Cleaning of Chilled Water PipesDocument9 pagesFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanNo ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningNo ratings yet

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Joseph Brodsky - A Room and A HalfDocument5 pagesJoseph Brodsky - A Room and A Halfkottzebue0% (1)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisNishar BalkavadeNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Hazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- SMX PDFDocument13 pagesSMX PDFlawkarl13No ratings yet

- Designhouse Digital BrochureDocument33 pagesDesignhouse Digital BrochureJaimasaNo ratings yet

- Period Ideas - June 2012 PDFDocument132 pagesPeriod Ideas - June 2012 PDFChapaliNo ratings yet

- JHA HondaDocument2 pagesJHA HondaJaycee QuinNo ratings yet

- Hirarc ScaffoldDocument2 pagesHirarc ScaffoldArinaAhmad100% (1)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- EDITED Q1-Cookery-Module-LESSON-02 Measuring-Tools-and-EquipmentDocument5 pagesEDITED Q1-Cookery-Module-LESSON-02 Measuring-Tools-and-EquipmentMay Ann GuintoNo ratings yet

- Fire HazardDocument12 pagesFire HazardJessa CapangpanganNo ratings yet

- 07 SWMS - Material Loading and UnloadingDocument6 pages07 SWMS - Material Loading and UnloadingPRIYESH . K. PRIYANNo ratings yet

- Plant and Traffic MovementDocument5 pagesPlant and Traffic MovementALTHAF HUSSAINNo ratings yet

- Practical Performance FileDocument13 pagesPractical Performance FileA royNo ratings yet

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- New Job Hazard Analysis (JHA) Hot Water Geyser InstallationDocument2 pagesNew Job Hazard Analysis (JHA) Hot Water Geyser Installationwaqar naeemNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- SWP 12 ForkliftOperation PDFDocument1 pageSWP 12 ForkliftOperation PDFAndre Santos SantosNo ratings yet

- Inbound 5425125211198410005Document3 pagesInbound 5425125211198410005Rabeh BàtenNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- SINOPEC-006-JSA Maintenance of Board Engine in Camp - Rev 0 (Aproved)Document3 pagesSINOPEC-006-JSA Maintenance of Board Engine in Camp - Rev 0 (Aproved)Marlen MunsyNo ratings yet

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchDocument6 pagesGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiNo ratings yet

- Risk Assessment and ControlDocument8 pagesRisk Assessment and Controlanand.v4491No ratings yet

- 7 Pillars of Spill ManagmentDocument1 page7 Pillars of Spill ManagmentAndy Mdl100% (2)

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- Baseline Risk Assessment (Bra)Document8 pagesBaseline Risk Assessment (Bra)aceNo ratings yet

- Risk Assessment ForDocument8 pagesRisk Assessment ForHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Safety Action PlanDocument2 pagesSafety Action PlanzaidoNo ratings yet

- Hazard Identification & Risk AssessmentDocument8 pagesHazard Identification & Risk Assessmentanand.v4491No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Health Safety Compliance Evaluation Checklist.Document19 pagesHealth Safety Compliance Evaluation Checklist.SAKTHIVEL NATARAJANNo ratings yet

- MX BrochureDocument2 pagesMX BrochureTríade MusicNo ratings yet

- Inter Tank Transfers - SWPDocument5 pagesInter Tank Transfers - SWPPriince MogomotsiNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Hazard Identification Plan: Sulayyil Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00612-0001Document7 pagesHazard Identification Plan: Sulayyil Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00612-0001Darius DsouzaNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- IELTS Speaking Mock Test 101Document7 pagesIELTS Speaking Mock Test 101BadaradaBistuberryNo ratings yet

- Steelhead Community Hall Hall LayoutDocument2 pagesSteelhead Community Hall Hall Layoutshubham kumarNo ratings yet

- Western Vs IndianDocument1 pageWestern Vs IndianDeep DenNo ratings yet

- Product Training Presentation - Kitchen AccessoriesDocument18 pagesProduct Training Presentation - Kitchen AccessoriesCharan ReddyNo ratings yet

- The Seasons Residences Haru Floor PlanDocument6 pagesThe Seasons Residences Haru Floor PlanJulianDayritNo ratings yet

- Yamuna Apartments: (Alaknanda)Document34 pagesYamuna Apartments: (Alaknanda)SakthiPriya NacchinarkiniyanNo ratings yet

- 2018 Greenville Parade of Homes GDRSS-042518Document32 pages2018 Greenville Parade of Homes GDRSS-042518Adams Publishing Group Eastern North CarolinaNo ratings yet

- York Region Properties Winter 2009Document60 pagesYork Region Properties Winter 2009denniston8462No ratings yet

- Mantra E-Brochure PDFDocument14 pagesMantra E-Brochure PDFAryan TyagiNo ratings yet

- Classified 2014 12 22 000000Document8 pagesClassified 2014 12 22 000000sasikalaNo ratings yet

- G12 Housekeeping Week1Document17 pagesG12 Housekeeping Week1Liza Laith LizzethNo ratings yet

- MDM Annual FormatDocument2 pagesMDM Annual Formathindunational102045No ratings yet

- Condominium Space ProgDocument28 pagesCondominium Space ProgBeiya MaeNo ratings yet

- Supertech ORBDocument9 pagesSupertech ORBGreen Realtech Projects Pvt LtdNo ratings yet

- Kitchen Equipment - Utility Data SheetDocument3 pagesKitchen Equipment - Utility Data Sheetmilindskulkarni2005@yahoo.co.inNo ratings yet

- WVSU Cafeteria's Catering Services: Happy Tummy or Not?Document9 pagesWVSU Cafeteria's Catering Services: Happy Tummy or Not?bradabonadoNo ratings yet

- Defined as the ancient art of Chinese placement مهمDocument55 pagesDefined as the ancient art of Chinese placement مهمAmr ElDisoukyNo ratings yet

- Inglés Módulo A2Document16 pagesInglés Módulo A2Nagely VillonNo ratings yet

- Adaptable Housing or Adaptable People - BeisiDocument24 pagesAdaptable Housing or Adaptable People - BeisiGustavo GarciaNo ratings yet

- IKEA Small Business 2010 Great Britian - EnglishDocument15 pagesIKEA Small Business 2010 Great Britian - Englishkarisma_bsNo ratings yet

- Detailed Lesson Plan - PANGALAYA - 4Document6 pagesDetailed Lesson Plan - PANGALAYA - 4Rose Ann MadenancilNo ratings yet

- Sdoc 08 18 SiDocument18 pagesSdoc 08 18 SiMyFullNo ratings yet