Professional Documents

Culture Documents

Threaded Mechanical Branch Tee

Uploaded by

Julian RiverosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Threaded Mechanical Branch Tee

Uploaded by

Julian RiverosCopyright:

Available Formats

FIG.

MT-1 Threaded Mechanical Branch Tee

Mechanical branch connections for reducing branch

outlets without welding. The MT-1 is a bolted saddle

type fitting with NPT female threaded outlets. Design

assures a superior sealing, full pipe support, excellent

stability and easy installation.

For Listing/Approval Details and Limitations,

visit our website at www.anvilstar.com or contact

an Anvil®/AnvilStar™ Sales Representative.

MATERIAL SPECIFICATIONS

HOUSING: LUBRICATION:

Ductile Iron conforming to ASTM A-536, Grade 65-45-12 Standard Gruvlok

Gruvlok Xtreme™ required for dry pipe systems and freezer applications.

ANSI BOLTS & HEAVY HEX NUTS:

Heat treated, oval-neck track head bolts conforming to ASTM A-183 Grade GASKETS: Materials

2 with a minimum tensile strength of 110,000 psi and heavy hex nuts of Properties as designated in accordance with ASTM D-2000.

carbon steel conforming to ASTM A-563 Grade A or Grade B, or SAE

Grade “E” EPDM (Green color code)

J995 Grade 2. Bolts and nuts are provided zinc electroplated as standard.

-40°F to 230°F (Service Temperature Range)(-40°C to 110°C)

COATINGS: Recommended for water service, diluted acids, alkalies solutions, oil-free

air and many chemical services.

Rust inhibiting paint Color: ORANGE (standard)

Hot Dipped Zinc Galvanized (optional) NOT FOR USE IN PETROLEUM APPLICATIONS.

Other available options: Example: RAL3000 or RAL9000 Series

For other coating requirements contact an AnvilStar Representative.

Project information Approval Stamp

Project: ❑ Approved

Address: ❑ Approved as noted

Contractor: ❑ Not approved

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

5/09

FIG. MT-1 Threaded Mechanical Branch Tee

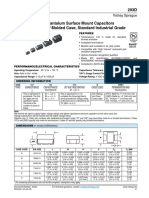

MT-1 THREADED MECHANICAL BRANCH TEE

Hole Dimensions Max. Dimensions

Nominal Bolt Approx.

O.D. Working V

Size Min. Diameter Max. Diameter T W Y Z Size Wt. Ea.

Pressure Threaded

In./DN(mm) In./mm In./mm In./mm PSI/bar In./mm In./mm In./mm In./mm In./mm In./mm Lbs./Kg

2x1 2.375 x 1.315 11⁄2 15⁄8 300 115⁄16 25⁄8 19⁄16 45⁄8 21⁄2 3

⁄8 x 2 1.7

50 x 25 60.3 x 33.7 38 41 20.7 50 67 40 117 63 0.8

2 x 11⁄4 2.375 x 1.660 13⁄4 17⁄8 300 115⁄16 25⁄8 19⁄16 45⁄8 21⁄2 3

⁄8 x 2 1.7

50 x 32 60.3 x 42.4 44 48 20.7 49 67 40 117 63 0.8

2 x 11⁄2 2.375 x 1.900 13⁄4 17⁄8 300 115⁄16 25⁄8 19⁄16 45⁄8 27⁄8 3

⁄8 x 2 1.7

50 x 40 60.3 x 48.3 44 48 20.7 49 67 40 117 73 0.8

21⁄2 x 1 2.875 x 1.315 11⁄2 15⁄8 300 27⁄16 31⁄8 113⁄16 59⁄16 33⁄8 1

⁄2 x 23⁄4 3.6

65 x 25 73.0 x 33.7 38 41 20.7 62 79 46 141 86 1.6

21⁄2 x 11⁄4 2.875 x 1.660 2 21⁄8 300 27⁄16 31⁄8 113⁄16 59⁄16 33⁄8 1

⁄2 x 23⁄4 3.6

65 x 32 73.0 x 42.4 51 54 20.7 62 79 46 141 86 1.6

21⁄2 x 11⁄2 2.875 x 1.900 2 21⁄8 300 27⁄16 31⁄8 113⁄16 59⁄16 33⁄8 1

⁄2 x 23⁄4 3.6

65 x 40 73.0 x 48.3 51 54 20.7 62 79 46 141 86 1.6

3x1 3.500 x 1.315 11⁄2 15⁄8 300 23⁄4 37⁄16 21⁄8 61⁄4 315⁄16 1

⁄2 x 23⁄4 3.8

80 x 25 88.9 x 33.7 38 41 20.7 71 87 55 159 99 1.7

3 x 11⁄4 3.500 x 1.660 2 21⁄8 300 23⁄4 37⁄16 21⁄8 61⁄4 315⁄16 1

⁄2 x 23⁄4 3.8

80 x 32 88.9 x 42.4 51 54 20.7 70 87 55 159 99 1.7

3 x 11⁄2 3.500 x 1.900 2 21⁄8 300 23⁄4 37⁄16 21⁄8 61⁄4 315⁄16 1

⁄2 x 23⁄4 3.8

80 x 40 88.9 x 48.3 51 54 20.7 70 87 55 159 99 1.7

3x2 3.500 x 2.375 21⁄2 25⁄8 300 23⁄4 37⁄16 21⁄8 61⁄4 315⁄16 1

⁄2 x 23⁄4 4.4

80 x 50 88.9 x 60.3 64 67 20.7 70 87 55 159 99 2.0

31⁄2 x 2 4.000 x 2.375 21⁄2 25⁄8 300 33⁄16 37⁄8 27⁄16 65⁄8 315⁄16 1

⁄2 x 23⁄4 4.6

90 x 50 101.6 x 60.3 64 67 20.7 81 98 62 168 99 2.1

4x1 4.500 x 1.315 11⁄2 15⁄8 300 35⁄16 4 25⁄8 71⁄4 313⁄16 1

⁄2 x 23⁄4 4.6

100 x 25 114.3 x 33.7 38 41 20.7 85 102 67 184 97 2.1

4 x 11⁄4 4.500 x 1.660 2 21⁄8 300 35⁄16 4 25⁄8 71⁄4 313⁄16 1

⁄2 x 23⁄4 4.6

100 x 32 114.3 x 42.4 51 54 20.7 84 102 67 184 97 2.1

4 x 11⁄2 4.500 x 1.900 2 21⁄8 300 35⁄16 4 25⁄8 71⁄4 313⁄16 1

⁄2 x 23⁄4 4.6

100 x 40 114.3 x 48.3 51 54 20.7 84 102 67 184 97 2.1

4x2 4.500 x 2.375 21⁄2 25⁄8 300 35⁄16 4 25⁄8 71⁄4 41⁄2 1

⁄2 x 23⁄4 4.8

100 x 50 114.3 x 60.3 64 67 20.7 84 102 67 184 115 2.2

4 x 21⁄2 4.500 x 2.875 23⁄4 27⁄8 300 31⁄16 4 25⁄8 71⁄4 41⁄2 1

⁄2 x 23⁄4 5.4

100 x 65 114.3 x 73.0 70 73 20.7 78 102 67 184 115 2.4

5 x 11⁄2 5.563 x 1.900 2 21⁄8 300 41⁄16 43⁄4 33⁄16 85⁄16 313⁄16 5

⁄8 x 4 7.4

125 x 40 141.3 x 48.3 51 54 20.7 103 121 81 211 97 3.4

5x2 5.563 x 2.375 21⁄2 25⁄8 300 41⁄16 43⁄4 33⁄16 85⁄16 313⁄16 5

⁄8 x 4 7.9

125 x 50 141.3 x 60.3 64 67 20.7 103 121 81 211 97 3.6

5 x 21⁄2 5.563 x 2.875 23⁄4 27⁄8 300 313⁄16 43⁄4 33⁄16 85⁄16 313⁄16 5

⁄8 x 4 7.9

125 x 65 141.3 x 73.0 70 73 20.7 97 121 81 211 97 3.6

6 x 11⁄2 6.625 x 1.900 2 21⁄8 300 47⁄16 51⁄8 311⁄16 93⁄8 37⁄8 5

⁄8 x 4 7.5

150 x 40 168.3 x 48.3 51 54 20.7 113 130 94 238 98 3.4

6x2 6.625 x 2.375 21⁄2 25⁄8 300 47⁄16 51⁄8 311⁄16 93⁄8 47⁄16 5

⁄8 x 4 8.0

150 x 50 168.3 x 60.3 64 67 20.7 112 130 94 238 112 3.6

6 x 21⁄2 6.625 x 2.875 23⁄4 27⁄8 300 43⁄16 51⁄8 311⁄16 93⁄8 47⁄16 5

⁄8 x 4 8.0

150 x 65 168.3 x 73.0 70 73 20.7 106 130 94 238 112 3.6

All sizes may be used as mechanical crosses.

Threads are NPT per ANSI/ASME B1.20.1

For dry pipe systems and freezer applications

lubrication of the gasket is required,

Gruvlok® Xtreme™ Lubricant is required.

5/09

You might also like

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 pagesMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- Come Back To Your Senses Use Your Body: Psychologyt LsDocument1 pageCome Back To Your Senses Use Your Body: Psychologyt LsMarina Moran100% (1)

- Girl Scouts ActivitiesDocument5 pagesGirl Scouts ActivitiessluttybitchNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- OTC Drug ListDocument7 pagesOTC Drug ListHong Diem100% (1)

- Torc 4 Abscohort1 - CompressDocument13 pagesTorc 4 Abscohort1 - CompressFaye MartinezNo ratings yet

- Major Emergencies in Power PlantDocument29 pagesMajor Emergencies in Power Plantsourav mahapatraNo ratings yet

- SWRO-200C Operation Manual AppendicesDocument38 pagesSWRO-200C Operation Manual AppendicestonbaldinNo ratings yet

- Septic Abortion PDFDocument4 pagesSeptic Abortion PDFmariachrismayaniNo ratings yet

- GRINNELL Figure 730 Mechanical Tees and Crosses Threaded / Grooved General Description Technical DataDocument8 pagesGRINNELL Figure 730 Mechanical Tees and Crosses Threaded / Grooved General Description Technical DataEdwin Collado FigueroaNo ratings yet

- Snap AnvilDocument2 pagesSnap AnvilhanselltechfireNo ratings yet

- Dimensions Victaulic ClampDocument12 pagesDimensions Victaulic ClampAries MunandarNo ratings yet

- Style 841Document7 pagesStyle 841Ummes AhmedNo ratings yet

- Style 889Document6 pagesStyle 889Ummes AhmedNo ratings yet

- Style W489Document4 pagesStyle W489Ummes AhmedNo ratings yet

- Victaulic Reducing Coupling Style 750: 1.0 Product DescriptionDocument6 pagesVictaulic Reducing Coupling Style 750: 1.0 Product Descriptionjagger7scribNo ratings yet

- Datasheet Rigid CouplingDocument6 pagesDatasheet Rigid Couplingaras aliNo ratings yet

- Mechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Document15 pagesMechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Kenix TehNo ratings yet

- Catalogo Junta VictaulicDocument7 pagesCatalogo Junta VictaulicandhucaosNo ratings yet

- Orifice Plate - Monobloc: DatasheetDocument8 pagesOrifice Plate - Monobloc: Datasheetbiomed systechNo ratings yet

- 4133 - GV Sub Fig7012Document6 pages4133 - GV Sub Fig7012Bryan STNo ratings yet

- Victaulic Firelock Low-Profile Sprinkler-Tee Style 912: 1.0 Product DescriptionDocument3 pagesVictaulic Firelock Low-Profile Sprinkler-Tee Style 912: 1.0 Product DescriptionRemus PacurarNo ratings yet

- En Pulsor170assemblyDocument2 pagesEn Pulsor170assemblysoorajssNo ratings yet

- Victaulic Quickvic Rigid Coupling Style 107N: 1.0 Product DescriptionDocument6 pagesVictaulic Quickvic Rigid Coupling Style 107N: 1.0 Product DescriptionLUCASNo ratings yet

- Victaulic Quick Vic Rigid CouplingsDocument7 pagesVictaulic Quick Vic Rigid Couplingsionut cerneaNo ratings yet

- FT Unión Flexible Style 177n EspDocument6 pagesFT Unión Flexible Style 177n EspJulian CristanchoNo ratings yet

- Datasheet LiYCY Cable PDFDocument1 pageDatasheet LiYCY Cable PDFResaKandhy100% (1)

- Datasheet LiYCY CableDocument1 pageDatasheet LiYCY CableResaKandhyNo ratings yet

- Begg Cousland Tower InternalsDocument4 pagesBegg Cousland Tower InternalsHavocFireNo ratings yet

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Victaulic Data IGSDocument15 pagesVictaulic Data IGSmas queretaroNo ratings yet

- Victaulic Carbon Steel Couplings and Grooved FittingsDocument16 pagesVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgNo ratings yet

- Tuyau en Fonte Ductile Ekoval ChoixDocument52 pagesTuyau en Fonte Ductile Ekoval ChoixmmfayistNo ratings yet

- Style 807NDocument7 pagesStyle 807NUmmes AhmedNo ratings yet

- Stainless Steel Flexible Hose Fitting SpecsDocument3 pagesStainless Steel Flexible Hose Fitting SpecsANAS GOGAZEHNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- NP Pressure Pipe SystemDocument11 pagesNP Pressure Pipe SystemMustafa AlluhaibiNo ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- ADPL718 Catalog Page 25 - Yellow B AckDocument1 pageADPL718 Catalog Page 25 - Yellow B AckSugeng DarmintoNo ratings yet

- Datasheet TBUT000400 enDocument2 pagesDatasheet TBUT000400 enpetkoNo ratings yet

- Self-Drilling Screws: Key BenefitsDocument8 pagesSelf-Drilling Screws: Key BenefitsGabriel MacedoNo ratings yet

- Victaulic Quickvic™ SD Installation-Ready™ System: 1.0 Product DescriptionDocument9 pagesVictaulic Quickvic™ SD Installation-Ready™ System: 1.0 Product DescriptionQuynh NguyenNo ratings yet

- M/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsDocument8 pagesM/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsBahador YazdiNo ratings yet

- Toggle-Injection-Moulding-Machines 2Document16 pagesToggle-Injection-Moulding-Machines 2Vimal AathithanNo ratings yet

- Victaulic Outlet Coupling Style 72Document5 pagesVictaulic Outlet Coupling Style 72George SobhyNo ratings yet

- Style 856Document9 pagesStyle 856Ummes AhmedNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Elastomer I C Bearings PDFDocument8 pagesElastomer I C Bearings PDFMiguel Belda DiezNo ratings yet

- Mechanical Tees: Figure 730 Mechanical Tee - GroovedDocument2 pagesMechanical Tees: Figure 730 Mechanical Tee - GroovedLuis PárragaNo ratings yet

- Reciprocating Saws 0815E 02Document4 pagesReciprocating Saws 0815E 02agiepanjiNo ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- LOW THERMAL INERTIA RADIATORDocument2 pagesLOW THERMAL INERTIA RADIATORMihajlo MoracaNo ratings yet

- Manual 80 81 Isolation RingsDocument10 pagesManual 80 81 Isolation RingsFelix UscangaNo ratings yet

- IN33080Document1 pageIN33080Khalid ZaeemNo ratings yet

- AL-905-R-11202 Spec AG01 Rev. T02Document3 pagesAL-905-R-11202 Spec AG01 Rev. T02altipatlarNo ratings yet

- Style 857Document6 pagesStyle 857Ummes AhmedNo ratings yet

- 6904 ST Sub Fige2Document1 page6904 ST Sub Fige2K NavinNo ratings yet

- ETube Brochure and Spec SheetDocument4 pagesETube Brochure and Spec SheetJavier espinosaNo ratings yet

- Vishay 293D475X9025C2TE3 DatasheetDocument9 pagesVishay 293D475X9025C2TE3 DatasheetMiguel VNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- Style 858Document7 pagesStyle 858Ummes AhmedNo ratings yet

- Colourbox - Studio: PRO12 / D2W / AC7Document2 pagesColourbox - Studio: PRO12 / D2W / AC7mosabNo ratings yet

- VIZY - Ex4054 - Metallic Sprinkler PipeDocument2 pagesVIZY - Ex4054 - Metallic Sprinkler PipeJulian RiverosNo ratings yet

- VIZY - Ex4054 - Metallic Sprinkler PipeDocument2 pagesVIZY - Ex4054 - Metallic Sprinkler PipeJulian RiverosNo ratings yet

- Anvil Henderson CoC 051910 PDFDocument1 pageAnvil Henderson CoC 051910 PDFJulian RiverosNo ratings yet

- Soportes EricoDocument12 pagesSoportes EricoJulian RiverosNo ratings yet

- 5-3 Hose Valves 5000 PDFDocument1 page5-3 Hose Valves 5000 PDFJulian RiverosNo ratings yet

- It'S Simple Math.: Caddy Pipe Supports Job-Site EfficiencyDocument27 pagesIt'S Simple Math.: Caddy Pipe Supports Job-Site EfficiencyJulian RiverosNo ratings yet

- SECTION 15140 Non-Continuous Hangers and Pipe Supports Part 1-General 1.1 SCOPEDocument2 pagesSECTION 15140 Non-Continuous Hangers and Pipe Supports Part 1-General 1.1 SCOPEJulian RiverosNo ratings yet

- Supports, Guides & RollersDocument19 pagesSupports, Guides & RollersJulian RiverosNo ratings yet

- Technical Information 20: Dimensional Legend FinishesDocument26 pagesTechnical Information 20: Dimensional Legend FinishesJulian RiverosNo ratings yet

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Child Rearing Practices Articles India & ChinaDocument14 pagesChild Rearing Practices Articles India & ChinaGeorgiana GattinaNo ratings yet

- Qualifications of Public Health NurseDocument2 pagesQualifications of Public Health Nursekaitlein_mdNo ratings yet

- SECTION 03380 Post-Tensioned Concrete Rev 1Document30 pagesSECTION 03380 Post-Tensioned Concrete Rev 1Abdalrahman AntariNo ratings yet

- RMD - Lightmix Modular CE IVD Assay BrochureDocument4 pagesRMD - Lightmix Modular CE IVD Assay BrochureDummy Tester JrNo ratings yet

- Different Surgical Modalities For Management of Postburn FL Exion Contracture of The ElbowDocument6 pagesDifferent Surgical Modalities For Management of Postburn FL Exion Contracture of The ElbowMadhuchandra HirehalliNo ratings yet

- Yoga & Diet To Prevent DepressionDocument5 pagesYoga & Diet To Prevent DepressionDietician Mrunmayee DixitNo ratings yet

- C612Document5 pagesC612dinhtung2210100% (1)

- The Dilemma of The Neighborhood BoardDocument2 pagesThe Dilemma of The Neighborhood BoardRosaNo ratings yet

- RV Failure: Pathophysiology, Diagnosis and TreatmentDocument16 pagesRV Failure: Pathophysiology, Diagnosis and TreatmentRizky Regia TriseynesyaNo ratings yet

- Edwards Auto 306 CharacteristicsDocument4 pagesEdwards Auto 306 CharacteristicsJuan Antonio Rubio-LaraNo ratings yet

- BiostastisticDocument2 pagesBiostastisticاحمد ماجد زبنNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- FD2000 DatasheetDocument2 pagesFD2000 DatasheetIvan MihajlovicNo ratings yet

- Counter-pressure filler valve for beveragesDocument3 pagesCounter-pressure filler valve for beveragesbimalishaNo ratings yet

- Roof Construction Dr. Fixit Newcoat PDFDocument1 pageRoof Construction Dr. Fixit Newcoat PDFRishabh VijayNo ratings yet

- W H G Kingston "Dick Cheveley": PrefaceDocument159 pagesW H G Kingston "Dick Cheveley": PrefaceGutenberg.orgNo ratings yet

- Aiesha Edward Resume2Document2 pagesAiesha Edward Resume2api-491571342No ratings yet

- Schlumber: Kevin: 16010072 Moch Rizky Setiawan: 16010068Document12 pagesSchlumber: Kevin: 16010072 Moch Rizky Setiawan: 16010068KevinNo ratings yet

- 1978 - 90 Day Study or Rhesus Monkey ToxicityDocument4 pages1978 - 90 Day Study or Rhesus Monkey Toxicitygrace poudrierNo ratings yet

- A4 RelationshipgridDocument32 pagesA4 RelationshipgridjamesNo ratings yet

- Berca Engineering SUBMITTEDDocument20 pagesBerca Engineering SUBMITTEDJohandika FerbiantokoNo ratings yet