Professional Documents

Culture Documents

Catalogue Spec PCW

Uploaded by

siranep0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

1682384908_catalogue_spec_PCW

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageCatalogue Spec PCW

Uploaded by

siranepCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

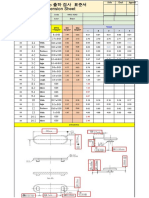

PC WIRE

MIN. MIN. MIN. PROOF LOAD MIN. LOW RELAXATION

NOMINAL DIAMETER CROSS SECTION

STANDARD NOMINAL WEIGHT TENSILE BREAKING REVERSE BENDS ELONGA TIME

NOTATION DIA. TOLERANCE AREA MIN YIELD REMARK

STRENGTH LOAD 0.1% 0.2% TION INITIAL FORCE AT

STRENGTH

mm. mm. 2 2

TYPE mm. TOLERANCE kg/1000m. TOLERANCE (N/mm ) kN. kN. kN. Min Number Radius (mm) % (kN) 60% 70% 80% hrs.

4.98 ± 0.05 1655 33.6 30.2

ASTM A 421/ TYPE BA 6.35 ± 0.05 1655 52.4 47.2

* Initial

A421M 7.01 ± 0.05 1620 62.5 56.3 force (70%

2.5% 3.5%

-2015 - 4.88 ± 0.05 - - - - 1725 32.3 - - - - 4.0 29.1 - 1000 or 80%) of

(Max.) (Max.)

4.98 ± 0.05 1725 33.6 30.2 min. tensile

TYPE WA strength

6.35 ± 0.05 1655 52.4 47.2

7.01 ± 0.05 1620 62.5 56.3

1670 4 12.6 98.4 ±2.0 1670 21.0 18.5 10

1770 4 12.6 98.4 ±2.0 1770 22.3 19.6 4 for 10

* Initial

BS 1620 4.5 15.9 124.2 ±2.5 1620 25.8 22.7 Plain wire 15 force (70%

5896 :2012 1670 5 19.6 153.1 ±3.1 1670 32.7 28.8 15 2.5% 4.5% or 80%) of

- - 3.5 - - 1000

1770 5 19.6 153.1 ±3.1 1770 34.7 30.5 3 for 15 (Max.) (Max.) actual

1670 6 28.3 221.0 ±4.4 1670 47.3 41.6 Indented & 15 breaking

load

1770 6 28.3 221.0 ±4.4 1770 50.1 44.1 Ribbed Wire 15

1670 7 38.5 300.7 ±6.0 1670 64.3 56.6 20

4 ± 0.04 12.57 98.7 21.1 18.6 3.5

5 ± 0.05 19.64 154.0 31.9 27.9 4.0 * Initial

JIS SWPR1 6 ± 0.05 28.27 222.0 44.1 38.7 4.0

force (70%)

2.5%

- and - - - - - - - - - 1000 of min.

G 3536 :1999 7 ± 0.05 38.48 302.0 58.3 51.0 4.5 (Max.)

SWPD1 tensile

8 ± 0.06 50.27 395.0 74.0 64.2 4.5 strength

9 ± 0.06 63.62 499.0 90.2 78.0 4.5

1670 4 12.6 98.9 ±2.0 1670 21.0 17.5 17.9 10

1770 4 12.6 98.9 ±2.0 1770 22.3 18.5 19.0 10

1670 5 19.6 154.0 ±3.1 1670 32.7 27.2 27.8 4 for 15

* Initial

AS/NZS 1770 5 19.6 154.0 ±3.1 1770 34.7 28.8 29.5 Plain wire 15

force (60%

4672.1.2007 1670 STRESS 6 28.3 222.0 ±3.7 1670 47.3 39.3 40.2 15 , 70% or

1.0% 2.0% 3.0%

1770 RELIEVED 6 - 28.3 - 222.0 ±3.7 1770 50.1 41.6 42.6 3 for 15 3.5 - 1000 80%) of

(Max.) (Max.) (Max.)

WIRE ±4.3 min.

1570 7 38.5 302.0 1570 60.4 50.1 51.3 Indented & 20

breaking

1470 8 50.3 395.0 ±5.9 1470 72.9 60.5 62.0 Ribbed Wire 20

load

1570 8 50.3 395.0 ±5.9 1570 79.0 65.6 67.1 20

1670 8 50.3 395.0 ±5.9 1670 84.0 69.7 71.4 20

1470 9 63.6 499.0 ±7.2 1470 93.5 74.8 76.7 25

Brazil ABNT 1770 CP-175 4 12.6 98.7 ±2.0 1720 21.0 18.9 30

2x for Initial force

NBR 7482 1770 CP-175 5 19.6 154.0 ±3.1 1720 33 29.7 indented (or 30 3.0% 80% of

2008 E for 5 NA NA 1000

1770 CP-175 6 28.3 222.0 ±3.7 1720 47.7 40.6 notched)wir 30 (Max) breaking

notched PC es

±4.3 load

Wires 1670 CP-170 7 38.5 302.0 1668 63.3 53.8 40

Reduction of area TORSION TEST

1740 4.88 ± 0.05 1530 32.5 to 36.3 35% 10

Stress

70% of min

ASTM A 648-12 1650 relieve wires 6.35 ± 0.05 1450 52.4 to 58.9 30% 8

breaking load

CLASS III

1520 7.92 ± 0.05 1390 75.2 to 85.4 30% 7

You might also like

- JIS G3452: Carbon Steel Pipes For Ordinary PipingDocument1 pageJIS G3452: Carbon Steel Pipes For Ordinary PipingHoJienHauNo ratings yet

- Pap 6600-20-v08Document3 pagesPap 6600-20-v08marc_lobert4808100% (2)

- Comparison PPC Eye Care (Paper Prop) - 1Document1 pageComparison PPC Eye Care (Paper Prop) - 1FarhanNo ratings yet

- Calculos CorregidosDocument4 pagesCalculos CorregidosJorge ReyNo ratings yet

- Motiongoo Stepper Motor Drawing-17HF19S4168Document1 pageMotiongoo Stepper Motor Drawing-17HF19S4168Make RownNo ratings yet

- BS 1387 PDFDocument3 pagesBS 1387 PDFAngga KurniawanNo ratings yet

- Detail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768Document1 pageDetail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768syaikulNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- 5000 V DatasheetDocument2 pages5000 V DatasheetViviana MatallanaNo ratings yet

- NIC Components NACS SeriesDocument3 pagesNIC Components NACS SeriesNICCompNo ratings yet

- Dominus Brochure v1Document8 pagesDominus Brochure v1leila lolita leila lilasNo ratings yet

- Silicon Power Transistor: Data SheetDocument4 pagesSilicon Power Transistor: Data SheetEdmundo VázquezNo ratings yet

- Motiongoo Stepper Motor Drawing-17HT19S6040Document1 pageMotiongoo Stepper Motor Drawing-17HT19S6040Make RownNo ratings yet

- WW Datasheet enDocument3 pagesWW Datasheet enChua YongNo ratings yet

- PC924Document6 pagesPC924tahir0732No ratings yet

- Potentiometer CP22EDocument1 pagePotentiometer CP22EDarlan AssinkNo ratings yet

- 3266 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesDocument3 pages3266 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesJulien SchweitzerNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Hybrid Stepper Motors 24HS SeriesDocument4 pagesHybrid Stepper Motors 24HS SeriesMike ChanNo ratings yet

- Motiongoo Stepper Motor Drawing-17HF13D6031Document1 pageMotiongoo Stepper Motor Drawing-17HF13D6031Make RownNo ratings yet

- MCB489 MCB1077 ACDC Series Product Guide LIT1617 2022 - R1Document2 pagesMCB489 MCB1077 ACDC Series Product Guide LIT1617 2022 - R1Soufiane El BazNo ratings yet

- Motiongoo Stepper Motor Drawing-17HT13S6095Document1 pageMotiongoo Stepper Motor Drawing-17HT13S6095Make RownNo ratings yet

- 092000-5360-1 Lionn Auto SoftwaresDocument3 pages092000-5360-1 Lionn Auto SoftwaresLionn MartinsNo ratings yet

- DRW 0002Document1 pageDRW 0002karpagavalli NNo ratings yet

- RJ26RJR26Document2 pagesRJ26RJR26joel alvaradoNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- Silicon NPN Triple Diffusion Mesa Type: Power TransistorsDocument1 pageSilicon NPN Triple Diffusion Mesa Type: Power TransistorsandibdgNo ratings yet

- Vishay Sfernice: FeaturesDocument4 pagesVishay Sfernice: FeaturesLTEC. Assistencia TécnicaNo ratings yet

- Lampiran LaksanDocument3 pagesLampiran LaksanbpuNo ratings yet

- OK OK: Shear BendingDocument46 pagesOK OK: Shear BendingAwais HameedNo ratings yet

- Cost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingDocument1 pageCost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingIqbal singh DhanjalNo ratings yet

- Minotrol 16: LOT Control L ABX LysebioDocument3 pagesMinotrol 16: LOT Control L ABX LysebioTristiana yuliantiNo ratings yet

- KoenigDocument14 pagesKoenigUday GurijalaNo ratings yet

- DM3 KNOB 출하검사 표준서Document4 pagesDM3 KNOB 출하검사 표준서cuong ngoNo ratings yet

- Layout 5abcdDocument2 pagesLayout 5abcdvikesh1993No ratings yet

- Prestressing Thread Steel BarDocument3 pagesPrestressing Thread Steel BarIsmantoTaufikNo ratings yet

- Abstract of DBM Mix Design Gr-Ii (50-75 MM Thick)Document6 pagesAbstract of DBM Mix Design Gr-Ii (50-75 MM Thick)Santu Ghosh100% (1)

- Cycle Drop Test 5/22/2021 5/22/2021 Unit-2 Unit-3Document3 pagesCycle Drop Test 5/22/2021 5/22/2021 Unit-2 Unit-3abhilash gokhaleNo ratings yet

- CV-C BS: Surface Mount Type Aluminum Electrolytic CapacitorsDocument1 pageCV-C BS: Surface Mount Type Aluminum Electrolytic CapacitorsbolsterNo ratings yet

- TSSC Steel Sheet SpecsDocument1 pageTSSC Steel Sheet SpecsriyazkaderNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- KGV 4 Uch Gate FinishDocument1 pageKGV 4 Uch Gate FinishMahendra PatilNo ratings yet

- Wet Lab Report PM # 3Document2 pagesWet Lab Report PM # 3Adi Wahyudi AdiwNo ratings yet

- SkyCiv Beam Summary Report - I6xHy4kqGcQ8e2mCU7dPAfCLRcvdpR3IDocument7 pagesSkyCiv Beam Summary Report - I6xHy4kqGcQ8e2mCU7dPAfCLRcvdpR3IBastian David Castro BastiasNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingM-NazimNo ratings yet

- Model 628Document4 pagesModel 628ortodoncia peresNo ratings yet

- CYLINDER - ktmHEAD Lay Out (ALICON)Document4 pagesCYLINDER - ktmHEAD Lay Out (ALICON)vikesh1993No ratings yet

- 1N5221A To 1N5272DDocument3 pages1N5221A To 1N5272DlavinelllNo ratings yet

- 1 N 52 XXBDocument2 pages1 N 52 XXB81968No ratings yet

- Minotrol 16: LOT Control L ABX LyseDocument3 pagesMinotrol 16: LOT Control L ABX LyseDWI NATULANINo ratings yet

- Cable Slickline SUPA 75Document1 pageCable Slickline SUPA 75Rafael EspinosaNo ratings yet

- MR301 NECElectronicsDocument12 pagesMR301 NECElectronicsFrancisco Palacios LópezNo ratings yet

- Bend 1Document1 pageBend 1karpagavalli NNo ratings yet

- ET-SGM37FE-1222 (20170810003-H16035) ModelDocument1 pageET-SGM37FE-1222 (20170810003-H16035) Modelruta0405No ratings yet

- Mosfet FS10KM-5Document2 pagesMosfet FS10KM-5Abel RodriguezNo ratings yet

- 103 - 714 SERIES: CharacteristicsDocument2 pages103 - 714 SERIES: CharacteristicsNGUYEN MEDICALNo ratings yet

- MX420 Lyse PDFDocument3 pagesMX420 Lyse PDFPearl BaskarNo ratings yet

- Effect of Compressive Strength of Concrete On Transmission Length of Pre-Tensioned Concrete SystemsDocument11 pagesEffect of Compressive Strength of Concrete On Transmission Length of Pre-Tensioned Concrete SystemssiranepNo ratings yet

- Award 36276Document25 pagesAward 36276siranepNo ratings yet

- RackDocument1 pageRacksiranepNo ratings yet

- YTL Group - Sustainability Report 2022Document126 pagesYTL Group - Sustainability Report 2022siranepNo ratings yet

- 1-S2.0-S2214509522001425-Main PFA ACIDDocument15 pages1-S2.0-S2214509522001425-Main PFA ACIDsiranepNo ratings yet

- Yinson Ar2015Document146 pagesYinson Ar2015siranepNo ratings yet

- E-Boarding Pass QR Code For Bag TagsDocument1 pageE-Boarding Pass QR Code For Bag TagssiranepNo ratings yet

- Himalayan Technical Specifications 1Document2 pagesHimalayan Technical Specifications 1siranepNo ratings yet

- CIHB - Annual Report 2022Document120 pagesCIHB - Annual Report 2022siranepNo ratings yet

- CIDB Technical Opinion Report YJACK (Amended)Document236 pagesCIDB Technical Opinion Report YJACK (Amended)siranepNo ratings yet

- User Manual Esh M7598BK Esh M9098BKDocument16 pagesUser Manual Esh M7598BK Esh M9098BKsiranepNo ratings yet

- Application of Distributed Fibre Optic Sensor in Instrumented Pile Load TestDocument10 pagesApplication of Distributed Fibre Optic Sensor in Instrumented Pile Load TestsiranepNo ratings yet

- Hospital 450-9-12Document1 pageHospital 450-9-12siranepNo ratings yet

- Nitomortar UA 0610 PDFDocument2 pagesNitomortar UA 0610 PDFsiranepNo ratings yet

- NORAMLightTowers (E)Document2 pagesNORAMLightTowers (E)siranepNo ratings yet

- Nitomortar GP, BC & UA: Two-Part Epoxy Resin MortarsDocument3 pagesNitomortar GP, BC & UA: Two-Part Epoxy Resin MortarssiranepNo ratings yet

- Fosroc Nitomortar UA: Two-Part Epoxy Resin Mortars Uses Application InstructionsDocument2 pagesFosroc Nitomortar UA: Two-Part Epoxy Resin Mortars Uses Application InstructionssiranepNo ratings yet

- HHK5A (880) : Hydraulic Impact HammerDocument2 pagesHHK5A (880) : Hydraulic Impact HammersiranepNo ratings yet

- Sika MonoTop-610 MY 2011-10 - 1Document4 pagesSika MonoTop-610 MY 2011-10 - 1siranepNo ratings yet

- MS 1314 Part 3Document5 pagesMS 1314 Part 3siranepNo ratings yet

- Msen1992 1-1-2010 Nationalannex PreDocument5 pagesMsen1992 1-1-2010 Nationalannex Presiranep0% (1)

- CBO9780511530159A007Document3 pagesCBO9780511530159A007Ali AzariunNo ratings yet

- Paper 20230906104745Document96 pagesPaper 20230906104745afifkadriNo ratings yet

- Scientific Paper MJBLDocument10 pagesScientific Paper MJBLMarie Joy LunaNo ratings yet

- Complex Analysis: Chapter V. Singularities V.1. Classification of Singularities-Proofs of TheoremsDocument23 pagesComplex Analysis: Chapter V. Singularities V.1. Classification of Singularities-Proofs of TheoremsTOM DAVISNo ratings yet

- Handout For 2022-23 MITRE ET H.S. Student Staff ReqDocument2 pagesHandout For 2022-23 MITRE ET H.S. Student Staff ReqJane PollyNo ratings yet

- 3.a) - Test On Pin Fin by Forced ConvectionDocument5 pages3.a) - Test On Pin Fin by Forced ConvectionJady chess24No ratings yet

- Time Series CharacteristicDocument72 pagesTime Series Characteristicsourabh gotheNo ratings yet

- Adopting and Adapting Arbitration For Climate ChangeRelated DisputesDocument9 pagesAdopting and Adapting Arbitration For Climate ChangeRelated DisputescontestantlauNo ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Numerical Analysis and Statistical TechniquesDocument40 pagesNumerical Analysis and Statistical Techniquesyour friendNo ratings yet

- OpenStax Psychology2e APA Guidelines MapDocument17 pagesOpenStax Psychology2e APA Guidelines MapmaritasvNo ratings yet

- Soal Bahasa Inggris KLS IxDocument5 pagesSoal Bahasa Inggris KLS IxIrvan RiandiNo ratings yet

- CH 01Document6 pagesCH 01MagehartNo ratings yet

- GenChem11 Q1 M6Document21 pagesGenChem11 Q1 M6kanekiNo ratings yet

- 1st Summative Test in Science 5Document5 pages1st Summative Test in Science 5CARICRIS MARATA100% (2)

- Module # 14 - Learning Activity 1Document3 pagesModule # 14 - Learning Activity 1Kyla MiguelNo ratings yet

- English NotesDocument2 pagesEnglish NotessachaNo ratings yet

- Name: - Yr/Section: - Date: - Activity No. 1 Define and Illustrate The Process of Ridge Counting and Ridge TracingDocument6 pagesName: - Yr/Section: - Date: - Activity No. 1 Define and Illustrate The Process of Ridge Counting and Ridge TracingMardy Hoyohoy BarraquioNo ratings yet

- MEEN 20052 - Week 4 - Salamat, Andre Agassi D.Document4 pagesMEEN 20052 - Week 4 - Salamat, Andre Agassi D.andreagassiNo ratings yet

- Sports PsychologyDocument26 pagesSports PsychologyHabiya TauseefNo ratings yet

- HFSSDocument40 pagesHFSSthoroftedalNo ratings yet

- Structural Geolgy MCQs With AnswerDocument11 pagesStructural Geolgy MCQs With Answerkumar Harsh100% (4)

- Sleeping Above A Stolen Crown (Plain Text) (PDF)Document63 pagesSleeping Above A Stolen Crown (Plain Text) (PDF)Gabriel VargasNo ratings yet

- 02 Midterm Module For Business MarketingDocument36 pages02 Midterm Module For Business MarketingMyren Ubay SerondoNo ratings yet

- MOdule GRADE 11 Module 1-2 Activity SHEETDocument1 pageMOdule GRADE 11 Module 1-2 Activity SHEETChristian Cabadongga100% (2)

- First Page PDFDocument1 pageFirst Page PDFMostafa SalahNo ratings yet

- Solution Manual For Quantitative Analysis For Management 12Th Edition Render Stair Hanna Hale 0133507335 978013350733 Full Chapter PDFDocument36 pagesSolution Manual For Quantitative Analysis For Management 12Th Edition Render Stair Hanna Hale 0133507335 978013350733 Full Chapter PDFdouglas.schrandt250100% (13)

- Lam Kam Chuen - Master Lam's Walking Chi Kung PDFDocument146 pagesLam Kam Chuen - Master Lam's Walking Chi Kung PDFSergej100% (4)

- Guidelines On Tender Evaluation Using Weighted Criteria For Building Works and ServicesDocument11 pagesGuidelines On Tender Evaluation Using Weighted Criteria For Building Works and Serviceschristopher hersantNo ratings yet

- Fundamentals of Public SpeakingDocument409 pagesFundamentals of Public SpeakingAndi RahmansyahNo ratings yet