Professional Documents

Culture Documents

5025 ITP Precast Panel Installation

Uploaded by

djzaiyuanyeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5025 ITP Precast Panel Installation

Uploaded by

djzaiyuanyeCopyright:

Available Formats

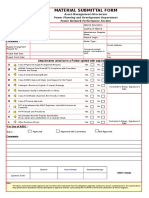

ITP - INSPECTION TEST PLAN

Inspection Test Plan

Title: Precast Panel Installation Contractor:

Project Name: Date:

Project Address: ITP No:

Client: ITP Work area:

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

Insert Reference

Prior to

W Ron 20/08/ To ensure reinforcing is installed as Documents here Ron 20/08/2021

EG Reinforcement inspection pouring Visual Structural Engineer’s Certificate

Perry 2021 per engineers design e.g. Engineers Perry

concrete

Drawing No. S1.10

Drawing No:

Rev:

Ensure current revision of

Prior to Drawing No:

1 Visual W design drawings and

Documentation start Rev:

specifications

Drawing No:

Rev:

Drawing No:

Rev:

Before Drawing No:

2 Shop drawings Visual H Approve shop drawings

Lifting Rev:

Drawing No:

Rev:

Have the shop drawings been

Before

Visual H reviewed and signed off by the

Lifting

Design and Erection Engineer?

If permanent fixings are to be

Before used during erection, has this

Visual H

Lifting been detailed on shop

drawings?

3 Before Visual H

Lifting Has the builder obtained from

Engineering the Design Engineer a

certificate of compliance,

advising that all elements have

been designed in line with the

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |1

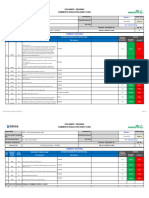

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

Australian Standard and

industry Standard?

If temporary supports such as

angle brackets are to be utilised

to support panels prior to

Before

Visual H permanent fixings being

Lifting

installed, have engineers

provided detail of the temporary

supports?

Have management obtained

Before written approval from an

Visual H

Lifting engineer in relation to the type

and position of the brace points.

The planning process should

take into account:

1. Site limitations.

2. Access Panel size.

Before

4 Visual H 3. Crane size, mobility &

Planning Lifting

access.

4. Casting sequence.

5. Overhead obstructions,

including overhead power lines

Has a Manufacturers Certificate

of Compliance (Birth Certificate)

5 Each Panel Visual H been provided by the precaster,

Certification for the panels being erected on

site?

Is the Manufacturers Certificate

Each Panel Visual H of Compliance (Birth Certificate)

available on site for review?

6 Each Panel Visual H

Provided by the precast

Component Schedule manufacturer or & must include

the following information:

1. Project name & address.

2. Element designation.

3. Element mass.

4. Concrete strength required at

the time of erection for the panel

&, where applicable, the bracing

footing.

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |2

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

5. Type, capacity & length of the

lifting inserts.

6.A diagram of the rigging

system/s between the crane &

the precast panel for both

rotation and erection [Shop

drawings may be used to form

the panel schedule]

Erector must nominate one

person in the erection crew to

be directly responsible for the

direction & co-ordination of the

77 Each Panel Visual H

Modifications erection sequence & to ensure it

is erected in accordance with

the designers & manufacturer’s

instructions.

Modifications to precast panels

should only be carried out with

Each Panel Visual H

the approval of the project

design engineer.

8 Each Panel Visual H Propping Pad Layout

Propping Design

9 Each Panel Visual H As per design drawings

Panel Setout

Check the ground conditions

and ascertain if there are any

underground services where the

crane is to be set up.

10 Each Lift Visual W

Crane Setup

Check for overhead power lines.

Engineer Certificate

As per shop drawings, spec and

11 Each Lift Visual W

Rigging Attachments manufacturers requirements.

As per shop drawings, spec and

12 Prior to Lift Visual W

Panel Finish manufacturers requirements.

13 Each Lift Visual W

As per shop drawings, spec and

Packers and Dowels manufacturers requirements.

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |3

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

14 Each Lift Visual W Erection Area has clear access

Erection

Each Lift Visual W Tail Ropes attached

A document prepared by the

builder to verify that the erection

Each Lift Visual H

platform can safely carry the

construction and erection loads?

Are all lateral restraints (dowel

bars, angle irons etc.) being

Each Lift Visual W installed and fixed in position

during the erection of the

precast concrete elements?

If lifting points are identified that

are incorrectly installed,

damaged or missed during

Each Lift Visual W manufacture of the precast

element, have alternate lifting

points been designed by the

Erection Design Engineer?

Check lateral restraints being

Each Lift Visual W installed as per the design

engineer’s detail?

Check rigging details available

Each Lift Visual W

for panels to be erected on site?

Check appropriately qualified

persons available on site to

undertake the erection

Each Lift Visual W procedure

(Advanced/Intermediate

Rigging, AR, IR) Appropriately

Licensed Crane Operator.

Is the area/s designated for the

Each Lift Visual W unloading of precast panels firm

and level?

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |4

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

If precast elements are to be

rotated on site by a single crane

to their final position for

Each Lift Visual W installation, can 70% of the total

weight of the lift be supported by

the tailing lifter and the auxiliary

winch?

Check for vertical and horizontal

Each Lift Visual W

alignment

Each Lift Visual W Check for plumb

Check alternative locations

Each Lift Visual W being utilised for the bracing of

precast components on site?

Erection Tolerances

Each Panel Visual W +/- ……..mm

(eg +/- 5mm)

As per shop drawings, spec and

15 Each Panel Visual W

Propping and Bracing manufacturers requirements.

Engineers

Each Panel Visual W

Inspection/Certification

Check prop requirements,

including positions detailed on

Each Panel Visual W shop drawings for each

individual precast element on

site?

Do braces have appropriate

Each Panel Visual W permanent identification in

place?

Check braces are erected

Each Panel Visual W between 40-60 degrees to the

horizontal?

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |5

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

Check braces erected +/-5

Each Panel Visual W

degrees to the perpendicular?

Check braces positioned at 2/3

of the height of the panels, or

are engineer’s documentations

available to advise that the

Each Panel Visual W

panels have been engineered to

enable the braces to be

positioned at an alternative

height?

Check locking pins constructed

Each Panel Visual W that the use of a tool is needed

to undo them?

Panel dowels grouted as per

16 Each Panel Visual W shop drawings, spec and

Grout engineers requirements

Dry pack grout to underside of

Each Panel Visual W

panels

Fill joints to at least 25mm depth

During

17 Construction

Visual W Check contractual requirement

Caulking for sealing / Caulking of joints,

i.e. colour

During Use Fire Rated Sealant for Fire

Construction

Visual W Fire Rating……………..mins

Rated Walls

Back with a continuous length of

During

Construction

Visual W compressible butyl impregnated

plastic foam.

Obtain from the project design

engineer or suitably qualified

18 Each Panel Visual H independent engineer, written

Removal Braces and Props approval to remove temporary

bracing?

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |6

ITP - INSPECTION TEST PLAN

Inspection / Verification / Test References NC

Sign off as Completed

Done By (Procedure, No

Item Inspection / Test Point Timing /

No.

Method Acceptance Criteria Specifications, Dwg Comments / Record Type

Work Activity Frequency

Contractor

Non-

No, Aust Standards, Conform

Client

Other

Persons Consultants Report) ance

Signature Date Name Signature Date

Name Number

Does the written approval from

the Erection Design Engineer

Each Panel Visual W state that all permanent

connections have been

inspected and approved?

Completed as per current

19 Final Inspection Each Panel Visual W

design documents/drawings

Position and alignment within

Each Panel Visual W

tolerances

Free from cracking, spalling and

Each Panel Visual W

honeycombing

Each Panel Visual W Colour consistency and texture

Free from projections,

Each Panel Visual W

depressions and grout spillage

Each Panel Visual W Filling of bracing bolt recesses

Each Panel Visual W Area is clean and tidy

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |7

ITP - INSPECTION TEST PLAN

Non-Conformances:

Item Date to be Verified as Date Closed

No.

NC No. Description Corrective Action Required Responsible Party

Completed Actioned By Out

Comments:

Verified by Client: if required Verified by Contractor: Verified by Other: if required

Company Name: Company Name: Company Name:

Print Name: Print Name: Print Name:

Position/Title: Position/Title: Position/Title:

Signature: Signature: Signature:

Date: Date: Date:

Legend

W = Witness The Contractor, Engineer or Consultant may inspect, test, review, witness the work. The activities however may proceed.

H = Hold Point Performance of an activity must be stopped and put on hold until specified actions are completed and have been passed/approved.

V = Verify A verification document, drawing, photo, specification, report or the like is provided and attached to this ITP.

NC = Non-Conformance A Non-Conformance is raised where a work item, activity or the like does not comply

S = Surveillance or monitoring Monitor the status of work and materials and analyses of records on a periodical basis to ensure that specified requirements are being fulfilled.

R = Review Review, record, document the results of inspection, examination or test to ensure the results have passed

PM Project Manager

CA Contracts Administrator

© Builderassist All Rights Reserved www.builderassist.com.au ITP No: 5025 P a g e |8

You might also like

- PPAP 3rd Edition Check List: PPAPKIT - F01 Rev. A (May - 03)Document6 pagesPPAP 3rd Edition Check List: PPAPKIT - F01 Rev. A (May - 03)api-3832465100% (5)

- Itp PlasteringDocument7 pagesItp PlasteringJervino RuahNo ratings yet

- QMS-17-SF Inspection and Test Plan TemplateDocument3 pagesQMS-17-SF Inspection and Test Plan TemplatearavinNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- FMCODocument66 pagesFMCOhot_blaster100% (1)

- 800 Series SCBA ManualDocument50 pages800 Series SCBA ManualmecambNo ratings yet

- Ravens APM Item Banked FAQsDocument5 pagesRavens APM Item Banked FAQsCH KarimNo ratings yet

- Service Standards For Elevators PDFDocument42 pagesService Standards For Elevators PDFx79133000100% (1)

- Vendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument3 pagesVendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Skid Sample ITPDocument2 pagesSkid Sample ITPSuraj ShettyNo ratings yet

- Inspection and Test PlanDocument1 pageInspection and Test PlanMohsin MohdNo ratings yet

- ITP SampleDocument4 pagesITP SampleKarthik S100% (1)

- FiringDocument3 pagesFiringISFI RAMADHANNo ratings yet

- Form SurveyDocument1 pageForm SurveyBagus KrisnawanNo ratings yet

- الأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفDocument1 pageالأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفanon_545606833No ratings yet

- Metallic Tanks - Sample ITPDocument2 pagesMetallic Tanks - Sample ITPSuraj ShettyNo ratings yet

- ITPDocument2 pagesITPKarthikeyan Shanmugavel100% (1)

- 9 ITP GypsumboardDocument1 page9 ITP Gypsumboardahmsami91No ratings yet

- Quality Example 1 - ITP or QCP - Footer ApprovalDocument2 pagesQuality Example 1 - ITP or QCP - Footer ApprovalBea MokNo ratings yet

- Company Logo Project Name / No.: Inspection & Test PlanDocument3 pagesCompany Logo Project Name / No.: Inspection & Test PlanAmr HamedNo ratings yet

- Itp Concrete WorksDocument1 pageItp Concrete WorksengmalaahendyNo ratings yet

- 3.itp-Installation of Water Supply Pipes & FittingsDocument2 pages3.itp-Installation of Water Supply Pipes & Fittingssarmad spectrumNo ratings yet

- Tightening BoltDocument10 pagesTightening Boltdoan gunawan100% (1)

- MS-ARCH-077 Steel Structure IPE and HEA ProfilesDocument5 pagesMS-ARCH-077 Steel Structure IPE and HEA ProfilesAlaa Al-habashNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- 3.ITP-Above Ground Draiange PipeDocument3 pages3.ITP-Above Ground Draiange Pipesarmad spectrumNo ratings yet

- Indus Towers LTD: Switching Panel (SP) Acceptance Check SheetDocument3 pagesIndus Towers LTD: Switching Panel (SP) Acceptance Check Sheetlaxman pscNo ratings yet

- EEMC-PQP-PF-09-Daily Work Monitoring SheetDocument1 pageEEMC-PQP-PF-09-Daily Work Monitoring SheetAzeem SheikhNo ratings yet

- ITP - Beams-R1Document1 pageITP - Beams-R1Anonymous zsBCtskzNo ratings yet

- Structural Steel Fabrication and Inspection ReportsDocument1 pageStructural Steel Fabrication and Inspection ReportsManoj PrabakaranNo ratings yet

- P07-F06a Inspection and Test Plan (ITP) TemplateDocument4 pagesP07-F06a Inspection and Test Plan (ITP) TemplateVinodh PalanichamyNo ratings yet

- Check List PHO Print 1Document1 pageCheck List PHO Print 1darkwalkerio90No ratings yet

- Check Sheet Blasting Inspeksi: Tanggal: No. DokumenDocument4 pagesCheck Sheet Blasting Inspeksi: Tanggal: No. DokumenQuality PatriaNo ratings yet

- Product RangeDocument1 pageProduct RangeRaju MistryNo ratings yet

- Fit-Up and Daily Welding Visual Inspection ReportDocument1 pageFit-Up and Daily Welding Visual Inspection ReportAws AbduljaleelNo ratings yet

- Maintenance / Fabrication Process Traceability Card: # Task description ةيلمعلا فيصوتDocument1 pageMaintenance / Fabrication Process Traceability Card: # Task description ةيلمعلا فيصوتmohamed hamedNo ratings yet

- BGR Tech Limited: Checklist - Equipment GadDocument2 pagesBGR Tech Limited: Checklist - Equipment GadThamotharanNo ratings yet

- Anpqp - Gauge Specification and Approval SheetDocument6 pagesAnpqp - Gauge Specification and Approval SheetSerchecko JaureguiNo ratings yet

- Itp - SorinoxDocument2 pagesItp - SorinoxsalahjallaliNo ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- Annexure-A Certificate Krishna Bhagya Jala Nigam Limited, Regd - Office, BangaloreDocument4 pagesAnnexure-A Certificate Krishna Bhagya Jala Nigam Limited, Regd - Office, BangaloreMahantesh PujeriNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemDocument3 pagesEtihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemSagar AliasjackeyNo ratings yet

- NDT ReportDocument4 pagesNDT ReportTHI SEN NGUYENNo ratings yet

- ALF-PRJ-EC-QC-CHK-0001 Installation of Gypsum Wall Boards System - Pre Installation Inspection - Checklist Alfanar PQMISDocument1 pageALF-PRJ-EC-QC-CHK-0001 Installation of Gypsum Wall Boards System - Pre Installation Inspection - Checklist Alfanar PQMISWaqar Ahmad MalikNo ratings yet

- Report F - U & Weld 1Document1 pageReport F - U & Weld 1ISFI RAMADHANNo ratings yet

- RFI Fit-UpDocument2 pagesRFI Fit-UpRadj SoLoNo ratings yet

- PMF-007-SCO-008 v1 Snag Form TemplateDocument1 pagePMF-007-SCO-008 v1 Snag Form TemplateAbdelrhman SaidNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportmujahed_muhammedNo ratings yet

- Material Submittal Form: Attachments (Shall Be in A Folder Splited With Separators) : A B C D E F G H I J K LDocument1 pageMaterial Submittal Form: Attachments (Shall Be in A Folder Splited With Separators) : A B C D E F G H I J K LEduardus PandikNo ratings yet

- Material Submittal Form: Attachments (Shall Be in A Folder Splited With Separators) : A B C D E F G H I J K LDocument1 pageMaterial Submittal Form: Attachments (Shall Be in A Folder Splited With Separators) : A B C D E F G H I J K LMohamedNo ratings yet

- PM210011-NUI900-EC1-00008 - R01 - LV Cable Sizing Calculation - (900-B903) - CommDocument37 pagesPM210011-NUI900-EC1-00008 - R01 - LV Cable Sizing Calculation - (900-B903) - CommPartha SundarNo ratings yet

- ITP For Structured Cabling System & Accessories InstallationDocument1 pageITP For Structured Cabling System & Accessories InstallationInfas YahyaNo ratings yet

- Welding Report For PipingDocument1 pageWelding Report For PipingRifki HasyaNo ratings yet

- Daily Welding Report: Quality Control FormDocument1 pageDaily Welding Report: Quality Control FormashwinNo ratings yet

- Qualified Welder ListDocument1 pageQualified Welder ListErwin Timbayo SuleNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Block WorksDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Block WorksSagar AliasjackeyNo ratings yet

- Inspection Test Plan (Itp) at Site: Disciplin RevDocument5 pagesInspection Test Plan (Itp) at Site: Disciplin RevEnryan Oreski RiyadiNo ratings yet

- Paintng ReportDocument1 pagePaintng Reportibrahim hegazyNo ratings yet

- Field Inspection Request (FIR) : Project Project No. 1702 Employer Package No. 02Document4 pagesField Inspection Request (FIR) : Project Project No. 1702 Employer Package No. 02Malek MahmoudNo ratings yet

- AVR1 - IR FOR BLINDING Plot 09Document1 pageAVR1 - IR FOR BLINDING Plot 09Suranga M.GNo ratings yet

- Inspection and Test Plan: Form No.: Revision No.: ITP Scope Description: Page No.: DateDocument2 pagesInspection and Test Plan: Form No.: Revision No.: ITP Scope Description: Page No.: DatetayyabNo ratings yet

- F-01 DWG-001 Design & Development Planning Rev-00Document5 pagesF-01 DWG-001 Design & Development Planning Rev-00Darshit VyasNo ratings yet

- ChecklistDocument1 pageChecklistKarthi KeyanNo ratings yet

- Design of Steel-Concrete Composite Buildings Using Eurocode 4Document2 pagesDesign of Steel-Concrete Composite Buildings Using Eurocode 4nuwan01No ratings yet

- Af302 Major Assignment Sem 1 2016Document3 pagesAf302 Major Assignment Sem 1 2016StingrayNo ratings yet

- 6ES72315PD300XB0 Datasheet enDocument4 pages6ES72315PD300XB0 Datasheet enAhmed SamirNo ratings yet

- Ai 420 MMSDocument37 pagesAi 420 MMSAdhitya Surya PambudiNo ratings yet

- EURAMET-Cg-20 Calibration of Climatic ChambersDocument11 pagesEURAMET-Cg-20 Calibration of Climatic ChambersBtdbtdNo ratings yet

- QS Evinrude JohnsonDocument4 pagesQS Evinrude JohnsonmohamedalibctNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingalberto rodriguezNo ratings yet

- New SEM Socio Economic Segmentation Tool ExplainedDocument3 pagesNew SEM Socio Economic Segmentation Tool ExplainedanzaniNo ratings yet

- VOLVO EC460C L EC460CL EXCAVATOR Service Repair Manual PDFDocument21 pagesVOLVO EC460C L EC460CL EXCAVATOR Service Repair Manual PDFjkdmsmemmd33% (3)

- LG BP335W PDFDocument85 pagesLG BP335W PDFboroda2410100% (1)

- MSCB-131 Acreditacion SisDocument5 pagesMSCB-131 Acreditacion SisMiguel Esteban Rojas ArevaloNo ratings yet

- Iec 62552 2 2015 Amd1 2020Document12 pagesIec 62552 2 2015 Amd1 2020ASSISFERREIRANo ratings yet

- Gradsko Osvetljenje TownGuideDocument24 pagesGradsko Osvetljenje TownGuidePustinjak SaharicNo ratings yet

- Connection Conditions For Generators of Electricity From Solar EnergyDocument12 pagesConnection Conditions For Generators of Electricity From Solar EnergyjayapalNo ratings yet

- Xirrus XD SeriesDocument662 pagesXirrus XD Serieser0zNo ratings yet

- Beyond Transparency: Unlocking The Full Potential of Green BondsDocument4 pagesBeyond Transparency: Unlocking The Full Potential of Green BondsNABIL BEN HADDOUNo ratings yet

- Anexo 05 - Process Planning and Audit v2 1Document33 pagesAnexo 05 - Process Planning and Audit v2 1QMS : Aswin Cold ForgeNo ratings yet

- Comprehensive Fire Stop TutorialDocument98 pagesComprehensive Fire Stop TutorialErica Lindsey100% (2)

- Cqi 11v2 Special Process Plating System Assessment PDFDocument15 pagesCqi 11v2 Special Process Plating System Assessment PDFaadmaadmNo ratings yet

- Internet Protocol (Ipv4) : Tcp/Ip Protocol SuiteDocument55 pagesInternet Protocol (Ipv4) : Tcp/Ip Protocol SuiteMuhammad ImranNo ratings yet

- 2010 Telecommunications Events Calendar: January 2010Document9 pages2010 Telecommunications Events Calendar: January 2010mr_karabassNo ratings yet

- LRFD Bridge Design ManualDocument936 pagesLRFD Bridge Design ManualPeter Jean-jacquesNo ratings yet

- Cosmoplast Upvc Drainage Pipes FittingsDocument34 pagesCosmoplast Upvc Drainage Pipes FittingsBahar AbdulqadirNo ratings yet

- Electrical Specifications, Division 16, SECTION 16425 SWITCHGEAR ASSEMBLIES MAIN DISTRIBUTION BOARDDocument21 pagesElectrical Specifications, Division 16, SECTION 16425 SWITCHGEAR ASSEMBLIES MAIN DISTRIBUTION BOARDeng_asayedNo ratings yet

- Girth Gear Failures - LinkedInDocument7 pagesGirth Gear Failures - LinkedInred patriotNo ratings yet