Professional Documents

Culture Documents

BW Clip Manual

BW Clip Manual

Uploaded by

Amin AminCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BW Clip Manual

BW Clip Manual

Uploaded by

Amin AminCopyright:

Available Formats

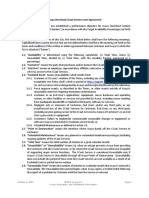

BW Clip

2 OR 3 YEAR H2S, CO, O2, SO2 SINGLE-GAS DETECTOR

Part Number 50115903-067 | OM-EN-PALO-A8 | BW Clip Operator Manual

BW Clip is a portable, single-gas detector manufactured by

BW Technologies by Honeywell (BW). BW Clip continuously measures the

Getting Started

LED

concentration of a specific gas in the ambient environment, and activates an alarm visual alarms Infrared port

when concentrations exceed alarm setpoints. It is your responsibility to respond

appropriately to the alarms.

BW Clip is a member of the GasAlert family of products. It is compatible with

IntelliDoX and MicroDock II automatic test and calibration stations, as well as Fleet Alligator

Manager II software version 4.0 or higher. For more information, visit the product LCD clip

website at www.honeywellanalytics.com

Safety Information: Read First Audible

alarm Pushbutton

a WARNING

1. Substitution of components may impair Intrinsic Safety. Sensor and

sensor grill

2. Periodically test the response of the sensor by exposing the detector to a

target gas concentration that exceeds the low alarm setpoint. Manually verify

that the audible and visual alarms are activated.

3. Detectors in hibernation mode are not functional.

a CAUTION

1. Activate the detector before the activation date on the package.

2. This product is a gas detector, not a measurement device. Bubble label Product label

3. Ensure that the sensor grill is free of dirt, debris, and is not obstructed. with product name

and gas type

4. Clean the exterior with a soft, damp cloth.

5. Bump test the detector in a normal atmosphere that is free of hazardous gas. LCD and Symbols

6. For optimal performance, periodically zero the sensor in a normal atmosphere

(20.9% v/v O2) that is free of hazardous gas.

Informations de sécurité – À lire au préalable

AVERTISSEMENT

1. Le remplacement d’un composant de l’appareil peut compromettre la sécurité

intrinsèque du détecteur.

Testez périodiquement la réponse du capteur en exposant le détecteur à une Pushbutton prompt. When this symbol is displayed, press

concentration de gaz supérieure au seuil d’alarme basse. Vérifiez manuellement and hold the pushbutton until the symbol disappears.

que les alarmes sonores et visuelles sont activées.

3. Détecteurs en mode veille prolongée ne sont pas fonctionnels. BW Clip O2 models only. Oxygen concentration is

measured as percent by volume.

MISE EN GARDE

1. Activez le détecteur avant la date d’activation sur l’emballage. BW Clip H2S, CO and SO2 models only. Toxic gas

2. Ce produit est un détecteur de gaz, pas un dispositif de mesure. concentration is measured in parts per million.

3. Veillez à assurer que la grille du capteur est exempt de saleté, les Low alarm and high alarm. These symbols are

débris, et ne soit pas obstrué. displayed when a gas concentration that exceeds alarm

4. Nettoyez l’extérieur de l’appareil à l’aide d’un chiffon doux et humide. setpoints is detected.

5. Veillez à effectuer un test fonctionnel du capteur dans une atmosphère normale

qui est exempte de gaz dangereux Non-compliance warning. This symbol is displayed when a

diagnostic or compliance test fails; when the operating life

6. Pour des performances optimales, zéro périodiquement le capteur dans une

countdown reaches 24 hours or less; and for up to 30 days

atmosphère normale (20,9% v/v O2) qui est exempte de gaz dangereux.

after operating life expiry. It is also displayed when certain

notifications are enabled through Fleet Manager II via an

IntelliDoX station.

Real-time clock. This symbol is displayed when real-time

clock is enabled through Fleet Manager II via an IntelliDoX

station.

End of operating life warning. This symbol is displayed when

the operating life countdown reaches 24 hours or less.

Peak reading. This symbol is displayed when a maximum gas

exposure event has occurred within the past 24 hours.

Bump test reminder. If the detector is configured to display a

bump test reminder, this symbol is displayed when a bump

test is due. indicates a failed test.

BW Clip O2 models only. This symbol is displayed when more

than 24 hours have elapsed since the last successful zero

procedure was performed. indicates a failed test.

Operating life remaining in months (MM) or days (DD).

BW Clip Factory Calibration Certificate

This instrument was factory inspected, tested and calibrated in accordance with the conditions and

requirements of our registered Quality System, Operating Standards and Sales Agreements.

BW Clip

2 OR 3 YEAR H2S, CO, O2, SO2 SINGLE-GAS DETECTOR

Activate a New Detector Alarms and Warnings

1. Move to a normal atmosphere (20.9% v/v O2) that is free of hazardous An alarm is initiated when the sensor is exposed to a gas concentration

gas. that exceeds alarm setpoints. The alarm persists until the alarm

2. Press and hold the pushbutton until a 5 second countdown is displayed, gas concentration returns to an acceptable range. You can use

and then continue to hold until the countdown is complete. Fleet Manager II via an IntelliDoX station to enable the display of the gas

3. When the countdown is complete, the LCD and LEDs turn on and then concentration reading during an alarm. Battery life decreases rapidly when

turn off. The detector performs an internal diagnostic test. the detector is in alarm condition.

4. When the diagnostic test is successful, the alarm setpoints are Low Alarm

displayed and the LEDs flash.

Audible: 1 beep per second

5. The sensor stabilization countdown is displayed. During the countdown,

the detector vibrates continuously for 20 seconds. The time required Visual: 1 flash per second

to stabilize varies depending on sensor type. When the countdown Vibration: 1 vibration per second

reaches 0, the LEDs flash and the audible alarm beeps.

6. When the type of gas detected and the operating life countdown are High Alarm

displayed, the detector is in normal operating mode. Audible: 2 beeps per second

Normal Operating Mode Visual: 2 flashes per second

When the detector is in normal operating mode, the type Vibration: 2 vibrations per second

of gas detected is permanently displayed. The remaining

operating life is displayed until it is disrupted by a Over-Limit and Under-Limit Alarms

pushbutton action, gas alarm, or error event.

If the gas concentration is beyond the sensor range, OL

Operating Life (over-limit) or -OL (under-limit) is displayed.

When the detector is activated for the first time, the Audible: 2 beeps per second

operating life countdown is displayed. The countdown Visual: 2 flashes per second

displays remaining operating life in months until the

countdown reaches 90 days or less before expiry. Vibration: 2 vibrations per second

90 Days or Less Remaining

When the operating life countdown reaches 90 days or Automatic Zero Reminder for O2 Models

less before expiry, the countdown display changes to

For O2 models only, the Automatic Zero Reminder is

days. The countdown displays the remaining operating

displayed when more than 24 hours have elapsed since

life in days until the countdown reaches 24 hours or less

the last successful zero procedure was performed.

before expiry.

24 Hours or Less Remaining

Peak Readings

When the operating life countdown reaches 24 hours or

less before expiry, the countdown display changes to The peak readings symbol is displayed when the sensor

hours, and the EXPIRY! warning and non-compliance is exposed to a gas concentration that exceeds the alarm

symbol are displayed. setpoints. It is no longer displayed when more than

24 hours have passed since the last alarm, or when a

End of Operating Life

successful bump test is performed via an IntelliDoX or MicroDock II station.

When the operating life countdown ends, the detector

deactivates and detector safety functions are disabled. It Non-compliance Symbol and LED Indicators

is possible to retrieve event logs for a limited time after The non-compliance warning symbol is displayed when:

expiry. The EXPIRY! warning and non-compliance symbol

• an internal diagnostic test fails;

are displayed for up to 30 days after expiry.

• a bump test or zero procedure fails;

Internal Diagnostic Tests • a bump test is due, if enabled;

• the sensor is exposed to a gas concentration that exceeds alarm

Activated detectors automatically perform one internal diagnostic test every

setpoints, if enabled.

24 hours. If the internal diagnostic test fails, the diagnostic fail-safe begins.

The non-compliance warning symbol is no longer displayed when more

Diagnostic Fail-Safe

than 24 hours have passed since the last alarm, or when a successful

1. The EXPIRY! warning and non-compliance symbol are displayed.

bump test is performed via an IntelliDoX or MicroDock II station. The non-

2. The detector beeps and vibrates.

compliance warning symbol is permanently displayed when the service-life

3. The LEDs flash 2 times per second for 15 seconds.

countdown reaches 24 hours or less before expiry, and for up to 30 days

4. OFF or an error code is displayed. The detector is deactivated.

after expiry.

It is possible to retrieve the event logs for a limited time after expiry. If you

are unable to retrieve the event logs, contact BW. When Non-compliance after gas exposure is enabled through

Fleet Manager II via an IntelliDoX station, the LEDs flash in an alternating

pattern when the non-compliance warning symbol is displayed. When the

symbol is first displayed, the top LEDs flash. After 30 seconds, the side

LEDs flash. After 30 seconds, the pattern repeats until the non-compliance

warning symbol is no longer displayed.

NOTE: When the detector is bump tested via a MicroDock II station, an

abnormal test result may occur if non-compliance LEDs are flashing.

To suspend the flashing for up to 10 minutes, press and release the

pushbutton. When the flashing stops, insert the detector and perform the

test. If the bump test fails, the LEDs resume flashing.

Recall Events and Settings Optional Settings

When the detector is in normal operating mode, press the pushbutton Use Fleet Manager II via an IntelliDoX station to enable the following

at any time to scroll through events and settings that are not empty or optional settings for BW Clip detectors.

disabled through Fleet Manager II via an IntelliDoX station. Events and Display Gas Reading During Alarm

settings are displayed in this order: When Display gas reading during alarm is enabled, the

1. Peak Reading, if available, and when a maximum gas exposure event gas concentration is displayed when a gas alarm event is

has occurred within the past 24 hours. detected. The gas concentration is displayed until the

2. Time of Peak Reading, if Real-time Clock display is enabled. alarm event ends.

3. Low Alarm Setpoint

4. High Alarm Setpoint Non-compliance After Gas Exposure

5. Real-time Clock, if enabled. When Non-compliance after gas exposure is enabled, the LEDs flash in

6. Firmware Version an alternating pattern when the sensor is exposed to a gas concentration

7. Next Bump Due, if enabled. that exceeds alarm setpoints. When the gas exposure is detected, the

8. Hibernation, for 2-year H2S and CO hibernation models only. top LEDs flash. After 30 seconds, the side LEDs flash. After 30 seconds,

the pattern repeats until more than 24 hours have passed since the last

While an event or setting is displayed, press the pushbutton to scroll to the

alarm, or when a successful bump test is performed via an IntelliDoX or

next available event or setting. If you do not press the pushbutton, or if you

MicroDock II station.

have reached the last available event or setting, the detector returns to

normal operation. Real-time Clock Display

When Real-time Clock Display is enabled, you can

Zero the Sensor display the current time by pressing the pushbutton to

Over time and through use, the sensor baseline at zero exposure may drift Recall Events and Settings, and then continuing to

from the manufacturer’s baseline. For optimal performance of O2 models, press the pushbutton until the time is displayed.

BW recommends that you zero the O2 sensor once every 24 hours or Time may be displayed in 12-hour or 24-hour

when the Automatic Zero Reminder is displayed. For all other models, clock format.

BW recommends that you zero the sensor periodically.

Zero Procedure

1. Move to a normal atmosphere (20.9% v/v O2) that is Hibernation

free of hazardous gas. Hibernation is a factory installed feature that is available for 24-month

2. Press and hold the pushbutton until a 5 second H2S and CO detectors. When Hibernation is activated, the operating life

countdown is displayed, and then continue to hold countdown is suspended. Use Hibernation to deactivate the detector for

until the countdown is complete. 7 days or longer, up to a maximum of 12 months. When Hibernation is

3. When the countdown is complete, the Zero procedure activated, all detector safety functions are disabled.

begins and ZErO is displayed.

Activate Hibernation via BW Clip Hibernation Case

4. When Zero is successful, PASS is displayed, and then

the detector returns to normal operation. 1. Have ready a BW Clip Hibernation Case. To purchase

5. If Zero is not successful, the non-compliance LED a Case, contact BW or an authorized distributor.

flashes. FAIL and the non-compliance warning symbol 2. Move to a normal atmosphere (20.9% v/v O2) that is

are displayed. Press the pushbutton to acknowledge free of hazardous gas.

the result and return to normal operation. The non- 3. Verify that the detector is in normal operating mode.

compliance warning symbol is displayed and the non- 4. Press the pushbutton to Recall Events and Settings,

compliance LED flashes. Perform the Zero procedure and then continue to press the pushbutton until Hib

again. If the procedure fails again, contact BW. is displayed.

5. While Hib is displayed, press the pushbutton until a 5 second

Bump Tests countdown is displayed. When the countdown is complete, the

When the detector is configured to display a bump test reminder, the bump 20-second Hibernation counter is displayed.

test symbol is displayed when a bump test is due. For best results, bump 6. While the Hibernation counter is displayed, place the detector into a

test the detector via an IntelliDoX or MicroDock II station. Bump tests BW Clip Hibernation Case and then close the case firmly. The detector

performed via an IntelliDoX or MicroDock II station are logged as bump enters Hibernation mode. All detector safety functions are disabled.

tests. Manual bump tests are logged as unsafe gas concentrations. 7. To reactivate the detector, open the case.

Event Logs Activate Hibernation through Fleet Manager II

via IntelliDoX

The detector stores the last 35 events that occurred, including peak 1. Use Fleet Manager II to activate Hibernation on Insertion via an

readings, bump tests and auto zeros. Each record contains: IntelliDoX station, and then insert the detector in the configured

• detector serial number, sensor type and life-remaining; station. The detector event logs are retrieved, and the detector enters

• total number of events that have occurred; Hibernation mode. All safety functions are disabled, and the detector

• event type and duration; may be removed from the IntelliDoX station.

• alarm level(s) in ppm or %; 2. To reactivate the detector, press and hold the pushbutton until a

• time elapsed since the alarm occurred in days/hours/minutes; 5 second countdown is displayed, and then continue to hold until the

• duration of the alarm (minutes/seconds). LCD and LEDs turn on and off. The detector performs a self-diagnostic

Use Fleet Manager II via an IntelliDoX or MicroDock II station to transfer test. When the test is successful, the type of gas detected and the

event logs from the detector to a computer. When logs are transferred via remaining operating life are displayed. The detector is in normal

an IntelliDoX station, the most recent 35 events are transferred. When logs operating mode.

are transferred via a MicroDock II station, the most recent 10 events are 3. For more information, refer to the operator manuals for the IntelliDoX

transferred. station and Fleet Manager II software version 4.0 or higher.

BW Clip

2 OR 3 YEAR H2S, CO, O2, SO2 SINGLE-GAS DETECTOR

About this Publication Use Fleet Manager II via an IntelliDoX Internal Vibrating • any damage or defects attributable to

This publication is an operator guide for station to adjust alarm setpoints. For 5% to 95% relative humidity (non- repair of the product by any person

BW Clip portable single-gas detectors more information, refer to the operator condensing) other than an authorized dealer, or the

manuals for Fleet Manager II software installation of unapproved parts on the

manufactured by BW Technologies by Audible Alarm

version 4.0 and the IntelliDoX automatic product.

Honeywell. It is intended for use with the ≈ 95 dB at 10 cm (3.9 in)

test and calibration station.

following models: Visual Alarm The obligations set forth in this warranty are

• 24- and 36-month H2S and CO Detectors conditional on:

Ratings and Certifications Flashing, wide-angled alarm lens with red

• 24-month O2 detector LEDs plus alarm LCD readout 1) proper storage, installation, calibration,

The BW Clip is in conformity with the

• 24-month SO2 detector use, maintenance and compliance with

following standards: Display

the product manual instructions and any

Copyright, Notice, Trademarks UL 913 8th Edition Liquid crystal display (LCD)

other applicable recommendations of BW;

While this information is presented in UL 60079-0:2013, Sensor Type 2) the buyer promptly notifying BW of any

good faith and believed to be accurate, UL 60079-11:2013 Electrochemical cells defect and, if required, promptly making

BW Technologies by Honeywell (BW) CSA C22.2 No. 157-92:2012, Battery the product available for correction.

disclaims the implied warranties of CSA C22.2 No. 60079-0:2011, No goods shall be returned to BW

Lithium, non-replaceable

merchantability and fitness for a particular CSA C22.2 No. 60079-11:2014 until receipt by the buyer of shipping

purpose and makes no express warranties Ingress Protection

EN 60079-0:2012 +A11:2013, instructions from BW; and

except as may be stated in its written IP 66/67

EN 60079-11:2012 3) the right of BW to require that the buyer

agreement with and for its customers. Alarm Setpoints provide proof of purchase such as the

In no event is BW liable to anyone for any Instant low and instant high original invoice, bill of sale or packing slip

IEC 60079-0:2011

indirect, special or consequential damages. Calibration to establish that the product is within the

IEC 60079-11:2011

The content in this document is subject to H2S not required warranty period.

change. CO not required THE BUYER AGREES THAT THIS

ABNT NBR IEC 60079-0:2008

SO2 not required WARRANTY IS THE BUYER’S SOLE AND

ABNT NBR IEC 60079-11:2009

Contact Us O2 Perform the Zero procedure

EXCLUSIVE REMEDY AND IS IN LIEU OF

Corporate Headquarters ALL OTHER WARRANTIES, EXPRESS

once every 24 hours or when the

UL OR IMPLIED, INCLUDING BUT NOT

BW Technologies by Honeywell Automatic Zero Reminder is

Suite 110 4411-6 Street SE Classified by UL to both US and LIMITED TO ANY IMPLIED WARRANTY OF

displayed.

Calgary, Alberta Canadian Standards as intrinsically safe MERCHANTABILITY OR FITNESS FOR A

for Class I, Division 1, Group A, B, C, D Intended Use PARTICULAR PURPOSE. BW SHALL NOT

Canada, T2G 4E8

and Class I, Zone 0, Group IIC. This product is classified for use in BE LIABLE FOR ANY SPECIAL, INDIRECT,

Toll-free: 1-800-663-4164

hazardous atmospheres that are not INCIDENTAL OR CONSEQUENTIAL

Americas ATEX

more than 21% v/v O2 DAMAGES OR LOSSES, INCLUDING LOSS

BW Technologies by Honeywell CE 0539 II 1G

OF DATA, WHETHER ARISING FROM

405 Barclay Blvd. Ex ia IIC T4 Ga IP66/67 Recycling BREACH OF WARRANTY OR BASED ON

Lincolnshire IL USA 60069 DEMKO 14 ATEX 1356 This instrument contains a lithium battery. Do CONTRACT, TORT OR RELIANCE OR ANY

Toll-free:1-888-749-8878 CE not mix with the solid waste stream. Spent OTHER THEORY.

Europe European Conformity batteries should be disposed of by a qualified

Since some countries or states do not allow

BW Technologies by Honeywell EU Declaration of Conformity recycler or hazardous materials handler.

limitation of the term of an implied warranty,

Hatch Pond House www.honeywellanalytics.com or exclusion or limitation of incidental or

4 Stinsford Road IECEx consequential damages, the limitations and

Nuffield Industrial Estate Products may contain materials that are exclusions of this warranty may not apply to

Ex ia IIC T4 Ga IP66/67

Poole Dorset BH17 0RZ United Kingdom regulated for transportation under domestic every buyer. If any provision of this warranty

IECEx UL 14.0063 and international dangerous goods

Toll-free: +44(0)1295 700300 is held invalid or unenforceable by a court of

INMETRO regulations. Return product in compliance competent jurisdiction, such holding will not

Other Ex ia IIC T4 Ga with appropriate dangerous goods affect the validity or enforceability of any other

BW Technologies by Honeywell DNV 15.0024

regulations. Contact freight carrier for further provisions.

Toll-free: 1-403-248-9226 KTL instructions.

info@gasmonitors.com 15-KA4BO-03061

www.honeywellanalytics.com Limited Warranty and

Warranty Registration Limitation of Liability

www.honeywellanalytics.com/support/ BW Technologies (BW) warrants this

product-registration product to be free from defects in material

Specifications and workmanship under normal use and

Maximum Operating Life Shelf Life service for a period of two or three years

H2S One (1) year before activation (depending upon detector), beginning on the

24-month Detector

date of activation. 24-month H2S and CO

2 years after activation, assuming CO One (1) year before activation

detectors are covered for up to an additional

2 minutes of alarm time per day. O2 Six (6) months before activation

12 months when hibernation is used, limited

Note: 24-month H2S and CO detectors SO2 One (1) year before activation by a total of 24 months of detector operation.

that use hibernation may extend the Instrument Weight This Warranty is valid only if the detector is

service period of the detector up to an alligator clip included activated by the date on the package. This

additional year. The service life will end 92 grams (3.2 ounces) warranty extends only to the sale of new and

once the detector reaches 24 months of unused products to the original buyer.

Instrument Dimensions

actual operation. Hibernation provides a

alligator clip included BW’s warranty obligation is limited, at BW’s

maximum service life of 36 months.

41 x 50 x 87 millimeters option, to refund of the purchase price, repair,

36-month Detector or replacement of a defective product that is

(1.6 x 2.0 x 3.4 inches)

3 years after activation, assuming returned to a BW authorized service center

Operating Temperatures

1 minute of alarm time per day. within the warranty period. In no event shall

H2S -40° to +50°C (-40° to +122°F)

Detection Range BW’s liability hereunder exceed the purchase

CO -30° to +50°C (-22° to +122°F)

H2S 0 to 100 ppm price actually paid by the buyer for the

O2 -20° to +50°C (-4° to +122°F) Product.

CO 0 to 300 ppm

SO2 -30° to +50°C (-22° to +122°F)

O2 0 to 25% by volume This warranty does not include:

Internal Vibrating

SO2 0 to 100 ppm • fuses, disposable batteries or the routine

Operates to -10°C (+14°F) replacement of parts due to the normal

Factory Alarm Setpoints Intrinsic Safety Temperature Range wear and tear of the product arising from

Low Alarm High Alarm -40 °C to +50 °C (-40 °F to +122 °F) use;

H 2S 10 ppm 15 ppm • any product which in BW’s opinion,

CO 35 ppm 200 ppm has been misused, altered, neglected

or damaged by accident or abnormal

O2 19.5% vol 23.5% vol 1 http://www.honeywellanalytics.com/ conditions of operation, handling or use; or

SO2 5 ppm 10 ppm ~/media/honeywell-analytics/products/bw-clip/

docu-ments/certi icates/korea-certi ication_bw-

clip-15ka-4bo0306

You might also like

- Battery Calculation & Gas Release PDFDocument26 pagesBattery Calculation & Gas Release PDFSanthosh MechNo ratings yet

- H&S Induction Training PresentationDocument10 pagesH&S Induction Training PresentationSanthosh MechNo ratings yet

- Aerosol System Functional Test QCDD FormDocument3 pagesAerosol System Functional Test QCDD FormMahmoud HassanNo ratings yet

- IEC 61892-6 Mobile and Fixed Offshore Units - Electrical InstallationsDocument2 pagesIEC 61892-6 Mobile and Fixed Offshore Units - Electrical InstallationsSanthosh Mech0% (1)

- Microcontroller-Based Temperature Monitoring and ControlFrom EverandMicrocontroller-Based Temperature Monitoring and ControlRating: 3.5 out of 5 stars3.5/5 (2)

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Industrial Safety Supply, Inc.: Francisco A. LopezDocument29 pagesIndustrial Safety Supply, Inc.: Francisco A. Lopezart031125100% (1)

- Clean Agent Fire Suppression System Test QCDD FormDocument3 pagesClean Agent Fire Suppression System Test QCDD FormMahmoud HassanNo ratings yet

- SCIO Identification and AuthenticationDocument9 pagesSCIO Identification and AuthenticationaalmotaaNo ratings yet

- The PIC Microcontroller: Your Personal Introductory CourseFrom EverandThe PIC Microcontroller: Your Personal Introductory CourseRating: 1 out of 5 stars1/5 (2)

- ChangeManagementAtNokia PDFDocument33 pagesChangeManagementAtNokia PDFShreya BajajNo ratings yet

- Complete Contact Book SynopsisDocument25 pagesComplete Contact Book Synopsisvdreams13No ratings yet

- Brute Force AttacksDocument9 pagesBrute Force AttacksAKSHITNo ratings yet

- Smart Sensor 4 Gases AS8900 - Manual de OperaçãoDocument12 pagesSmart Sensor 4 Gases AS8900 - Manual de OperaçãoRogerioPascualNo ratings yet

- Royal Enfield Bullet Service Manual by P. SnidalDocument4 pagesRoyal Enfield Bullet Service Manual by P. SnidalRafiNo ratings yet

- MGC Simple User Manual v1.00Document20 pagesMGC Simple User Manual v1.00giannis2No ratings yet

- COT 1 BalbinDocument5 pagesCOT 1 BalbinJoan BalbinNo ratings yet

- BW Gas Detector ManualDocument3 pagesBW Gas Detector ManualYume HendraNo ratings yet

- BW Honeywell Micro Clip XLDocument2 pagesBW Honeywell Micro Clip XLpgas pjk3No ratings yet

- Reinna Presentation PDFDocument20 pagesReinna Presentation PDFMIGUEL RAZONNo ratings yet

- XT XWHM y Na Cs DatasheetDocument2 pagesXT XWHM y Na Cs DatasheetHafed HafedNo ratings yet

- Operator's Manual: iERP: 129535 D6558/0 (English) © BW Technologies 2010. All Rights ReservedDocument22 pagesOperator's Manual: iERP: 129535 D6558/0 (English) © BW Technologies 2010. All Rights ReservedLusy Gusti EfendiNo ratings yet

- SGT Manual EngDocument13 pagesSGT Manual EngdouglasncamiloNo ratings yet

- Watchgas PDMDocument14 pagesWatchgas PDMNemz CervantesNo ratings yet

- GasAlertMaxXTII - Datasheet (6570 0 EN) PDFDocument2 pagesGasAlertMaxXTII - Datasheet (6570 0 EN) PDFChinNo ratings yet

- GasAlertMicroClip - QRG (D5867 2 EN)Document19 pagesGasAlertMicroClip - QRG (D5867 2 EN)GMNo ratings yet

- Portable Multi Gas Detector: Operation ManualDocument24 pagesPortable Multi Gas Detector: Operation Manuallion GuveraNo ratings yet

- The Most User-Friendly, Reliable and Cost-Effective Way To Ensure Safety, Compliance and ProductivityDocument2 pagesThe Most User-Friendly, Reliable and Cost-Effective Way To Ensure Safety, Compliance and ProductivityluckyamruNo ratings yet

- Gas Detector Manual (Gaz Ölçer Manueli̇)Document2 pagesGas Detector Manual (Gaz Ölçer Manueli̇)cozdimNo ratings yet

- 01.SP2nd Manual v2.2 EnglishDocument19 pages01.SP2nd Manual v2.2 EnglishSijo JoyNo ratings yet

- SENKO SP2 ManualDocument16 pagesSENKO SP2 ManualGMNo ratings yet

- Biogas Analyzer - Operating ManualDocument16 pagesBiogas Analyzer - Operating Manualforest52girlNo ratings yet

- BW Clip Se: Maintenance-Free Single-Gas DetectorsDocument2 pagesBW Clip Se: Maintenance-Free Single-Gas DetectorsMashur Al JunaibiNo ratings yet

- Honeywell XT Gas DetectorDocument24 pagesHoneywell XT Gas DetectorAvinashNo ratings yet

- BWClip DatasheetDocument3 pagesBWClip Datasheetfrankie6368No ratings yet

- Pac ExDocument8 pagesPac Exs.kurpishNo ratings yet

- CO Monitor 2Document2 pagesCO Monitor 2Naveed Ahmed Get-InfoNo ratings yet

- 7 Transport Incubator (Tende Elektronik Yazilim Muh)Document4 pages7 Transport Incubator (Tende Elektronik Yazilim Muh)Swaroop PozhaylNo ratings yet

- Manual Del GPT100Document4 pagesManual Del GPT100Johannita Chavez GalanNo ratings yet

- BW - GasAlertMax - XT - II Manual de UsoDocument23 pagesBW - GasAlertMax - XT - II Manual de UsojairNo ratings yet

- SENSIT HXG 2d Instruction Manual ULDocument24 pagesSENSIT HXG 2d Instruction Manual ULPrabudeva MNo ratings yet

- M07664 Detective User Manual Iss 7 GB 120618Document48 pagesM07664 Detective User Manual Iss 7 GB 120618Wong Chung MengNo ratings yet

- ClemcoCMS-3 Carbon Monoxide Monitor - Alarm - Clemco Abrasive Blasting EquipmentDocument2 pagesClemcoCMS-3 Carbon Monoxide Monitor - Alarm - Clemco Abrasive Blasting EquipmentNaveed Ahmed Get-InfoNo ratings yet

- ALTAIR 4X Cuatro EquisDocument4 pagesALTAIR 4X Cuatro EquisPedro PérezNo ratings yet

- Upgrade Your Existing Blenders and Always Have A Lookout On Duty!Document2 pagesUpgrade Your Existing Blenders and Always Have A Lookout On Duty!Lily Villalobos MelgarejoNo ratings yet

- SF 50GLP ManualDocument2 pagesSF 50GLP ManualDigitalNo ratings yet

- The Most User-Friendly, Reliable and Cost-Effective Way To Ensure Safety, Compliance and ProductivityDocument2 pagesThe Most User-Friendly, Reliable and Cost-Effective Way To Ensure Safety, Compliance and ProductivityAnonymous h9kxYJf3NNo ratings yet

- Manual de JL269LCDDocument4 pagesManual de JL269LCDJohannita Chavez GalanNo ratings yet

- TSC Bomba SPDocument3 pagesTSC Bomba SPdarwin jumboNo ratings yet

- Operation ManualDocument21 pagesOperation ManualDurell GracenNo ratings yet

- Detector de Co Bx170Document8 pagesDetector de Co Bx170oscarNo ratings yet

- DS PD1 MC WWS (H)Document2 pagesDS PD1 MC WWS (H)Mohamed ArrabNo ratings yet

- I-9102 Intelligent Photoelectric Smoke Detector Issue1.03Document2 pagesI-9102 Intelligent Photoelectric Smoke Detector Issue1.03Seagull MarineNo ratings yet

- Bundguard: Automatic Bund Dewatering SolutionDocument6 pagesBundguard: Automatic Bund Dewatering SolutionGUSTAVO MENDOZANo ratings yet

- Honeywell BW Max XT II Datasheet PDFDocument2 pagesHoneywell BW Max XT II Datasheet PDFFaldi HarisNo ratings yet

- KM260 Inst EngDocument13 pagesKM260 Inst EngFermalux FermaluxNo ratings yet

- Operation Manual: E6000 Portable Multi-Gas DetectorDocument24 pagesOperation Manual: E6000 Portable Multi-Gas Detectorrenzo andradeNo ratings yet

- Rabee IncubatorDocument2 pagesRabee IncubatorJohnny CotzitoNo ratings yet

- Grove - Gas Sensor (O2) : Release Date 9/20/2015Document12 pagesGrove - Gas Sensor (O2) : Release Date 9/20/2015Prasika DroidNo ratings yet

- GD BW Honeywell ManualDocument48 pagesGD BW Honeywell Manualمحمد غزالي شريف الدينNo ratings yet

- Macurco Single-Gas XL Series Monitor, CM-1 Carbon Monoxide (CO), HS-1 Hydrogen Sulfide (H S) User InstructionsDocument22 pagesMacurco Single-Gas XL Series Monitor, CM-1 Carbon Monoxide (CO), HS-1 Hydrogen Sulfide (H S) User InstructionsAlexandreClaudiaRochaNo ratings yet

- Honeywell BW™ MicroClip X3 Multi Gas DetectorDocument2 pagesHoneywell BW™ MicroClip X3 Multi Gas DetectorAbdul KareemNo ratings yet

- HP21 22aDocument4 pagesHP21 22agreggles69No ratings yet

- Ad PVC Iq: User ManualDocument28 pagesAd PVC Iq: User ManualEsteve PermanyerNo ratings yet

- Agilent G3388B Leak Detector: Operation ManualDocument20 pagesAgilent G3388B Leak Detector: Operation Manualrnd labNo ratings yet

- Crowcon Detective+Document48 pagesCrowcon Detective+tranquocvinhtechNo ratings yet

- Datasheet ToxiRAE20Pro20PID DS-1063-07 EMEA-EN LRDocument2 pagesDatasheet ToxiRAE20Pro20PID DS-1063-07 EMEA-EN LRSatish KumarNo ratings yet

- Intelligent Photoelectric Smoke SensorsDocument2 pagesIntelligent Photoelectric Smoke Sensorsmubs73No ratings yet

- H&S Induction Training PresentationDocument11 pagesH&S Induction Training PresentationSanthosh MechNo ratings yet

- Poweredge m640 - Owners Manual - en UsDocument108 pagesPoweredge m640 - Owners Manual - en UsLawrenceNo ratings yet

- Speed Limit Chapter 1Document21 pagesSpeed Limit Chapter 1kalu chimdiNo ratings yet

- MU325 Answer 4Document6 pagesMU325 Answer 4SuhendiNo ratings yet

- HND - BI - W2 - Introduction To BI 2Document16 pagesHND - BI - W2 - Introduction To BI 2rashidumilan100No ratings yet

- Steering Behaviors For Autonomous Characters: Craig W. ReynoldsDocument21 pagesSteering Behaviors For Autonomous Characters: Craig W. ReynoldsCamilo Andres HuertasNo ratings yet

- Bist Tutorial 2 PDFDocument9 pagesBist Tutorial 2 PDFjcfermosellNo ratings yet

- A Compiler Is A Computer ProgramDocument6 pagesA Compiler Is A Computer Programapi-26190816No ratings yet

- Lecture 7Document25 pagesLecture 7Jayaraj JoshiNo ratings yet

- Power Electronics Lab ManualDocument54 pagesPower Electronics Lab ManualYeduresapu SantoshNo ratings yet

- Muhammad Haikal Daniel Bin Jamal - 2020890508Document23 pagesMuhammad Haikal Daniel Bin Jamal - 2020890508Muhd Haikal DanielNo ratings yet

- Dove Soft SMS Pricing Guide 2016Document81 pagesDove Soft SMS Pricing Guide 2016Anna LaClairNo ratings yet

- Feedback and Control Systems ProjectDocument9 pagesFeedback and Control Systems ProjectDino Ligutan100% (2)

- Modules in PythonDocument14 pagesModules in PythonDr.D.Palanikkumar Associate ProfessorNo ratings yet

- Buk98150-55 - 2 MOSFETDocument9 pagesBuk98150-55 - 2 MOSFETOlga PlohotnichenkoNo ratings yet

- Forex Tester 4 QuickStartGuideDocument151 pagesForex Tester 4 QuickStartGuideempelNo ratings yet

- Ovonic Unified MemoryDocument6 pagesOvonic Unified MemoryMonika KhatriNo ratings yet

- Personalized Medicine Is The Future (Final)Document6 pagesPersonalized Medicine Is The Future (Final)SHANE KIRSTEN SALATANDRENo ratings yet

- MurphyDocument18 pagesMurphyRoger Pozo AriasNo ratings yet

- Married Is Your - .: For Both Men and Women Has Improved Greatly in The Past 20 YearsDocument4 pagesMarried Is Your - .: For Both Men and Women Has Improved Greatly in The Past 20 YearsPhuc CaoNo ratings yet

- V1 T4 Metering Products Ca08100002eDocument142 pagesV1 T4 Metering Products Ca08100002eomarlgonzNo ratings yet

- Core JavaDocument28 pagesCore JavaNATIONAL XEROXNo ratings yet

- LS12-50&LS16-60/75LF 50&60HZ: Stationary Screw Compressor Operation & Maintenance ManualDocument67 pagesLS12-50&LS16-60/75LF 50&60HZ: Stationary Screw Compressor Operation & Maintenance ManualAmmar ShabanNo ratings yet

- Avaya OneCloud CCaaS SLA 10 6 21Document3 pagesAvaya OneCloud CCaaS SLA 10 6 21shan76palNo ratings yet

- PCOWeb - User Manual 2.0Document92 pagesPCOWeb - User Manual 2.0davidriveroNo ratings yet

- User Guide For PV Dynamic Model Simulation Written On PSCAD PlatformDocument61 pagesUser Guide For PV Dynamic Model Simulation Written On PSCAD PlatformJairo LimaNo ratings yet