Professional Documents

Culture Documents

LKM Stell Chart

Uploaded by

agus miptahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LKM Stell Chart

Uploaded by

agus miptahCopyright:

Available Formats

LKM Steel Rainbow Chart

11-2012

Comparable Standard Delivered Hardness Typical Analysis on Major Chemical Content Austenitizing Quenching Tempering Temp. and Hardness Cross Reference

Manufacturer Material Grade Characteristics Temperature Method Applications

AISI / JIS / DIN / UNS (At Original Surface) C Si Cr Ni Mn Mo V W / OC 180OC 225OC 300OC 570OC

High hardness and toughness. With nitriding process, surface hardness can be

Prehardened to HB 350 - 400

attained to 800HV or above

Strict and tight control on chemical composition and metallurgical grain structure,

excellent toughness, excellent resistance to heat checking

Strict and tight control on chemical composition and metallurgical grain structure,

homogeneous and stable quality, high material cleanliness, better toughness

comparing to AISI H13, good resistance to heat fatigue

High quality mould inserts, best suitable for plastic moulding of PS, PE, PP, ABS

Special Steel Good polishability and texturability. Superior EDMing property and Plastic injection moulds like LCD TV, automobile, packaging. Holder material for

NIMAX

machiniability. High toughness, Very good weldability forging and die-casting dies. Machine parts

420 Mod., ESR

MIRRAX S136 SUP Annealed to HB 250 Max.

420 Mod., ESR

MIRRAX S136H SUP

420 Mod. (ESR+VAR),

Optical Grade

Plastic mould bases with requirement of long run, corrosion resistance and

ROYALLOY Special Stainless Steel 0.05 0.4 12.6 1.2 high precision. Suitable for plastic and rubber moulds, machine parts that

does not require high surface quality

Good high tempering strength and high toughness, good high temperature Please refer to corresponding product catalogues for the detail of heat Al, Mg die casting mould, die casting parts, Al extrustion molds,

DIEVAR 8418 Special steel Annealed to HB 160 (Max) 0.35 0.2 5.0 0.75 2.3 0.8 strength, excellent hardenability and good temper resistance treatment procedures plastic hard tooling

High strength plastic mould and compacting die, suitable for molding

fibre-reinforced plastics

Special Steel Homogenous structure and hardness. Polishing up to #5000. Good weldability,

PAC5000 Prehardened to HB 336-362 special alloying composition to reduce sensitivity due to weld crack Suitable for plastic moulds requiring high hardness without heat treatment

(PX88/PX4 Mod.)

Pre-hardened type with high hardness, good polishability,excellent

0.15 0.3 - 3.0 1.5 0.3 - -

photo-etchability, good EDM machining and weldability

Newly developed from the concept of NAK80 with improvement on toughness, Moulds with requirement of mix of toughness, polishability, corrosion resistance,

NAK-PRM Special Steel polishability and corrosion resistance e.g. rapid heat and cool technology. Suitable for making LCD TV/Monitor,

Plasma TV housing

Suitable for making plastic moulds with the adoption of rapid heat and cool

Special alloying design and steel making process to provide the material with

PAT 868 integrated properties of high toughness, anti-corrosion and good polishability technology. Good for plastic moulds with the requirement of high toughness,

anti-corrosion and high polishability

S-STAR

S-STAR-A

Good through-hardening properties especially for large moulds, excellent resistance

to thermal shock and to thermal fatigue, excellent resistance to heat erosion

Medium to big size Al, Mg Diecasting mould with prolong tool life

DHA-WORLD Special Steel

Suitable for plastic moulds that require higher wear resistance & toughness.,

DRX (S7) S7 Annealed to HB200 (Max) 0.5 0.3 3.25 0.7 1.4 High strength and high toughness. wear resistance with good shock resistance 940 Oil / Air 58 56 55 49 e.g. thin wall, high GF (30-50%) plastic mould, hot foring, puching die., also the

heavy duty (10mm thick material) cold shear, forming and bending tools

Gröditz

Homogenous hardness. Improved properties such as machinability, heat Large plastic moulds such as car bumper, dashboard and housing for

XPM P20 Modified Prehardened to HRC 38-42 0.26 - 1.50 1.05 - 0.5 conductivity, polishability, etchability and weldability which are better than AISI

(HB 352-390) photocopier and printer

P20 tool steels

Prehardened to HRC 38-42 0.26 ESR version of XPM. Reduction of anisotropy, impurities and segregation to Suitable for large plastic moulds that require high surface quality, such as

XPM V ESR P20 Modified - 1.50 1.05 - 0.5 automobile headlights, rear view mirror, docerative parts, housing for lighting,

(HB 352-390) provide better polishability

LCD/LED TV, photocopier and printer

LKM also provides SWG738, SWG738H, SWG2711, SWG2083, SWG2083H, SWG2316, SWG2083mod V ESR, SWG2316H, SWG2316H ESR, SWG2344, SWG2344 ESR, SWG2343, SWG2343 ESR and SWG2767 on stock. For inquiry, please contact our Sales or Steel Marketing departments.

LKM P20 MOD P20 Mod. Prehardened to HB 250-330 Suitable for core parts of plastic moulds and mould base

P20 / DIN 1.2311 High quality plastic mould with medium run production

P20 + S / DIN 1.2312 High strength plastic mould base plates or core parts without surface requirements

P20 + Ni / DIN 1.2738

With special adjustment to the chemical composition and steel making process, LKM838HS

LKM 838HS Suitable for plastic moulds requiring high hardness, good polishability and wear resistance

possesses a better polishability than LKM738H and LKM838H. Good EDM-ability

DIN 1.2711

P21 Mod., ESR

Plastic mould with requirement of anti-rusting

Plastic mould or mould base with requirement of anti-rusting

LKM 420HM 420, Modified Prehardened to HB 260-320 High Anti-rusting Suitable for mould base that requires anti-rusting

Corrosion resistance plastic moulds

LKM 2316(Annealed)

Annealed to HB 250 max.

(Old Name: LKM2316A)

DIN 1.2316 High corrosion resistance plastic moulds

LKM 2316H(Prehardened)

(Old Name: LKM2316)

LKM 2316H ESR(Prehardened)

High cleanliness, high corrosion resistance High corrosion resistance moulds with good polishability

(Old Name: LKM2316 ESR) DIN 1.2316 ESR

Good hardenability and toughness Suitable for through hardened plastic moulds,sliders, zinc die casting dies

Good high tempering strength and high toughness, good resistance to heat checking Suitable for die casting moulds for Aluminium & Zinc alloys, plastic moulds

Suitable for die casting moulds for Magnesium, Aluminium & Zinc alloys,

LKM 2343 ESR H11,ESR Excellent toughness and ductility in all directions, good strength plastic molds, high polishing required plastic moulds

Good high temperature strength, suitable for die casting mould

Homogenous structure and good isotropic property. Good plastic mould with Suitable for die casting for aluminium and zinc alloys,through hardened

high polishing requirement plastic moulds

O1 Low alloy cold work tool steel with good hardenability and wear resistance

High Chromium cold work tool steel with good wear resistance

LKM 2767 High strength and toughness, can be hardened to HRC 50~54 840-870 Suitable for shearing and blanking of sheet metal with 10mm thick or above

Moulds for high quality plastic or die-casting parts with thin wall or intricated structure.

PORCERAX II PM-35 Remedy for quality and productivity problems due to gas trapping during injection moulding.

MOLDMAX HH Solution and aged to High strength beryllium copper alloy, very high thermal conductivity, shorten moulding

cycle effectively Best suitable for mould core and insert which require rapid cooling

(MM 40) HRC 36 - 42

Thermoforming, blow moulding, ultrasonic welding and machine parts

Plastic injection moulding, blow moulding, ultrasonic welding and machine parts

Ref: S024

Prehardened plastic mould steel Mould base and core part of plastic mould

Prehardened plastic mould steel Mould base and core part of plastic mould

11-2012

S50C - S55C 1050 - 1055 Suitable for plastic mould base and machinery parts

Approval

Certificate

No: HKG0991050 20/F., Crocodile Center, 79 Hoi Yuen Road Tel : (86) 0762-321 0502 Tel : (86) 0571-8213 3281 Tel : (86) 022-5881 8255 Tel : (86) 020-8222 2895 Ext.240

Kwun Tong, Kowloon, Hong Kong Fax : (86) 0762-321 0501 Fax : (86) 0571-8213 3280 Fax : (86) 022-5881 8257 Fax : (86) 020-8222 2897

Tel : (852) 2342 2248, 2341 2321

Fax :(852) 2343 0990, 2341 8544

You might also like

- LKM Steel Rainbow Chart 2014 UpmoldDocument1 pageLKM Steel Rainbow Chart 2014 UpmoldsrinivasaNo ratings yet

- Metal Rainbow Chart (English)Document2 pagesMetal Rainbow Chart (English)jaz99tanNo ratings yet

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocument7 pagesAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNo ratings yet

- MOULD Material DescriptionDocument17 pagesMOULD Material Descriptionworku nurieNo ratings yet

- Material Properties ChartDocument2 pagesMaterial Properties ChartNick PieperNo ratings yet

- Bab 3 MaterialsDocument36 pagesBab 3 MaterialsrWin doNo ratings yet

- Reinforcement Bars: Also Know As TMT Bars (Thermo Mechanically Treated Bars)Document6 pagesReinforcement Bars: Also Know As TMT Bars (Thermo Mechanically Treated Bars)Aishwarya ChhajedNo ratings yet

- Difference Between Austenitic, Ferritic, and MartensiticDocument3 pagesDifference Between Austenitic, Ferritic, and Martensitickihal zohirNo ratings yet

- Advanced Tool MaterialsDocument8 pagesAdvanced Tool MaterialsSry Putri AbdullahNo ratings yet

- H13 1.2344 SKD61 Flat BarDocument4 pagesH13 1.2344 SKD61 Flat BarMANJEET KUMARNo ratings yet

- 1.4542 - X5Crnicunb16-4 1.4548 - X5Crnicunb17-4-4 Alloy 17-4 PHDocument6 pages1.4542 - X5Crnicunb16-4 1.4548 - X5Crnicunb17-4-4 Alloy 17-4 PHSiva GanaNo ratings yet

- Answers To The Review QuestionsDocument16 pagesAnswers To The Review QuestionsMohamed AbdoNo ratings yet

- Frp-Reinforced Concrete Design PDFDocument50 pagesFrp-Reinforced Concrete Design PDFJames NeoNo ratings yet

- PotraitDocument1 pagePotraitanushka moreNo ratings yet

- 1.4 CompositesDocument3 pages1.4 CompositesFuzail NaseerNo ratings yet

- Duplexmakalemm TestingDocument8 pagesDuplexmakalemm TestingViktor -stNo ratings yet

- Amirul Afiq Bin Ab Hisham 2017220378 J4Em1102GDocument3 pagesAmirul Afiq Bin Ab Hisham 2017220378 J4Em1102GFarah RashidNo ratings yet

- gmw3399 2006 04 Multiphase Ultra High Strength Sheet Steel PDFDocument14 pagesgmw3399 2006 04 Multiphase Ultra High Strength Sheet Steel PDFbathu2301No ratings yet

- Boedeker Plastics Polyurethane - Technical GuideDocument26 pagesBoedeker Plastics Polyurethane - Technical GuideJagdish PatelNo ratings yet

- High Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsDocument18 pagesHigh Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsRicardo UriasNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- Influence - of - Strain - Rate - Temperature (R) On FCD 500-7Document8 pagesInfluence - of - Strain - Rate - Temperature (R) On FCD 500-7Jason WuNo ratings yet

- Qurain PP Raffia 3 Mfi Ht031Document1 pageQurain PP Raffia 3 Mfi Ht031Engr HasnainNo ratings yet

- Qurain Polypropylene Technical Data Sheet: Injection Molding Resins Film ResinsDocument1 pageQurain Polypropylene Technical Data Sheet: Injection Molding Resins Film ResinsTychNo ratings yet

- Charpy VnotchDocument11 pagesCharpy VnotchRami GhorbelNo ratings yet

- Product Design With PlasticsDocument256 pagesProduct Design With PlasticsPrachi LoharNo ratings yet

- Why StainlessDocument2 pagesWhy StainlessklopssNo ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewS RNo ratings yet

- Case Hardening SteelsDocument52 pagesCase Hardening SteelsGururaja TantryNo ratings yet

- Creusabro 4800: IndusteelDocument6 pagesCreusabro 4800: IndusteelLuân LêNo ratings yet

- Plastic Product DesignDocument256 pagesPlastic Product DesignManohar BNo ratings yet

- Artículo#2 PDFDocument11 pagesArtículo#2 PDFJo HanNo ratings yet

- Fiber Reinforced Polymer PDFDocument64 pagesFiber Reinforced Polymer PDFmirzaNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- 20 Years of Production Experience, Customized Products, ISO9001 CertificationDocument2 pages20 Years of Production Experience, Customized Products, ISO9001 CertificationErikas AbepaNo ratings yet

- G Mohan 2021 Eng. Res. Express 3 025023Document13 pagesG Mohan 2021 Eng. Res. Express 3 025023DilipSinghNo ratings yet

- Cu ZN 10Document2 pagesCu ZN 10wjjt6chgtmNo ratings yet

- Filament Vs Convolute TubesDocument1 pageFilament Vs Convolute TubesGanesh.MahendraNo ratings yet

- Loctite EA 3476: Technical Data SheetDocument4 pagesLoctite EA 3476: Technical Data SheetKarsa SambasNo ratings yet

- Buchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaDocument6 pagesBuchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaEdson FelixNo ratings yet

- Indo MIM Article in Industrial Business Mart Magazine (April 2011)Document3 pagesIndo MIM Article in Industrial Business Mart Magazine (April 2011)Indo-MIMNo ratings yet

- Good Practices With TMT BarsDocument87 pagesGood Practices With TMT BarsNIBEDITA DEYNo ratings yet

- Unit 202: Principles of Engineering Technology: Handout 1: Range of Materials Materials Commonly Used in EngineeringDocument3 pagesUnit 202: Principles of Engineering Technology: Handout 1: Range of Materials Materials Commonly Used in EngineeringyasirNo ratings yet

- Steel The Basics PDFDocument8 pagesSteel The Basics PDFMark Vista AgusNo ratings yet

- Other Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979Document1 pageOther Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979apurv bhartiNo ratings yet

- LKM Steel For Mould Base and Special Material Eng 12-2012Document1 pageLKM Steel For Mould Base and Special Material Eng 12-2012NazriNo ratings yet

- TS931 Techsupport 60 enDocument8 pagesTS931 Techsupport 60 enMOHAC KILICASLANNo ratings yet

- Physics Based MachiningDocument22 pagesPhysics Based MachiningGirija MNo ratings yet

- Essar - Steel - Colour - Coated TdsDocument5 pagesEssar - Steel - Colour - Coated Tdsyash shah100% (1)

- The Effect of Heat Treatment Parameters and Grain Refinement On Microstructure and Mechanical Properties of A357 AlloyDocument6 pagesThe Effect of Heat Treatment Parameters and Grain Refinement On Microstructure and Mechanical Properties of A357 AlloydbpublicationsNo ratings yet

- Corrosion Failures - Inspection in HRSGDocument12 pagesCorrosion Failures - Inspection in HRSGOwais Malik100% (1)

- AMEDocument2 pagesAMEKiran KumarNo ratings yet

- Web Dew Tool-Steel-Charts EN A1 20171110Document1 pageWeb Dew Tool-Steel-Charts EN A1 20171110Mohammed Abdul HasanNo ratings yet

- Mechanical and Wear PropertiesDocument5 pagesMechanical and Wear PropertiesSyehifful FadlinNo ratings yet

- Quick View For Damage MechanismsDocument7 pagesQuick View For Damage MechanismsRamniza Mat RaniNo ratings yet

- High Performance Austenitic Welded Stainless Tubular ProductDocument2 pagesHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNo ratings yet

- Types of Materials: MetalsDocument33 pagesTypes of Materials: MetalsKutsu ShidaNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Tabel UlirDocument21 pagesTabel Ulirmulyana-50% (6)

- Brochure WONILSpecialSteelDocument38 pagesBrochure WONILSpecialSteelagus miptahNo ratings yet

- E-Catalogue Anniversary Thanks Sale FinalDocument20 pagesE-Catalogue Anniversary Thanks Sale Finalagus miptahNo ratings yet

- Recommended Cutting Conditions: Recommended Depth of Cut For Long Cutting Edge TypeDocument4 pagesRecommended Cutting Conditions: Recommended Depth of Cut For Long Cutting Edge Typeagus miptahNo ratings yet

- Injection Mold Standards 80 Eng D 20Document21 pagesInjection Mold Standards 80 Eng D 20Deep ShahNo ratings yet

- Overmold Design GuideDocument18 pagesOvermold Design GuideCuco MartinezNo ratings yet

- Design and Modeling of Cooling Circuit of Injection MouldingDocument8 pagesDesign and Modeling of Cooling Circuit of Injection Mouldingagus miptahNo ratings yet

- Troubleshooting Guide For Blow MoldingDocument3 pagesTroubleshooting Guide For Blow Moldingwoongs73100% (1)

- SolidworksTips-V2 0Document58 pagesSolidworksTips-V2 0dullecncNo ratings yet

- Phase Transformations in Metals and Alloys, Porter y Easterling (2ed.) BC-305-331Document13 pagesPhase Transformations in Metals and Alloys, Porter y Easterling (2ed.) BC-305-331NIKOLEE LIZETH TORRES ZUÑIGANo ratings yet

- Prorod Spec SheetDocument2 pagesProrod Spec SheetBala SingamNo ratings yet

- Duplex SteelsDocument231 pagesDuplex SteelsDavindRa SoniNo ratings yet

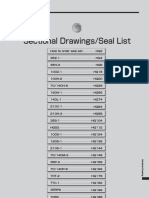

- Sectional Drawings/Seal ListDocument95 pagesSectional Drawings/Seal ListRudi HasibuanNo ratings yet

- Thermal Equilibrium (Phase) DiagramsDocument11 pagesThermal Equilibrium (Phase) DiagramscataiceNo ratings yet

- 2004 12 WJDocument116 pages2004 12 WJJoel CristobalNo ratings yet

- Kaiser Aluminum 6033 PDFDocument4 pagesKaiser Aluminum 6033 PDFAhmed KandeelNo ratings yet

- ToolingFiles NGK PDFDocument215 pagesToolingFiles NGK PDFfernando brasolinNo ratings yet

- Guidelines On Materials Requirements For Carbon and Low Alloy Steels For H2S Containing Environments in Oil and Gas Production (EFC 16)Document53 pagesGuidelines On Materials Requirements For Carbon and Low Alloy Steels For H2S Containing Environments in Oil and Gas Production (EFC 16)zaxaderNo ratings yet

- Effect of Solution Heat Treatment and AdditivestsDocument12 pagesEffect of Solution Heat Treatment and AdditivestsagustingrtNo ratings yet

- Measuring Hydrogen in Aluminum Alloys PDFDocument5 pagesMeasuring Hydrogen in Aluminum Alloys PDFJinsoo KimNo ratings yet

- Kent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDocument1,505 pagesKent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDougKneNo ratings yet

- GP 36-20 - Materials Selection For Subsea EquipmentDocument58 pagesGP 36-20 - Materials Selection For Subsea EquipmentTeymur Regenmaister80% (5)

- Aluminium RollingDocument5 pagesAluminium RollingChetna BarochiyakalolaNo ratings yet

- 316 LVMDocument1 page316 LVMMetehan AgacaNo ratings yet

- The ScienceDocument271 pagesThe Sciencemayra_patiñoNo ratings yet

- Submerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelDocument17 pagesSubmerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelManish MNo ratings yet

- Metallurgy Module One Notes CompleteDocument45 pagesMetallurgy Module One Notes CompleteMutai Daniel50% (2)

- Rate The Quality of Your Steel - Free Webinar and Report - Learn & Share - Leica MicrosystemsDocument18 pagesRate The Quality of Your Steel - Free Webinar and Report - Learn & Share - Leica MicrosystemsharieduidNo ratings yet

- S.williams 2Document42 pagesS.williams 2Damo Daran GNo ratings yet

- Kou2003 PDFDocument6 pagesKou2003 PDFGe EffgenNo ratings yet

- ASM Handbook of Case Histories in Failure Analysis, Vol 3, 2019Document709 pagesASM Handbook of Case Histories in Failure Analysis, Vol 3, 2019Tony Rizzo100% (10)

- Desk Handbook - Phase Diagrams For Binary Alloys 2010Document904 pagesDesk Handbook - Phase Diagrams For Binary Alloys 2010Sam Weber67% (3)

- HSE - Design Codes - PlantDocument32 pagesHSE - Design Codes - PlantPaul EkeNo ratings yet

- Wrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Document6 pagesWrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Tomy lee youngNo ratings yet

- SA253MA DetailDocument16 pagesSA253MA Detailksquare2001100% (1)

- Astm A781 A781m - 2016Document11 pagesAstm A781 A781m - 2016Jose ManuelNo ratings yet

- Answer of QuestionsDocument3 pagesAnswer of QuestionsItaakNo ratings yet

- Medical Device Materials - Stainless SteelDocument5 pagesMedical Device Materials - Stainless Steelmaran.suguNo ratings yet

- 2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Document17 pages2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Bilel MahjoubNo ratings yet