Professional Documents

Culture Documents

Sac26-27 Machanical

Sac26-27 Machanical

Uploaded by

ansarmulla7110 ratings0% found this document useful (0 votes)

14 views5 pagesOriginal Title

SAC26-27 MACHANICAL

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views5 pagesSac26-27 Machanical

Sac26-27 Machanical

Uploaded by

ansarmulla711Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Delta Metallurgical Laboratory & Services

(AN ISO/IEC17025 NABL Accredited Testing Laboratory)

Sumeru Plaza, Neminath Nagar, Dhamani Road, Sangli - 416 416

© : (0233) 2333310 @ : www.deltalabsangli.in s : lab@deltalabsangli.in

Report No: _DMLs20202418-so4ot7767 ULR NazTosse523000020825°

i TatRapor amd

= |eamamars Toe DHL SETAE :

savant steeteauiovs [Sample Woroata Souter

Behind Wine Pare, cw Satara iRewet bars en

Rong. Go1028 Bamba, era aa? fea Det

[" ate of Sample Receved orton

leat No:23SAC-26, Sample Description: Machined tensile test bar & Piece,

[Material Standard Specification: ASTM A890-18a/A995-20 Gr.5A/ CE3MN UNS.

(Discipline: Mechanical Group : Mechanical Properties of Metals

[Test Method-Tensile Test ASTM A370-2023/ ASTM EGIEGM - 21 Date of Testing : 26-11-2023

Test Details

Parameter Min Value] Max Value] Observed Value]

[Specimen Shape 7 = sit eee ‘Solid round,

‘Gauge length(mnm) z ; 30.007

[Area of specimen(mm2) 179.403)

al Gauge length(ram) 274

load At Peak(kN)_ 707.583)

(Gauge diameter(mm) cs ae ‘ 72.33

[Ukimate tensile strength('imma) 680.00) 350.844) —

'% Elongation site | BSPSRREEREREES |) 25.48)—

‘Yield Load 1(eN) ie - 7esi8'~

|Yield Stress 1 (0.2)% (Nim) 515.00 L 40.835--

[Fracture WG.

Remark _|Sample confirms tensile requirements as per standard ASTM A890-18a/A995-20 Gr. SA/ CESMN UNS J63404

Witness |Mr. Ansar Mulla, (TUV Rheinland)

End of report...

Disclaimer: “Statements of conformity (e., Pass! Fi) to specications are mage ints report without aking measurement uncetinty ins account

‘xcept when requested bythe customer

rn

Oreviewea [9]

TOvRheinlahd pate 2&-N-23 |= Z

For Delta Metallyriga|LaboratolyaServioes

Auifirized Signator

MR. K. K, CHOUG'

4) This Report relates only to the sample(s) submitted & tasted. 2) Samples are not drawn by DELTAMETALLURGH "ATOR a SERVICES,

3)Resuls portainto the samples testad only. 4) Test cortical shalnol be e-prodicedexcoptin fallout wiltenapprovaoflaboratoy.

! 7 e mae P.T.O. for Terms & Conditions:

@ scanned with OKEN Scanner

Delta Metallurgical Laboratory & Services

(AN ISO/IEC17025 NABL Accredited Testing Laboratory)

Sumeru Plaza, Neminath Nagar, Dhamani Road, Sangli - 416 416

© : (0233) 2333310 @ : www.deltalabsangli.in = : lab@deltalabsangli.in

Report No.: _DMLS/2023-24/S-8041/17788 ULR No.:TC552523000020526F

Test Report oma: on

Customer: TMRN : [DMLS/2028-240F S508

SAWANT STEEL&ALLOYS —_ [Sample No/Teatld 5-6041717768

Behind Wine Park Ol Satara |Report Date: 26-19-2028

Histol Bice [Customer refldate = ja62 2617-0028

[Date of Sample Received: 26-17-2028,

‘Sample Description provided by

‘

y customer: Heat No:23SAC-27, Sample Description:Machined tensile test bar & Piece.

Group : Mechanical Properties of Metals

‘Test Method-Tensile Test ASTM A370-2023/ ASTM EG/EM -21

Date of Testing : 26-11-2023)

Test Details

[Parameter Min Value] Max Value Observed Value)

‘Specimen Shape es 7 ___ Solid round)

Gauge | length(mm) 7 ~ | 50.00

(Area of specimen(mma} 7 T a 125.086,

‘Finer ‘Gauge length(mr ~ _ 62.54

Toad At Peak(kN) ~ 107.965)

jameter(an) - I T262-

Ultimate tensile ‘strength(Nimm2)_ a 7 ‘815.159—

% Elongation + 1 18.00) = 25.08.-

Yield Load 1(RN) i i t i 73.823)

Vietd Stress 1 (0.2)% (NrIn2) 00) : woo 081..

Fracure WGL

Remark _|Sample cor Tensile requirements as per Standard ASTM ‘A890-18a/A995-20 Gr, SA] CESNIN UNS J93404,_

[Witness [Mr. Ansar Mulla, (TUV

Disclaimer: “Statements of contormity (2.9. Pace Fai

except ten requested by the customer,

ind).

End of report...

‘ntnessed

Creviewea

1

TWvireiniahd pater ZEN-23}|

1-000

specications are made in hs Yepet withou taking measurement uncertainty into secount

MR. a K. CHOUGULE

iaghatenl ReRASaO ea GeRvices

esulls pertain othe samples tested only. 4) Test certiicale shallnal be re-produced exceptin fullwitrout he wien approval laboratory.

3) Resulls pertain tothe samples estedonly. 4) Test cetiieate shall ol be rep approval

1) This Report relates onto the samples) submited sted 2) Samples aro ol awn by DELTA RYRERS

@ scanned with OKEN Scanner

Delta Metallurgical Laboratory & Service:

(AN ISO/IEC17025 NABL Accredited Testing Laboratory)

Sumeru Plaza, Neminath Nagar, Dhamani Road, Sangli - 416 416

© : (0233) 2333310 @ : www.deltalabsangli.in 62 : lab@deltalabsangli.in

Report Nos _OMLS'2028-24e040/17760 ULRNo:Tossasas00.020sz4F

Teak Ropor Tones ra]

Gustomer: aN pL Saab

SAwaNTsteet 6 auovs [Sample NtTeata aosorer7e8

Behind Wine Park, Oe Satara |Report Date: eti-2008

end GNo:1026,Bambavde, —|estomer ref aie? robe 29-11-2008

Date of Sample Received 2008

‘Sample Description provided by custor

Material Specificatior

= -26, Sample Description: Machined tensile test bar &

‘STM AB90-18a/A995-20 Gr.5A/ CESMN UNS 93404

: Mechanical ‘Group : Mechanical Properties of Metals |

‘Test Method-Brinell Hardness: ASTM A370-2023/ASTM E10- 2018 Date of Testing:26-17-2023|

2S

Test Details J

Location Test Load indenter RI R23 Avg,

Surface HBW —750Kgf Smm Ball 229 226 229 228.00

Witness: all Mr, Ansar Mulla, (TUV Rheinland) _

ve End of report

Disclaimer: “Statements of conformity (e.g. Pass! Fate specications are made is report without taking measurement uncertainty into account

except when requested bythe customer,

(Gwitnessed

Qeviewea |%

TWvanenie"s Gare BEA, [2

& tested. 2) Samplas are notdravn by DELTAMETALLURGICAL LABORATORY & SERVICES.

not be re-produced except Full without the written approval of laboratory.

P.O. for Terms & Conditions

41) This Report rolates only tothe samplo(s) submit

3) Results pertain tothe samples tested only. 4) Test certificate:

@ scanned with OKEN Scanner

Delta Metallurgical Laboratory & Services

(AN ISO/IEC17025 NABL Accredited Testing Laboratory)

‘Sumeru Plaza, Neminath Nagar, Dhamani Road, Sangli - 416 416

© : (0233) 2333310 @ : www.deltalabsangli.in e3 : lab@deltalabsangli.in

Report No.: _ DMLS/2023-24/8041/17790 ULR No.:T0552523000020523F

C Test Report Toman: ea

3 [Customer : MRN = [DMLS/2023-24/F/3508,

5 SAWANT STEEL & ALLOYS [Sample NofTest ld [sos1/17790

[Behind Wine Park , Old Satara [Report Date [26-11-2028

—[Roas.Go:1026 Bambavde, Customer ref fdate ana 26-11-2023,

[Date of Sample Received : 26-17-2028 7

(Sample Description provided by customer: Heat No:23SAC-27, Sample Descrilion'Machined tensile test bar & Piece.

[Material Specification: ASTM A890-18a/A995-20 Gr.5A/ CE3MN UNS 93404 |

Discipline: Mechanical Group : Mechanical Properties of Metals

(Test Method-Brinell Hardness: ASTM A370-2023/ASTM E10- 2018

Date of Testing:26-11-2023

Test Details ]

R2 R3 Avg.

232 230,00

Location Test

Hew

Load Indentor Rt

Surface 750 Kgf Smm Ball 229

~ (Mr. Ansar Mulla, (TUV Rheinland)

229

Witness

End of report

Disclaimer: “Statements of conformity (.g. Pass! Fai) to spcicaons re made inthis apor without taking measurement uncertainty into account

‘except when requested by the customer.

Witnessed

Cireviewea

veins pater2G-UI-2R

TN 000)

For Delta Metallurgical LabgratoryaSehvices

MRaithotized SiGHIGAILE

Dy. Tachnioal mi

7 ego t/t

1) ThisReportrelatos onto th somple(s) submited & tested 2) Samples aro nol drawn by DELTAMETALLURGICAL LABORATORY & SERVICES.

3)Results pertain o he samples tested only. 4) Test certicate shall nol be re-produced excopt in full without the written approval oflaboratory.

P.T.O. for Terms & Conditions

@ scanned with OKEN Scanner

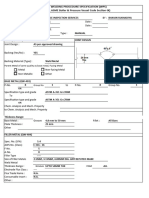

SAWANT STEEL & ALLOYS

"Wiob-9730111110,Fa7-(02346)223296, E-mail:sawantsteel2008@yahoo.in

Web-wmw.sawantsteelfoundary.com

MATERIAL TEST CERTIFICATE SSAF TE

3.2 AS PER EN 10204

(CUSTOMER: _ KALAPI ENGINEERING ASSOCIATES PVT LTD. [F.cNvo:23/2712 [INVOICE NO:SSA/23-24/2712

SPECIFICATION: ASTM A995/AS95M Type CE3MN(SA) [DATE:26/11/2023,

(CONDITION OF SUPPLY:Solution Annealing At 1120" Soak For 04 Hrs, quench in water

‘CHEMICAL ANALYSIS.

HEAT | c% | sim [ mn%[ p% | 5% | cr% | Ni% | Mo% | cu% | N% | PRN

MIN : : - - : zm if 6 | 4 ~ [01 [40

MAX | 0.03 a as [oo [oom | 26 | 8 | 5 eae |e038) a

23SAC 26] 0.024) 0.687 “| 0.892 | 0.023 | 0.0087| 24.67] 6.97] 4.157 0.2024 41.62

2354C27| 0.0284] 0.733~| 0.546 0.0234 0.0117] 24.17] 6.8] 4.56. 0.2 42.42]

MECHANICAL PROPERTIES

HEAT [TS] ¥.S mpa [%Elogn] 9Red | Hardnes | Shear Impact(Joules) Bend

0.2%

UNIT | Mpa | offset ‘area_| sun | Area | temp | 1 a

min [690 |" sis [as | - : 7 alee : oa] ae 7

MAX : : : 5 : Il : alae :

[23saczs] aso.8a [640.83 [25.48 sie ales 7 a= :

238 27| 815.15 590.981 | 25.08 230

DESPATCH DETAILS

HEAT ITEM DESCRIPTION DRAWING NO DESPATCH QTY.

23SAC26[° _ FUNDICION BUJE ‘OXI6DADA07A 16NOS

235AC 277 FUNDICION BUIE 1OX16DADA07A 11Nos ~

235AC 277 FUNDICION BUJE 10X16DAD407A osNos ~

Tested By

2 CERTIFY THAT THE TEMS MENTIONED ABOVE HAVE BEER TESTED THEY ARE FOUNDED TO BE WW ACCORDANCE WH THE

’yTHE ReauiREMAENT OF ASTM A. 995/A995M Type CE3MN(SA)

\ f For Sawant ee

7 _ in Charge aubalify Control Department.

witnessed

Fheviewes

TWynneioand pare ZEAZD |

TN -000

@ scanned with OKEN Scanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- Training CardDocument9 pagesTraining Cardansarmulla711No ratings yet

- Visual Inspection Reports Format No. SKMF-F - 49Document3 pagesVisual Inspection Reports Format No. SKMF-F - 49ansarmulla711No ratings yet

- Supp. Rating FormDocument1 pageSupp. Rating Formansarmulla711No ratings yet

- ISO Documents List 4Document1 pageISO Documents List 4ansarmulla711No ratings yet

- Ut SKMF-F-38Document1 pageUt SKMF-F-38ansarmulla711No ratings yet

- Res Irn Ris-Am-177Document1 pageRes Irn Ris-Am-177ansarmulla711No ratings yet

- Fir Ris-Am-116Document1 pageFir Ris-Am-116ansarmulla711No ratings yet

- Main Gate Visiter Instructions 1Document1 pageMain Gate Visiter Instructions 1ansarmulla711No ratings yet

- Irn Ris-Am-158Document1 pageIrn Ris-Am-158ansarmulla711No ratings yet

- Fir Ris-Am-239Document1 pageFir Ris-Am-239ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- Fir Ris-Am-242Document1 pageFir Ris-Am-242ansarmulla711No ratings yet

- Ir# Am-127Document1 pageIr# Am-127ansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- WPS CD3MNDocument8 pagesWPS CD3MNansarmulla711No ratings yet

- Adapter A4-122 New Doc 02-11-2024 16.02 - 3Document1 pageAdapter A4-122 New Doc 02-11-2024 16.02 - 3ansarmulla711No ratings yet

- LK 40Document3 pagesLK 40ansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- New Doc 02-14-2024 17.21Document2 pagesNew Doc 02-14-2024 17.21ansarmulla711No ratings yet

- Hazard Identification ChecklistDocument2 pagesHazard Identification Checklistansarmulla711No ratings yet

- Unit 2Document25 pagesUnit 2ansarmulla711No ratings yet

- Ris Am 129Document1 pageRis Am 129ansarmulla711No ratings yet