Professional Documents

Culture Documents

Certificado UL E205607 Vol1 Sec21 Proc. NJB1 YW, X, Y, S

Uploaded by

donifan bernalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificado UL E205607 Vol1 Sec21 Proc. NJB1 YW, X, Y, S

Uploaded by

donifan bernalCopyright:

Available Formats

Northbrook

Division

333 Pfingsten Road

Northbrook, IL 60062-2096

USA

www.ul.com

tel: 1 847 272 8800

fax: 1 847 272 8129

Customer service: 1 877 854

3577

File E205607 Vol 1 Issued: 2002-06-19

Revised: 2005-09-09

FOLLOW-UP SERVICE PROCEDURE

(TYPE R)

COMPONENT - AUXILIARY DEVICES

(NKCR2,NKCR8)

Manufacturer: ZHEJIANG CHINT ELECTRICS CO LTD

(111876-001) CHINT INDUSTRIAL ZONE

WENZHOU,

ZHEJIANG 325604 CHINA

Applicant: SAME AS MANUFACTURER

(111876-001)

Recognized Company: SAME AS MANUFACTURER

(111876-001)

This Procedure authorizes the above Manufacturer to use the marking specified by

Underwriters Laboratories Inc. only on products covered by this Procedure,

in accordance with the applicable Follow-Up Service Agreement.

The prescribed Mark or Marking shall be used only at the above manufacturing location

on such products which comply with this Procedure and any other applicable

requirements.

The Procedure contains information for the use of the above named Manufacturer and

representatives of Underwriters Laboratories Inc. and is not to be used for any other

purpose. It is lent to the Manufacturer with the understanding that it is not to

be copied, either wholly or in part, and that it will be returned to Underwriters

Laboratories Inc. upon request.

This PROCEDURE, and any subsequent revisions, is the property of UNDERWRITERS

LABORATORIES INC. and is not transferable.

UNDERWRITERS LABORATORIES INC.

Sajeev Jesudas

Chief Operating Officer

An independent organization working for a safer world with i n t e g r i t y, precision and k n o w l e d g e.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

Underwriters Laboratories Inc. Page 1

Multiple Recognition Correlation Sheet

ML FILE NO. E244412

Issued: 2004-06-21

Revised: 2008-07-23

This page replaces the Multiple Recognition Correlation sheet between files E244412 and E205607,

Volume 1

WITHDRAWN - W-C

Client's Request

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

Underwriters Laboratories Inc. Page 1

Multiple Recognition Correlation Sheet

ML FILE NO. E155557

Issued: 2007-01-31

Revised: 2008-06-10

This page replaces the Multiple Recognition Correlation sheet between files E155557 and E205607,

Volume 1

WITHDRAWN - W-P

Procedures Combined

The ML's File E155557 has been Combined in to File E303503, Basic E205607 Volume 1.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

Underwriters Laboratories Inc. Page 1

Multiple Recognition Correlation Sheet

ML FILE NO. E303503

Issued: 2007-01-31

Revised: 2008-06-10

MULTIPLE RECOGNITION

of

AUXILIARY DEVICES - COMPONENT

(NKCR2, NKCR8)

for

[250431-001] ELECTRICAL & ELECTRONIC CONTROLS INC

Basically Recognized for:

[111876-001] ZHEJIANG CHINT ELECTRICS CO LTD (NBK)

Basically Recognized products covered by Procedure and/or Reports under File No. E205607, Volume 1

Basic Applicant's

Products Report (Supplier's) Multiple Listee's

Covered Date Product Designation Product Designations

Thermal overload relay 2002-06-19 NR2-25-Z ECX-.4-.63A

NR2-25-Z ECX-.63-1A

NR2-25-Z ECX-1-1.6A

NR2-25-Z ECX-1.25-2A

NR2-25-Z ECX-1.6-2.5A

NR2-25-Z ECX-2.5-4A

NR2-25-Z ECX-4-6A

NR2-25-Z ECX-5.5-8A

NR2-25-Z ECX-7-10A

NR2-25-Z ECX-9-13A

NR2-25-Z ECX-12-18A

NR2-25-Z ECX-17-25A

NR2-36-Z ECX-23-32A

NR2-36-Z ECX-28-36A

NR2-93-Z ECX95-23-32A

NR2-93-Z ECX-30-40A

NR2-93-Z ECX-37-50A

NR2-93-Z ECX-48-65A

NR2-93-Z ECX-63-80A

NR2-93-Z ECX-80-93A

Manually operated switches 2004-05-14 NP2 EXT-ST

Indicator 2004-06-28 ND16 B22-LED

LITERATURE IS IDENTICAL TO BASICS

MARKING: Same as that described in Follow-Up Service Procedure and/or Report except for

Multiple Listee's name, ML Tradename, when applicable, and product designation.

UL INSPECTION CENTER HANGZHOU - 325

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Index Page 1 Issued: 2008-01-07

Revised: 2008-12-30

INDEX

Section Product Covered Report Date

1 Transferred to Volume 2 Section 1 2002-06-19

2 Model JQC-3F(T73). 2003-08-26

3 Model JQX-102F. 2003-08-27

4 Model JQX-13F. 2003-08-28

5 Model JQX-15F (T90) 2003-08-29

6 Model JQX-21F. 2003-08-30

7 Model JZC-32F. 2003-08-31

8 Models NP2, or NP4 followed by up to 2004-05-14

three numbers or letters.

9 Indicator: ND16 Series. 2004-06-28

10 LAY36 pushbutton. 2004-12-17

11 Model YBLX-P1 Auxiliary Switch. 2005-03-14

12 Electronic overload relays, Type NRE8 2005-04-21

followed by 25, 40, or 100. May be

followed by additional letters

and/or numbers.

13 Open Type Magnetic Relays, Model JQX, 2006-07-18

JTX or MK Series.

14 Open Type Magnetic Relay, Model JQX- 2006-07-19

115F Series.

15 Open Type time relays, Model JSZ3 2006-07-20

series.

16 Open Type micro-computer time control 2006-07-21

switches, KG10D or KG10M.

17 Open type electromagnetic relays, 2006-07-22

Model NJQC-3FW Series.

18 Open Type Magnetic Relay, Model NJX- 2006-07-23

13FW.

19 Open Type time relays, Model NJS1 2006-07-24

series, Model NJS, followed by 1,

followed by A, C, J or blank,

followed by 2Z, 11, S or blank, may

be followed by additional suffixes.

20 Open Type phase-loss and phase 2006-07-25

sequence relays, Model XJ Series,

followed by 3, followed by D, G or

S, may be followed by additional

suffixes.

21 Open Type Magnetic Relays, models, 2008-12-26

NJB1, followed by YW, X, X1, Y or S.

22 Open Type Magnetic Relays, Series JZX- 2008-12-27

22F, may be followed by D, B, or M,

followed by 3 digits, followed by 2,

3, or 4, followed by Z, followed by

1 or 6, may be followed by 1 or 2.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. Gen. Page 1 Issued: 2008-01-07

GENERAL

PRODUCT COVERED:

COMPONENT - MOTOR CONTROLLERS, MAGNETIC.

ENGINEERING CONSIDERATIONS (NOT FOR FIELD REPRESENTATIVE'S USE):

Spacings – Spacings have been evaluated in accordance with the Standard

for Industrial Control Equipment, UL 508, Seventeenth Edition.

CONSTRUCTION DETAILS:

General – Unless specified otherwise, the products covered in this

Procedure volume shall be constructed in accordance with the following

description.

Tolerances – All indicated dimensions are nominal.

Corrosion Protection – All parts are of corrosion resistant material or

are plated or painted as corrosion protection.

Printed Wiring Boards – All printed wiring boards shall be R/C (ZPMV2)

whose solder time and temperature are not exceeded and which can be confirmed

in the Recognized Component Directory and whose maximum operating temperature

is 105C or higher.

Marking – Refer to individual reports.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. Gen. Page 2 Issued: 2008-01-07

GENERAL

COVERAGE BASED ON CANADIAN STANDARDS:

The products tabulated below also comply with the requirements of CSA

Standard for Industrial Control Equipment, C22.2 No. 14-05 dated April 2005,

10th edition.

Marking Requirements - These products are intended to be marked in

Canada. Markings shall be based on the "Marking" provisions of the Section

General and each individual section within this volume.

The necessity for a bilingual marking (i.e., English and French) shall

be determined by the Listee depending upon which Provinces in Canada the

product will be marketed. When the product identification is also required in

French, the French translation shall be consistent with the English version

as described in each individual section. The above CSA Standard, presently,

only requires bilingual marking of warning and cautionary statements when

applicable. Unless specified otherwise, the products are not required to be

marked with any warning or cautionary statements.

Model/Type Type of Product Section

All COMPONENT - MOTOR All

CONTROLLERS, MAGNETIC

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607

Project 08NK16870

December 26, 2008

REPORT

on

COMPONENT – AUXILIARY DEVICES

Zhejiang Chint Electrics Co.Ltd.

Wenzhou, Zhejiang, China

Copyright 2008 Underwriters Laboratories Inc.

Underwriters Laboratories Inc. authorizes the above named company to reproduce

this Report provided it is reproduced in its entirety.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 Page 1 Issued: 2008-12-26

and Report

DESCRIPTION

PRODUCT COVERED:

USR, CNR - Open Type Magnetic Relays, models, NJB1, followed by YW, X, X1, Y

or S.

GENERAL:

These devices are an Open Type Magnetic Relays intended to be used in

Industrial Control Equipment.

RATINGS:

Model Input (Control) Relay Output

NJB1-YW: 1Z(1C) 220Vac, 380Vac 3A, 220/240Vac

NJB1-X or X1: 1Z(1C) 3 phase/3 wire, 380Vac, 3A, 220/240Vac

400Vac, 415Vac, 480Vac

or

3 phase/4 wire, 220Vac,

230Vac, 240Vac, 277Vac

NJB1-Y: 1Z(1C) 24Vac, 110Vac, 220Vac; 3A, 220/240Vac

24Vdc

NJB1-S: 1Z(1C) 220Vac, 380Vac; 24Vdc NO: 3A, 220/240Vac;

5A, 28Vdc

NC: 2A, 220/240Vac;

3A, 28Vdc

ENVIRONMENTAL:

Open Type

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 Page 2 Issued: 2008-12-26

and Report

NOMENCLATURE:

N JB 1 - YW / X

I II III IV V

I - Company code

II – Relays

III – Design sequence No.

IV – Function code

YW for floatless relay

Y for single-phase voltage relay

X or X1 for phase-sequence, phase-loss relay

S for time relay

V – Control voltage

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 Page 3 Issued: 2008-12-26

and Report

CONSTRUCTION DETAILS:

General - Reference may be made to accompanying photographs and itemized

descriptive pages for the essential details of construction.

Corrosion Protection - All parts of the device are constructed of

corrosion resistant material or are suitably plated or painted as a protection

against corrosion.

Tolerance - Unless specified otherwise, the indicated dimensions are

nominal.

Marking - Ink-stamped adhesive backed labels secured to or printed on the

devices designated with the Recognized Company's name or file number, and

model number. Devices may be marked appropriately for the intended use in

amperes, volt-amperes or watts or any combination thereof.

ENGINEERING CONSIDERATIONS (NOT FOR FIELD REPRESENTATIVE'S USE):

USL - Complies with UL 508, Seventeenth edition.

CNL - Complies with CSA C22.2 No. 14-2005, 10th

Spacings - Spacings were evaluated per Table 36.1 of UL 508, the

Standard for Industrial Control Equipment, Seventeenth Edition.

Conditions of Acceptability

1. These devices should be used within their Recognized ratings as

specified below.

2. Open type devices should be mounted in enclosures having adequate

strength and thickness and in the intended manner and with acceptable spacings

being provided.

3. The terminals are not suitable for field wiring. They are to be

factory wired only and the suitability of the connection (including spacings

between factory connectors) shall be determined.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 Page 4 Issued: 2008-12-26

and Report

RELAY MODEL NJB1 SERIES – FIG. 1

1. Terminal Case (1) – R/C (QMFZ2), DSM Engineering Plastics B V, designated

P A 6 K-FK GS6, with minimum thickness 0.8mm, overall dimension

21.2×19.5×26.3 mm.

2. Terminal Case (2) - R/C (QMFZ2), DSM Engineering Plastics B V, designated

PA6 K-FK GS6, with minimum thickness 1.2mm, overall dimension

21.2×12.7×26.3mm.

3. Panel - R/C (QMFZ2), DSM Engineering Plastics B V, designated PA6 K-FK GS6,

with minimum thickness 0.8mm, overall dimension 48.4×10×21.9mm.

4. Enclosure (1) - R/C (QMFZ2), DSM Engineering Plastics B V, designated PA6

K-FK GS6, with minimum thickness 0.9mm, overall dimension 90×17.5×100mm.

5. Enclosure (2)- R/C (QMFZ2), DSM Engineering Plastics B V, designated PA6 K-

FK GS6, with minimum thickness 0.9mm, overall dimension 90×17.3×100mm.

6. Limiting part - R/C (QMFZ2), KOREA ENGINEERING PLASTICS CO LTD, designated

F30-(xx)(+), with minimum thickness 1mm, overall dimension 19.1×3.5×35mm.

7. Rotating knob - R/C (QMFZ2), KOREA ENGINEERING PLASTICS CO LTD, designated

F30-(xx)(+), with minimum thickness 1.9mm, overall dimensionφ6×14.4mm.

8. Relay – R/C (NRNT2), Xiamen Hongfa Electroacoustic Co. Ltd., designated

HF41F 24-ZS

9. PCB – R/C (ZPMV2), Zhejiang SUNHOPE, rated 105C minimum, suitable for

direct support.

10. Terminals - cold-rolled sheet steel, designated Q195, measuring

11.7 by 6.2 by 4.9mm.

11. Electric slice (1) – brass, designated H62, measuring 15.6 by 5.5 by

0.8mm.

12. Electric slice (2) – brass, designated H62, measuring 12.7 by 9.8 by

0.8mm.

13. Electric slice (3) – brass, designated H62, measuring 16 by 12.7 by

0.8mm.

14. Screw – Fe/Ep Ni3, measuringφ5 by 10.6mm.

15. Transformer Models NJB1-S, NJB1-Y, NJB1-YW - R/C (FQGS2), ZHENJIANG

HONGDA ELECTRIC APPLIANCES CO LTD, designated BD-5-02A, having LVLC

outputs.

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 Page 5 Issued: 2008-12-26

and Report

16. Capacitor – rated 0.33uF/1000V (only for NJB1-X)

17. Resistor (R1~R10) - ratings 1MΩ

18. Varistor (RV2) – R/C (XUHT2), Model 10K112

19. Varistor (RV1) – R/C (XUHT2), Model 10K112

MODEL NJB1-S

20. Varistor (RV1) – R/C (XUHT2), Model 10K471

21. Capacitor(C11) – rated 220uF/50V

22. Capacitor(C9,C13) – rated 0.1uF/16V

23. Capacitor(C12) – rated 100uF/50V

MODEL NJB1-Y

24. Varistor (RV2) – R/C (XUHT2), Model 07K270/07K271

25. Varistor (RV1) – R/C (XUHT2), Model 07K471/07K271

26. Varistor (RV3) – R/C (XUHT2), Model 07K270/07K470/07K271

27. Varistor (RV4) – R/C (XUHT2), Model 07K270/07K271/10K821

28. Resistor(R1,R2) – model RC1206 ratings 16.5KΩ, RC1206 ratings 604KΩ,

RC1206 ratings 768KΩ

29. Resistor(R3,R4) – model RC1206 ratings 3.4KΩ, RC1206 ratings 100KΩ,

RC1206 ratings 249KΩ

30. Resistor(R5,R6) – model RC1206 ratings 4.99KΩ, RC1206 ratings 49.9KΩ,

RC1206 ratings 511KΩ

31. Resistor(R7,R8) – rated 10KΩ

MODEL NJB1-YW

32. Varistor (RV1) - R/C (XUHT2), Model 10K150/10K471/10K821

33. Capacitor (C102) – rated 100nF/63V

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

File E205607 Vol. 1 Sec. 21 FIG-1 Issued: 2008-12-26

and Report

Created by UL Document Assembler 2010-05-16 01:51:02 -05:00

You might also like

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- UL Certification CCFLDocument7 pagesUL Certification CCFLCCFLNo ratings yet

- UL Database ABPDocument2 pagesUL Database ABPCarlos TradeNo ratings yet

- IECEx UL09 0025 - NFMVDocument5 pagesIECEx UL09 0025 - NFMVJunardi SilabanNo ratings yet

- 25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisDocument15 pages25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisAnonymous FHkX0ANo ratings yet

- Next Assy REV DCO Description BY Approval DateDocument4 pagesNext Assy REV DCO Description BY Approval DateNats NatoyNo ratings yet

- Nl-Lei-Wi-252-05 Electrical Engineering & Design Manual - 1.Document2 pagesNl-Lei-Wi-252-05 Electrical Engineering & Design Manual - 1.Gerry MalapitanNo ratings yet

- AMZ-XXXX IECExDocument4 pagesAMZ-XXXX IECExtuandanhbk10No ratings yet

- Electrostatic PrecipitatorDocument52 pagesElectrostatic PrecipitatorsergioNo ratings yet

- Technical & Safety Information - Commtest BATT0206: Specifications Cell PackDocument11 pagesTechnical & Safety Information - Commtest BATT0206: Specifications Cell PackMuhammad Fahmmi Bin MahmudNo ratings yet

- Iecex Bas 04.0017XDocument6 pagesIecex Bas 04.0017XFrancesco_CNo ratings yet

- Cert Perno Hex 3.4 X 2-3.4Document5 pagesCert Perno Hex 3.4 X 2-3.4Abril SalinasNo ratings yet

- ESS-3245508 - Application For Electrical AuthorisationDocument12 pagesESS-3245508 - Application For Electrical AuthorisationhassanNo ratings yet

- 2 E D 3 0 0 E 1 7 - S F O: Evaluation Board For 2ED300C17-S/-ST IGBT DriverDocument18 pages2 E D 3 0 0 E 1 7 - S F O: Evaluation Board For 2ED300C17-S/-ST IGBT Driverbharath prabhuNo ratings yet

- OBPF Technical BulletinDocument10 pagesOBPF Technical BulletinLance Cydrick Paggao GuaricoNo ratings yet

- UL Certificate-ML SeriesDocument7 pagesUL Certificate-ML Seriesquality qcNo ratings yet

- Cert Perno Hex A325 5.8 (11) X 1-1.2Document4 pagesCert Perno Hex A325 5.8 (11) X 1-1.2Abril SalinasNo ratings yet

- 12 - AE1172-&EPA010-7120-026117 - Equipment List Including KKS No. - Rev00Document7 pages12 - AE1172-&EPA010-7120-026117 - Equipment List Including KKS No. - Rev00MayurNo ratings yet

- 711300Document704 pages711300duythienddt100% (1)

- MA497257 - AutoMet 250 Base User Manual - English - Rev1.0 - 11.2018 (1) - 3Document42 pagesMA497257 - AutoMet 250 Base User Manual - English - Rev1.0 - 11.2018 (1) - 3Yan Jumbo MerinoNo ratings yet

- Cert Perno Hex A325 5.8X1-3.4Document4 pagesCert Perno Hex A325 5.8X1-3.4Abril SalinasNo ratings yet

- ConstructiION 10122016Document2 pagesConstructiION 10122016Yogesh PrajapatiNo ratings yet

- Ups Train3Document157 pagesUps Train3Younes SaifiNo ratings yet

- EnecDocument2 pagesEnecErik Marcelo BarrenecheaNo ratings yet

- SE CER Certificate SII For Israel Fronius Eco ENDocument15 pagesSE CER Certificate SII For Israel Fronius Eco ENisan.structural TjsvgalavanNo ratings yet

- TR5801 Af60-Hd En55035 02Document40 pagesTR5801 Af60-Hd En55035 02kian pecdasenNo ratings yet

- 69987-FE-01-328920 - Erection Instruction of Reformer Casing (Reviewed) - DSPDocument53 pages69987-FE-01-328920 - Erection Instruction of Reformer Casing (Reviewed) - DSPlathifah hanimNo ratings yet

- Datasheet iE10-R2 5306529 enDocument4 pagesDatasheet iE10-R2 5306529 ennguyen HungNo ratings yet

- Application 3153+MR6000 Motorstator E2 230425Document5 pagesApplication 3153+MR6000 Motorstator E2 230425samir samsamNo ratings yet

- UNO001/Nordmyr SWE002/Westerbegr CAV005/Abrahamsson: Created by Checked by Approved by ENG. NoDocument24 pagesUNO001/Nordmyr SWE002/Westerbegr CAV005/Abrahamsson: Created by Checked by Approved by ENG. Nofarm numNo ratings yet

- Us 20130160808Document25 pagesUs 20130160808elnurorucluNo ratings yet

- Nexxt Solutions Etl Verified Certificate For Cat5e 3 Connector ChannelDocument1 pageNexxt Solutions Etl Verified Certificate For Cat5e 3 Connector ChannelnormNo ratings yet

- IECEx FMG 16.0014X 011Document7 pagesIECEx FMG 16.0014X 011Zahir MokhtarNo ratings yet

- EOS Power: Looking For A Discount?Document4 pagesEOS Power: Looking For A Discount?Joule ManutençãoNo ratings yet

- Rfi 7022518871-00Document25 pagesRfi 7022518871-00Carlos LiceaNo ratings yet

- Wiring Diagram SCH01-1 (I-ECU Equipped) : Service InformationDocument2 pagesWiring Diagram SCH01-1 (I-ECU Equipped) : Service InformationPower Mobile100% (1)

- MQ SP e 6018Document8 pagesMQ SP e 6018jaseel kNo ratings yet

- Dio Doss 18001Document5 pagesDio Doss 18001silvertronicNo ratings yet

- 50 20-RP1Document10 pages50 20-RP1h1234bNo ratings yet

- Zeus - 400,300,200 Op Manual - SignedDocument42 pagesZeus - 400,300,200 Op Manual - SignedX-SamsulNo ratings yet

- 220 3PS Ekl1 00002 000Document16 pages220 3PS Ekl1 00002 000faradioNo ratings yet

- EETT Salas ElectricasDocument22 pagesEETT Salas ElectricasleonardoNo ratings yet

- IECEx BAS 10.0045X 005Document6 pagesIECEx BAS 10.0045X 005Marcos SiqueiraNo ratings yet

- IECEx KEM 08.0010X 2Document4 pagesIECEx KEM 08.0010X 2mlutfimaNo ratings yet

- CN202400-8002 On/ Off Valves: C/o Chemetics IncDocument2 pagesCN202400-8002 On/ Off Valves: C/o Chemetics IncImam Zulfir RamandhaNo ratings yet

- Service Advisory 161216 - 1Document6 pagesService Advisory 161216 - 1Debaabeck CostaNo ratings yet

- Mag6000 MidDocument8 pagesMag6000 MidzaidNo ratings yet

- Bohler E7018 Ø4.00mm LT-8105848Document1 pageBohler E7018 Ø4.00mm LT-8105848Ivonne Yana EnriquezNo ratings yet

- Certificate of Analysis: Print DateDocument2 pagesCertificate of Analysis: Print DateClément JacquetNo ratings yet

- Iecex Certificate of ConformityDocument4 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- AS:NZS 4836-2001 Safe Working On Low-Voltage Electrical InstallationsDocument47 pagesAS:NZS 4836-2001 Safe Working On Low-Voltage Electrical Installations-Amber TengridollsNo ratings yet

- Motor Manual PDFDocument28 pagesMotor Manual PDFJulio CesarNo ratings yet

- IECEx BAS 10.0099X 001Document6 pagesIECEx BAS 10.0099X 001Marcos SiqueiraNo ratings yet

- Certificate of Analysis: Print DateDocument3 pagesCertificate of Analysis: Print DateClément JacquetNo ratings yet

- Nexxt Solutions Etl Verified Certificate For Cat6 3 Connector ChannelDocument1 pageNexxt Solutions Etl Verified Certificate For Cat6 3 Connector ChannelnormNo ratings yet

- K32LCD+ EN Certificate 30063-03-19-INTDocument3 pagesK32LCD+ EN Certificate 30063-03-19-INTinterhamNo ratings yet

- Lsu 4.9Document22 pagesLsu 4.9fabio batistaNo ratings yet

- Datacard CE870 CE840 Instant Issuance System: Embosser Illustrated Parts ManualDocument46 pagesDatacard CE870 CE840 Instant Issuance System: Embosser Illustrated Parts ManualDaniel Vargas100% (1)

- WWW - Tycoelectronics.com Commerce Pcnws PCNForms PcndateDocument3 pagesWWW - Tycoelectronics.com Commerce Pcnws PCNForms PcndateVatsal UpadhyayNo ratings yet

- 23 Ray Optics Formula Sheets Getmarks AppDocument10 pages23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikNo ratings yet

- White Paper: 1 Definitive Guide To Data QualityDocument18 pagesWhite Paper: 1 Definitive Guide To Data QualityGonçalo MartinsNo ratings yet

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDocument15 pages4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNo ratings yet

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- Manhole Head LossesDocument11 pagesManhole Head Lossesjoseph_mscNo ratings yet

- Eccentric FootingDocument3 pagesEccentric FootingVarunn VelNo ratings yet

- Unit 1 PrinciplesDocument17 pagesUnit 1 PrinciplesRohit YadavNo ratings yet

- Amity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorDocument23 pagesAmity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorMayank TayalNo ratings yet

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationDocument32 pagesCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYNo ratings yet

- 28 TerminalsDocument42 pages28 TerminalsAlin FazacasNo ratings yet

- Table of Reinforcement Anchorage Length & Lap Length - Eurocode 2Document7 pagesTable of Reinforcement Anchorage Length & Lap Length - Eurocode 2NgJackyNo ratings yet

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDocument16 pagesJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarNo ratings yet

- Abilash - Subramanian CV - 003 PDFDocument4 pagesAbilash - Subramanian CV - 003 PDFAbilash SubramanianNo ratings yet

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Document7 pagesMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimNo ratings yet

- SievesDocument3 pagesSievesVann AnthonyNo ratings yet

- 2013-01-28 203445 International Fault Codes Eges350 DTCDocument8 pages2013-01-28 203445 International Fault Codes Eges350 DTCVeterano del CaminoNo ratings yet

- MATM1534 Main Exam 2022 PDFDocument7 pagesMATM1534 Main Exam 2022 PDFGiftNo ratings yet

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010No ratings yet

- Chapter 11 AssignmentDocument2 pagesChapter 11 AssignmentsainothegamerNo ratings yet

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocument12 pagesIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsNo ratings yet

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantNo ratings yet

- 5.1 Behaviour of Water in Rocks and SoilsDocument5 pages5.1 Behaviour of Water in Rocks and SoilsHernandez, Mark Jyssie M.No ratings yet

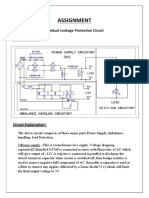

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNo ratings yet

- Halloween EssayDocument2 pagesHalloween EssayJonathan LamNo ratings yet

- End-Of-Chapter Answers Chapter 7 PDFDocument12 pagesEnd-Of-Chapter Answers Chapter 7 PDFSiphoNo ratings yet

- Taylor Series PDFDocument147 pagesTaylor Series PDFDean HaynesNo ratings yet

- 12 Step Worksheet With QuestionsDocument26 pages12 Step Worksheet With QuestionsKristinDaigleNo ratings yet

- Categorical SyllogismDocument3 pagesCategorical SyllogismYan Lean DollisonNo ratings yet

- SDS ERSA Rev 0Document156 pagesSDS ERSA Rev 0EdgarVelosoCastroNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesFrom EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet