Professional Documents

Culture Documents

Ra Lighting Pole

Uploaded by

mutasim.jadallaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ra Lighting Pole

Uploaded by

mutasim.jadallaCopyright:

Available Formats

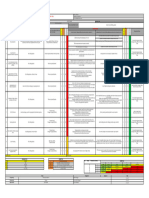

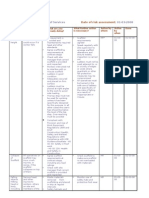

RA No: RISK ASSESSMENT: LIGHTING POLE INSTALLATION WORK ALONG THE JUC RING ROAD.

Reviewed date: 05-08-2023

TASK / SPECIFIC LOCATION

OPERATION / ACTIVITY TOOLS &

DESCRIPTION:

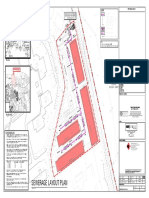

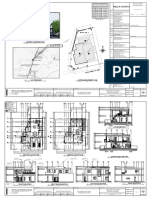

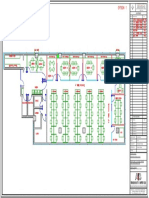

LIGHTING POLE INSTALLATION WORK ALONG THE JUC RING ROAD EQUIPMENT IN EXCAVATOR, LOADER, COMPACTOR ROLLER, WATER TRUCK,BOOM TRUCK & CRANE.

097-C73R USE:

S WITH CONTROLS

RISK SCORE

Tasks Hazards identified with each task Harm / Consequence / Parties

SEVERITY (S)

RISK RATING

PROBABILITY (P)

PROBABILITY (P)

e (What one does in logical (What can hurt one / others?) affected (What can happen / go

SEVERITY (S)

RISK RATING

Current Controls / Safeguards (What do we do to prevent incidents?) Additional & Site Control ( What

RISK SCORE

r steps) wrong)

additional could we do to reduce the Responsible Person

N Risk?)

o

.

1 The supervisor should secure the STARRT CARD prior to start the activity and give a briefing to the 2 2 4 Low Electrical engineer+ Civil

crew involved in the activity. Cordon off the area. Deploy the flagman to control the traffic flow control. Engineer + Civil foreman +

Place a fire extinguisher in the radius of the working area. Keep the emergency numbers posted at the HSE Officer

The absence of the work permit can site to counter any unwanted scenario.Secure an approved road permit and plan prior to start the

lead to a serious breach of the safety activity from the RC Authorities. Provide high-visibility vest for Flagman while performing task during Construction Manager,

and the lives of the people can be at the work activity as per CSM. Provide proper and appropriate Personal Protective Equipment to all Electrical/Mechanical engineer must

Obtaining a valid work permit 3 4 12 High personnel involved in the work activity prior to deploy at the work site. Provide stand by vehicle and

No work permit no activity. stake, the damage to the property conduct frequent visits of site to ensure

for the execution of the work designate a driver with SAG license who are familiar of the route to the nearest approved medical

and absence of competent and key that all the activity is going on as per the

personals can cause too much centers. Designate First Aiders certified by authorized 3rd party with complete set of First Aid Kits and standards of RC

issues. must be available physically at the site all the time.

The supervisor should secure the STARRT CARD prior to start the activity and give a briefing to the 2 2 4 Low CM+ Civil Engineer+

crew involved in the activity. Cordon off the area. Deploy the flagman to control the traffic flow control. Foreman and HSE Officer.

Place a fire extinguisher in the radius of the working area. Keep the emergency numbers posted at the

site to counter any unwanted scenario.Secure an approved road encroachment permit and plan prior

Human injury/loss can occur, to start the activity from the RC Authorities. Provide high-visibility vest for Flagman while performing

damage to the property and the task during the work activity as per CSM. Provide proper and appropriate Personal Protective

Traffic control and road equipment. Skin irritation or eye Equipment to all personnel involved in the work activity prior to deploy at the work site. Provide stand Construction Manager, Project engineer ,

closure, placing all the Struck by over speeding vehicles and contact can affect the workers. by vehicle and designate a driver with SAG license who are familiar of the route to the nearest

2 3 3 9 Medium approved medical centers. Designate First Aiders certified by authorized 3rd party with complete set of Site supervisor must conduct frequent

barriers, warning signs as per moving compact roller, slip, trip & Fall Improper use of machine can lead visits of site to ensure that all the activity

traffic plan the worker to an injury and First Aid Kits and must be available physically at the site all the time.Deploy firewatch during the is going on as per the standards of RC

mismanagment of cable can create activity and he will leave the site after the 30 minutes of finishing the task.

triping hazard.

Shall provide protection by installing machine guarding devices on exposed rotating or revolving parts 3 4 12 High CM+HSE Officer

Incomplete barricades, any groups of the machineries. Shall isolate area where the inspection and checking of equipment by barricading

Caught in between.

Preparations of equipment, and contractor may enter into the around and display warning signs to alert other workers during the testing, checking, and warming up Site foremen Civil supt monitor the job

Unauthorized operation of equipment by an 3 4 12 High

3 machineries, tools and area. of the equipment’s engine. Post warning safety signs regarding the nature of the activity and the Previous inspection will be available for

untrained person.

materials Physical PPE's. working at height.

Unauthorized use of equipment at site

injury.

Ensure that the STARRT Card is provided prior to the execution of the activity, Compliance to the 1 3 3 Low

PPE's prior to execute the activity, dust mask, dewatering to be conducted prior to the survey marking

for the marking of exact location of the switch station to be installed. Color coding of the hand tools

Air pollution Respirator illness. 2 3 6 Medium and the electrical tools along the mechanical tools. Supervision By competernt person site supervisor/ foreman

Marking of the location of the

4 Avoid direct contact to the soil and water, use proper hand protections PPE's. Frequently wash out the 1 1 1 Low

installation of lighting poles.

hands to make sure that there is no contamination left. Avoid the splashes of the water as well if any.

Microbiological Hazard from soil & water. Biological illness. 1 2 2 Low Supervision By competernt person site supervisor/ foreman

Excavation & trenching activity will take place in accordance to the RC Standard # 211 & 212 ,Valid 2 4 4 Low

Fall into excavations. Serious injury to the worker. 2 3 6 Medium work permits, certified operators. Ensure that the underground utilities are detected if any present

using GPR/EML devices, no mechanical excavations until the underground utilities are

exposed.Access& egress of the work area should be free of any obstruction, deploy the flagman, Red

2 4 8 man & Green man system should be implemented, provide the barricades at the working area & make

Collision with the excavator during the Fatality to the workers. Medium

sure that the warning signs related to the confined space ,deep excavation and heavy equipment

digging activity. operating in area are posted at the work area.Make sure the competent person is deployed at the work Supervision By competernt person &

Excavation of the marked site throughout the activity.Heavy equipments checklist should be maintained on daily basis and the always use the hand tools to expose the

5 area for the installation of the Fatality to the workers. 3 4 12 High MEPI TBT to be provided prior to execute the activity. Provide slope or benches at the edges of the undeground utilities no mechanical site supervisor/ foreman

lighting poles. Collapse of the excavation. excavation to prevent any cave in or collapse of the excavation.The excavation competent person will excavations near the under ground

be available at the site.Fuel exhaust generating equipment to be placed outside the excavation. utilities area.

Asphyxia/Suffocation Fatality to the workers. 2 4 8 Medium Machine operators to stay away from the exhaust gases. Never use CO2 fire extinguisher in confined

space.Plans and drawing verification. Permit to Dig. Ground survey using traces or detector.

Care for digging above or near

Injuries secondary to hitting 3 4 12

underground utilities which were High

underground utilities.

constructed long time ago.

Ser No. Tasks Hazards identified with each task Harm / Consequence / Parties WITH CONTROLS Responsible Person

PROBABILITY (P)

PROBABILITY (P)

(What one does in logical (What can hurt one / others?) affected (What can happen / go

SEVERITY (S)

SEVERITY (S)

RISK RATING

RISK RATING

Current Controls / Safeguards (What do we do to prevent incidents?) Additional & Site Control ( What

RISK SCORE

RISK SCORE

steps) wrong)

additional could we do to reduce the

Risk?)

The lifting operations will take place in accordance to the RC standard # 221. Operator should position 3 3 9 Medium Confined Space

Serious injury to ground on the opposite side of the truck to that which the lighting pole will be lifted & lowered. STARRT talks. Construction Manager, Project engineer , Competent Person +

Hitting to the existing facilities or persons. 3 4 12 High

workers/Property damage. 3rd-party certified Crane/Boom Truck Backhoe Operator. 3rd-party certified Crane/Boom Truck. 3rd- Site supervisor must conduct frequent Scaffolding Competent

6

Serious injury to ground party certified Rigger. Certified rigging equipment. Taglines. Redman trained banksman or spotter. visits of site to ensure that all the activity person+ CM+ Civil

Crane Lifting general Equipment failure.

workers/Property damage.

3 4 12 High Use PPE.Trained and TUV certified operator, good condition of equipment with third party inspection. is going on as per the standards of RC Engineer+ Foreman and

operation. Operator should have clear view of the area where load lift and lowerd onto. Attach tag line while HSE Officer.

lifting. Ensure that the lifting calculation is in place prior to execute the lifting activity.Verify the valid

TUV for the Rigger depending upong the load the level of the Rigger will be decided. Cardon off the

Fall of load. 3 4 12 High area no unauthorized entry in the 10 meter radius of the crane boom. Post warning signs lifting in

progress.

2 2 4 Low CM+ Civil Engineer+

Foreman and HSE Officer.

All work to be planned in advance

and experienced personal to be used Safety supervision.+ area site supervisor

TheFRP Lining activity will take place as per the RC standads, monitoring the weather, if the heat

to carry out work. Monitor the must be present on site.Provide ample of

index is 50C tha stop work . Deploy the flag man to control the traffic controls. All the rotation

7 Heat Stress High temperature during the work. temperature on hourly basis and 3 3 9 Medium drinking water with suficient ice to the

equipment of the concrete grinder should be guarded properly. The tools should be color coded.

record it. If the temperature employees working. Record the

Provision of the cold drinking water should be ensured. Record the temperature on the hourly basis.

exceeds/reaches 50 °C immediately temperature on hourly basis.

stop the work.

8 Hand and physical injury by manual Back Injury poor manual handling. Housekeeping will be in accordance to the RC standard # 206.Heavy weight materials shall be shifted After every shift shall conduct regular 2 2 4 Low PM, SM, CM and site

handling. Un-attended material cause No proper inspection after job by equipment. Follow the employees for proper lifting techniques. Wear proper hand gloves for manual housekeeping. alkthrough shall condut supervisor. Area foreman

tripping hazards. Environmental hazards. completion lead poor housekeeping. handling. Supervisor and area safety shall conduct inspect the area after every shift for proper perior back filling area. Continuous and HSE Officer.

Falling material and scarps into Un-attended Hazards materials like housekeeping. Supervisor and area safety shall conduct inspect the area after every shift makesure monitoring shall be available by area

Housekeeping and site employees. painting,coding concrete materials 2 3 6 Medium there is proper housekeeping. All scaffolding material such clamps and scaps shall removed . Guard supervisor. Final walhrhrough shall be

cleaning could soil contamination. working rails shall installed untill the final house keeping is conducted by project management team.

employees and neaeby employees done.

who working underneath of

buildings.

Power

connectio

n

9 In effective emergency plan. lack No proper inspection and Writen emergency plan shall be available at site. The plan properly estabilised and implemeted. RC Plan already on place. RC Plan 2 2 4 Low Site manager,Safety

communication and lack awareness. No continuance improvement affect conditiuous improvemt shall be make for efectivenss. Accountable leader appointed and already on place and estabilished. Manager, Safety officer,

accountable leader and communication emergency plan. No proper communication flows shall on place. Orientation Session shall have part include emergency plan and Approved MEPI champion available on construction managers,site

flows communication and drills. No arrengement. Periodic drill shall be conducted. duty. suprt Accountable leader

Emergency plan effective communication fliows High Tool box meeting must conduct about emerginy plan. Supervisor and CM,MEPI champion shall part of appointed and

3 4 12

emergency plan. Communication chart shall estabilish and based site as per written procedure. The communication flows

incident commander and MEPI champion name and contact number must estabilished. Revise and

update where necessary.

Std PPE: Safety helmet, safety glasses, safety shoes, reflective vest and safety gloves Additional PPE: Face shield, fullbody harnes, Rubber gloves, cartridge respirator and Anti cut gloves

SEVERITY

1 First Aid or slight injury

2 Recordable, medical and restricted work

3 Lost time injury or permanent disability

4 Single fatality or permanent disability of 3 or more person

5 multiple fatalities

1 Unlikely Probability x Severity 1 2 3 4 5

2 Rare 1 1 - Low 2 - Low 3 Low 4 - Low 5 - Med

3 Possible 2 2 - Low 4 - Low 6 - Medium 8 - Medium 10 - High

4 Likely 3 3 Low 6 - Medium 9 - Medium 12 - High 15 - High

5 Very Likely 4 4 - Low 8 - Medium 12 - High 16 - High 20- High

5 5 - Medium 10 - High 15 - High 20- High 25 - High

Name Designation Signature Date

Prepared by: Adeel Anis Lodhi Safety Manager 2-Aug-23

Reviewed by: Bahaa El-din khalil Civil Engineer 2-Aug-23

Approved by: Engr. Muhammad ElRefai Project Manager 2-Aug-23

Royal Commission ASE Contact Number: 0533451450

Civil Engineer Contact Number: 0563640891

Electrical Engineer Contact Number: 0542608075

Note: In case of any emergency assemble at the assembly point area.

You might also like

- Scaffolding Risk AssessmentDocument1 pageScaffolding Risk AssessmentIrfan AliNo ratings yet

- Risk Assessment For LIFTINGDocument5 pagesRisk Assessment For LIFTINGsak388036No ratings yet

- Royal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesDocument2 pagesRoyal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesLenaj Ebron100% (3)

- HIRA FormatDocument7 pagesHIRA Formatvikram.knNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Risk Assessment LogisticDocument3 pagesRisk Assessment LogisticHasnaoui AsmaaNo ratings yet

- 1 PDFDocument1 page1 PDFNoothan JXNo ratings yet

- TabindaDocument1 pageTabindaAnonymous BZQOJwWIh6No ratings yet

- Security Symbols: Diagram For Lab Building Security Intercom Single-LineDocument1 pageSecurity Symbols: Diagram For Lab Building Security Intercom Single-LineMohammed IrfanNo ratings yet

- Abts Uqair-B.2Document1 pageAbts Uqair-B.2Anonymous BZQOJwWIh6No ratings yet

- HSSE Manual Table of ContentDocument40 pagesHSSE Manual Table of ContentTao Qu100% (1)

- Saudi Arabian Oil Company: SEC-801 Restricted J95 O VA-933167 008 00Document1 pageSaudi Arabian Oil Company: SEC-801 Restricted J95 O VA-933167 008 00Mohammed IrfanNo ratings yet

- Prepared HIRA For Reference, Coke Oven, BPPDocument8 pagesPrepared HIRA For Reference, Coke Oven, BPPvikram.knNo ratings yet

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- HIRA For Mech Work SalcompDocument3 pagesHIRA For Mech Work SalcompNaveenNo ratings yet

- Iwk KM LayoutDocument1 pageIwk KM LayoutArman ManNo ratings yet

- PM-1 Front Side ViewDocument1 pagePM-1 Front Side Viewdelvi.panjaitan097No ratings yet

- 4124 Aa DC 21710L101S01 Is01Document1 page4124 Aa DC 21710L101S01 Is01titir bagchiNo ratings yet

- Dela Cruz For Blueprint Checking 12-05-2022Document14 pagesDela Cruz For Blueprint Checking 12-05-2022Patrick Jerald CamilonNo ratings yet

- ITTO Matrix 6thed MatrixDocument13 pagesITTO Matrix 6thed MatrixGillianiNo ratings yet

- 924H and 924HZ Wheel Loader Hydraulic SistemDocument4 pages924H and 924HZ Wheel Loader Hydraulic SistemJose A. Basanta H.No ratings yet

- Sheet - E-2 - POWER PLANDocument1 pageSheet - E-2 - POWER PLANMartha RinconNo ratings yet

- 785C Cat NewDocument10 pages785C Cat NewMuhammad AlwiNo ratings yet

- Lighting Management System Schematic DiagramDocument1 pageLighting Management System Schematic DiagramDani WaskitoNo ratings yet

- HIRA (INST'L OF 1-Unit PHE & PIPING WORKS)Document1 pageHIRA (INST'L OF 1-Unit PHE & PIPING WORKS)Riemel IdjaoNo ratings yet

- JP AD 2.24.1 RJAA en JPDocument1 pageJP AD 2.24.1 RJAA en JPmetro752No ratings yet

- GA Drawings For ProcurementDocument19 pagesGA Drawings For ProcurementRAJESHWARNo ratings yet

- Sistema Eléctrico C7 CaterpillarDocument2 pagesSistema Eléctrico C7 CaterpillarDana CarvajalNo ratings yet

- Plano ElectricoDocument2 pagesPlano Electricomauricio suarezNo ratings yet

- KIL2189 - 200 - 0001 - REV08 - Proposed LayoutDocument1 pageKIL2189 - 200 - 0001 - REV08 - Proposed LayoutNiemNo ratings yet

- Enlarged View Showing Anchor Bolt Positions On Foundation AngleDocument1 pageEnlarged View Showing Anchor Bolt Positions On Foundation AngleMohamedHussein MohamedHusseinNo ratings yet

- Hot Work PermitDocument2 pagesHot Work Permitnorazlan othmanNo ratings yet

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocument2 pagesDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionAfzaalUmairNo ratings yet

- XLP Pre L15 WL15P51Document2 pagesXLP Pre L15 WL15P51Aria NickbakhtNo ratings yet

- Zaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Document1 pageZaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Trung LêNo ratings yet

- Working Environmental HazardsDocument5 pagesWorking Environmental HazardsSri100% (1)

- 109018AE0026-27 - Rev - 0 Layout Panel de ControlDocument2 pages109018AE0026-27 - Rev - 0 Layout Panel de ControlAlonzo Rueda PeraltaNo ratings yet

- Sapphire Plaza - OPT 1Document1 pageSapphire Plaza - OPT 1Navdeep GopamwarNo ratings yet

- FHDC Aureo Phase 6: PhilmepsincDocument1 pageFHDC Aureo Phase 6: PhilmepsincSEDFREY DELA CRUZNo ratings yet

- Sample DiagramsDocument6 pagesSample DiagramsNeneng KunaNo ratings yet

- Ndumndum Ps SDPDocument1 pageNdumndum Ps SDPKaka KuxNo ratings yet

- Ewan Engineering Consultancy: Engineered/Contractor To Verify and Submit Calculation For The Approval of EngineersDocument1 pageEwan Engineering Consultancy: Engineered/Contractor To Verify and Submit Calculation For The Approval of EngineersAbid AyubNo ratings yet

- Project SU RigDocument1 pageProject SU RigBrett SmithNo ratings yet

- M 03 PDFDocument1 pageM 03 PDFprokjongNo ratings yet

- Porte Cochere Repair SetDocument10 pagesPorte Cochere Repair SetjavierjimenezcholletNo ratings yet

- 20024-000000u-D003 - Ufd - Plant Water Rev 0Document1 page20024-000000u-D003 - Ufd - Plant Water Rev 0oscar alfredoNo ratings yet

- CoverPage 01 PDFDocument1 pageCoverPage 01 PDFJustine LevamuievosNo ratings yet

- P20c30ug01prw Aecg Civugsdwg 34801 1 (A)Document1 pageP20c30ug01prw Aecg Civugsdwg 34801 1 (A)kaizen.hameshaNo ratings yet

- Caja Eléctrica Central (CJB) - RHD 4WDRHD RWD PDFDocument2 pagesCaja Eléctrica Central (CJB) - RHD 4WDRHD RWD PDFSamuel SouzaNo ratings yet

- Umbac Layout1 1Document1 pageUmbac Layout1 1Carlo Recilla CanillasNo ratings yet

- Risk Assessment EvidenceDocument4 pagesRisk Assessment EvidenceBlister PatchNo ratings yet

- General Structural Notes:: Typ. Det. For Beam or Slab Change Soffit Typ. Det. For Sleeves Thru RC BeamDocument1 pageGeneral Structural Notes:: Typ. Det. For Beam or Slab Change Soffit Typ. Det. For Sleeves Thru RC BeamJan Lawrence AlbertoNo ratings yet

- Descaling JobDocument20 pagesDescaling JobPrem Preetham DsouzaNo ratings yet

- M 02Document1 pageM 02prokjongNo ratings yet

- 1risk and Opportunity Assessment Sheet EMB5 IPNE SignedDocument2 pages1risk and Opportunity Assessment Sheet EMB5 IPNE SignedStella Joan LitaNo ratings yet

- Cat 924K Hydraulic SchematicDocument4 pagesCat 924K Hydraulic SchematicJacques Van Niekerk100% (3)

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- This Site: Exterior PerspectiveDocument1 pageThis Site: Exterior PerspectiveNikki Marie A. CabahugNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Ele Mos Eq1Document17 pagesEle Mos Eq1mutasim.jadallaNo ratings yet

- ELE MOS MV & LV CablesDocument17 pagesELE MOS MV & LV Cablesmutasim.jadallaNo ratings yet

- ELE MOS Lighting PolesDocument10 pagesELE MOS Lighting Polesmutasim.jadallaNo ratings yet

- QTY Cables ELEDocument1 pageQTY Cables ELEmutasim.jadallaNo ratings yet

- Mos 7006&7030Document8 pagesMos 7006&7030mutasim.jadallaNo ratings yet

- Method Statement of Locating Existing Utilities and Trial PitsDocument36 pagesMethod Statement of Locating Existing Utilities and Trial Pitsmutasim.jadallaNo ratings yet

- Method Statement ELECTRICAL WORKSDocument28 pagesMethod Statement ELECTRICAL WORKSmutasim.jadallaNo ratings yet

- CPP-NGCP-CM-MS-0014 - 1 Method Statement Procedure For Electrical Works-1Document56 pagesCPP-NGCP-CM-MS-0014 - 1 Method Statement Procedure For Electrical Works-1mutasim.jadallaNo ratings yet

- Hidraulico HY50193 B1200 50.193Document83 pagesHidraulico HY50193 B1200 50.193Moises Carrera AnguloNo ratings yet

- Iso 14971 V2Document3 pagesIso 14971 V2rakesh marwahNo ratings yet

- Company Profile: © Confederation of Indian Industry Pradip Nikam - HSE Manager Irfan Ahmed - Project ManagerDocument9 pagesCompany Profile: © Confederation of Indian Industry Pradip Nikam - HSE Manager Irfan Ahmed - Project ManagerAnoop PrajapatiNo ratings yet

- REX Ovuv AccuracyDocument454 pagesREX Ovuv AccuracyngocanhvyNo ratings yet

- Prospectus 2021Document27 pagesProspectus 2021Marius BuysNo ratings yet

- Pressurevessel Sop 0082 PDFDocument9 pagesPressurevessel Sop 0082 PDFGafour ParadizNo ratings yet

- What Will You Bring in A Lifeboat If The Ship Is AbandonedDocument6 pagesWhat Will You Bring in A Lifeboat If The Ship Is AbandonedWahyu Muhamad RomadoniNo ratings yet

- EMD Overhaul and Maintenance of MotorsDocument24 pagesEMD Overhaul and Maintenance of MotorssingenaadamNo ratings yet

- FAG-ENG-070 Rev.0Document120 pagesFAG-ENG-070 Rev.0emmanuel renigenNo ratings yet

- 087819E-A Operation & Service Manual PDFDocument123 pages087819E-A Operation & Service Manual PDFadrian gutierrez100% (1)

- Nissar - Permit To Work - JGCDocument32 pagesNissar - Permit To Work - JGCDelta akathehuskyNo ratings yet

- HEMPDocument87 pagesHEMPNid Piks100% (1)

- Toxic Gas Exposure Limits and Alarm Levels, Portable Gas DetectionDocument1 pageToxic Gas Exposure Limits and Alarm Levels, Portable Gas DetectionwisnukerNo ratings yet

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- SOP NM ReportingDocument2 pagesSOP NM ReportingsbmmlaNo ratings yet

- Atkins ReportDocument41 pagesAtkins ReportSteve Chilcott0% (1)

- Final ExamDocument23 pagesFinal ExamRalphNicholaiApostolUlepNo ratings yet

- Road Freight Transport Industry: Hazard Identification ChecklistDocument6 pagesRoad Freight Transport Industry: Hazard Identification ChecklistMuhammad IrfanNo ratings yet

- Nebosh August 2021 Obe AnswersDocument8 pagesNebosh August 2021 Obe AnswersVISHNURAJ G100% (1)

- Functional Academics Science 3Document13 pagesFunctional Academics Science 3Riza Pearl LlonaNo ratings yet

- Diesel COSHHDocument4 pagesDiesel COSHHJohn Geddes100% (1)

- Iom Manual Ivp enDocument47 pagesIom Manual Ivp enmohamed hamedNo ratings yet

- CAL-117 (California Technical Bulletin 117-2013)Document1 pageCAL-117 (California Technical Bulletin 117-2013)danielNo ratings yet

- SD65075 - Swellseal 3V - (GB)Document6 pagesSD65075 - Swellseal 3V - (GB)nlmiNo ratings yet

- Makkah First Ring Rad (Bc148) :: Use of MEWPDocument2 pagesMakkah First Ring Rad (Bc148) :: Use of MEWPansarimf1980gmailcomNo ratings yet

- 3 Community Health and SafetyDocument12 pages3 Community Health and SafetyTopfan AdamNo ratings yet

- Tower Climbing SafetyDocument125 pagesTower Climbing Safetyakinola emmanuel100% (1)

- Scooba Drydock: Charging and Drying StandDocument8 pagesScooba Drydock: Charging and Drying Standir3678No ratings yet

- Designation As DRRM CoordinatorDocument2 pagesDesignation As DRRM CoordinatorJade Sibonga DingcoNo ratings yet

- MCM Module 1 Risk Management PDFDocument27 pagesMCM Module 1 Risk Management PDFFranciz Nicole RadanNo ratings yet