Professional Documents

Culture Documents

Turbine Engine Assignment1

Uploaded by

jamostkolwanlohOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbine Engine Assignment1

Uploaded by

jamostkolwanlohCopyright:

Available Formats

1.

Fixed Pitch Propeller: As the name implies, a fixed-pitch propeller has the blade pitch, or blade

angle, built into the propeller. The blade angle cannot be changed after the propeller is built.

Generally, this type of propeller is one piece and is constructed of wood or aluminum alloy.

Fixed-pitch propellers are designed for best efficiency at one rotational and forward speed. They

are designed to fit a set of conditions of both airplane and engine speeds and any change in

these conditions reduces the efficiency of both the propeller and the engine. The fixed-pitch

propeller is used on airplanes of low power, speed, range, or altitude. Many single-engine

aircraft use fixed-pitch propellers and the advantages to these are less expense and their simple

operation. This type of propeller does not require any control inputs from the pilot in flight.

Advantages:

• Simple and cost-effective

• Easy to maintain and repair.

• Reliable design

• Lower cost compared to other types.

Disadvantages:

• Lack of adjustability limits performance across different flight conditions.

• Less efficient compared to variable pitch propellers.

2. Ground Adjustable Propeller: The ground-adjustable propeller operates as a fixed-pitch

propeller. The pitch, or blade angle, can be changed only when the propeller is not turning, its

blade pitch is adjustable on the ground, not in flight. This is

done by loosening the clamping mechanism that holds the

blades in place. After the clamping mechanism has been

tightened, the pitch of the blades cannot be changed in flight to

meet variable flight requirements. The ground-adjustable

propeller is not often used on present-day airplanes.

Advantages:

• Allows optimization for specific flight conditions.

• Flexibility to adjust the propeller’s characteristics as needed.

• Offers better efficiency over a wider range of speeds when compared to fixed-pitch propellers.

Disadvantages:

• Requires ground adjustments, which may be time-consuming.

• Limited adjustability compared to controllable pitch or constant-speed propellers.

3. Controllable Pitch Propeller: The controllable-pitch propeller permits a change of blade pitch, or

angle, while the propeller is rotating. This allows the propeller to assume a

blade angle that gives the best performance for particular flight conditions.

The number of pitch positions may be limited, as with a two-position

controllable propeller, or the pitch may be adjusted to any angle between

the minimum and maximum pitch settings of a given propeller.

The use of controllable-pitch propellers also makes it possible to attain the

desired engine rpm for a particular flight condition. With the controllable-

pitch type, the blade angle can be changed in flight, but the pilot must change the propeller

blade angle directly. The blade angle will not change again until the pilot changes it.

Advantages:

• Offers better performance across different flight conditions.

• Allows the pilot to adjust the propeller’s characteristics as needed.

• Enables efficient engine power management.

Disadvantages:

• More complex and expensive compared to fixed pitch propellers.

• Requires regular maintenance and adjustment.

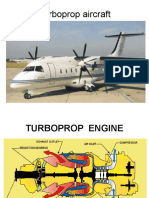

4. Constant-Speed or Automatic Propeller: Constant-speed, also known as automatic, propellers

maintain a constant rotational speed regardless of the engine load or

aircraft speed. These propellers use a governor system to automatically

adjust the blade angle and maintain a consistent RPM. Constant-speed

propellers are predominantly used in larger aircraft with piston engines

and most turboprop engines.

Advantages:

• Automatically adjusts to maintain optimal engine RPM for various flight conditions.

• Provides efficient power management.

• Reduces workload for the pilot.

Disadvantages:

• Complex and expensive.

• Requires regular maintenance and inspection.

5. Reversible Pitch Propeller: A reverse-pitch propeller is a controllable propeller in which the

blade angles can be changed to a negative value during operation. The purpose of the reversible

pitch feature is to produce a negative blade angle that

produces thrust opposite the normal forward direction.

Normally, when the landing gear is in contact with the

runway after landing, the propellers blades can be

moved to negative pitch (reversed), which creates thrust

opposite of the aircraft direction and slows the aircraft.

As the propeller blades move into negative pitch, engine

power is applied to increase the negative thrust. This

aerodynamically brakes the aircraft and reduces ground roll after landing. Reversing the

propellers also reduces aircraft speed quickly on the runway just after touchdown and

minimizes aircraft brake wear. It is primarily used in turboprop engines.

Advantages:

• Enhances braking performance during landing, reducing the required runway length.

• Allows for better control during ground operations, reducing the need for wheel brakes.

Disadvantages:

• Adds complexity and weight to the propeller system.

• Requires additional maintenance.

• Reduced Speed

• Increased Weight

6. Feathering Propeller: Feathering propellers are designed to minimize drag and windmilling

effects during an engine failure or shutdown. When feathered, the blades

align with the airflow, reducing drag and preventing them from being

driven by the wind. Feathering is typically present in controllable pitch

propellers. The blades are held in feather by aerodynamic forces.

Advantages:

• Minimizes drag during an engine failure or shutdown.

• Helps maintain aircraft control during single-engine operations.

Disadvantages:

• Requires pilot intervention to feather the propeller.

• Adds complexity to the propeller system.

You might also like

- Aircraft Propeller: Submitted TO-Gagan Varshney Submitted BY - Abdullah RaghibDocument26 pagesAircraft Propeller: Submitted TO-Gagan Varshney Submitted BY - Abdullah RaghibAbdullah Raghib SiddiquiNo ratings yet

- Turboprop PropDocument46 pagesTurboprop PropJohan100% (2)

- Airbus Flight Control Laws: The Reconfiguration LawsFrom EverandAirbus Flight Control Laws: The Reconfiguration LawsRating: 4.5 out of 5 stars4.5/5 (16)

- Propellers PrintDocument17 pagesPropellers Printrizkykusumastuti112No ratings yet

- PapelDocument8 pagesPapelignacio galindoNo ratings yet

- Types of Aircraft PropellerDocument10 pagesTypes of Aircraft PropellerFlorenceNo ratings yet

- Controllable Pitch Propellers NotesDocument4 pagesControllable Pitch Propellers NotesRamneek Arora100% (2)

- Types of PropulsionDocument64 pagesTypes of PropulsionAnitha Raja BNo ratings yet

- Propeller Performance: Professor Von Kliptip's Twelve All-Time Favorite Questions and Answers AboutDocument16 pagesPropeller Performance: Professor Von Kliptip's Twelve All-Time Favorite Questions and Answers AboutaviationMYNo ratings yet

- 1.JSA-Mechanical Work Hydrant InstallationDocument9 pages1.JSA-Mechanical Work Hydrant InstallationMuhammad Umar GondalNo ratings yet

- Forces Acting On A PropellerDocument21 pagesForces Acting On A Propellercasandra joaquin100% (2)

- Unit 2Document64 pagesUnit 2Jabez RichardsNo ratings yet

- PropellersDocument153 pagesPropellersjaafartm100% (6)

- Types of PropellersDocument34 pagesTypes of Propellersjagan k j100% (1)

- Propeller Theory: Baldoz, Lowell T. Briz, Mac Arman BDocument25 pagesPropeller Theory: Baldoz, Lowell T. Briz, Mac Arman BMak Briz100% (1)

- Aircraft Propulsion - Complete NotesDocument275 pagesAircraft Propulsion - Complete NotesTAMILSELVAM NALLUSAMY50% (2)

- Mccauley Tech GuideDocument20 pagesMccauley Tech GuideZfasNo ratings yet

- rh436 PDF 141215000247 Conversion Gate01 PDFDocument357 pagesrh436 PDF 141215000247 Conversion Gate01 PDFStephane FlotatNo ratings yet

- Wind Turbine DesignDocument18 pagesWind Turbine Designmaha vishnu ENo ratings yet

- Helicopter Assignment Helicopter Systems: Main Rotor SystemDocument10 pagesHelicopter Assignment Helicopter Systems: Main Rotor SystemMarc LumabanNo ratings yet

- 4 Propeller FundamentalsDocument16 pages4 Propeller FundamentalsRaul Deonarain100% (1)

- Doing Great in A Weak EconomyDocument2 pagesDoing Great in A Weak EconomyAJ0% (2)

- Propeller PresentationDocument27 pagesPropeller PresentationIkhwan Hadi100% (1)

- TOA - Mock Compre - AnswersDocument12 pagesTOA - Mock Compre - AnswersChrissa Marie VienteNo ratings yet

- Propeller PDFDocument41 pagesPropeller PDFJulian Zuñiga100% (1)

- Controllable Pitch PropellerDocument4 pagesControllable Pitch PropellerRamonValdezNo ratings yet

- Ardupilot VtolDocument16 pagesArdupilot VtolNorman Sanchez (drraganflx8)100% (1)

- Tech GuideDocument20 pagesTech GuideBivin K Balan100% (1)

- Forces On Ship: OE 1010 Introduction To Ocean EngineeringDocument62 pagesForces On Ship: OE 1010 Introduction To Ocean EngineeringdhruvbhagtaniNo ratings yet

- But What Is A Fixed Pitch Propeller or The FPP?Document7 pagesBut What Is A Fixed Pitch Propeller or The FPP?Baso AmirullahNo ratings yet

- Types of Propellers and MaterialsDocument3 pagesTypes of Propellers and MaterialsMariza Margueritte VillacampaNo ratings yet

- Caparas Z1A Ass1 AirPropLecDocument3 pagesCaparas Z1A Ass1 AirPropLecRojan Eros CaparasNo ratings yet

- Controllable and Fixed Pitch Proprller: BY, Ajay G 623 BDocument18 pagesControllable and Fixed Pitch Proprller: BY, Ajay G 623 BGiri VenkatesanNo ratings yet

- Blade TwistDocument4 pagesBlade TwistJabez RichardsNo ratings yet

- Special Pitch ModesDocument4 pagesSpecial Pitch ModesMaruf AminNo ratings yet

- USARM 405 Propeller QUESTION BANKDocument30 pagesUSARM 405 Propeller QUESTION BANKPathan FatimaNo ratings yet

- Propeller ClassificationsDocument17 pagesPropeller ClassificationsJose carlos CandelaritosNo ratings yet

- School of Aviation: Fixed Pitch PropellerDocument3 pagesSchool of Aviation: Fixed Pitch PropellerRojan Eros CaparasNo ratings yet

- Type of PropellersDocument5 pagesType of PropellersRichard EspinosaNo ratings yet

- With Tools On The Ground: From A Single Blade To 6 or More Blades Fine Coarse PitchDocument6 pagesWith Tools On The Ground: From A Single Blade To 6 or More Blades Fine Coarse Pitchsean buenaventuraNo ratings yet

- Gas Turbine Engine: Assignment 2Document9 pagesGas Turbine Engine: Assignment 2levitranNo ratings yet

- Constant-Speed Propellers: Blade Bearing Areas in HubDocument1 pageConstant-Speed Propellers: Blade Bearing Areas in Hubmirza pratamaNo ratings yet

- Fixed Pitch PropellersDocument15 pagesFixed Pitch PropellersKirito kunNo ratings yet

- CH3B - Turboprop PropellerDocument3 pagesCH3B - Turboprop PropellerPavan SushantNo ratings yet

- Konst & Stab SMT 3 2020 PPT Rev 2 Meet 6Document31 pagesKonst & Stab SMT 3 2020 PPT Rev 2 Meet 6Yufansza RayhanNo ratings yet

- Gas Turbine Engine: Assignment 2Document5 pagesGas Turbine Engine: Assignment 2levitranNo ratings yet

- BAA AGK Lesson 1 - 3-StabilizersDocument61 pagesBAA AGK Lesson 1 - 3-StabilizersReece BhaveNo ratings yet

- Jel Practical Reviewer 2Document24 pagesJel Practical Reviewer 2Jeremiah DumpNo ratings yet

- Gas Turbine Engine: Assignment 1Document10 pagesGas Turbine Engine: Assignment 1levitranNo ratings yet

- Helicopter Midterm ReviewerDocument5 pagesHelicopter Midterm ReviewerjohnclientebooklibraryNo ratings yet

- Special Features of PropellerDocument17 pagesSpecial Features of PropellerShubham SharmaNo ratings yet

- Propeller SystemsDocument45 pagesPropeller SystemsAma Serwaa YeboahNo ratings yet

- Co Axial PropellerDocument31 pagesCo Axial PropellerKalai SelvanNo ratings yet

- Co Axial Propeller 2dDocument30 pagesCo Axial Propeller 2dKalai SelvanNo ratings yet

- PROPELLERSDocument53 pagesPROPELLERSMohd akifNo ratings yet

- Lecture 2Document26 pagesLecture 2moezzbomb100% (1)

- Caparas Z1A LW2 AirPropLabDocument2 pagesCaparas Z1A LW2 AirPropLabRojan Eros CaparasNo ratings yet

- PropellersDocument13 pagesPropellerstatomhNo ratings yet

- Propeller AerodynamicsDocument6 pagesPropeller AerodynamicsMuhammedNayeemNo ratings yet

- Propeller TheoryDocument9 pagesPropeller TheoryFlorenceNo ratings yet

- Compressor SurgeDocument6 pagesCompressor SurgeJabez RichardsNo ratings yet

- Propeller, Types of Propellers and Construction of PropellersDocument4 pagesPropeller, Types of Propellers and Construction of PropellersZhenyan ChenNo ratings yet

- Airport CompleteDocument107 pagesAirport CompleteAbhishek NarineNo ratings yet

- Roff Master Fix Adhesive Mfa Tds DownloadDocument5 pagesRoff Master Fix Adhesive Mfa Tds DownloadsanjayNo ratings yet

- Xwatermark GuideDocument25 pagesXwatermark GuideKingsukNo ratings yet

- European J of Haematology - 2020 - Rasmussen - Unexpected Isolated Activated Partial Thromboplastin Time Prolongation ADocument7 pagesEuropean J of Haematology - 2020 - Rasmussen - Unexpected Isolated Activated Partial Thromboplastin Time Prolongation Akallolchakraborty779204No ratings yet

- BioCycle Magazine Article OpenRoad CompostingDocument6 pagesBioCycle Magazine Article OpenRoad CompostingPaula Hewitt AmramNo ratings yet

- Block-1 - Marketing ManagementDocument146 pagesBlock-1 - Marketing ManagementSachin JunejaNo ratings yet

- Singapore Institute of Surveyors and Valuers: Valuation Guidelines For Collective SalesDocument2 pagesSingapore Institute of Surveyors and Valuers: Valuation Guidelines For Collective SalesThe PariahNo ratings yet

- Sexual HarassmentDocument11 pagesSexual HarassmentKrip KNo ratings yet

- Hazard Register: Type Make Model Location Sale Number Lot Number Serial NumberDocument3 pagesHazard Register: Type Make Model Location Sale Number Lot Number Serial NumberShawn WairisalNo ratings yet

- Waiting Line Part I PDFDocument10 pagesWaiting Line Part I PDFJankiNo ratings yet

- Midterm - Psychological StatisticsDocument6 pagesMidterm - Psychological StatisticsrieNo ratings yet

- Ford Focus PCMDocument58 pagesFord Focus PCMEl OhmimetroNo ratings yet

- Bop Systems Function / Field Drawdown TestDocument1 pageBop Systems Function / Field Drawdown Testislam atifNo ratings yet

- Manual: CODE No: 8608Document40 pagesManual: CODE No: 8608Aamir FurqanNo ratings yet

- Release Notes For Altium Designer Version 14.3 - 2014-05-29Document7 pagesRelease Notes For Altium Designer Version 14.3 - 2014-05-29Luiz Ricardo PradoNo ratings yet

- Jurnal Penelitian Tolak AnginDocument9 pagesJurnal Penelitian Tolak AnginAnton WahyudiNo ratings yet

- Log Vsszzz1pzcr030942Document6 pagesLog Vsszzz1pzcr030942Abdula TanerNo ratings yet

- Argan Oil TDSDocument3 pagesArgan Oil TDSgabriela_moron_aNo ratings yet

- Home About Us Executive Body Bar Council Contact UsDocument5 pagesHome About Us Executive Body Bar Council Contact UsT v subbareddyNo ratings yet

- Government Memo On Claimed Farms - Part 1Document25 pagesGovernment Memo On Claimed Farms - Part 1noko-makgato-6232No ratings yet

- Essay For Effects of ForceDocument1 pageEssay For Effects of ForceCheng NieNo ratings yet

- MOTIVATION Reyes & CuestaDocument2 pagesMOTIVATION Reyes & CuestaLoiweza AbagaNo ratings yet

- Austria Oracle LocalizationDocument8 pagesAustria Oracle LocalizationGanesh VenugopalNo ratings yet

- Image Enhancement in The Spatial DomainDocument60 pagesImage Enhancement in The Spatial DomainSurenderMalanNo ratings yet

- Primer Size and Bullet Diameter Chart: 4050 S. Clark, Mexico, MO 65265Document3 pagesPrimer Size and Bullet Diameter Chart: 4050 S. Clark, Mexico, MO 65265lyndondrNo ratings yet

- Calculating Average Cycle StockDocument6 pagesCalculating Average Cycle StockPuneet PuriNo ratings yet