Professional Documents

Culture Documents

CCCCCCCCCCC: C CCC

Uploaded by

Joydeep SarenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CCCCCCCCCCC: C CCC

Uploaded by

Joydeep SarenCopyright:

Available Formats

MEJIA, UNDER DVC

ThermaI Power PIant

v0CATl0tAl TRAltlt6 PR0JFCT RFP0RT ]

Mejia ThermaI Power Station is

Iocated at 35 km from Durgapur city

in West BengaI. The power pIant is

one of the coaI based power pIants

of DVC. Commissioned on 1996,

MTPS is the Iargest thermaI power

pIant, in terms of generating capacity

in the state of West BengaI as weII as

among other DVC power pIants.

1PlS 8LC81 PAS uCnL Cn 1PL 8ASlS Cl 1PL

knCWLAuCL 1PA1 WL CA1PL8Lu uu8lnC Cu8

vCCA1lCnAL 18AlnnlnC Cl 4 WLLkS uCnL l8CM !unL

61P 1C 41P !uL? 2011

sus::..t: s? -

O JOYDEEP SAHEN

O AHNA AHUA

O ANlHUDHYA SlHCAH

O MADHUMONTl HOY

O CHANDHlMA DAS

3

8u

?LA8 LLLC18lCAL LnCC uL1

!AuAvu8 unlvL8Sl1?

OJOYDEEP SAHEN

OAHNA AHUA

OANlHUDHYA SlHCAH

OMADHUMONTl HOY

OCHANDHlMA DAS

v0CATl0tAl TRAltlt6

PR0JFCT RFP0RT

THFRHAl P0wFR PlAtT

HFJlA, ut0FR 0vC

sus::..t: s? .

,.'... u.~.

.

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

Thls ls a project report on the baslc overvlew oI a

THERMAL POWER PLANT and all other systems that are

requlred to carry out the process oI power generatlon. Thls

project was a part oI our currlculum oI Iour years B.Tech degree

course. Thls was a tralnlng program Ior 2B days at Mejla

Thermal Power Statlon under Damodar Valley Corporatlon,

carrled out by 5 students oI Jadavpur Unlverslty, named as 1>

Joydeep Saren , 2> Arnab Barua , 3> Anlrudhya Slrcar, 4>

Madhumantl Roy and 5>Chandrlma Das, belonglng to Electrlcal

Englneerlng Department , at the end oI oth semester.

We have carrled out thls tralnlng under well eperlenced

and hlghly quallIled englneers oI MTPS, DVC oI varlous

departments' wlse Mechanlcal, Electrlcal, Chemlcal and Control

& Instrumentatlon depts. Thls report covers an overvlew oI a

thermal power statlon, detalled speclIlcatlons oI MTPS,DVC,

mechanlcal overvlew, electrlcal overvlew , varlous cycles and

processes [vlz. Steam Generatlon,Turbo Generatlon and Balance

oI Plantj oI power generatlon and detalls oI control and

lnstrumentatlon requlred ln thermal power plant. We have

taken the opportunlty to eplore the Electrlcal, Control &

Measurement Department, lts use, necesslty ln power plant

and malntenance oI varlous lnstruments used Ior monltorlng

and controlllng the numerous processes oI power generatlon.

We have trled our best to cover all the lnstruments and thelr

brleI detalllng ln thls project report. We have also lncluded our

Ileld eperlences oI MTPS and malntenance sectlon oI C&I

[Control & Instrumentatlonj oI MTPS and Loglc Panels provlded

by BHEL [known as FSSSj and DCS/Mlcroprocessor based system

provlded by SIEMENS and also Loglc and Mlcroprocessor based

system by MAX-DNA.

All the above mentloned toplcs wlll be presented ln the

precedlng pages oI thls report. The maln alm to carry out thls

tralnlng was to Iamlllarlze ourselves wlth the real lndustrlal

scenarlo, so that we can relate what we study ln our tetbooks

and thelr practlcal appllcatlons. Thls project report wlll also help

us ln our Iuture ln many ways when we Iace the lndustrlal world.

ACKt0wlF06FHFtT

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

Wc,

JoYocc SAncN

AnNAa AnuA

ANinuoHYA SincAn

MAoHumANTi HoY

CHANonimA DAs

HAvc cAnnico ouT THis oisscnTATioN TnAiNiNc nconT aAsco

oN THc vocATioNAL TnAiNiNc ooNc aY us iN THc HicHLY

AnAisco, oNc or THc mosT TccHNicALLY AovANcco ANo

oNc or THc LAnccsT THcnmAL owcn sTATioN iN WcsT cNcAL

THc McJiA THcnmAL Powcn STATioN ,uNocn DVC .

Wc wouLo LiKc To cxncss oun HcAnTrcLT cnATiTuoc

To THc AuTHoniTY or JADAVPUH UNlVEHSlTY ron

novioiNc us THc nAnc oonTuNiTY To uNocnTAKc

TnAiNiNc iN THc owcn LANT.

Wc wouLo ALso wANT To THANKs THc HicHLY suonTiNc

ANo cxcnicNcco cNciNccns wiTHouT wHom wc couLo NoT

HAvc KNowN THc LANT acTTcn.

Wc wouLo cnsoNALLY LiKc To THANKs To

HuAK NAc

P.K.DuacY

MANAs MALiK

HAvnAJAN SiNc

G.K.CHowoHunY

KALYANi MAm

A0uT 0vC

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

Power Generation

Entrusted with the responsibiIities of providing the vitaI

input power for industriaI growth in the resource rich Damodar

VaIIey region, DVC has been practicaIIy operating as a pioneer,

using Iatest avaiIabIe technoIogies to suppIy buIk power at

reasonabIe rates to the major industries.

DVC has maintained its Iead roIe in the eastern region by

adopting itseIf to the chaIIenges of time and technoIogy during the

course of Iast 59 years. DVC has been generating and transmitting

power since 1953 and has succeeded not onIy in meeting the

needs of consumers but has aIso heIped to increase the demand of

power which itseIf is an index of deveIopment.

Joint Venture Project

MAlTHON POWEH LlMlTED a joint venture company by

DVC and Tata Power has been formed to impIement 1000 MW

Maithon Right Bank ThermaI Power Project for meeting the

energy needs of power deficient regions on export basis.

OKAHO POWEH SUPPLY CO LTD (BPSCL) a joint

venture company of DVC and SAIL has been estabIished to

operate and maintain the captive power and steam

generation pIant, hived off by SAIL and its Bokaro SteeI PIant

and suppIy power and steam excIusiveIy to Bokaro SteeI Ltd.

DVC EMTA COAL MlNES LTD, a joint venture company

formed with Eastern MineraIs & Trading Agency for

deveIopment and operation of Captive CoaI Mine BIocks and

suppIy of coaI excIusiveIy to DVC ThermaI Power Projects of

10th and 11th pIan.

0vC P0wFR STATl0tS AT A 6lAtCF

NAmc LocATioN CAAciTY CommissioNiNc

THERMAL

Bokaro 'B'

Dist- Bokaro

State- Jharkhand

630 MW

(3 X 210 MW)

U-I Mar 86

U-II Nov 90

U-III Aug 93

Chandrapura

Dist- Bokaro

State- Jharkhand

390 MW

(3 X 130 MW)

U-I Oct 64

U-II May 65

U-III JuIy 68

Durgapur

Dist.- Barddhaman

State- WestBengaI

350 MW

(1X140 MW)

+

(1X210 MW)

U-III Dec 66

U-IV Sept 82

Mejia

Dist.- Bankura

State- WestBengaI

1340 MW

(4 X 210 MW) +

(2 X 250 MW)

U-I Mar 96

U-II Mar 98

U-III Sept 99

U-IV Feb 05

U-V Feb 08

U-VI Sept 08

Total Thermal

2710 MW

NAmc LocATioN ExisTiNc CAAciTY CommissioNiNc

HYDEL

TiIaiya

River- Barakar

Dist.-Hazaribagh

State- Jharkhand

4 MW

(2 X 2 MW)

U-I Feb'53

U-II JuIy'53

Maithon

River- Barakar

Dist.- Burdhaman

State- West BengaI

60 MW

(3 X 20 MW)

U-I Oct'57

U-II Mar'58

U-II Dec'58

Panchet

River- Damodar

Dist.- Dhanbad

State -Jhankhand

80 MW

(2 X 40 MW)

U-I Dec'59

U-II Mar'91

Total Hydel . 144 MW

GRAND TOTAL

2854 MW

ASlC tFF0S At0 0vFRvlFw

0F A THFRHAl P0wFR PlAtT

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

The idea that STEAM has potentiaI energy and can be converted into

kinetic energy was given by famous Scientist, Sir. James Watt. This idea

became the governing principaI of many mechanicaI processes and finaIIy Ied

to the success of ThermaI Power Energy. The need of estabIishing a

ThermaI Power PIant came to engineers by the reaIization of the fact that

HydeI Power couId be utiIized onIy for certain period of time in a year. This

section wiII give the basic requirements for ThermaI Power PIant.

SITE REQUIREMENT: -

The basic requirements of thermaI power pIant is determined by

the Type , size and other specifications of the pIant. It is required to know the

immediate capacity of the power pIant after construction and the extension of

capacity in the future, to determine the area required for construction of the

pIant. The basic things that are taken into consideration are 1>Station

BuiIding <2> CoaI Store <3> CooIing Towers <4>Switch yard compound <5>

Surrounding areas and approaching.

GEOLOGY : - The geoIogy of the site shouId be cost effective and

the subsoiI must be abIe to withstand huge Ioad of foundation.

WATEH HEQUlHEMENT: -Water is required in power pIant for two

basic needs, first is for steam Generation and second is for cooIing

purpose. ThermaI Power PIant requires huge voIume of water, nearIy of

about 3 to 4 Tons/hr/MW onIy for steam generation. So site of pIant must

aIso have reIiabIe and huge water sources Iocated near to it.

COAL: -CoaI is the prime requirement of any thermaI power pIant, it is

the main source of fueI as it is most economic and residue of coaI after

combustion is aIso used by many industries Iike cement industries, so

the pIant must have reIiabIe sources of coaI and reguIar suppIy in

huge amount Iike 20,000 Tons per week.

THANSPOHT: - It is one of the another vitaI factor of the pIant as

huge burden Iies on transportation in daiIy basis because of huge

need of coaI, furnace oiI, hydrochIoric acid and other chemicaI

products aIong with mechanicaI products.

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

DlSPOSAL OF EFFLUENTS: -Due to heavy rate of coaI combustion

residuaI voIume is aIso high. The main residuaI product is ash. The pIant

must have faciIities Iike ash pond to dispose them safeIy without harming

the environment.

THANSMlSSlON: -The pIant area must have route avaiIabIe for

transmission over head cabIes to the nearest grid Iines or Ioad points

which wiII be capabIe of accepting the generated power output of the

power station.

CLlMATlC COND lTlON: -The tropicaI cIimate is best for erection of

thermaI power pIant, because areas having high humidity and fIuctuating

temperature Iead to dew point and condensation which as a resuIt

damages the eIectricaI machines and corrodes the insuIation Andover

head cabIes.

PHOXlMlTY OF AlHFlELDS: -The airfieIds must be studied properIy to

avoid mishaps as the chimney height ranges from 500 to 600 fits and

boiIer housing is of 200 fits in generaI.

PEHSONNEL HEQUlHEMENTS: -To run a pIant smoothIy requirement

of skiIIed and unskiIIed personneI is very important. So recruitment of

workers and skiIIed personneI shouId be made carefuIIy and in adequate

amount.

AMENlTlES: -Some considerations Iike avaiIabiIity of hospitaI,

educationaI institutes and other faciIities must be taken into account

HFJlA THFRHAl P0wFR STATl0t AT A 6lAtCF

Mejia Thermal ower Station also known as MTPS is located at Durlavpur in

the Bankura district in West Bengal. It has two units of 500 MW four units of 210

MW each and two unit of 250 MW. Special features of MTPS include its 16.2 km long

spiral welded MS water pipeline for transporting water from the right bank of

Damodar river and 220 mtrs high RCC multi flue stack which helps in preventing air

pollution. Its affluent water utilization plant has a dual purpose of water

conservation and minimization of liquid affluent discharge. The plant also employs 3

ring granulator type crushers for its coal handling system reducing the mill rejection

from the tube mill. It is one oI the 5 Thermal Power Stations oI Damodar Valley

Corporation in the state oI West Bengal. The total power plant campus area is

surrounded by boundary walls and is basically divided into two major parts, Iirst the

Power Plant area itselI (This also have two parts MTPS-A & MTPS-B) and the

second is the Colony area Ior the residence and other Iacilities Ior MTPS s

employees.

TECHNICAL SPECIFICATI0N 0F THE

P0WER PLANT AL0NG WITH SPECIALITIES

)

O Total number of Units : - MW with Brush Type Generators

MW with Brush less Type Generators

MW with Brush less Type Generators

O Total Energy Generation :-

Gen.

Unit

Name Of The

Manufacturers

OriginaI

Capacity

Present

Capacity

Year of

commissioning

SpeciaI

Features

BoiIer TG

1 BHEL BHEL 210 210 March , 1996

DIPC BoiIers

with zero

reject tube

miIIs.

BHEL BHEL 210 210 March, 1998

BHEL BHEL

210 210

September,

1999

BHEL BHEL

210 210

February, 2005

5 BHEL BHEL

210 210

February, 2008

BHEL BHEL

210 210

2009

7 BHEL BHEL

210 210

2010

8 BHEL BHEL

210 210

2010

.

v0CATl0tAlTRAltl6

PR0JFCTRFP0RT

THFRHAlP0wFRPlAtT

HFJlA, ut0FR0vC

O $ource of Water : - Damodar River (internal

storage)

O $ources of Coal : - B.C.C.L and E.C.L, also

Imported From Indonesia

O Required Water Consumption : -

O Approximate coal requirement : - 73, 00,000Tons/annum at 75

PLF(Plant Load Factor)

O Ash Deposited per annum : - 1.30 million Tons /annum

$PECIALITIE$ OF ME1IA THERMAL POWER PLANT

a. The pIant is designed and engineered by both Bharat Heavy

EIectricaIs Ltd (BHEL) and Damodar VaIIey Corporation.

b. PipeIines of 17km Iong and 1473mm in diameter spiraI weIded MS

pipes Iaid to transport river water from upstream of Durgapur barrage

by pump sets of 500KV pump motor set.

c. RaiI cum Road Bridge across Damodar River near Raniganj Station.

d. 2KM Merry Go Round RaiIway System.

e. 20mtr high RCC muItipIe fIues stack.

f. Direct ignition of puIverized coaI introduced for reduction in consumption

of fueI oiI.

g. BaII and Tube type MiIIs for more miII rejects and Iess maintenance cost.

h. BoiIer of 200ft height and four corner firing system for better combustion.

i. AII major and hazardous systems Iike Steam Generation and Turbo

Generation section are incorporated with FSSS (Furnace Safety

Supervisory System) for better safety.

j. Other Iogic systems Iike EAST and ATRS are aIso incorporated.

k. Water treatment PIants aIong with two artificiaI water reservoirs and

Two DemineraIization

I. PIants Ioaded with PLC system.

m.Chimney height up to 600fts for Iess poIIution.

n. The pIant is Ioaded with Iatest technoIogy sensor, transducers and

transmitters for more accurate anaIyzing of various processes.

o. AII the units are Ioaded with inteIIigent smart microprocessor based

systems known to be

p. DCS systems provided by KELTRON, SIEMENS and MAX-DNA for

process controI.

q. Station Service Transformers of 6.6KV step-down type are aIso

avaiIabIe for better distribution of power inside the pIant for various

requirements.

r. 16) Switchyard with individuaI step-up generator transformers of

ONAN/ANOF/AFOF cooIing Transformers of 220KV for suppIy to nationaI

grid, aIong with other safety instruments.

You might also like

- DVC Mejia ReportDocument23 pagesDVC Mejia ReportRahul Roy100% (1)

- Durgapur Project Ltd. Training ReportDocument49 pagesDurgapur Project Ltd. Training ReportSanjiv Shome0% (1)

- NTPC Sipat Report 495555Document94 pagesNTPC Sipat Report 495555er_ppravinNo ratings yet

- Condition Monitoring DocumentationDocument49 pagesCondition Monitoring DocumentationSanthosh Penugonda0% (1)

- NTPC - Industrial Training ReportDocument84 pagesNTPC - Industrial Training ReportMd Khalid Akhtar100% (1)

- Bhel ReportDocument41 pagesBhel ReportshvmalokNo ratings yet

- Industrial Training Report-IPGCL& PPCLDocument92 pagesIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Industrial Training Report-IPGCL& PPCLDocument49 pagesIndustrial Training Report-IPGCL& PPCLBrajesh YadavNo ratings yet

- Training Report Npcil Rapp RawatbhataDocument53 pagesTraining Report Npcil Rapp Rawatbhatarakesh535100% (3)

- Training Report at RPS Power Plant RawatbhataDocument33 pagesTraining Report at RPS Power Plant RawatbhataDevendra Saini100% (1)

- Design of A Micro Hydropower PlantDocument15 pagesDesign of A Micro Hydropower PlantArgiel John LlagasNo ratings yet

- Kota Super Thermal Power Station: Electronics & Communication EngineeringDocument17 pagesKota Super Thermal Power Station: Electronics & Communication Engineeringanon_580385145No ratings yet

- 2003 Mtps Project ReportDocument48 pages2003 Mtps Project ReportSunil Giri100% (1)

- Project Report - Subham Saini (New)Document22 pagesProject Report - Subham Saini (New)Vishvajeet SinghNo ratings yet

- Indian Power System Structure and Present ScenarioDocument33 pagesIndian Power System Structure and Present ScenarioSouymyadeep100% (2)

- Report ShiviDocument54 pagesReport ShivigargshiviNo ratings yet

- Rishu NewDocument37 pagesRishu NewAbhay AswalNo ratings yet

- Untitled DocumentDocument16 pagesUntitled DocumentHemant SharmaNo ratings yet

- Training at Rana Pratap Sagar Hydro Power StationDocument55 pagesTraining at Rana Pratap Sagar Hydro Power StationJatin Pannu50% (2)

- Final Training ReportDocument70 pagesFinal Training ReportkushalchandelNo ratings yet

- Power Point Presentation Summer Training, NHPC, JammuDocument39 pagesPower Point Presentation Summer Training, NHPC, JammuAashish Singhal60% (5)

- Kota Super Thermal Power Station, Kota: Submitted To: Submitted byDocument76 pagesKota Super Thermal Power Station, Kota: Submitted To: Submitted byKunal BhadanaNo ratings yet

- Ramagundam Super Thermal Power Station A Project Report OnDocument38 pagesRamagundam Super Thermal Power Station A Project Report OncharanNo ratings yet

- Summer Training Report: Submitted byDocument23 pagesSummer Training Report: Submitted byShashank SaurabhNo ratings yet

- Pvunl: Pre-Feasibility Report For Patratu Super Thermal Power Project Phase-1 (3x800 MW)Document18 pagesPvunl: Pre-Feasibility Report For Patratu Super Thermal Power Project Phase-1 (3x800 MW)blazeglory100% (1)

- Wrec 1996Document4 pagesWrec 1996Meden PareNo ratings yet

- Brief History of Kothagudem Thermal Power Station:: 1.1 Introduction To ApgencoDocument71 pagesBrief History of Kothagudem Thermal Power Station:: 1.1 Introduction To ApgencoSrikanth SriNo ratings yet

- Industry Profile: Power Sector Reforms in IndiaDocument54 pagesIndustry Profile: Power Sector Reforms in Indiamidhun babuNo ratings yet

- A Snapshot of Morocco'S Power Sector: Tarik HamaneDocument3 pagesA Snapshot of Morocco'S Power Sector: Tarik HamaneBenhar ImadNo ratings yet

- Summer Training Report NTPC BadarpurDocument68 pagesSummer Training Report NTPC BadarpurKavish Kumar50% (2)

- Training 400 KV SubstaionDocument69 pagesTraining 400 KV SubstaionDeepak Yadav100% (1)

- Solar System InstallationDocument48 pagesSolar System Installation20bee070No ratings yet

- Zesco Solar Gyser ProjectDocument23 pagesZesco Solar Gyser ProjectGulbanu KarimovaNo ratings yet

- CBIP Tranformer ManualDocument422 pagesCBIP Tranformer ManualAnchal M. Pahwa78% (9)

- Vocational Training ReportDocument19 pagesVocational Training ReportarpitaNo ratings yet

- 03-4000mw Mundra Ultra Mega Power Project Brief Overview-BrrangaswamyDocument23 pages03-4000mw Mundra Ultra Mega Power Project Brief Overview-BrrangaswamyPrashant PatilNo ratings yet

- Submitted By:-: Pawan Bhakuni EL-1833-2K13 (B.Tech 4 Year)Document36 pagesSubmitted By:-: Pawan Bhakuni EL-1833-2K13 (B.Tech 4 Year)Pawan BhakuniNo ratings yet

- GHTP Lehra MohabbatDocument23 pagesGHTP Lehra MohabbatDivanshu Garg40% (5)

- Gandham Ravi Kumar Electrical EngineerDocument3 pagesGandham Ravi Kumar Electrical EngineerOwais MalikNo ratings yet

- Energy AuditDocument32 pagesEnergy AuditromeshmoreyNo ratings yet

- Bembla Hep-Tefr Final - RevisedDocument140 pagesBembla Hep-Tefr Final - RevisedShreyas PandeNo ratings yet

- Vocational Training Report On Thermal Power PlantDocument51 pagesVocational Training Report On Thermal Power PlantShubham Agrawal100% (4)

- NTPC Barh Summer Training Report (Electrical)Document44 pagesNTPC Barh Summer Training Report (Electrical)Mithilesh91% (35)

- BEM SingrauliDocument102 pagesBEM SingrauliGyandeep PradhanNo ratings yet

- Steam Turbine MaintenanceDocument54 pagesSteam Turbine MaintenanceGovindarajan Chandrasekaran100% (3)

- KTPS o and M of TurbinesDocument41 pagesKTPS o and M of TurbinesKrishna Kishor100% (1)

- Chaptre 1 1.1 About The Company National Thermal Power CooperationDocument36 pagesChaptre 1 1.1 About The Company National Thermal Power CooperationSanjoy Kumar DasNo ratings yet

- Power Sector Scenario in India: Krishna Murari (009909) Dhiraj Arora (009915) Ranjan Kumar (009949) B.Subhakar (009910)Document38 pagesPower Sector Scenario in India: Krishna Murari (009909) Dhiraj Arora (009915) Ranjan Kumar (009949) B.Subhakar (009910)SamNo ratings yet

- TPS SikkaDocument53 pagesTPS SikkaAnkleshwariya SidhNo ratings yet

- NTPC Vindhyachal ReportDocument13 pagesNTPC Vindhyachal Reportblackswan_07No ratings yet

- Summer Training Report: Sarvjeet Mor EEE (Roll No. 4350, 7 Sem)Document48 pagesSummer Training Report: Sarvjeet Mor EEE (Roll No. 4350, 7 Sem)Saransh DeswalNo ratings yet

- Presentation 1Document20 pagesPresentation 1Parveen Bairagi100% (1)

- Boiler Tube CoatingsDocument61 pagesBoiler Tube CoatingsRahul DeshmukhNo ratings yet

- Final ProjectDocument45 pagesFinal Projectrahulshandilya2k100% (1)

- Ihp Microproject 2Document38 pagesIhp Microproject 2Vishal SahaneNo ratings yet

- Report 1Document117 pagesReport 1geetanjalinitkNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- SmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2From EverandSmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2No ratings yet

- P5 P6 The Principles of Signal Theory PDFDocument12 pagesP5 P6 The Principles of Signal Theory PDFfaisal saghirNo ratings yet

- FB MultiPier Help Manual PDFDocument544 pagesFB MultiPier Help Manual PDFQuangKhảiNo ratings yet

- 39 Duroxite Overlay Productslingyuen WeiExtranetDocument29 pages39 Duroxite Overlay Productslingyuen WeiExtranetGraylab TechnologiesNo ratings yet

- Xitanium 75W 0 12A 0 4A 220V 1 10V 230VDocument7 pagesXitanium 75W 0 12A 0 4A 220V 1 10V 230Vgenerallux378No ratings yet

- Decision Support System Q&ADocument50 pagesDecision Support System Q&AManidhar ReddyNo ratings yet

- VAG Airbag Reset ManualDocument12 pagesVAG Airbag Reset ManualGabriel DrideanuNo ratings yet

- Introduction To Phased Array AntennasDocument7 pagesIntroduction To Phased Array AntennasNaniNo ratings yet

- DX DiagDocument38 pagesDX DiagAndy KristiantoNo ratings yet

- 2015.02.11 - Load Transfer To and Through Shear WallsDocument50 pages2015.02.11 - Load Transfer To and Through Shear WallsUALU333100% (1)

- Farwell - Shroud - Full ScoreDocument11 pagesFarwell - Shroud - Full ScoremarcmaesbpNo ratings yet

- Final HBD PresentationDocument24 pagesFinal HBD Presentationccrkota100% (1)

- MR2405 Waste Water TreatmentDocument1 pageMR2405 Waste Water TreatmentGrady HopkinsNo ratings yet

- 06-250 Old Farm EquipmentDocument191 pages06-250 Old Farm EquipmentJoseph Thomas Weber Jr.No ratings yet

- What's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersDocument7 pagesWhat's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersRanjani J DeepakNo ratings yet

- f2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDocument21 pagesf2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDeyvi Vasquez PittmanNo ratings yet

- Civil EngineeringDocument63 pagesCivil EngineeringNaniNo ratings yet

- ASM Vs File SystemDocument3 pagesASM Vs File SystemhlapsNo ratings yet

- LEXE0047-02 Data SheetDocument4 pagesLEXE0047-02 Data Sheetsklm123No ratings yet

- Co Working ProjectDocument8 pagesCo Working ProjectshawonNo ratings yet

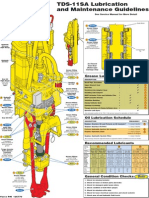

- Top Drive Varco TDS 11 Lubrication PDFDocument1 pageTop Drive Varco TDS 11 Lubrication PDFWilliam TuckerNo ratings yet

- A Review of Electromechanical Actuation System ForDocument9 pagesA Review of Electromechanical Actuation System ForHassanNo ratings yet

- Tutorial 3 - DMCF 2223 (Manometer)Document4 pagesTutorial 3 - DMCF 2223 (Manometer)zul hilmiNo ratings yet

- 11072/KAMAYANI EXP Sleeper Class (SL)Document2 pages11072/KAMAYANI EXP Sleeper Class (SL)skhushi9980No ratings yet

- English Proficiency Test OkDocument19 pagesEnglish Proficiency Test OkNoelle Mendes100% (5)

- Memorandum: Bureau of Jail Management and Penology National HeadquartersDocument9 pagesMemorandum: Bureau of Jail Management and Penology National HeadquartersBen DhekenzNo ratings yet

- Simple LC Filter IIDocument3 pagesSimple LC Filter IIdhananjaymohapatra2009No ratings yet

- Title: How To Use This TemplateDocument6 pagesTitle: How To Use This TemplateRAIZZNo ratings yet

- En 1555-4 (2002)Document15 pagesEn 1555-4 (2002)joaoferreiraprfNo ratings yet

- Introduction To Supply Chain ManagementDocument45 pagesIntroduction To Supply Chain ManagementAsha ChikkaputtegowdaNo ratings yet

- 11 - Effective Pages: Beechcraft CorporationDocument44 pages11 - Effective Pages: Beechcraft CorporationMartín LaraNo ratings yet