Professional Documents

Culture Documents

07 Control Plan

07 Control Plan

Uploaded by

Manoharar RCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 Control Plan

07 Control Plan

Uploaded by

Manoharar RCopyright:

Available Formats

SUPREME PRESSTECH CONTROL PLAN

Prototype Pre-launch Production Vendor Code

Vendor Name: SUPREME PRESSTECH Control Plan No. SPT/ZFR/CP/- Azadi Bkt-3003 Control Plan Date: 20.01.2024

Customer Name : ZF Rane Automotive India Private Limited

Vendor Contact Person / Phone: Manoharan R / 9698712440 CP Rev. No. : 00 Rev. Date: -

Part Number : 019 3003 00

Part Name / Description : Mounting Bracket Assembly Core Team members: Manopharan R, Rajeh Mistri, Chirag, Jagdeesh, Suresh R, Sunil,

Supplier/Plant Approval / Date:

Manjunath, Jayasheela

Customer Drg. Rev.No. : 6 / 02.07.2019 Approved by

Prepared by Checked by

Other Approval / Date (If required):

Manoharan R Manoharan R Rajesh Mistry

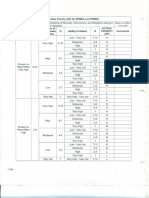

Characteristics Sample

Process Name / Machine, Device, Product/Process Evaluation /

MFG Process Process Special Mistake Reaction Plan &

Operation Jig, Tools , facillities Specification Measurement Control Method Resp. Resp

Flow Diagram No. for manufacturing CP. Char # Proofing Corrective action

Description Product Process /Tolerance Techniques Size Freq.

Sl.No

CR sheet

1 Material Grade QA Engineer

(IS 513-D)

2 Sheet Thickness 1.5±0.10 Digital Micrometer

As per

3 Sheet Length 1250*470 Measuring tape Sampling

Receiving Insp. Plan No. Incoming

1000 EVERY LOT

Of Raw Material 4 Chemical Inspection Report Receiving

Supplier RM Inform to Supplier

As per incoming Testcertificate & Inspector

5 Mechanical ---

report External Lab Test

6 Others Report &

Free from rust, Dent

7 Appearance Manager QA

and damages

Free from rust, Dent

1 APPEARANCE Physical counting

Raw Material and damages

1010 100% EVERY LOT DC --- Stores Incharge Inform to Supplier Stores & PPC

Storage

QTY / Sheet VISUAL COUNTING /

2 QTY AS PER DC

LENGTH WEIGHING M/C

1 Thi kness 1.5±0.10 Vernier 5 No's Shift

2 Slot Length 9.0+0.2 Digital Vernier 5 No's 1 hr

3 Slot Width 7.0+0.2 Digital Vernier 5 No's 1 hr

Quarantine the QA Engineer,QA

Setup Approval &

Blanking & Hole QC / exisiting produced MANAGER &

1020 Press 4 Width 20.±0.5 Digital Vernier 5 No's 2 hr Inprocess -

Piercing INSPECTOR parts and segregate PRODUCTION

inspection report

the parts MANAGER

5 Hole diameter 7.0+0.2 Digital Vernier 5 No's 1 hr

6 Hole diameter 4.50+0.1 Digital Vernier 5 No's 1 hr

Free from rust, Dent

7 Appereance Visual 100%

and damages

SUPREME PRESSTECH CONTROL PLAN

Prototype Pre-launch Production Vendor Code

Vendor Name: SUPREME PRESSTECH Control Plan No. SPT/ZFR/CP/- Azadi Bkt-3003 Control Plan Date: 20.01.2024

Customer Name : ZF Rane Automotive India Private Limited

Vendor Contact Person / Phone: Manoharan R / 9698712440 CP Rev. No. : 00 Rev. Date: -

Part Number : 019 3003 00

Part Name / Description : Mounting Bracket Assembly Core Team members: Manopharan R, Rajeh Mistri, Chirag, Jagdeesh, Suresh R, Sunil,

Supplier/Plant Approval / Date:

Manjunath, Jayasheela

Customer Drg. Rev.No. : 6 / 02.07.2019 Approved by

Prepared by Checked by

Other Approval / Date (If required):

Manoharan R Manoharan R Rajesh Mistry

Characteristics Sample

Process Name / Machine, Device, Product/Process Evaluation /

MFG Process Process Special Mistake Reaction Plan &

Operation Jig, Tools , facillities Specification Measurement Control Method Resp. Resp

Flow Diagram No. for manufacturing CP. Char # Proofing Corrective action

Description Product Process /Tolerance Techniques Size Freq.

Sl.No

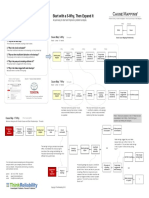

1 Height 0.50±0.1 DHG 5 No's Shift

2 Width 6.0±0.5 VMM 5 No's Shift Quarantine the QA Engineer,QA

Setup Approval &

QC / exisiting produced MANAGER &

1030 Rib Forming Press Inprocess -

INSPECTOR parts and segregate PRODUCTION

3 Thickness 20.0±0.5 Digital Vernier 5 No's Shift inspection report

the parts MANAGER

Free from rust, Dent

4 Appereance Visual 100%

and damages

1 Distance 33.0±1.0 Digital Vernier 5 No's Setting

2 Center Distance 23.0±1.0 VMM 5 No's Setting

3 Distance 8.50+2.50 Digital Vernier /VMM 5 No's Setting

4 Radius 5.0±1.0 VMM 5 No's Setting

1040 Leg Pending Press

5 Distance 7.50+2.50 Digital Vernier /VMM 5 No's Setting

Quarantine the QA Engineer,QA

Setup Approval &

QC / exisiting produced MANAGER &

Inprocess -

INSPECTOR parts and segregate PRODUCTION

6 Distance 9.0±0.5 Digital Vernier / VMM 5 No's Setting inspection report

the parts MANAGER

7 Center distance 14.0±0.5 VMM 5 No's Setting

Free from rust, Dent

8 Appereance Visual 100%

and damages

Quarter (1/4) Free from rust, Dent

1050 1 Appereance Visual 100%

Bending and damages

Free from rust, Dent

1060 Half (1/2) Bending 1 Appereance Visual 100%

and damages

SUPREME PRESSTECH CONTROL PLAN

Prototype Pre-launch Production Vendor Code

Vendor Name: SUPREME PRESSTECH Control Plan No. SPT/ZFR/CP/- Azadi Bkt-3003 Control Plan Date: 20.01.2024

Customer Name : ZF Rane Automotive India Private Limited

Vendor Contact Person / Phone: Manoharan R / 9698712440 CP Rev. No. : 00 Rev. Date: -

Part Number : 019 3003 00

Part Name / Description : Mounting Bracket Assembly Core Team members: Manopharan R, Rajeh Mistri, Chirag, Jagdeesh, Suresh R, Sunil,

Supplier/Plant Approval / Date:

Manjunath, Jayasheela

Customer Drg. Rev.No. : 6 / 02.07.2019 Approved by

Prepared by Checked by

Other Approval / Date (If required):

Manoharan R Manoharan R Rajesh Mistry

Characteristics Sample

Process Name / Machine, Device, Product/Process Evaluation /

MFG Process Process Special Mistake Reaction Plan &

Operation Jig, Tools , facillities Specification Measurement Control Method Resp. Resp

Flow Diagram No. for manufacturing CP. Char # Proofing Corrective action

Description Product Process /Tolerance Techniques Size Freq.

Sl.No

1 Angle 60°±1° VMM 2 No's Setting

2 Distance 26.0±0.5 VMM 2 No's Setting

3 Distance 50.0±1.0 DHG / VMM 2 No's Setting Quarantine the QA Engineer,QA

Setup Approval &

QC / exisiting produced MANAGER &

1070 Round Forming Press Inprocess -

INSPECTOR parts and segregate PRODUCTION

inspection report

4 Radius R15.0±2.0 VMM 2 No's Setting the parts MANAGER

5 Radius R 10.0±2.0 VMM 2 No's Setting

Free from rust, Dent

6 Appereance Visual 100%

and damages

SUPREME PRESSTECH CONTROL PLAN

Prototype Pre-launch Production Vendor Code

Vendor Name: SUPREME PRESSTECH Control Plan No. SPT/ZFR/CP/- Azadi Bkt-3003 Control Plan Date: 20.01.2024

Customer Name : ZF Rane Automotive India Private Limited

Vendor Contact Person / Phone: Manoharan R / 9698712440 CP Rev. No. : 00 Rev. Date: -

Part Number : 019 3003 00

Part Name / Description : Mounting Bracket Assembly Core Team members: Manopharan R, Rajeh Mistri, Chirag, Jagdeesh, Suresh R, Sunil,

Supplier/Plant Approval / Date:

Manjunath, Jayasheela

Customer Drg. Rev.No. : 6 / 02.07.2019 Approved by

Prepared by Checked by

Other Approval / Date (If required):

Manoharan R Manoharan R Rajesh Mistry

Characteristics Sample

Process Name / Machine, Device, Product/Process Evaluation /

MFG Process Process Special Mistake Reaction Plan &

Operation Jig, Tools , facillities Specification Measurement Control Method Resp. Resp

Flow Diagram No. for manufacturing CP. Char # Proofing Corrective action

Description Product Process /Tolerance Techniques Size Freq.

Sl.No

1 Bush Diameter 15.0±0.2 Digita Vernier 5 No's Setting

2 Bush Length 14.50±0.2 Digita Vernier 5 No's Setting

3 Bush ID 7.0+0.2 Digita Vernier 5 No's Setting

No. of Tack /

4 2 Places Visual 100%

Projection welding

Distance (After

5 92.50+0.5 Receving Gauge 5 No's 1 Hr

assembly)

Distance (After

6 82.0+0.5 Receving Gauge 5 No's Setting

assembly)

Distance (After

7 78.0±0.5 Receving Gauge 5 No's Setting

assembly)

Distance (After

8 106.0+0.5 Receving Gauge 5 No's 1 Hr

assembly)

Distance (After

9 115.0+0.5 Receving Gauge 5 No's Setting

assembly)

Quarantine the QA Engineer,QA

Setup Approval &

Welding Diameter (After QC / exisiting produced MANAGER &

1080 Bush Welding 10 83.0+1.0 Receving Gauge 5 No's Setting Inprocess -

Machine assembly) INSPECTOR parts and segregate PRODUCTION

inspection report

the parts MANAGER

DVC/ Receiving

11 Distance 14.50+0.5 5 No's Setting

Gauge

12 Distance 40.0±0.5 Receving Gauge 5 No's 1 Hr

DVC/ Receiving

13 Length 56.0±0.8 5 No's Setting

Gauge

Free from rust, Dent

14 Appereance Visual 100%

and damages

15 Wire Diameter 0.8±0.02 Micrometer 5 No's Setting

16 Current 195±5 A Controller 5 No's Setting

17 Voltage 4±2 Kv Controller 5 No's Setting

18 Gas flow 1-2 kg/cm2 Pressure Gauge 5 No's Setting

19 Speed 5.0±0.3 m/min Controller 5 No's Setting

SUPREME PRESSTECH CONTROL PLAN

Prototype Pre-launch Production Vendor Code

Vendor Name: SUPREME PRESSTECH Control Plan No. SPT/ZFR/CP/- Azadi Bkt-3003 Control Plan Date: 20.01.2024

Customer Name : ZF Rane Automotive India Private Limited

Vendor Contact Person / Phone: Manoharan R / 9698712440 CP Rev. No. : 00 Rev. Date: -

Part Number : 019 3003 00

Part Name / Description : Mounting Bracket Assembly Core Team members: Manopharan R, Rajeh Mistri, Chirag, Jagdeesh, Suresh R, Sunil,

Supplier/Plant Approval / Date:

Manjunath, Jayasheela

Customer Drg. Rev.No. : 6 / 02.07.2019 Approved by

Prepared by Checked by

Other Approval / Date (If required):

Manoharan R Manoharan R Rajesh Mistry

Characteristics Sample

Process Name / Machine, Device, Product/Process Evaluation /

MFG Process Process Special Mistake Reaction Plan &

Operation Jig, Tools , facillities Specification Measurement Control Method Resp. Resp

Flow Diagram No. for manufacturing CP. Char # Proofing Corrective action

Description Product Process /Tolerance Techniques Size Freq.

Sl.No

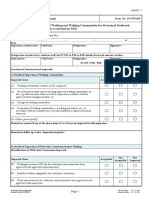

1 Coating Thickness 50 microns max Thickness Tester 5 No's Batch

Quarantine the

Incoming Inform To sub

Supplier PDIR - parts , Reject /

Inspector supplier

CED Coating Free from Coating Rework

1090 2 Appereance Visual 100%

(Sub Supplier) Defects

Process

3 As per Sub supplier Control plan

Parameters

Free From Stamping

1 Appereance and Coating visual VISUAL 100% - ---

defects INFORM QA Engineer,QA

100% Visual

FINAL STAGE SUPERVISOR IF MANAGER &

2000 Inspection & Final

INSPECTOR ANY POSSIBILITY PRODUCTION

Inspectio

DIMENSIONS OF RE- WORK MANAGER

Dimensional Measuring Instrume ts/ PDIR

2 Parameters

REQUIRED AS PER

Receving Gauge

5 No's Batch ---

DRAWING / AOI

QA Engineer,QA

AS PER PACKING

PACKING & INFORM TO MANAGER &

2010 1 FINISHED GOODS STD PO & INVOICE 100% PACKING SLIP --- QA

DESPATCH SUPERVISOR PRODUCTION

MANAGER

Reaction plan C1 :

Stop production, isolate the suspected products, Inform In-charge, analyse the cause and carry action as mentioned below, Re-run verify parts and continue production.

MAN Machine Material Method Measurement

Conduct Machine Stock - Adjust stock in ejector pins / tools spares

Quarantine and or continue production with Ensure Calibration status, verify error, wear and use the

Provide awareness/ Train the operator Capability, Re-validate Tool - Ensure Tool holder, tools

accepted lot calibrated Instrument / Gauging

and Re-run Tool Wear - Re-grind / Polish / Change the tool

Special Char. Class # g Process Characteristics + Product Characteristics

REV. No. Revion Date REVISION DETAILS Intials Remarks

00 20.01.2024 New Release MNR

You might also like

- Audit ChecklistDocument18 pagesAudit ChecklistManoharar RNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- Supplier Change Request (SCR) : Approved PSWDocument3 pagesSupplier Change Request (SCR) : Approved PSWswaran autoqaNo ratings yet

- Allergan Final Deck q1 2018Document41 pagesAllergan Final Deck q1 2018medtechyNo ratings yet

- PDF Process Audit Vda 63Document9 pagesPDF Process Audit Vda 63Shahrazed ZineNo ratings yet

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- INGFRT-11 Run at RateDocument3 pagesINGFRT-11 Run at RateMarisol RubioNo ratings yet

- CG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0Document30 pagesCG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0masprast.devegaNo ratings yet

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- PPAP GuidelinesDocument19 pagesPPAP GuidelinesmoezNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- Quality Management System Software A Complete Guide - 2019 EditionFrom EverandQuality Management System Software A Complete Guide - 2019 EditionNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Supplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingDocument17 pagesSupplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingRicky MarkNo ratings yet

- ISO9 - IATF16 - Combo - GAP - March - 2017 - 1Document100 pagesISO9 - IATF16 - Combo - GAP - March - 2017 - 1vitortavaresNo ratings yet

- Escalation Procedure Updated 020915Document30 pagesEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- Supplier Controlled - Safe Launch PlanDocument6 pagesSupplier Controlled - Safe Launch PlanMario RojasNo ratings yet

- Customer Specific Requirements AL FormatDocument1 pageCustomer Specific Requirements AL FormatSridharan VenkatNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- 8D Problem Solving Process: Houston, We Have A ProblemDocument53 pages8D Problem Solving Process: Houston, We Have A ProblemAnonymous 7yN43wjlNo ratings yet

- Fraud Detection How Machine Learning Systems Help Reveal Scams in Fintech Healthcare and ECommerceDocument24 pagesFraud Detection How Machine Learning Systems Help Reveal Scams in Fintech Healthcare and ECommerceSolomon100% (1)

- 5.1.1.2 - Process Effectiveness EfficiencyDocument1 page5.1.1.2 - Process Effectiveness EfficiencyPrakash kumarTripathiNo ratings yet

- IATF Rules Dec2016Document14 pagesIATF Rules Dec2016anthony dunnNo ratings yet

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- Emd Millipore Contamination Monitoring Product Guide PDFDocument16 pagesEmd Millipore Contamination Monitoring Product Guide PDFManoharar R0% (1)

- What Are APQP and PPAPDocument3 pagesWhat Are APQP and PPAPignaunaqNo ratings yet

- APQP Timing Plan TemplateDocument9 pagesAPQP Timing Plan Templateramchandra rao deshpandeNo ratings yet

- VDA Band 05.2 EnglischDocument50 pagesVDA Band 05.2 EnglischManuel NevarezNo ratings yet

- NcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Document8 pagesNcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Abhishek DahiyaNo ratings yet

- Matrix CSRDocument6 pagesMatrix CSRDiego Jordan Hernández100% (1)

- Understanding The SMRP Body of Knowledge WebinDocument18 pagesUnderstanding The SMRP Body of Knowledge WebinJenny Beatriz Rivera Meenen100% (1)

- Danone: Leading Change by Rejigging Purpose?: CentreDocument18 pagesDanone: Leading Change by Rejigging Purpose?: Centresalonig1703No ratings yet

- KPMG Report Exec SummaryDocument19 pagesKPMG Report Exec SummaryNawin KumarNo ratings yet

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- Supplier Assesment MaxionDocument23 pagesSupplier Assesment Maxionesivaks2000No ratings yet

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- Traceability of Vehicle Components and Identifiability of Their Technical DesignDocument19 pagesTraceability of Vehicle Components and Identifiability of Their Technical DesignR JNo ratings yet

- 7 QC Tools - TrainingDocument27 pages7 QC Tools - TrainingRadhika GuptaNo ratings yet

- FMEA TablesDocument7 pagesFMEA TablesMohamedNo ratings yet

- CQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Document24 pagesCQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Jintara KaewrayaNo ratings yet

- Iatf 16949:2016 Qms Audit ChecklistDocument8 pagesIatf 16949:2016 Qms Audit ChecklistAddinda Zurainie100% (1)

- CQI UpdatesDocument3 pagesCQI UpdatesManoharar R100% (1)

- CQI UpdatesDocument3 pagesCQI UpdatesManoharar R100% (1)

- Statistical Process Control For Attribute Data (SPC)Document45 pagesStatistical Process Control For Attribute Data (SPC)RajanishshettyNo ratings yet

- 02 Manufacturing Process Design InputsDocument3 pages02 Manufacturing Process Design InputsRaja DuraiNo ratings yet

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- Volkswagen Group Customer Specific Requirements March 2022 1Document6 pagesVolkswagen Group Customer Specific Requirements March 2022 1Tania HernandezNo ratings yet

- Grafica XRDocument1 pageGrafica XRAlfonso CruzNo ratings yet

- VDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationDocument1 pageVDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationYo GoldNo ratings yet

- CQI 9 Internal Audit Observations 07.04.11Document2 pagesCQI 9 Internal Audit Observations 07.04.11Asif AliNo ratings yet

- 1) PPAP YHA VIBRACOUSTIC Production)Document31 pages1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNo ratings yet

- 5 Why WeldingRobot ToyotaDocument1 page5 Why WeldingRobot ToyotaMickloSoberanNo ratings yet

- Supplier APQP TrainingDocument32 pagesSupplier APQP TrainingvivekNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- IATF 16949 Corporate Processes/ Clause Matrix: Process Owner(s) Process # Context of The Organization Clause NoDocument6 pagesIATF 16949 Corporate Processes/ Clause Matrix: Process Owner(s) Process # Context of The Organization Clause NoshekarNo ratings yet

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFDocument9 pagesMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeNo ratings yet

- Appendix - 9 - APQP - Timing - PlanDocument1 pageAppendix - 9 - APQP - Timing - PlanChandru JattiNo ratings yet

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocument1 pageOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNo ratings yet

- UntitledDocument19 pagesUntitledSuresh KumarNo ratings yet

- F16 (SOP - hrd.01) Kaizen Implementation SheetDocument1 pageF16 (SOP - hrd.01) Kaizen Implementation SheetRAHUL YADAVNo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Sensor KistlerDocument2 pagesSensor KistlerFco JavierNo ratings yet

- Rane Part PPAP Audit MOMDocument4 pagesRane Part PPAP Audit MOMManoharar RNo ratings yet

- Customer Specific Requirements ChecklitDocument1 pageCustomer Specific Requirements ChecklitManoharar RNo ratings yet

- DockauditchecklistDocument1 pageDockauditchecklistManoharar RNo ratings yet

- Inspection Report Filter Bracket Step 21SK119 1Document2 pagesInspection Report Filter Bracket Step 21SK119 1Manoharar RNo ratings yet

- Audit ObservationDocument8 pagesAudit ObservationManoharar RNo ratings yet

- Powder Caoting Defects and ActionsDocument8 pagesPowder Caoting Defects and ActionsManoharar RNo ratings yet

- 05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsDocument75 pages05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsManoharar R100% (1)

- COPQDocument1 pageCOPQManoharar RNo ratings yet

- Visitor Gate Pass Format in ExcelDocument2 pagesVisitor Gate Pass Format in ExcelManoharar R0% (1)

- Best Rubber Prodcuts Internal Audit Observation SheetDocument1 pageBest Rubber Prodcuts Internal Audit Observation SheetManoharar RNo ratings yet

- RM Third Party Plan-2019Document1 pageRM Third Party Plan-2019Manoharar RNo ratings yet

- I, Handle Bar N360 Rejection Data - SKB-SEP - 2022Document7 pagesI, Handle Bar N360 Rejection Data - SKB-SEP - 2022Manoharar RNo ratings yet

- HH Cap - AOIDocument1 pageHH Cap - AOIManoharar RNo ratings yet

- HH Cap-AOIDocument1 pageHH Cap-AOIManoharar RNo ratings yet

- HH Cap-PSWDocument1 pageHH Cap-PSWManoharar RNo ratings yet

- Fmea PDFDocument5 pagesFmea PDFManoharar RNo ratings yet

- MECHANICAL DEPARTMENT LABOR UNION SA PHILIPPINE NATIONAL RAILWAYS, Petitioner, v. COURT OF INDUSTRIAL RELATIONS, and SAMAHAN NG MGA MANGGAGAWA SA CALOOCAN SHOPS, Respondents.Document4 pagesMECHANICAL DEPARTMENT LABOR UNION SA PHILIPPINE NATIONAL RAILWAYS, Petitioner, v. COURT OF INDUSTRIAL RELATIONS, and SAMAHAN NG MGA MANGGAGAWA SA CALOOCAN SHOPS, Respondents.Mhoe Baladhay100% (1)

- The Concept of UX and UY DesignDocument3 pagesThe Concept of UX and UY DesignMaël NdjoudeNo ratings yet

- Waiting Line PDFDocument73 pagesWaiting Line PDFhannah hopin'No ratings yet

- Griha Trophy 2021-22Document9 pagesGriha Trophy 2021-22Prdeep SinghNo ratings yet

- Kotak Mahindra BankDocument3 pagesKotak Mahindra BankK. SwathiNo ratings yet

- 5.4 NegotiatingDocument2 pages5.4 NegotiatingarthurNo ratings yet

- A Project Report On: Indian BankingDocument35 pagesA Project Report On: Indian BankingRishabh GoyalNo ratings yet

- Right Against ExploitationDocument11 pagesRight Against ExploitationBhawnaNo ratings yet

- Nms6000 Class 1 Dynamic Positioning SystemDocument2 pagesNms6000 Class 1 Dynamic Positioning SystemAmit UtekarNo ratings yet

- Lucknow TO aHDDocument2 pagesLucknow TO aHDViral PatelNo ratings yet

- Strategic Management Assignment On PidiliteDocument5 pagesStrategic Management Assignment On PidiliteNaveenParameswarNo ratings yet

- Assignment: 1Document6 pagesAssignment: 1Deepak YadavNo ratings yet

- The Routledge Companion To Accounting Information Systems (Quinn, Martin Strauss, Erik) (Z-Library)Document332 pagesThe Routledge Companion To Accounting Information Systems (Quinn, Martin Strauss, Erik) (Z-Library)Jonathan FerueloNo ratings yet

- E ManufacturingDocument13 pagesE ManufacturingIkramNo ratings yet

- Australian Telecom Threat of SubstitutesDocument2 pagesAustralian Telecom Threat of SubstitutesAdeel KhalidNo ratings yet

- Mx2 Bussiness Technology NaoimisantosDocument10 pagesMx2 Bussiness Technology NaoimisantosJan ReyNo ratings yet

- WEGMANS SUPERMARKET Operation ManagementDocument2 pagesWEGMANS SUPERMARKET Operation Managementbae joohyunNo ratings yet

- Annex 5 - Checklist For Site Inspection of Welding and Welding Consumables For Structural SteelworkDocument2 pagesAnnex 5 - Checklist For Site Inspection of Welding and Welding Consumables For Structural SteelworkSuntech Testing Limited STLNo ratings yet

- 2G BioEthanol-Civil Works Tender-BridgeRoof-BPCL-TCEDocument85 pages2G BioEthanol-Civil Works Tender-BridgeRoof-BPCL-TCEtsrinivasan5083No ratings yet

- Aqa Gcse Food Technology Coursework ExemplarDocument8 pagesAqa Gcse Food Technology Coursework Exemplarafiwhhioa100% (2)

- And Displays: Structural Design, Manufacturing and Communication For PackagingDocument12 pagesAnd Displays: Structural Design, Manufacturing and Communication For PackagingNikolche MitrikjevskiNo ratings yet

- Chapter 3-Theory of ProductionDocument8 pagesChapter 3-Theory of ProductionYonas D. EbrenNo ratings yet

- Cutting Speed, Feed, and Depth of Cut: Session 8Document22 pagesCutting Speed, Feed, and Depth of Cut: Session 8Thanin AmnuayviboonphonNo ratings yet

- LilliputDocument10 pagesLilliputamit_singh_328No ratings yet

- Running Head: Techno RSDocument25 pagesRunning Head: Techno RSLiam GreenNo ratings yet