Professional Documents

Culture Documents

eMAX-MR52 Series3 Manual - Jan18

Uploaded by

dube2012Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

eMAX-MR52 Series3 Manual - Jan18

Uploaded by

dube2012Copyright:

Available Formats

eMAX-MR52

DUAL DOOR CONTROLLER – Series 3

Installation Guide and Specifications

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference

(2) This device must accept any interference received,

including interference that may cause undesired operation.

This device meets CE Specifications, and is RoHS Certified.

This device is UL 294 Recognized. JANUARY 2018

TABLE OF CONTENTS

Paragraph Title Page No.

1. General …………………………………………………………………………………………….. 3

2. Supplying Power to the eMAX-MR52 …….……………..…………….………….………...… 4

3. Communication Wiring (SIO Communication Port) ….……………………………………. 4

4. Reader Wiring ……………………………………..…………….……………………………….. 5

5. Alarm Contact Wiring …………………………………………………………………………… 7

6. Inputs for Cabinet Tamper/Power Fault ………………………………………….…………. 7

7. Control Output Wiring ………………..……………………….……………………………….. 8

8. Jumper & Dip Switch Usage …………….……………...…………….………….…………… 8

9. Status LEDs ………………………………………………………………..……………………. 10

10. Specifications …………………………………………………………………...………………. 11

Warranty and Liability ……………………………………………………………………………….. 12

Change History:

Original Original document creation January, 2018

January, 2018 eMAX-MR52 Series 3-Manual Page 2 of 12

eMAX-MR52 DUAL DOOR CONTROLLER

Series 3

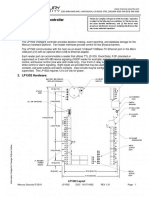

1. General:

The eMAX-MR52 Dual Door Controller (Series 3) provides a solution to the OEM system integrator for

interfacing to TTL (D1/D0, Clock/Data), F/2F, or 2-wire RS-485 Reader-type devices and associated door

hardware. It also provides tristate LED control and buzzer control. The Boards includes six (6) form-C contact

relay outputs which may be used for door lock control or alarm signaling. Eight inputs are provided that may

be used for monitoring the door contact, request to exit devices, and other alarm contacts. Input circuits can

be configured as unsupervised or supervised.

Communication to the MR52 is via a 2-wire RS-485 circuit. The eMAX-MR52 requires 12 or 24 Vdc for power.

See the following figure for component location (some components shown are not present on the MR52).

STATUS LEDs

.50 [12.70]

6.00 [152.40]

5.50 [139.70] .25 [6.35]

A B 1 2 3 4 5 6 7 8 TMP PFL R1 R2

TB1

GND DAT CLKBZRLED VO GND DAT CLKBZRLED VO

IN1

READER 1

READER

INTERFACE

IN2

D0 D1

TB2

2.00 [50.80]

IN3

TB8

INPUTS

TB9

READER 2

IN4

TB3

IN5

D0 D1

INPUTS

IN6

TB4

S2

4321

IN7

MR52+

ON

IN8

|^

S1

DIP SWITCHES

8765432 1

TB5

8.00 [203.20]

TMP

3.00 [76.20]

GND

PFL

GND TB10

NO C NC NO C NC NO C NC NO C NC NO C NC NO C NC

RLY 1

RLY 2

K1

TB6

OUTPUT

RLY 3

12V PT

TR+

RELAYS

K2

J4

TR-

RS-485

J1

NC

2.00 [50.80]

RLY 4

K3

NC

GND

TB11 Ø.156 [Ø4.0]

TB7 TB12

K4

VIN 8 PLACES

RLY 5

VOUT

K5

GND

DC INPUT

K6

RLY 6

POWER

EARTH

GROUND

January, 2018 eMAX-MR52 Series 3-Manual Page 3 of 12

2. Supplying Power to the eMAX-MR52:

The eMAX-MR52 accepts 12 or 24 Vdc for power on TB7 TB7

(VIN and GND). Locate the power source as close to the

MR52 as possible. Install the power connection with

minimum of 18 AWG wires.

+ VIN

12 TO 24 Vdc VOUT

- GND

Ensure that you observe POLARITY on VIN!

The VOUT terminal on TB7 is the same as VIN.

3. Communication Wiring (SIO Communication Port):

The eMAX-MR52 communicates to a Maxxess EP Series

TO OTHER DEVICES

Intelligent Area Controller (EP2500 for example) via a 2- ON THE BUSS

wire RS-485 interface. The MR52 allows for multi-drop

communication on a bus of up to 4,000 feet (1,200m).

Use twisted pair (minimum 24 AWG) with drain wire and

shield for communication. See specifications section.

Install RS-485 termination jumper, J4, on the interface

boards at each end of the communication line only. TB6

TR+

TR-

NC

NC

GND

TO OTHER DEVICES

ON THE BUSS

2-WIRE RS-485

(ONLY 2-WIRE RS-485 IS SUPPORTED)

January, 2018 eMAX-MR52 Series 3-Manual Page 4 of 12

4. Reader Wiring:

Each reader port of the eMAX-MR52 supports a reader with TTL (D1/D0, Clock/Data), F/2F, or 2-wire RS-485

signaling. Source Power to the reader is selectable: 12 Vdc created on the Board (VIN must be greater than

20 Vdc), or power that is passed-through (PT) from the input voltage of the MR52 (TB7-VIN), 300 mA maximum

per reader port. Readers that require different voltage or have high current requirements must be powered

separately. Refer to the reader manufacturer specifications for cabling requirements.

J1 – Reader Port Power Select

!! - If the input voltage to the MR52 is 12 Vdc, jumper J1 MUST be in the PT position.

In the 2-wire LED mode the buzzer output is used to drive the second LED. Reader port configuration is set

via the host software.

To fully utilize each reader port:

➢ TTL signaling requires a 6-conductor cable (18 AWG)

➢ F/2F signaling requires a 4-conductor cable

➢ RS-485 signaling requires two 2-conductor cables. Use one cable for power (18 AWG) and one cable

for communication (24 AWG, with drain wire and shield)

1 TB4

1 TB4

GND

GND

BZR

BZR

LED

LED

D1/CLK/TR+

D1/CLK/TR+ D0/DAT/TR-

D0/DAT/TR- VO

VO

Typical D1/D0 or Clock/Data Reader Typical RS-485 Device

January, 2018 eMAX-MR52 Series 3-Manual Page 5 of 12

* Inputs on supervised F/2F readers may be unsupervised or supervised (supervised shown).

1 TB4

GROUND 1 TB4

GND GROUND

GND

DO (GREEN LED) DO(GREEN LED)

BZR BZR

LED LED

D1

D1 D1/CLK/TR+

D1/CLK/TR+

D0/DAT/TR-

D0/DAT/TR- +12 Vdc

VO

+12 Vdc

VO 1K,1%

1K,1%

DOOR MONITOR SWITCH

NORMALLY CLOSED CONTACT *

1K,1%

1K,1%

F/2F Reader

REQUEST TO EXIT SWITCH

NORMALLY OPEN CONTACT *

F/2F Reader

Typical Unsupervised F/2F Reader Typical Supervised F/2F Reader

Jumper D1 to LED on supervised F/2F readers

January, 2018 eMAX-MR52 Series 3-Manual Page 6 of 12

5. Alarm Contact Wiring:

The eMAX-MR52 includes 8 inputs that are typically used to monitor door position, request to exit devices, or

alarm contacts. Input circuits can be configured as:

• Unsupervised alarm (2 states); reporting as open or closed contact.

• Supervised alarm (6 states); reporting as open or closed contact, open circuit, shorted circuit, grounded

circuit *, or foreign voltage*.

A supervised input circuit requires adding two (2) EOL resistors with value of 1k ohm, 1% to the circuit to

facilitate proper monitoring and reporting. The Resistors should be located as close to the sensor as

possible. Custom end of line (EOL) resistances may be configured via the host software.

* Grounded and foreign voltage states are not a requirement of UL 294 and therefore not verified by UL.

The input circuit wiring configurations shown are supported but may not be typical.

IN1

Standard Supervised Circuit, 1K,1%

Normally Closed Contact 1K,1%

IN2

Standard Supervised Circuit, 1K,1%

Normally Open Contact

IN3 IN4

1K,1%

Unsupervised Circuit,

Normally Closed Contact

Unsupervised Circuit,

Normally Open Contact

6. Inputs for Cabinet Tamper/Power Fault:

Input CT and input BA are used for monitoring cabinet tamper and power failure with normally closed contacts.

These two inputs are for contact closure monitoring only, and do not use EOL resistor(s). If these inputs are

not used, install a short jumper wire across the input to indicate a safe condition.

TB5

CABINET TMP

TAMPER GND

POWER FLT

FAULT GND

January, 2018 eMAX-MR52 Series 3-Manual Page 7 of 12

7. Control Output Wiring:

The eMAX-MR52 include six (6) Form-C contact relays used for controlling door strikes/locks or other such

devices. Load switching can cause abnormal contact wear and premature contact failure. Switching of

inductive loads (strike) also causes EMI (electromagnetic interference) which may interfere with normal

operation of other equipment. To minimize premature contact failure and to increase system reliability, a contact

protection circuit must be used. The following circuit is recommended. Locate the protection circuit as close to

the load as possible (within 12 inches [30 cm]), as the effectiveness of the circuit will decrease if it is located

further away.

Use sufficiently large gauge of wires for the load current as to avoid voltage loss.

DIODE SELECTION:

Diode current rating > 1x strike current

NC Diode break down voltage: 4x strike

C voltage

NO For 12 Vdc or 24 Vdc strike, diode

NC 1N4002

C (100V /1A) typical

NO

8. Jumper and DIP Switch Usage:

JUMPER DESCRIPTION

J1 Reader Power Select

12V = 12 Vdc at reader ports. *** See note below ***

PT = VIN “Passed Through" to reader ports

J4 RS-485 Termination, install in first and last units only

All other jumpers are for factory use only

NOTE: The input power (VIN) must be 20 Vdc minimum if the 12 Vdc selection is to be used.

January, 2018 eMAX-MR52 Series 3-Manual Page 8 of 12

Switches 1 to 5 select the device address. Switch 6 and 7 select the communication baud rate. Switch 8

enables encrypted communication. All other configuration settings are set via host software.

S8 S7 S6 S5 S4 S3 S2 S1 SELECTION

OFF OFF OFF OFF OFF Address 0

OFF OFF OFF OFF ON Address 1

OFF OFF OFF ON OFF Address 2

OFF OFF OFF ON ON Address 3

OFF OFF ON OFF OFF Address 4

OFF OFF ON OFF ON Address 5

OFF OFF ON ON OFF Address 6

OFF OFF ON ON ON Address 7

OFF ON OFF OFF OFF Address 8

OFF ON OFF OFF ON Address 9

OFF ON OFF ON OFF Address 10

OFF ON OFF ON ON Address 11

OFF ON ON OFF OFF Address 12

OFF ON ON OFF ON Address 13

OFF ON ON ON OFF Address 14

OFF ON ON ON ON Address 15

ON OFF OFF OFF OFF Address 16

ON OFF OFF OFF ON Address 17

ON OFF OFF ON OFF Address 18

ON OFF OFF ON ON Address 19

ON OFF ON OFF OFF Address 20

ON OFF ON OFF ON Address 21

ON OFF ON ON OFF Address 22

ON OFF ON ON ON Address 23

ON ON OFF OFF OFF Address 24

ON ON OFF OFF ON Address 25

ON ON OFF ON OFF Address 26

ON ON OFF ON ON Address 27

ON ON ON OFF OFF Address 28

ON ON ON OFF ON Address 29

ON ON ON ON OFF Address 30

ON ON ON ON ON Address 31

OFF OFF 115,200 BPS, See note 1 below.

OFF ON 9,600 BPS

ON OFF 19,200 BPS

ON ON 38,400 BPS

Encrypted communication not required

OFF See note 2 below.

Encrypted communication required

ON See note 2 below.

Note 1: Firmware revisions prior to 1.38.1, this setting is 2,400 BPS

Note 2: Firmware revisions prior to 1.38.1, SW8 is not defined. Set to the OFF position

January, 2018 eMAX-MR52 Series 3-Manual Page 9 of 12

9. Status LEDs:

Power-up: All LED’s OFF

Initialization: Once power is applied, initialization of the module begins

When initialization is completed, LEDs A through R2 are briefly sequenced ON then OFF

Run time: After the above sequence, the LEDs have the following meanings:

A LED: Heartbeat and On-Line Status:

Off-line: 1 sec rate, 20 % ON

On-line:

Non-encrypted communication: 1 sec rate, 80 % ON

Encrypted communication:

.1 sec ON, .1 sec OFF, .1 sec ON, .1 sec OFF, .1 sec ON, .1 sec OFF, .1 sec ON, .3 sec OFF

A LED Error Indication:

Waiting for application firmware to be downloaded: .1 sec ON, .1 sec OFF.

B LED: SIO Communication Port Status:

Indicates communication activity on the SIO communication port

1 LED: Input Status: IN1

2 LED: Input Status: IN2

3 LED: Input Status: IN3

4 LED: Input Status: IN4

5 LED: Input Status: IN5

6 LED: Input Status: IN6

7 LED: Input Status: IN7

8 LED: Input Status: IN8

TMP: Cabinet Tamper

PFL: Power Fault

Input in the inactive state: OFF (briefly flashes ON every 3 seconds)

Input in the active state: ON (briefly flashes OFF every 3 seconds)

Input in a trouble state: Rapid Flash

R1 LED: reader port 1:

Clock/Data Mode: Flashes when data is received, either input

D1/D0 Mode: Flashes when data is received, either input

RS-485 Mode: Flashes when transmitting data

F/2F Mode: Flashes when data/acknowledgment is received

R2 LED: reader port 2:

Clock/Data Mode: Flashes when data is received, either input

D1/D0 Mode: Flashes when data is received, either input

RS-485 Mode: Flashes when transmitting data

F/2F Mode: Flashes when data/acknowledgment is received

K1 through K6 LEDs: Illuminates when output relay RLY 1 (K1) through RLY 6 (K6) is energized.

Every three seconds, LEDs A through R2 are pulsed to their opposite state for 0.1 sec.

January, 2018 eMAX-MR52 Series 3-Manual Page 10 of 12

10. Specifications:

Revision D assembly:

The eMAX-MR52 Interface is for use in low voltage, class 2 circuits only.

The installation of this device must comply with all local fire and electrical codes.

Primary power: 12 to 24 Vdc ± 10 %, 550 mA maximum (reader current not included)

Outputs: Six Form-C relays:

Normally open contact (NO) contact: 5 A @ 30 Vdc resistive

Normally closed contact (NC) contact: 3 A @ 30 Vdc resistive

Inputs: Eight unsupervised/supervised, standard EOL: 1k/1k ohm, 1%, ¼ watt

Two unsupervised, dedicated for cabinet tamper and UPS fault monitoring

Reader Interface:

Power: 12 Vdc ± 10 % regulated, 300 mA maximum each reader

(jumper selectable) (input voltage (VIN) must be greater than 20 Vdc)

or

12 to 24 Vdc ± 10 % (input voltage passed through), 300 mA maximum each

reader

Data Inputs: TTL compatible, F/2F or 2-wire RS-485

LED Output: TTL compatible, high > 3 V, low < 0.5 V, 5 mA source/sink maximum

Buzzer Output: Open collector, 12 Vdc open circuit maximum, 40 mA sink maximum

Communication: 2-wire RS-485: 9600, 19200, 38400 or 115200 bps

Cable requirements:

Power: 1 twisted pair, 18 AWG

RS-485 I/O devices: 1 twisted pair with drain wire and shield, 24 AWG, 120 ohm impedance,

4,000 feet (1,200 m) maximum

Alarm inputs: One twisted pair per input, 30 ohms maximum

Outputs: As required for the load

Reader data (TTL): 6-conductor, 18 AWG, 500 feet (150 m) maximum

Reader data (F/2F): 4-conductor, 18 AWG, 500 feet (150 m) maximum

Reader data (RS-485): 1 twisted pair with drain wire and shield, 24 AWG, 120 ohm impedance,

2,000 feet (610 m) maximum

Mechanical:

Dimension: 6 in. (15 2mm) W x 8 in. (203 mm) L x 1 in. (25 mm) H

Weight: 11 oz. (312 g) nominal

Environment:

Temperature: -55 to +85 °C, storage

0 to +70 °C, operating

Humidity: 5 to 95 % RHNC

UL294, 6th edition Performance Levels:

Feature Level

Standby Power I

Endurance IV

Line Security I

Destructive Attack I

January, 2018 eMAX-MR52 Series 3-Manual Page 11 of 12

Warranty

Maxxess Systems, Inc. warrants the product is free from defects in material and workmanship under normal

use and service with proper maintenance for one year from the date of factory shipment. Maxxess Systems

assumes no responsibility for products damaged by improper handling or installation. This warranty is limited

to the repair or replacement of the defective unit.

There are no expressed warranties other than set forth herein. Maxxess Systems does not make, nor intends,

nor does it authorize any agent or representative to make any other warranties, or implied warranties, and

expressly excludes and disclaims all implied warranties of merchantability or fitness for a particular purpose.

Returns must be accompanied by a Return Material Authorization (RMA) number obtained from customer

service, and prepaid postage and insurance.

Liability

The Interface should only be used to control exits from areas where an alternative method for exit is available.

This product is not intended for, nor is rated for operation in life-critical control applications. Maxxess Systems

is not liable under any circumstances for loss or damage caused by or partially caused by the misapplication or

malfunction of the product. Maxxess System’s liability does not extend beyond the purchase price of the

product.

January, 2018 eMAX-MR52 Series 3-Manual Page 12 of 12

You might also like

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Konica Minolta Bizhub C220 C280 C360 SERVICE MANUALDocument0 pagesKonica Minolta Bizhub C220 C280 C360 SERVICE MANUALYury Kobzar83% (24)

- Console A320Document1 pageConsole A320KeilaeFrancisco ArceNo ratings yet

- Dell Latitude E6430 (Compal LA-7781P) PDFDocument62 pagesDell Latitude E6430 (Compal LA-7781P) PDFndaru setyoNo ratings yet

- AVEVA ManualsDocument279 pagesAVEVA ManualsAhmad Aliyan Alif Bin IsmailNo ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Spectralwave V-Node: Cid Setup Menu ExplanationDocument88 pagesSpectralwave V-Node: Cid Setup Menu ExplanationjanNo ratings yet

- Mr52-S3 Reader Interface: Installation and SpecificationsDocument7 pagesMr52-S3 Reader Interface: Installation and Specificationslorgi vanegas cardonaNo ratings yet

- eMAX EP4502 ManualDocument11 pageseMAX EP4502 Manualdube2012No ratings yet

- eMAX LP1501 ManualDocument22 pageseMAX LP1501 Manualdube2012No ratings yet

- eMAX LP4502 ManualDocument20 pageseMAX LP4502 Manualdube2012No ratings yet

- eMAX LP1502 ManualDocument20 pageseMAX LP1502 Manualtp.segarNo ratings yet

- Dell Latitude E4310 Compal LA-5691P SchematicsDocument51 pagesDell Latitude E4310 Compal LA-5691P SchematicsCarlos ZarateNo ratings yet

- LNL-X2220 - Rev - C ModelDocument1 pageLNL-X2220 - Rev - C ModelMark John EstebanNo ratings yet

- Slaae 57Document9 pagesSlaae 57fabiolmtNo ratings yet

- Jura XJ9 Wiring DiagramDocument3 pagesJura XJ9 Wiring DiagramGrom Neposeda50% (2)

- Mr50-S3 Reader Interface: 1. GeneralDocument6 pagesMr50-S3 Reader Interface: 1. Generalwillian paivaNo ratings yet

- 500d6 Compal LA-5691P PDFDocument51 pages500d6 Compal LA-5691P PDFIon PetruscaNo ratings yet

- 1a319 Compal La-7741p r0.1Document57 pages1a319 Compal La-7741p r0.1Syed Ahtasham ul haqNo ratings yet

- M237 7 12LVOI-T 12LVOI-P A4 E ScreenDocument11 pagesM237 7 12LVOI-T 12LVOI-P A4 E Screen王志晓No ratings yet

- LP1502 Intelligent Controller: 1. GeneralDocument9 pagesLP1502 Intelligent Controller: 1. GeneralLifarith Ortega MorenoNo ratings yet

- BLF6G27-135 BLF6G27LS-135: 1. Product ProfileDocument14 pagesBLF6G27-135 BLF6G27LS-135: 1. Product ProfileJEFFREY DEE MAURY NORIEGANo ratings yet

- Dalmore 15 UMA: Compal ConfidentialDocument59 pagesDalmore 15 UMA: Compal ConfidentialTaylor ManuelNo ratings yet

- bll6h1214l 250 - 1214ls 250Document13 pagesbll6h1214l 250 - 1214ls 250eduardoNo ratings yet

- Compal LA-7762ADocument71 pagesCompal LA-7762AEnrique SorianoNo ratings yet

- Dell Latitude d420 - Compal La-3071pDocument59 pagesDell Latitude d420 - Compal La-3071pEdson HenriqueNo ratings yet

- BLF573 BLF573S: 1. Product ProfileDocument16 pagesBLF573 BLF573S: 1. Product ProfileCarlos OtzoyNo ratings yet

- A320 PedestalDocument1 pageA320 PedestalAdriano LaraNo ratings yet

- SCR Monitor Board User's Manual - Watchdog EUU-7-102583000 - 2013 Rev 1 - 504756-002 PDFDocument11 pagesSCR Monitor Board User's Manual - Watchdog EUU-7-102583000 - 2013 Rev 1 - 504756-002 PDFRoberto C RuizNo ratings yet

- St151prod-2 - Kah-3755 Icp1 (Category 3)Document22 pagesSt151prod-2 - Kah-3755 Icp1 (Category 3)Ryan DuhonNo ratings yet

- MR50Document5 pagesMR50Ahmad ElhamdaouiNo ratings yet

- Compal LS-5656P r10 PWR BoardDocument1 pageCompal LS-5656P r10 PWR BoardQuenitoLucianoJoãoNo ratings yet

- LNL-3300 Power Source Tamper PFDocument1 pageLNL-3300 Power Source Tamper PFsskhanNo ratings yet

- A250 Series Explosion Proof Limit Switch Boxes PDFDocument1 pageA250 Series Explosion Proof Limit Switch Boxes PDFMehmet KahyaNo ratings yet

- EP1501 Intelligent Controller: 1. GeneralDocument10 pagesEP1501 Intelligent Controller: 1. Generalmiluva175No ratings yet

- Voltas Screw Chiller Drawing 3Document1 pageVoltas Screw Chiller Drawing 3Mihir GaurNo ratings yet

- Radiator Fan Circuit: 1998 ES 300. Using The EWD Fill in The Blanks in Your Workbook: 1. Verify The SymptomsDocument8 pagesRadiator Fan Circuit: 1998 ES 300. Using The EWD Fill in The Blanks in Your Workbook: 1. Verify The SymptomsLong HàNo ratings yet

- EDS-728 828 HIG 3eDocument16 pagesEDS-728 828 HIG 3eCh Muhammad Furqan ShafiqNo ratings yet

- Dell Latitude E6430 Compal LA-7782PDocument66 pagesDell Latitude E6430 Compal LA-7782Pmattew188No ratings yet

- Voltas Screw Chiller Drawing 2Document1 pageVoltas Screw Chiller Drawing 2Mihir GaurNo ratings yet

- Series 551,552,553,14-12 AluminiumDocument20 pagesSeries 551,552,553,14-12 AluminiumPrathamesh GangalNo ratings yet

- AL1916 WCDocument24 pagesAL1916 WCKrit JakkritNo ratings yet

- P3768 A04 OrCAD Schematics (Base Version)Document25 pagesP3768 A04 OrCAD Schematics (Base Version)sdhuangwei263.netNo ratings yet

- Experiment 04Document5 pagesExperiment 04Zunair NazirNo ratings yet

- Quanta Computer: Change List GD3 Main BoardDocument7 pagesQuanta Computer: Change List GD3 Main BoardCarlos Alberto Miranda PerezNo ratings yet

- eMAX-MR50 Series3 Manual - Jan18Document9 pageseMAX-MR50 Series3 Manual - Jan18dube2012No ratings yet

- Y510 - TP DB - Sit - 20161125-1300 - For Gerber PDFDocument2 pagesY510 - TP DB - Sit - 20161125-1300 - For Gerber PDFDurah CNo ratings yet

- eMAX EP1501 Man REV - BDocument28 pageseMAX EP1501 Man REV - Bdube2012No ratings yet

- BIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyDocument10 pagesBIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyHamza AbbasiNo ratings yet

- Acer Iconia Tab A100 - SchematicsDocument35 pagesAcer Iconia Tab A100 - SchematicsEdgar Jose Aranguibel MorilloNo ratings yet

- FB5204B3Document4 pagesFB5204B3Renato RodriguesNo ratings yet

- VAR10 La-9781ppDocument68 pagesVAR10 La-9781ppВосточная Лаосская ИмперияNo ratings yet

- Penggantian Diff & OCR LV TRF 2 GI CibatuDocument10 pagesPenggantian Diff & OCR LV TRF 2 GI CibatuedwarNo ratings yet

- FRC NI RoboRIO User Manual PDFDocument31 pagesFRC NI RoboRIO User Manual PDFJuan de Dios Alardín HernándezNo ratings yet

- RoboRIO ManualDocument31 pagesRoboRIO ManualHectorNo ratings yet

- Electrical Appliance Using TV RemoteDocument65 pagesElectrical Appliance Using TV RemoteGopal Krishna Reddy Thotli100% (1)

- Dell Latitude E6520 Compal LA-6561P Rev 1.0 (A00) Schematics PDFDocument77 pagesDell Latitude E6520 Compal LA-6561P Rev 1.0 (A00) Schematics PDFFadli Aries100% (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Project Cost Managment 1Document18 pagesProject Cost Managment 1mohaNo ratings yet

- PB SeriesDocument108 pagesPB SeriesGerman LiernurNo ratings yet

- Spectra ACT 1000Document1 pageSpectra ACT 1000nareshbhardwajNo ratings yet

- NTCP AnalysisDocument12 pagesNTCP AnalysisParas KhuranaNo ratings yet

- openSAP Suse1-Pc Week 1 All SlidesDocument36 pagesopenSAP Suse1-Pc Week 1 All SlidesPedro Fernández HernándezNo ratings yet

- 96boards Iot Edition: Low Cost Hardware Platform SpecificationDocument15 pages96boards Iot Edition: Low Cost Hardware Platform SpecificationSapta AjieNo ratings yet

- Arduino ReportDocument10 pagesArduino ReportSrinan MarvelNo ratings yet

- 5-Patch Cord Cat6a STP Azul 1m BARPADocument3 pages5-Patch Cord Cat6a STP Azul 1m BARPAMarco Antonio RubinaNo ratings yet

- Nekemt City Data CaseDocument6 pagesNekemt City Data CaseAnleyNo ratings yet

- Legal and Ethical Issues in Computing Mid Exam SolutionDocument6 pagesLegal and Ethical Issues in Computing Mid Exam SolutionMalik KashifNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Subject-Verb-Prepositional Phrase Identification Worksheet #1Document3 pagesSubject-Verb-Prepositional Phrase Identification Worksheet #1lovelNo ratings yet

- Electrical 8 Years Bits PDFDocument65 pagesElectrical 8 Years Bits PDFSasi Kanth Kola100% (1)

- Kurmitar Sub-Vendor ListDocument52 pagesKurmitar Sub-Vendor Listmukherjeemohul25No ratings yet

- DB2 - SQL Error CodesDocument24 pagesDB2 - SQL Error CodesMudit RanaNo ratings yet

- 285 Relee Tip URF Pentru ComutatoareDocument8 pages285 Relee Tip URF Pentru ComutatoarehaggNo ratings yet

- Chapter-V CLASSIFICATION & CLUSTERINGDocument153 pagesChapter-V CLASSIFICATION & CLUSTERING21053259No ratings yet

- A and Weighted A Search: Maxim Likhachev Carnegie Mellon UniversityDocument55 pagesA and Weighted A Search: Maxim Likhachev Carnegie Mellon UniversityAvijit GhoshNo ratings yet

- Letter: Dept. of Computer Science and EngineeringDocument4 pagesLetter: Dept. of Computer Science and EngineeringSneha V LNo ratings yet

- WSA Nominees 2020 PDFDocument21 pagesWSA Nominees 2020 PDFLuke SkywalkerNo ratings yet

- Rajalakshmi Engineering CollegeDocument2 pagesRajalakshmi Engineering CollegeBulky MoniNo ratings yet

- Datasheet 114C April 2017Document82 pagesDatasheet 114C April 2017Prakash AnnamalaiNo ratings yet

- Image, Impact and Making An Impression - Unit 7Document12 pagesImage, Impact and Making An Impression - Unit 7Sai AmruthaNo ratings yet

- Swing, Layout ManagersDocument11 pagesSwing, Layout ManagersadamNo ratings yet

- Policy and Procedure Manual: (A Unit of Hindustan Group of Institutions)Document77 pagesPolicy and Procedure Manual: (A Unit of Hindustan Group of Institutions)Sairam SaiNo ratings yet

- Spring2017 Exam 2 PDFDocument8 pagesSpring2017 Exam 2 PDFToqa A.No ratings yet

- Dynamic Position MoveDocument17 pagesDynamic Position MoveRoberto MontoyaNo ratings yet