Professional Documents

Culture Documents

Quotation of XMY 4-450-30U

Uploaded by

anupamabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

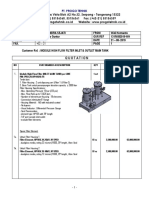

Quotation of XMY 4-450-30U

Uploaded by

anupamabCopyright:

Available Formats

郑州优尼特机械设备有限公司

ZHENGZHOU UNIWIN MACHINERY AND EQUIPMENT CO.,LTD

No 10 Hanghai road, Zhengzhou,45000, CHINA NO.: 2023YLJ-SL0906

TEL: +86-371-55002603 FAX: +86-371-55002600 DATE: 2023-09-06

EMAIL: bruce@press-filter.com WEB: www.press-filter.com

QUOTATIONS

Name Model QTY Unit Price Amount

Hydraulic filter press XMY 4/450-30U 1 SET

Filter Cloth Optional 2 SETS

NOTE: FOB Qingdao price and one set filter cloth for free.

Period of validity of this quotation list: 30 days

1. TERM OF PAYMENT: BY T/T

a) The 30% deposit by T/T within 3 days once both parties signed the Sales Contract.

b) The 70% balance by T/T should be paid before delivery.

2. DATE OF DELIVERY: 30 days from the time we received the down payment.

3. WARRANTY: ONE year from the time the machine is fully installed.

Parameters:

Model: XMY 4/450-30U

Voltage: 380v 50hz

Filtering area:4 m2

Type: Electrical hydraulic type, auto closing.

Material of the filter plates:PP

Volume of the chamber:60 L

Number of filter plates :9 pieces;

Cake thickness:30 mm

Thickness of the filter plate - 50 mm;

Max feeding pressure at the inlet to the filter press - 0.6 MPa;

Squeezing pressure plates - 16-18 MPa;

The temperature of the medium being filtered : 0 - 70 C;

Dimensions of the filter press l*w*h: 1950*700*900 mm

Weight:860 kg;

Introduction of hydraulic filter press:

Filter press is a common used filtration and separation equipment,It has been widely used in the chemical production in

the early 18th century and now is widely used in chemical industry, pharmaceutical industry, metallurgy industry, dyes

industry, food factories, brewing, ceramics, and environmental protection industries.

Its main structure is :frame,filter plates,filter cloth,hydraulic station,PLC electric control system.The filter plates and filter

plates frame forms the chamber ,the sludge (slurry)is pumped into the chamber and with the pressure ,filter cake will be

formed in the chamber and filtrate will flow out through the outlet of the filter plates.

The automatic filter press is batch operation,which means that the operation must be stopped to discharge the filter cake

before the next batch can be startedone filtering cycle usually takes from 20 minutes to 2 hours ,depending on the

different characteristics of filtering material.There are 3 types filter press,ie recessed filter press,plate and frame filter

press and vertical filter press.our filter plates have the advantages of stable permance,easy operation,accurate size,can

endure high pressure and high temperature.

The process of one batch filtration is:

(pressing---feeding material---filtering---discharging cake)

1- Closing of the filter plates: when start the press button on the PLC control cabinet, the moving head plates will be

activated by the hydraulic calmps the plates.

2- Filling:The sludge (or slurry) will be pumped into the chamber one by one.when all chamber is full of filter cake,the

filtration is finished.

3- Filter opening: The moving head is drawn back to disengage the first filtration chamber. The cake falls will drop from

the plates because of gravity.

4- Washing: Usually for washing of clothes should be carried out every 15-100 batches.

Working platform animation:

Certifications:

You might also like

- Quotation of The Chamber Filter Press XY16-450-30U (210824)Document7 pagesQuotation of The Chamber Filter Press XY16-450-30U (210824)Sebastian Sanchez PolancoNo ratings yet

- Primer Manual Granulador OriginalDocument20 pagesPrimer Manual Granulador Originalsixto zeladaNo ratings yet

- Quotation of YTB-21200 For Non-Woven Double 20200724Document10 pagesQuotation of YTB-21200 For Non-Woven Double 20200724Amr KamelNo ratings yet

- Operation Manuals of Filter PressDocument7 pagesOperation Manuals of Filter PressmichaelspivakNo ratings yet

- 50-250PVC Pipe ExtruderDocument4 pages50-250PVC Pipe ExtruderzakariaNo ratings yet

- 211002-Datong-10-8-3 Water Filling MachineDocument18 pages211002-Datong-10-8-3 Water Filling MachineHuong NguyenNo ratings yet

- 450BPH 5 Gallon Filling Machine+ 9T Water Treatment + Ink PrinterDocument15 pages450BPH 5 Gallon Filling Machine+ 9T Water Treatment + Ink PrinteraghyadhNo ratings yet

- 6 Heads Automatic Filling MachineDocument10 pages6 Heads Automatic Filling MachineCITRO GREENNo ratings yet

- Heat Pump DryerDocument8 pagesHeat Pump DryerIvan LourensNo ratings yet

- PVC Granuels Making Machine-ChinaDocument12 pagesPVC Granuels Making Machine-Chinapratikgarg03No ratings yet

- Semi-Automatic Blowing Machine B-IDocument5 pagesSemi-Automatic Blowing Machine B-IHitendra Nath BarmmaNo ratings yet

- 1500MM Film Blowing Machine QuotationDocument6 pages1500MM Film Blowing Machine QuotationPearls of WisdomNo ratings yet

- Plate and Frame Filter PressDocument16 pagesPlate and Frame Filter Pressraneshkumar19920% (1)

- 2021年9月15日Konjac Process Line-lijie (3) -DikonversiDocument9 pages2021年9月15日Konjac Process Line-lijie (3) -DikonversiPorang PekanbaruNo ratings yet

- Mono BeltDocument4 pagesMono BeltAlexandru IgnatNo ratings yet

- KM 450bph 5 Gallon Water Production LineDocument39 pagesKM 450bph 5 Gallon Water Production LineaghyadhNo ratings yet

- 10''+20"string Wound Filter Cartridge Making Machine PDFDocument3 pages10''+20"string Wound Filter Cartridge Making Machine PDFAbhishek KumarNo ratings yet

- Quotation of CF-350Document2 pagesQuotation of CF-350RamachandranTKarthikNo ratings yet

- Xtfy Series Psa Oxygen Generation System Scheme: Purity: (Pressure:200Barautomatic Filling System)Document18 pagesXtfy Series Psa Oxygen Generation System Scheme: Purity: (Pressure:200Barautomatic Filling System)Luzmila MutoNo ratings yet

- Global: Enviro Air Systems (P) LTDDocument3 pagesGlobal: Enviro Air Systems (P) LTDSreenbabuNo ratings yet

- Regal Roots - Grading and Sorting MachineryDocument14 pagesRegal Roots - Grading and Sorting MachineryAkshay JadhavNo ratings yet

- Technical QuotationDocument7 pagesTechnical QuotationJHON SEGURA GONZALEZNo ratings yet

- FIN400 Production LineDocument5 pagesFIN400 Production LineMd Masudur RahmanNo ratings yet

- (PROGO) Q.131-19 MODULE FILTER MAIN TANK PT. SIS ADMO (Bp. Guntur)Document3 pages(PROGO) Q.131-19 MODULE FILTER MAIN TANK PT. SIS ADMO (Bp. Guntur)Rio aji RiyantoNo ratings yet

- Ppep PMB Evaluation Wdid 100Document4 pagesPpep PMB Evaluation Wdid 100whalenonNo ratings yet

- (181028) Quotation of BG-80E High-Efficiency Intelligent Film Coating Machine-2Document19 pages(181028) Quotation of BG-80E High-Efficiency Intelligent Film Coating Machine-2Unison Homoeo LaboratoriesNo ratings yet

- SJSZ80-156 For PVC Pipe Making Machine 50-250mmDocument8 pagesSJSZ80-156 For PVC Pipe Making Machine 50-250mmzakariaNo ratings yet

- MAYJOY 1760 Toilet Paper ProductionDocument5 pagesMAYJOY 1760 Toilet Paper ProductionSaraNo ratings yet

- Proforma Invoice: Guangdong Liansu Machinery Manufacturing Co.,LTDDocument9 pagesProforma Invoice: Guangdong Liansu Machinery Manufacturing Co.,LTDaariefmaulanaNo ratings yet

- Compactor Machine - ReviewDocument68 pagesCompactor Machine - Reviewชยากร เวชสวรรค์No ratings yet

- 4 - PPR63 Pipe Extrusion Line-160kgDocument15 pages4 - PPR63 Pipe Extrusion Line-160kgDennis machariaNo ratings yet

- Steam Sterilizer Technical Parameters PDFDocument7 pagesSteam Sterilizer Technical Parameters PDFSivaNo ratings yet

- Quote For Semi-Automatic 2000bph Water Prodution Line 20200831Document17 pagesQuote For Semi-Automatic 2000bph Water Prodution Line 20200831Mathias NsimbeNo ratings yet

- Q Filter ENGDocument4 pagesQ Filter ENGayari med aliNo ratings yet

- 10L Spray Dryer, from Thalia 2023.06.06 10l喷雾方案唯一 1Document12 pages10L Spray Dryer, from Thalia 2023.06.06 10l喷雾方案唯一 1EdwuarNo ratings yet

- CM-A30A, A30B, A36A, A36B, A22A Fully-Automatic Dough Divider & RounderDocument1 pageCM-A30A, A30B, A36A, A36B, A22A Fully-Automatic Dough Divider & RounderHanafi MansorNo ratings yet

- Manual Low Cost Non Pressure Solar Water Heater Production LineDocument3 pagesManual Low Cost Non Pressure Solar Water Heater Production LineAbdul Sami Abdul LatifNo ratings yet

- Finishing MachinariesDocument46 pagesFinishing MachinariesBodiuzzaman BodiNo ratings yet

- Injection Mould MachineDocument8 pagesInjection Mould MachineRizky AntikawatiNo ratings yet

- PVC PipesDocument35 pagesPVC PipesifiokNo ratings yet

- Achinta Pran Sarmah QuotationDocument8 pagesAchinta Pran Sarmah QuotationAgro SolutionNo ratings yet

- 700T Extrusion Press - Back Loading - Long Stroke 240407Document9 pages700T Extrusion Press - Back Loading - Long Stroke 240407amitsehgal9No ratings yet

- Quote For Fully Automatic 2000bph Water Prodution Line 20200831Document18 pagesQuote For Fully Automatic 2000bph Water Prodution Line 20200831Mathias NsimbeNo ratings yet

- Quotation-Automatic Napkin Tissue Production LineDocument7 pagesQuotation-Automatic Napkin Tissue Production LineRAUL lopezNo ratings yet

- 2019-10-14 Invoice For Awel Water LineDocument2 pages2019-10-14 Invoice For Awel Water LineA Wahid KemalNo ratings yet

- Mehmud Industries (PVT (1) .) LTD (18tons)Document4 pagesMehmud Industries (PVT (1) .) LTD (18tons)SarkarArdhenduRiponNo ratings yet

- GL-213-1300 Bopp Tape Slitting Rewinding MachineDocument8 pagesGL-213-1300 Bopp Tape Slitting Rewinding MachineA.jamilNo ratings yet

- FVQZD-2600C Gluer and Stitching All-In-One MachineDocument8 pagesFVQZD-2600C Gluer and Stitching All-In-One MachineJunaid MazharNo ratings yet

- Quotations-24 Spindle Rope Braiding MachineDocument3 pagesQuotations-24 Spindle Rope Braiding MachineCrall Daniel GeorgeNo ratings yet

- Shoe Upper Knitting MachineDocument10 pagesShoe Upper Knitting MachineYoussef eljamiNo ratings yet

- Quotation For Dough Divider and Rounder MachineDocument4 pagesQuotation For Dough Divider and Rounder MachinePereNo ratings yet

- Quotation For Concrete Pump From Peggy +8615837159290Document12 pagesQuotation For Concrete Pump From Peggy +8615837159290Mehari GizachewNo ratings yet

- Introduction To BlowroomDocument21 pagesIntroduction To Blowroomsujal jha100% (1)

- 51 105 PVC Dual Pipe - 20 50Document9 pages51 105 PVC Dual Pipe - 20 50Ankit PrajapatiNo ratings yet

- Quotation Sheet: 500Kg/H Pork Feed Production LineDocument10 pagesQuotation Sheet: 500Kg/H Pork Feed Production LineAlexis FlexyNo ratings yet

- HLPT-W2000 Automatic Egg Tray Making MachineDocument12 pagesHLPT-W2000 Automatic Egg Tray Making MachineManuel Castillo FernandezNo ratings yet

- Plastic ProductionDocument5 pagesPlastic ProductionJoseph KfouryNo ratings yet

- Filtomat M100-6800 - GRPDocument17 pagesFiltomat M100-6800 - GRPJose Angel Malpica PNo ratings yet

- Technical DataDocument16 pagesTechnical DataAdrian DumitruNo ratings yet

- Water TestingDocument5 pagesWater TestingJo KingNo ratings yet

- 2022 Physics Mid-Year EXAM G9Document10 pages2022 Physics Mid-Year EXAM G9Imon BrownNo ratings yet

- Goulds e SH Stainless Steel Pumps Technical Brochure BeSH R2Document60 pagesGoulds e SH Stainless Steel Pumps Technical Brochure BeSH R2Daniel Ortiz GonzálezNo ratings yet

- Study On Mechanical Properties of Concrete-Filled Steel Tubular Short Columns Under Different Curing TemperaturesDocument12 pagesStudy On Mechanical Properties of Concrete-Filled Steel Tubular Short Columns Under Different Curing TemperaturesTJPRC PublicationsNo ratings yet

- Charcoal Assignment 3Document14 pagesCharcoal Assignment 3Abdul GhaffarNo ratings yet

- Acronal PLUS 4641: Formulation 4641-010Document2 pagesAcronal PLUS 4641: Formulation 4641-010Thanh VuNo ratings yet

- Empirical Formula For Magnesium OxideDocument6 pagesEmpirical Formula For Magnesium OxidesophiaNo ratings yet

- Crystallization PDFDocument74 pagesCrystallization PDFMohammed Akif ShaikhNo ratings yet

- Options For High Temperature Well StimulationDocument11 pagesOptions For High Temperature Well StimulationFra FraNo ratings yet

- Table 6.2. Acidity of Some Hydrocarbons: Entry Hydrocarbon Cs (CHA) Cs (THF) K (DMSO)Document1 pageTable 6.2. Acidity of Some Hydrocarbons: Entry Hydrocarbon Cs (CHA) Cs (THF) K (DMSO)panda biruNo ratings yet

- Experiment 2 MergedDocument74 pagesExperiment 2 Mergedseecktskatrina03No ratings yet

- Dokumen - Tips - Pompe de Caldura BuclaDocument96 pagesDokumen - Tips - Pompe de Caldura BuclaAnonymous oKTCFZNTmNo ratings yet

- D 2251 - 96 R00 - RdiynteDocument2 pagesD 2251 - 96 R00 - RdiynteRuben YoungNo ratings yet

- STD G0566 RepeatDocument2 pagesSTD G0566 RepeatTirtana PrasetiaNo ratings yet

- ACCC-BRUSSELS Data-SheetDocument1 pageACCC-BRUSSELS Data-SheetZoran PetrovićNo ratings yet

- Layers-Of-The-Earth-Webquest-Worksheet1-6 1Document4 pagesLayers-Of-The-Earth-Webquest-Worksheet1-6 1api-268569185No ratings yet

- Chemistry (Whitten), 10th Ed - 2Document3 pagesChemistry (Whitten), 10th Ed - 2juan herreraNo ratings yet

- Final Exam Review ProblemsDocument8 pagesFinal Exam Review ProblemsIrina StefaniaNo ratings yet

- Experiment 28Document12 pagesExperiment 28William RamirezNo ratings yet

- Many Body Physics NotesDocument239 pagesMany Body Physics NotesAnonymous oK0EuQNo ratings yet

- Ketene Production and Utilization Experimental StudyDocument4 pagesKetene Production and Utilization Experimental Studyspedhome1No ratings yet

- Safavi 2022 - Mathematical Modeling and Experiments On Pyrolysis of (ChemEngineering)Document11 pagesSafavi 2022 - Mathematical Modeling and Experiments On Pyrolysis of (ChemEngineering)Christiaan RichterNo ratings yet

- Sop WTP CombinedDocument17 pagesSop WTP CombinedsiccppNo ratings yet

- The Geotechnical Properties of Jamshoro Soil (Shale) With CementDocument6 pagesThe Geotechnical Properties of Jamshoro Soil (Shale) With CementijmremNo ratings yet

- Doc-20231126-Wa0008. 20231126 161647 0000Document13 pagesDoc-20231126-Wa0008. 20231126 161647 0000chanchal.x04No ratings yet

- Pritt Stick SafetyDocument6 pagesPritt Stick SafetynorthernmeldrewNo ratings yet

- MSDS Malaysia Kahf Humbling Forest Eau de ToiletteDocument4 pagesMSDS Malaysia Kahf Humbling Forest Eau de ToiletteyeniNo ratings yet

- 2018-2019 Exams STNHSDocument5 pages2018-2019 Exams STNHSMajorica Cepeda MillanNo ratings yet

- Degree Programme Table: Advanced Chemical Engineering (MSC) - 1 Year (Full-Time)Document3 pagesDegree Programme Table: Advanced Chemical Engineering (MSC) - 1 Year (Full-Time)Petra SitanggangNo ratings yet

- Ethyl Alcohol, 70%, in Water: Safety Data SheetDocument6 pagesEthyl Alcohol, 70%, in Water: Safety Data SheetAmalia Desy SaputriNo ratings yet

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsFrom EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo ratings yet

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldFrom EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldRating: 4 out of 5 stars4/5 (87)

- Power System Control and ProtectionFrom EverandPower System Control and ProtectionB. Don RussellRating: 4 out of 5 stars4/5 (11)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Build Your Own Electronics WorkshopFrom EverandBuild Your Own Electronics WorkshopRating: 3.5 out of 5 stars3.5/5 (3)