Professional Documents

Culture Documents

Lift Plan - Rev 00

Uploaded by

Mohammed HamzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lift Plan - Rev 00

Uploaded by

Mohammed HamzaCopyright:

Available Formats

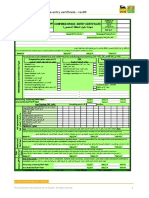

L&T HYDROCARBON ENGINEERING Document No.

:

LTHE/QHSE/HSE/F/21.1

Revision No.: 00

LIFT PLAN Date: 18.10.2016

LIFTING OPERATION PLAN Lift Plan No:

Location: Area:

Permit Number: Risk Assessment Number:

Method Statement Number:

Is Diagram/Sketch/Calculations Of Lifting Operation Enclosed? YES/NO : ( If Yes attach the

documents)

Description Of Lifting Operation:

Load Rigging

1. Load Weight ____________ 1. Hitch Type(s) __________________

2. Wt. of Aux. Block ____________ 2. No.of Slings __________________

3. Wt. main Block ____________ 3. Sling Type __________________

4. Wt. of Lifting Beam ____________ 4. Sling Assembly Capacity __________________

5. Wt. of Sling/Shackles ____________ 5. Shackle rated Capacity __________________

6. Wt. of Jib/Ext (erected/stowed) ____________

7. Wt. of Hoist Report ____________

8. Other: ____________

Total Weight ________________________________ Hoist Rope

Note: Source of load weight (Drawings, Calcs, etc.) must be 1. Rope Diameter (Main & Aux) ____________

attached 2. Capacity ____________

Size of the Load _____________________________

Crane

Crane 1 Crane 2 Crane 3

1. Type of Crane ____________ ____________ ____________

2. Maximum Crane capacity ____________ ____________ ____________

3. Radius (Max & Min) ____________ ____________ ____________

4. Boom Length (Max & Min) ____________ ____________ ____________

5. Boom Angle (Max & Min) ____________ ____________ ____________

6. Crane Capacity (Max. Radius) ____________ ____________ ____________

7. Cane Capacity (Min. Radius) ____________ ____________ ____________

8. Gross Load of Crane ____________ ____________ ____________

9. Lift is % of the cranes ____________ ____________ ____________

rated capacity

10. If Jib/Ext is used

Length____________ ____________ ____________

Offset ____________ ____________ ____________

11. Rated Capacity of Jib/Ext ____________ ____________ ____________

Please tick appropriate

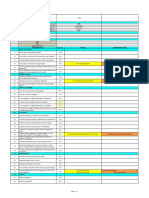

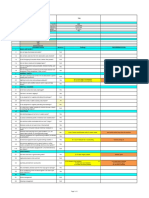

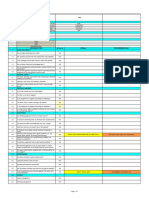

L&T HYDROCARBON ENGINEERING Document No.:

LTHE/QHSE/HSE/F/21.1

Revision No.: 00

LIFT PLAN Date: 18.10.2016

Gross load is greater than 10 tonnes (for Transferring the load from one lifting appliance to

construction sites) or 50 tonnes (for fabrication another

yards) In environmental conditions likely to affect

Gross load represents more than 80% of the load

equipment performance

chart at working radius.

Continuation of a lifting operation with different Load with unknown / difficult to estimate weight

equipment (due to malfunction, inadequacy or and / or center of gravity

unsuitability) Load is special and / or expensive whose loss

Within sensitive, difficult or restricted areas would have a serious impact on production

Over or in sensitive areas – active or energized operations

hydrocarbon-containing process equipment, near Mobile crane on untested / uneven ground

overhead electrical power lines Non-standard rigging arrangements

Tandem lift Load lowered into or lifted from a confined space

Task Details (Step By Step)

Method(s) Of Communication To Be Used

Radio Verbal Hand Signals

Steps taken to eliminate danger to personnel involved and others (including barriers where appropriate):

De-brief and learning points:

Prepared By/Name: Signature: Date:

Approved By/Name: Signature: Date:

You might also like

- Lifting PermitDocument1 pageLifting PermitFrank Abuda50% (4)

- Hoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesDocument5 pagesHoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesAdm Rigger Crane Sac100% (1)

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasFrom EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasRating: 5 out of 5 stars5/5 (11)

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Green Ports: Inland and Seaside Sustainable Transportation StrategiesFrom EverandGreen Ports: Inland and Seaside Sustainable Transportation StrategiesRating: 5 out of 5 stars5/5 (1)

- Test Bank For Financial Management Principles and Applications 10th Edition by KeownDocument19 pagesTest Bank For Financial Management Principles and Applications 10th Edition by KeownPria Aji PamungkasNo ratings yet

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFHadiwinata DjakariaNo ratings yet

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Critical Lift PlanDocument10 pagesCritical Lift PlanMohammad Anwar Hossain50% (2)

- Roads and Bridges Projects ChecklistDocument14 pagesRoads and Bridges Projects ChecklistThe Corner House 168No ratings yet

- AML Presentation & KYC Ver 1.9Document58 pagesAML Presentation & KYC Ver 1.9nehal10100% (1)

- SC Licensing HandbookDocument75 pagesSC Licensing HandbookYff DickNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift Planmahir_feelNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift Plansaquib eqbalNo ratings yet

- Nmo Critical Lift Plan SheetDocument2 pagesNmo Critical Lift Plan SheetIhsan AhmedNo ratings yet

- Critical Lift Plan Form - Sa 9644 Rev.01Document1 pageCritical Lift Plan Form - Sa 9644 Rev.01Anuraj0% (1)

- Mobile Crane Normal Lift and Rigging Plan FormDocument4 pagesMobile Crane Normal Lift and Rigging Plan FormTarek HareedyNo ratings yet

- Lift Plan FormDocument1 pageLift Plan Formخالد نسیمNo ratings yet

- Critical Lift PlanDocument1 pageCritical Lift PlanRajanNo ratings yet

- Hoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesDocument5 pagesHoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesAfdalNo ratings yet

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFRaja GuruNo ratings yet

- 007-Attach G Critical Lift Permit PDFDocument1 page007-Attach G Critical Lift Permit PDFFAISAL RAZANo ratings yet

- Bpwe Critical Lift Permit: Revision Date: 19MAY2011Document1 pageBpwe Critical Lift Permit: Revision Date: 19MAY2011AnilNo ratings yet

- Attach G Critical Lift Permit PDFDocument1 pageAttach G Critical Lift Permit PDFAnilNo ratings yet

- Prelift Check List: Section 1 - Review For All Lifts: All Lifts Rigging - TechnicalDocument3 pagesPrelift Check List: Section 1 - Review For All Lifts: All Lifts Rigging - TechnicalHumza NasirNo ratings yet

- Ohs-Pr-09-19-F15 (I) Critical Lift WorksheetDocument1 pageOhs-Pr-09-19-F15 (I) Critical Lift WorksheetShafie ZubierNo ratings yet

- Stockton Crane PermitDocument2 pagesStockton Crane PermitAndri SubektiNo ratings yet

- SF 23 & 24 Work Permit Lifting - Tandem LiftingDocument8 pagesSF 23 & 24 Work Permit Lifting - Tandem LiftingNirajan Marwait100% (2)

- Safe Rigging PracticeDocument81 pagesSafe Rigging PracticeAlvinSuparmanNo ratings yet

- Critical Lift Plan FormDocument2 pagesCritical Lift Plan FormSagun AlmarioNo ratings yet

- Mini Hydro Power Plants: Initial Environmental Examination (Iee) ChecklistDocument13 pagesMini Hydro Power Plants: Initial Environmental Examination (Iee) ChecklistavieNo ratings yet

- Critical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)Document4 pagesCritical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)cute1t100% (1)

- Form 5068A Crane Use Planning Process REV 2015Document4 pagesForm 5068A Crane Use Planning Process REV 2015Samuel LumbanrajaNo ratings yet

- Critical Lift WorksheetDocument1 pageCritical Lift WorksheetShafie ZubierNo ratings yet

- Critical Lift WorksheetDocument1 pageCritical Lift WorksheetShafie ZubierNo ratings yet

- Basic Lifting Plan 5MTDocument1 pageBasic Lifting Plan 5MTshahhussain1031No ratings yet

- New TC Failure FormatDocument6 pagesNew TC Failure Formatmallikarjun aeNo ratings yet

- PCI Big - Beam - BrochureDocument7 pagesPCI Big - Beam - BrochureJuan Carlos PlasenciaNo ratings yet

- Ecc Roads-and-Bridges-ProjectsDocument14 pagesEcc Roads-and-Bridges-ProjectsDan DianardNo ratings yet

- Standard Lift Plan TemplateDocument2 pagesStandard Lift Plan TemplateInbarajNo ratings yet

- Training Manual HydromaxDocument92 pagesTraining Manual HydromaxlordwarioNo ratings yet

- Material Lifting Plan - Revised Format 10 05 2018Document2 pagesMaterial Lifting Plan - Revised Format 10 05 2018nitesh dayamaNo ratings yet

- Tapovan Vishnugad Hep Segmental Methodology For HRT Concrete LiningDocument31 pagesTapovan Vishnugad Hep Segmental Methodology For HRT Concrete LiningSenthilkumar SubramanianNo ratings yet

- Construction of Barangay Road: See Attach Plan by ContractDocument3 pagesConstruction of Barangay Road: See Attach Plan by ContractCarmel Ares LuzanoNo ratings yet

- Crane Lift PlanDocument6 pagesCrane Lift PlanHamidullah Asady WardakNo ratings yet

- Rasgas Company Limited: Cranes and Lifting Gear Integrity ManualDocument2 pagesRasgas Company Limited: Cranes and Lifting Gear Integrity ManualReda Elawady100% (1)

- Lifting Operation ChecklistDocument8 pagesLifting Operation ChecklistHein SiNo ratings yet

- Authorisation For Layig GSB and WMM-Rev-R2Document1 pageAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranNo ratings yet

- AvaraDocument10 pagesAvaraElchin SattarovNo ratings yet

- DSV - 110-120mDocument109 pagesDSV - 110-120mmahudin58No ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift PlanMd Wãșéèm ÁkrãmNo ratings yet

- Critical Lift Plan: - Load Is Greater Than 85 Percent of Mobile Crane Rated Capacity, or Greater Than 90 Percent ofDocument6 pagesCritical Lift Plan: - Load Is Greater Than 85 Percent of Mobile Crane Rated Capacity, or Greater Than 90 Percent ofberatcansuNo ratings yet

- 01 - Lifting Personnel Basket - ADNOCDocument4 pages01 - Lifting Personnel Basket - ADNOCEmad ZakiNo ratings yet

- 18.lifting Plan Unisco (PF) - 18Document3 pages18.lifting Plan Unisco (PF) - 18ibrahimNo ratings yet

- FRM-4.04.10-PTFI-002 Crane Lift Plan - EngDocument1 pageFRM-4.04.10-PTFI-002 Crane Lift Plan - EngFrans PepuhoNo ratings yet

- Lifting Plan: General Information: LP - 01 / Rev 00Document8 pagesLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNo ratings yet

- Material HandlingDocument25 pagesMaterial HandlingKhoirul UmamNo ratings yet

- USA Lift Plan Reference Booklet 809 2010Document5 pagesUSA Lift Plan Reference Booklet 809 2010jairseguraNo ratings yet

- Floodable Length - Unit IVDocument19 pagesFloodable Length - Unit IVsomasundaramNo ratings yet

- Reliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisFrom EverandReliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex DDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex DMohammed HamzaNo ratings yet

- Techno Gym - Gym Equipment Maintenance Report ReportDocument1 pageTechno Gym - Gym Equipment Maintenance Report ReportMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex GDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex GMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined SpacesDocument31 pagesPro Hse 024 Eni Iraq r00 - Working in Confined SpacesMohammed Hamza100% (1)

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- 04 - Accomdation Room Iso Corner MSKU 938908 0 - CompressedDocument1 page04 - Accomdation Room Iso Corner MSKU 938908 0 - CompressedMohammed HamzaNo ratings yet

- Office 7 InspectionDocument1 pageOffice 7 InspectionMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex CDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex CMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex HDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex HMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex BDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex BMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex EDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex EMohammed HamzaNo ratings yet

- Security Bar SafetyDocument1 pageSecurity Bar SafetyMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex FDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex FMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex ADocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex AMohammed HamzaNo ratings yet

- Required Equimpent For Ro Station and Blackwater TreatmentDocument2 pagesRequired Equimpent For Ro Station and Blackwater TreatmentMohammed HamzaNo ratings yet

- M InspectionDocument1 pageM InspectionMohammed HamzaNo ratings yet

- EI InspectionDocument1 pageEI InspectionMohammed HamzaNo ratings yet

- CA InspectionDocument1 pageCA InspectionMohammed HamzaNo ratings yet

- CA InspectionDocument1 pageCA InspectionMohammed HamzaNo ratings yet

- Action Log For 22 of AugDocument1 pageAction Log For 22 of AugMohammed HamzaNo ratings yet

- Smoke Alarms Disability Safety TipsDocument1 pageSmoke Alarms Disability Safety TipsBarkat UllahNo ratings yet

- Smoke AlarmsDocument1 pageSmoke AlarmscristoferNo ratings yet

- Smoking SafetyDocument1 pageSmoking SafetyBinoy GopinathanNo ratings yet

- Action Log For 22 of JulyDocument1 pageAction Log For 22 of JulyMohammed HamzaNo ratings yet

- Office 8 InspectionDocument1 pageOffice 8 InspectionMohammed HamzaNo ratings yet

- Grilling SafetyDocument1 pageGrilling SafetyShaikJeelanBashaNo ratings yet

- Generator Safety TipsDocument1 pageGenerator Safety TipsMohammed HamzaNo ratings yet

- Electrical SafetyDocument1 pageElectrical SafetyDougNewNo ratings yet

- Halloween Fire Safety Tips: Did You Know?Document1 pageHalloween Fire Safety Tips: Did You Know?Mohammed HamzaNo ratings yet

- Gel Fuel Safety TipsDocument1 pageGel Fuel Safety TipsMohammed HamzaNo ratings yet

- Measuring Innovation: A New PerspectiveDocument24 pagesMeasuring Innovation: A New PerspectiveJoshua RitongaNo ratings yet

- Budgeting: Accounting: A Malaysian Perspective, 5e (Adapted From Accounting 26e: Warren, Reeve & Duchac)Document58 pagesBudgeting: Accounting: A Malaysian Perspective, 5e (Adapted From Accounting 26e: Warren, Reeve & Duchac)Asyikin OsmanNo ratings yet

- Navistar Capacity Verification: Supplier / Part InformationDocument4 pagesNavistar Capacity Verification: Supplier / Part InformationAnurag TiwariNo ratings yet

- ChackaoDocument13 pagesChackaoChackaNo ratings yet

- A CAT Corp MRP SolnDocument12 pagesA CAT Corp MRP Solnakshay kushNo ratings yet

- Bullying Behaviour in Corporate: What Is Workplace Bullying?Document5 pagesBullying Behaviour in Corporate: What Is Workplace Bullying?prabhuhateNo ratings yet

- BSBCMM401 Make A Presentation (Task1 Part B)Document4 pagesBSBCMM401 Make A Presentation (Task1 Part B)pidchayapon sawangvongNo ratings yet

- Dwnload Full Thermodynamics An Interactive Approach 1st Edition Bhattacharjee Solutions Manual PDFDocument36 pagesDwnload Full Thermodynamics An Interactive Approach 1st Edition Bhattacharjee Solutions Manual PDFjefferyphillips68roj100% (9)

- Letter of Offer - SIHE - Lokraj PoudelDocument12 pagesLetter of Offer - SIHE - Lokraj PoudelPrabesh TiwariNo ratings yet

- Strategic Management ProjectDocument9 pagesStrategic Management ProjectUsama AdenwalaNo ratings yet

- Business Insights & Analytics ManagerDocument1 pageBusiness Insights & Analytics ManagerAndrew ZinkinNo ratings yet

- RFBT-08 (Negotiable Instruments)Document22 pagesRFBT-08 (Negotiable Instruments)Erlinda MolinaNo ratings yet

- Philippine Bank of Communications vs. Commissioner of Internal Revenue (GR 112024. Jan. 28, 1999)Document2 pagesPhilippine Bank of Communications vs. Commissioner of Internal Revenue (GR 112024. Jan. 28, 1999)Col. McCoyNo ratings yet

- Print - Udyam Registration CertificateDocument1 pagePrint - Udyam Registration CertificatearvindNo ratings yet

- Name: Student ID: 19P00024 Subject: Date: Submitted To: Ume LailaDocument6 pagesName: Student ID: 19P00024 Subject: Date: Submitted To: Ume LailaUmme Laila JatoiNo ratings yet

- Executive Summary: Sources and Application of FundsDocument6 pagesExecutive Summary: Sources and Application of FundsJimmy DagupanNo ratings yet

- ALARP - Demonstration STD - AUSDocument24 pagesALARP - Demonstration STD - AUSMahfoodh Al AsiNo ratings yet

- Session6 - OD InterventionDocument4 pagesSession6 - OD InterventionPriyam BatraNo ratings yet

- Creating Advertising Programe Message, Headlines, Copy, LogoDocument18 pagesCreating Advertising Programe Message, Headlines, Copy, LogoHiren ShahNo ratings yet

- Sr. Acc Suroor ResumeDocument2 pagesSr. Acc Suroor ResumeVaibhav VermaNo ratings yet

- The Foreign Exchange MarketDocument3 pagesThe Foreign Exchange MarketDavina AzaliaNo ratings yet

- Nonprofit Org Chart: Board of Directors Board of DirectorsDocument1 pageNonprofit Org Chart: Board of Directors Board of DirectorssamNo ratings yet

- PepperfryDocument8 pagesPepperfrySakshiNo ratings yet

- Yahoo Symbol ListDocument21 pagesYahoo Symbol ListShubham RohatgiNo ratings yet

- Building Permit ChecklistDocument1 pageBuilding Permit Checklistar desNo ratings yet

- Spreadsheet Home GameDocument7 pagesSpreadsheet Home GameJorge Augusto de Moura LimaNo ratings yet

- 2 ABBOT VS. NLRC G.R. No. 76959 October 12, 1987Document2 pages2 ABBOT VS. NLRC G.R. No. 76959 October 12, 1987Kornessa ParasNo ratings yet