Professional Documents

Culture Documents

1 KS20 Concise Manual English 21 10 13

Uploaded by

darrel gimoteaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 KS20 Concise Manual English 21 10 13

Uploaded by

darrel gimoteaCopyright:

Available Formats

Universal Input 1 and Digital Inputs 1 & 2: Status LED Indicators

KS 20-1/PRO-16 INDUSTRIAL CONTROLLER Loc Local-operation adjustment via front-panel possible

Manual mode is active rem Remote-operation adjustment via front-panel not possible

CONCISE PRODUCT MANUAL 59533-1

Timer or profiler is active blc.P Configuration-, parameter and calibration-level blocked

CAUTION: Installation should be only performed by blc.C Configuration-level blocked

technically competent personnel. Local Regulations Setpoint SP.2 or SP.E is in use u.blc All blocking cancelled

regarding electrical installation & safety must be observed. After opening the list the display will show the actual setting of the first section.

The host equipment is required to provide a suitable Heat / valve open output is active

Use the ENTER key to scroll to the next section and UP/DOWN-Keys to select

electrical, mechanical and fire enclosure to meet relevant functions. To activate the selected setting press ENTER or just wait 2 seconds before

Cool / valve close output is active

safety standards. Impairment of protection will occur if the proceeding to the next screen.

product is used in a manner not specified by the Alarm is active

manufacturer. Example: Select setpoint SP.2

Press the F-key (display will show Err)

Press ENTER until you see SP, SP.E or SP.2

Behaviour after power-on Select SP.2 with the UP/DOWN-Keys

After the supply voltage is switched-on, the unit starts in the operator mode. Press ENTER to activate

The unit will be in the condition in which it was before power-off.

1. INSTALLATION If the controller was in manual mode before power-off, the controller starts with the

Press the F-key to leave the function level

last output value before power-off. Self-tuning

Panel-Mounting Options 1, 2 and 3:

The mounting panel must be rigid, and may be up to If the permissions in the configuration menu allow, self-tuning can be initiated by

Operator screens simultaneously pressing the UP and ENTER key. The lower display line will toggle

6.0mm (0.25inch) thick. Cut-out sizes: In operator mode the unit displays the key screens for controller operation. Two

B between the setpoint and the self-tuning state. Press the same keys to abort an

screens for the controller (PV with setpoint or output value) and one for the profiler (if active self-tuning.

Cut-out Dim A Cut-out Dim B configured). The operating level can be expanded with an “Extended operating level”

1 1

/16 DIN = 45mm /16 DIN = 45mm Furthermore the user can access the “function level” with the F-key. Please refer to the full manual to learn about the meaning of the state messages and

For n multiple instruments mounted side-by-side, cut-out A

see the different optimization methodologies available.

A is 48n-4mm. Tolerance +0.5, -0.0mm

See the full user manual for details. Download at:

1. Insert instrument into http://www.west-cs.com/products/models/pro-16-single-loop-controller

the panel cut-out.

Mounting Panel

2. Hold front bezel firmly 4. PROFILER OPERATION

Instrument (without pressing on

Housing display area), and re-fit Operating the Profiler

mounting clamp. Push The F-key opens the profiler control menu in the

Ratchets clamp forward, using a lower display line. The display will show “P:”

tool if necessary, until Option A: followed by the actual state. Depending on the

Gasket gasket is compressed configuration, the menu allows the user to select

and instrument held firmly run/stop or run/stop/reset with the UP/DOWN-keys.

in position. Press ENTER to make the selected state active.

CAUTION: For an effective IP65 seal against dust and moisture, ensure

OFF Stop program execution and reset

gasket is well compressed against the panel, with the 4 tongues located in

Stop Stop program execution

the same ratchet slot.

run Start program execution

It is essential that the controller is installed with a minimum of 20mm of free space

around the case in order to allow adequate ventilation. The profiler start screen is shown above. The upper display line shows the program

or segment execution time.

The lower line shows the program-number or segment-number and the state of the

profiler. Details for both lines can be configured.

Rear Terminal Wiring CAUTION: Check information label on housing for correct operating

All connections to the device must be made through a spade format or similar voltage before connecting supply to Power Input The content of the extended operating level and the function level is based on Screen sequence shown below:

connection, with connection to the spade terminal touching both the Fuse: 100 – 240V ac – 1A anti-surge 10A breaking capacity at 250V configurations made with the configuration utility BlueControl. Parameters used

insulation and conductor material. (Use a standard crimping tool). 24V ac/dc – 315mA anti-surge 3.5A breaking capacity at 48V frequently or important measured values can be placed into the extended operating

All connections must be mechanically secured so as to prevent any wiring level.

becoming loose and coming in contact with other wires or the instrument Electrical shock can result in death or serious injury. Avoid contact

casing. with the leads and terminals. High voltages that may be present on See the full user manual for details. Download at:

leads can cause electrical shock http://www.west-cs.com/products/models/pro-16-single-loop-controller

The above applies to any and all connection to hazardous Note: At first power-up please check that settings of input and output usage fit

mains supply either direct or indirect (through a switch or relay) to your needs and wiring. 3. CONTROLLER OPERATION

Use copper conductors (except for T/C Inputs)

This is the start screen in controller mode.

Use Screened Cable on Retransmission Options The upper display line always shows the process

Single Strand wire gauge: Max 1.2mm (18 SWG) 2. FRONT PANEL AND OPERATION BASICS value. The lower line is used for the setpoint.

Cabling must have a minimum temperature rating of 80 deg C.

A second screen shows the output value in the lower

line. The status line has six LED beacons which

Assignment of connectors to options modules: indicate the following (left to right): controller in

manual operation, timer or program is active, Program/segment selection

alternative setpoint used, heat mode active or valve Prerequisite: Programmer is in the reset or stop condition and program / segment

open, cool mode active or valve close and limit selection (Pr.no / Pr.SG) is set in the extended operating level.

alarm active.

The procedure to select a defined program (Pr.no) followed by a segment (Pr.SG) is

shown below. When starting the programmer now, program operation starts at the

Changing the setpoint beginning of the selected segment in the selected program.

The setpoint can be adjusted by pressing the UP/DOWN-keys.

Control Functions

The F-key opens the function list in the lower display line. Depending on

configurations (LOGI) the list contains the following groups of parameters:

Err No reset of the error list

Ereset Resetting the error list

SP Internal setpoint active

SP.E External setpoint active

1. Process value display SP.2 Second setpoint active

2. Set-point, controller output or parameter

3. Status LED indicators – see next column On Controller/Signaler and Limit 1 are active

4. Ramp gradient is active Off Controller/Signaler and Limit 1 are switched off

5. F-key to alter or activate functions

6. UP/DOWN to change set-point or controller output value Auto Automatic operation

7. ENTER to accept value and show next screen Man Manual operation

Lim: Contains alarm limits

End: OUTPUTS

Search run at programmer start End of Program

The last setpoint remains active When in a sub-section, the display will toggle between the parameter name and its Relay – option 1-3

The programmer starts the first segment at the actual process value (search run). value. Use the UP/DOWN-keys to change settings and ENTER to move to the next Contacts: Potential free changeover

This may change the effective runtime of the first segment. parameter. When at the end of a sub-section the display will show “done” and then Max contact rating: 2A@ 250V 48…62Hz

the next sub-section name. At the end of the sub-section list the display will show Min contact rating: 6V, 1mA

“End” and return to the operator level. Duty cycle: I = 1A/2A, 250,000/150,000 operations @ 250V

See the full user manual for details. Download at: resistive

http://www.west-cs.com/products/models/pro-16-single-loop-controller See the full user manual for details. Download at:

http://www.west-cs.com/products/models/pro-16-single-loop-controller

Dual relay – option 2

5. ALARM MESSAGES Note: It is highly recommended that the controller is used in conjunction with Contacts: 2 NO contacts with

the BlueControl configuration utility. This will increase ease of use, save set- shared common

In case of an alarm the lower display line will toggle between red and green and an Max contact rating: 2A@ 250V 48…62Hz

up time and help prevent controller malfunction.

alarm screen will be added to the list of operator screens. Navigate to the alarm Min contact rating: 6V, 1mA

screen by pressing the ENTER-key. You will find one of the following messages: Duty cycle: I = 1A/2A, 500,000/200,000 operations @ 250V resistive

A demonstration version of the BlueControl configuration utility is available as a free

Alarm Description Corrective Action download from http://www.west-cs.com. The full “Expert” version is available to

purchase from your local dealer. SSR - option 1-3

Fbf.1/2/3 Feedback failure Check sensor and wiring Voltage: 10V into 500Ω minimum

Input 1/2/3

Sht.1/2/3 Short circuit Check input wiring 7. SPECIFICATION Dual SSR - option 1-3

Input 1/2/3

Voltage: 10V into 500Ω minimum

POL.1/3 polarity reversal Check input wiring

Input 1/3 INPUTS Linear DC output option 1 & 3

HCA Heater current Check heating element and wiring

alarm (1) Current output

SSr Solid state relay Check SSR and output circuit Process Value Input INP1

LooP Loop alarm Check fuses, heaters and wiring Resolution: > 14 bit 0/4mA...20 mA, configurable.

Decimal point: 0 to 3 decimal places Signal range: 0...approx. 22mA

AdA.H Adaption Heat refer to auto tuning section in full manual

Digital input filter: adjustable 0.000...9999 s Load: ≤ 500 Ω

Ada.C Adaption Cool refer to auto tuning section in full manual

Scanning cycle: 100 ms Load effect: none

Lim. 1/2/3 Limit alarm Check process Measured value Resolution: (0.1%)

Inf.1 Info service correction: 2-point or offset correction Error: (0.2%)

General Profiler Overview interval

(life time counter)

Thermocouples (2) Voltage output

Programs 16 Inf.2 Info service

interval Input impedance: 1 MΩ

Control outputs 4 Effect of source 0-10 V

(relay cycle

Segments 16 per program resistance: 1 V/Ω Signal range: 0...11 V

counter)

Segment types ramp (set-point and time) Thermocouple types: B, C, D, E, J, K, L, N, R, S, T Load: ≥ 2KΩ

E.1 Hardware problem Contact repair department /service centre Resolution: ≤ 0.1 %

ramp (set-point andv gradient) Resistance thermometer: PT100, PT1000, KTY 11-6

hold segment (holding time) Error: ≤ 0.2 %

step segment (with alarm suppression) E.2 Internal problem Check for EMC issues Cold junction compensation

end segment Try power on reset Max. additional error: < 0.5 K Bus interface - option 3 or option A

All segment types can be combined E.4 Option module Check option module fitting or contact repair Physical: RS485, at 1200, 2400, 4800, 9600 or 19200 bps.

with ”Wait at the end and call operator” problem department /service centre Sensor break monitoring Protocol: Modbus RTU Communications

Time units configurable in hours:minutes or Sensor current: ≤ 1 µA

minutes:seconds Operating sense configurable Transmitter power supply

Maximum segment duration 9999 hours = 1 year 51 days

6. SETUP AND CALIBRATION Output: 22 mA / ≥ 18 V

Maximum program duration 16 x 9999 hours = > 18 years Resistance thermometer

Gradient 0.01°C/h ( /min) to 9999°C/h ( /min) After power-up, the controller will show the operating level in the lower level text line. Connection: 3-wire 8. ENVIRONMENTAL

Program name 8 characters, adjustable via The controller status is retained and will be the same as before the last power-down. Lead resistance: max. 30Ω Operating Conditions (For indoor use)

BlueControl software To access the options for parameter set-up, configuration and calibration, press Input circuit monitor: Break and short circuit

ENTER for more than 3 seconds. Ambient 0°C to 60°C (Operating), –20°C to 70°C (Storage).

Bandwidth control bandwidth high and low (b.Lo,b.Hi) Temperature:

limits definable for each program This will now allow the options to be accessed: Use the UP/DOWN-keys to select Current and voltage signals

the option and ENTER to go to the next option. Relative Humidity: 75% yearly average no condensation

Span start, end of span: anywhere within measuring range

Scaling: Selectable -1999...9999 Supply Voltage and 100 to 240V AC ±10%, 50/60Hz, 11.5VA (mains voltage input

Linearization: 16 segments, configurable with BlueControl Power: version)

Decimal point: adjustable 24V AC ±10%, 50/60Hz, 11.5VA or 24V DC ±10%, 10W (low

Input circuit monitor: 12.5% below span start (2mA, 1V) voltage input version)

Resolution: > 14 bit

Scanning cycle: 100 ms Certification

Accuracy: Better than 0.1% Standards: CE, UL, cUL

EMI: Complies with EN61326 (Susceptibility & Emissions).

Heating current measurement via current transformer Safety Complies with EN61010-1

Measuring range: 0...30mA AC Considerations: Pollution Degree 2, Installation Category II.

Scaling: adjustable -1999..0,000..9999 A

Front Panel Sealing: To IP65 (IP20 behind the panel).

Accuracy: 0.25%

Physical

Remote setpoint measurement range Front Bezel Size:

1

/16 DIN = 48 x 48mm.

Input resistance: approx. 120Ω

Span: configurable within 0 to 20mA Depth Behind Panel: 110mm.

Scaling: adjustable -1999...9999 Weight: 0.21 Kg maximum.

Input circuit monitor: 12.5% below span start (4..20mA 2mA) Cleaning

If cleaning is necessary, the front panel should be cleaned by washing with warm

soapy water and drying immediately using a dry, lint free cloth.

CONTROL INPUT DI1 & DI2

Manufacturing site

Sections: Configurable as direct or inverse switch or push-button. Address:

PROG: This is used to edit programs for the profiler. Connection of a potential-free contact suitable for switching “dry“ circuits. The Hyde Business Park

PARA: This allows access to the two sets of PID parameters, setpoint limits, Switched voltage: 3.3V

Brighton

Examples of profiler displays: scaling of input signals, alarm limits and the program selection. . Switched current: < 10mA

CONF: Used to select the controller function, activate the profiler, to set input BN2 4JU

types, to choose alarm functions, to assign functions to outputs and to configure United Kingdom

the user interface. CONTROL INPUTS DI3 & DI4

Profiler OFF.

Program 01 selected

CAL: This section is used for calibration of the process inputs. (OPTIONAL) Full user documentation

More comprehensive user documentation is available in the full user manual which

Internal controller setpoint is active

After choosing a section the display will show the first option of the sub-section. Use is available to download at:

the same procedure to choose and enter the desired sub-section. These inputs (if ordered) are in the option A position and are configurable as direct http://www.west-cs.com/products/models/pro-16-single-loop-controller

or inverse.

Profiler in run mode Sub-sections: (for example PARA) Nominal voltage: 24 V DC, external current sink (IEC 1131 Type 1) Symbol Explanation

Cntr: Contains PID parameters. Logic “0”: -3...+5V

Program 02 or Segment 02 active

Par.2: Contains a second set of PID parameters. Logic “1”: +15...+30V

Setpoint is ramping up “/”

Current requirement: approx. 5mA Caution: general danger to life or limb

Setp: Contains setpoint limits

Inp.1: Contains scaling and input filter

Inp.2: Contains scaling

You might also like

- MZC 4 NJ MX X01 HBN VHB F83 NTM3 NV9 FTL VF X1 D TRL JFSQDocument3 pagesMZC 4 NJ MX X01 HBN VHB F83 NTM3 NV9 FTL VF X1 D TRL JFSQYang LiaNo ratings yet

- Connections, Displays and Operating Elements: G F MN HDocument10 pagesConnections, Displays and Operating Elements: G F MN HdogasanchesNo ratings yet

- VF30 Pro Series Quick Guide - V1.3 - ENDocument2 pagesVF30 Pro Series Quick Guide - V1.3 - ENRamón Aranceta OdriozolaNo ratings yet

- Manual Dixell x120Document4 pagesManual Dixell x120Alejandro AlomotoNo ratings yet

- C50 1/16-Din Process Controller: Concise Product Manual - Im/C50Document2 pagesC50 1/16-Din Process Controller: Concise Product Manual - Im/C50AnthonyNo ratings yet

- Yasnac J50M Upgrading Function ManualDocument81 pagesYasnac J50M Upgrading Function ManualsunhuynhNo ratings yet

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 pagesAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinNo ratings yet

- Ac-160-C en MLZ54604Document2 pagesAc-160-C en MLZ54604deepak6_7No ratings yet

- Names and Functions of Parts : User's ManualDocument2 pagesNames and Functions of Parts : User's ManualSHAMNo ratings yet

- Dixell 121C ControllerDocument4 pagesDixell 121C ControllerDorin50% (2)

- 2020 02 13 en GateBox Instrukcja MailDocument6 pages2020 02 13 en GateBox Instrukcja MailAntonios EfentakisNo ratings yet

- Manual Pulsador de Emergencia FP2 SingleDocument1 pageManual Pulsador de Emergencia FP2 SingleFernando MoralesNo ratings yet

- Electronic Digital Thermometer With Maximum / Minimum Temperature LogDocument2 pagesElectronic Digital Thermometer With Maximum / Minimum Temperature LogHoàngViệtAnhNo ratings yet

- Modrol DriveDocument23 pagesModrol DriveMarcelo Lescano89% (9)

- XT11S GB-IT r1.0 06.11.2013Document2 pagesXT11S GB-IT r1.0 06.11.2013Jennifer Eszter SárközyNo ratings yet

- E510 Compact QuickstartDocument2 pagesE510 Compact QuickstartEduardo LegorretaNo ratings yet

- XT130C - XT131C - XT130D - XT131D: Dead Band Digital Controllers With Multi Probe InputDocument4 pagesXT130C - XT131C - XT130D - XT131D: Dead Band Digital Controllers With Multi Probe InputJennifer Eszter SárközyNo ratings yet

- XT120C - XT121C - XT120D - XT121D: Two Stages Digital Controllers With Multi Probe InputDocument4 pagesXT120C - XT121C - XT120D - XT121D: Two Stages Digital Controllers With Multi Probe InputaliNo ratings yet

- XJM60D EN r1.1 29.11.2013Document6 pagesXJM60D EN r1.1 29.11.2013Jennifer Eszter SárközyNo ratings yet

- Yasnac J50L Upgrading Function ManualDocument76 pagesYasnac J50L Upgrading Function ManualsunhuynhNo ratings yet

- PP505 Printer For FE700 Operator's ManualDocument20 pagesPP505 Printer For FE700 Operator's ManualIGORNo ratings yet

- ME-AGS-N Wiring Diagram - For Generac Home Standby Generators (Evolution 2.0 Controller)Document1 pageME-AGS-N Wiring Diagram - For Generac Home Standby Generators (Evolution 2.0 Controller)Sidali KilardjNo ratings yet

- Rcf-230d Inst en SV de FRDocument15 pagesRcf-230d Inst en SV de FRkuatifansyahNo ratings yet

- STA20 BasicQuickSetUpwithQRCodeDocument12 pagesSTA20 BasicQuickSetUpwithQRCodeMiroslava BiroNo ratings yet

- CF805T Series User's ManualDocument10 pagesCF805T Series User's ManualRama ChandiranNo ratings yet

- Selectable Volt Free: InstructionmanualDocument12 pagesSelectable Volt Free: InstructionmanualPerDormire MagacinNo ratings yet

- Malis CMC V Quick Setup Guide ELS-38-000Document4 pagesMalis CMC V Quick Setup Guide ELS-38-000Manoj VarmanNo ratings yet

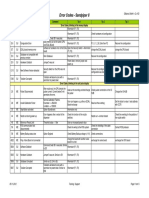

- Error Codes Sandpiper II, Index FDocument5 pagesError Codes Sandpiper II, Index FCharlie ShowNo ratings yet

- User's Manual: 3-Axis Compact Keyboard ControllerDocument2 pagesUser's Manual: 3-Axis Compact Keyboard ControllerEDGAR ALARCONNo ratings yet

- Folsom Screen ProDocument83 pagesFolsom Screen ProAdrian GardnerNo ratings yet

- Emcp3.1 SinopticoDocument1 pageEmcp3.1 SinopticoAdolfo Dario SaavedraNo ratings yet

- 1480 Concise Indicator ManualDocument17 pages1480 Concise Indicator ManualjolinoraidiasNo ratings yet

- XT141C-D GB r1.0 06.03.2007Document4 pagesXT141C-D GB r1.0 06.03.2007Jennifer Eszter SárközyNo ratings yet

- N1020 Temperature Controller: Instructions Manual - V1.1X BDocument8 pagesN1020 Temperature Controller: Instructions Manual - V1.1X BAdonay HenriquezNo ratings yet

- Series: Intuitively Innovative!Document48 pagesSeries: Intuitively Innovative!Hector Velez PizaNo ratings yet

- CD Radio Cassette-Corder: CFD-G30 CFD-G50Document36 pagesCD Radio Cassette-Corder: CFD-G30 CFD-G50Steve RochNo ratings yet

- Micro Power 3 V Linear Hall Effect Sensor Ics Withtri-State Output and User-Selectable Sleep ModeDocument16 pagesMicro Power 3 V Linear Hall Effect Sensor Ics Withtri-State Output and User-Selectable Sleep ModeDomRuanNo ratings yet

- BCS WS QS LMSW 105 23272r2Document8 pagesBCS WS QS LMSW 105 23272r2ddNo ratings yet

- 1490 ManualDocument19 pages1490 ManualAlejandroNo ratings yet

- Apollo EU Error Codes, DraftDocument7 pagesApollo EU Error Codes, Draftisraelpilin123No ratings yet

- HA470631U100Document2 pagesHA470631U100Hayden LovettNo ratings yet

- The User Interface Installation: Electronic Thermostat With Single OutputDocument3 pagesThe User Interface Installation: Electronic Thermostat With Single Outputdyaza_1No ratings yet

- Zaio MiDocument1 pageZaio MiRabie MahmoudNo ratings yet

- Owner 'S Manual: Di Ital ThermostatDocument44 pagesOwner 'S Manual: Di Ital ThermostatPaulitha AlejithaNo ratings yet

- Ausonia - Automatic Control Panel PSC-1Document14 pagesAusonia - Automatic Control Panel PSC-1nicolaecomiciNo ratings yet

- Proportional-Pressure RegulatorDocument4 pagesProportional-Pressure Regulatorcuong nguyenNo ratings yet

- BC-2000 - K2 User ManualDocument1 pageBC-2000 - K2 User Manualamad4youNo ratings yet

- Integrated amplifier Amplificateur intégré Integrierter Verstärker Geïntegreerde versterker Amplificador integrado Встроенный усилитель Amplificatore integratoDocument67 pagesIntegrated amplifier Amplificateur intégré Integrierter Verstärker Geïntegreerde versterker Amplificador integrado Встроенный усилитель Amplificatore integratoElla MariaNo ratings yet

- Master Alarm Service Manual 550731Document24 pagesMaster Alarm Service Manual 550731David Ronald Chambi AverangaNo ratings yet

- Nold OpenDocument14 pagesNold OpenCatalin HoratiuNo ratings yet

- E2d SW4 US PDFDocument164 pagesE2d SW4 US PDFGrudi JordanovNo ratings yet

- Features: LMR PLUS Electric Fire Pump ControllersDocument11 pagesFeatures: LMR PLUS Electric Fire Pump ControllersDecsih RuizNo ratings yet

- Control Panel Keys Status KeyDocument1 pageControl Panel Keys Status Keysalinschi iulianNo ratings yet

- Manual de Usuario Comet Zwave BDA EngDocument2 pagesManual de Usuario Comet Zwave BDA EngMathieu JMNo ratings yet

- Esg 300 QRGDocument10 pagesEsg 300 QRGThiet biNo ratings yet

- Indicator N1500: Universal Process Indicator - Instructions Manual - V2.3 ADocument10 pagesIndicator N1500: Universal Process Indicator - Instructions Manual - V2.3 AenglishferNo ratings yet

- Indicator N1500: Universal Process Indicator - Instructions Manual - V2.3 ADocument7 pagesIndicator N1500: Universal Process Indicator - Instructions Manual - V2.3 Avalter mNo ratings yet

- ADEMCO 6152RF Keypad / Transceiver - Installation and Setup GuideDocument8 pagesADEMCO 6152RF Keypad / Transceiver - Installation and Setup GuidejhongudyNo ratings yet

- Engineering Data On Valve Selection Sizing and Location CSA Air Valves PDFDocument27 pagesEngineering Data On Valve Selection Sizing and Location CSA Air Valves PDFtruss85No ratings yet

- Electric CircuitsDocument7 pagesElectric CircuitsEzio AuditoreNo ratings yet

- Medical Ethics in Clinical PracticeDocument216 pagesMedical Ethics in Clinical PracticeSonali MishraNo ratings yet

- Kastle - Meyer Presumptive TestDocument2 pagesKastle - Meyer Presumptive TestKatleen Ann LaysonNo ratings yet

- Daylight Factor - Wikipedia, The Free EncyclopediaDocument2 pagesDaylight Factor - Wikipedia, The Free EncyclopediadasaNo ratings yet

- B. Tech Scheme - 2016 Batch PDFDocument8 pagesB. Tech Scheme - 2016 Batch PDFAlex HalesNo ratings yet

- Luningetal2005 - SiluriansourcerocksandpetroleumplayJordanDocument32 pagesLuningetal2005 - SiluriansourcerocksandpetroleumplayJordanMary DNo ratings yet

- Fiori & Pratolongo-2021 - The Bahía Blanca EstuaryDocument579 pagesFiori & Pratolongo-2021 - The Bahía Blanca EstuarykevinNo ratings yet

- Grammar Subject For Elementary - 5th Grade - Coordinating Conjunctions by SlidesgoDocument56 pagesGrammar Subject For Elementary - 5th Grade - Coordinating Conjunctions by SlidesgoAr NitaNo ratings yet

- Lebanese Medical LSK - pdf2Document96 pagesLebanese Medical LSK - pdf2Alaor LopesNo ratings yet

- DissertationDocument193 pagesDissertationCARLA VIZARRETA PISSANINo ratings yet

- Mandowsky RicercheintornoallIconologia 1939Document22 pagesMandowsky RicercheintornoallIconologia 1939Alejandro Jaquero EsparciaNo ratings yet

- Ava de JongeDocument2 pagesAva de Jongeapi-543815662No ratings yet

- Calculating Speed Time and Distance (3) .PPT 3rd Quarter Math 6Document25 pagesCalculating Speed Time and Distance (3) .PPT 3rd Quarter Math 6Wilma Ganit BalasNo ratings yet

- DLP 1 - WEEK 1-Food Processing-Tools, EquipmentDocument4 pagesDLP 1 - WEEK 1-Food Processing-Tools, EquipmentAnalyn B. AbelaNo ratings yet

- Simple and Multiple Regression Models For Relationship Between Electrical Resistivity and Various Soil Properties For Soil Characterization PDFDocument10 pagesSimple and Multiple Regression Models For Relationship Between Electrical Resistivity and Various Soil Properties For Soil Characterization PDFPato MeraNo ratings yet

- BSBLDR523 Lead and Manage Effective Workplace Relationships Assessment BookletDocument21 pagesBSBLDR523 Lead and Manage Effective Workplace Relationships Assessment BookletJeremiah Noromor Ronquillo100% (1)

- WMM Mix DesignDocument44 pagesWMM Mix DesignAshok amlapure100% (1)

- COMTEC LeafletDocument4 pagesCOMTEC Leafletariksyaiful82No ratings yet

- Take Home ExamDocument10 pagesTake Home ExamRaine PiliinNo ratings yet

- TI-EN-UVACURID C81 FarbserieDocument12 pagesTI-EN-UVACURID C81 FarbseriePatxi hernandez suellesNo ratings yet

- NASA 162514main Human NeedsDocument17 pagesNASA 162514main Human NeedsNASAdocuments100% (1)

- College For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityDocument2 pagesCollege For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityLove JcwNo ratings yet

- Term-2 Cycle Test Schedule 2023-24Document2 pagesTerm-2 Cycle Test Schedule 2023-24sarassinging22No ratings yet

- Truth About Reptilian Alien RacesDocument12 pagesTruth About Reptilian Alien RacesSuripeddi Koundinya60% (5)

- Mini - First Lecture SymmetryDocument19 pagesMini - First Lecture SymmetryKhaled AbeedNo ratings yet

- Bs - Civil Engineering 2023 24Document1 pageBs - Civil Engineering 2023 24DawnNo ratings yet

- Aldous Huxley Between The Wars - Essays and Letters. - Free Online LibraryDocument4 pagesAldous Huxley Between The Wars - Essays and Letters. - Free Online LibraryHasan ArslanNo ratings yet

- PMT Class XI Chemistry Atomic StructureDocument39 pagesPMT Class XI Chemistry Atomic StructureAurobinda MaharanaNo ratings yet

- Structure and Bonding in Crystalline Materials - G. Rohrer (Cambridge, 2004) WW PDFDocument552 pagesStructure and Bonding in Crystalline Materials - G. Rohrer (Cambridge, 2004) WW PDFOmar Alejandro Salazar0% (1)