Professional Documents

Culture Documents

HH Cap-AOI

Uploaded by

Manoharar RCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HH Cap-AOI

Uploaded by

Manoharar RCopyright:

Available Formats

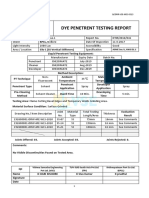

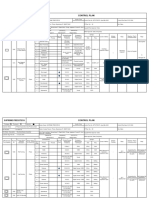

INSPECTION REPORT (FORM -3)

SUPPLIER NAME: SUPREME PRESSTECH GI NUMBER: GI DATE: CLEARED DATE:

PART NO: 28458924 DRAWING NO. : 28458924 INVOICE NUMBER: Prepared Verified Approved

PART NAME: HYDRAULIC HEAD CAP DRAWING REVISION :004 / 13.10.2015 LOT QTY: Vendor 02.04.2022 Manoharan R Suresh Rajesh

AOI ISSUE NO: 01 AOI ISSUE DATE: 02-04.2022 DTVS

APPROVED REJECTED OTHERS

VENDOR OBSERVATION DTVS DTVS OBSERVATION

DWG Supplier Inspection Supplier Sample DTVS Sample

Sl.No. Specification Criticity JUDGE-MENT Inspection JUDGE-MENT REMARKS

Ballon Method Size size

1 2 3 4 5 Method 1 2 3 4 5

1 33 Flatness 0.2 Max QCI CMM 3 nos/ Batch

2 21 Height 1.50±0.08 - Micrometer 5 nos

3 23 Diameter 27.8±0.03 - CMM 5 nos / Batch

4 19 Distance 11.1 min - Height gauge 5 nos

5 10 Diameter 7.20+0.2 Digital Vernier 5 nos

6 130 Profile of Surface 0.2 max QCI CMM 5 nos / Batch

7 131 Finish Ra 1.2 max QCI Roughness Tester 5 nos / Batch

8 142 Finish Rz 16 max QCI Roughness Tester 5 nos / Batch

9 124 Diameter 30.0±0.1 - CMM 5 nos / Batch

10 165 Wall thickness 1.0 Min - Point Micrometer 5 nos

11 126 Distance 2.0 min - Contoure 5 nos

12 128 Depth 1.29 - Contoure 5 nos

13 141 Distance 3.0 Max - Contoure 5 nos

14 53 Distance 4.50 min - Contoure 5 nos

15 159 Total Lerngth 12.80±0.1 Height gauge 5 nos

16 127 Chamfer Angle 45°±1° CMM 5 nos / Batch

17 85 Thickness 5.0±0.1 VMM 5 nos

18 62 Thickness 3.80±0.1 VMM 5 nos

19 162 Symmetry 0.5 Max VMM 5 no's

20 58 Distance 22.75±0.2 VMM 5 no's

21 143 Distance 20.80±0.2 VMM 5 no's

22 35 Angle 120°±1° VMM 5 no's

23 57 Angle 76°±1° VMM 5 no's

24 90 Profile of Line 0.4 max CMM 2 no's / Batch

25 49 Position 0.30 max CMM 2 no's / Batch

Free from Dent &

26 Appereance

Damages

- VMM 100%

28 1 Material SS304 or Equellant - Supplier TC Every Lot

REMARKS: ( * ) Stylus make,tip dia,stem dia, & stem length details…..To be mentioned REMARKS: ( * ) Stylus make,tip dia,stem dia, & stem length details…..To be mentioned

NOTE: 1. As per agreed AOI (Form 1) 100% inspected parts like EPC,QCI…. traceability to be submitted by Supreme Presstech NOTE: 1.As per agreed AOI (Form 1) 100% inspected parts like EPC,QCI... traceability to be verified by DTVS Quality inspector

2. CMM ,Contour and Roughness - Profile report as applicable Hard / soft copy ( Hand written values not acceptable) of Supreme presstech to be verified and signed

2. CMM ,Contour and Roughness - Profile report as applicable Hard / soft copy to be submitted with every Lots ( Hand written values not acceptable)

accordingly

3. RM TC, RM Mill TC, Heat treatment report to be submitted with every lot .(If same heat no: then for balance qty with details mentioned, same heat reports can be submitted) 3.RM TC, RM Mill TC, Heat treatment report (If same heat no: then for balance qty with details mentioned, same heat reports) submitted by Supreme Presstech to be verified

4. Two different HT lots not to be sent in same invoice. 4. Two different HT lots not to be received in same invoice.

5. Packing & Handling should be as per agreed standard 5.Packing & Handling to be verified as per agreed standard

6. A.In case of PRR pending, Quality inspector to verify with respective engineer for lot acceptance. B.In case, if any Q- issue faced in previous lots, DTVS quality inspector to check additional sample of

6. In case of PRR pending & if any lot to be despatched, Supreme Presstech should get prior approval or confirmation from DTVS SQA

30nos(Visual/Dimensional) and attach records respectively, till the Q-issue is closed.

SUPPLIER REPRESENTATIVE DTVS SQA REPRESENTATIVE

NAME : Manoharan R NAME:

SIGNATURE : SIGNATURE :

You might also like

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Cam Rear Brake Forging In-Process InspectionDocument2 pagesCam Rear Brake Forging In-Process InspectionVikas Kashyap100% (1)

- HH Cap - AOIDocument1 pageHH Cap - AOIManoharar RNo ratings yet

- CAR NO: BN20892/PRA/01 Corrective Action RequestDocument160 pagesCAR NO: BN20892/PRA/01 Corrective Action RequestAbhishekDwivediNo ratings yet

- PDIR F2L09399 (1)Document1 pagePDIR F2L09399 (1)Shankar JadhavNo ratings yet

- Qa & QC UusdaDocument40 pagesQa & QC UusdaAmir SohailNo ratings yet

- PDIR FMG0599.Document1 pagePDIR FMG0599.Shankar JadhavNo ratings yet

- Qa & QC UusdaDocument40 pagesQa & QC UusdaAmir SohailNo ratings yet

- Pdir 5PM Ad3532001 - 1a31892004b 04.06.2022Document1 pagePdir 5PM Ad3532001 - 1a31892004b 04.06.2022RohitNo ratings yet

- Plate Bearing Inspection ReportDocument6 pagesPlate Bearing Inspection ReportFrans ManurungNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- QC 64256-1 Ring Spacer Inspection ReportDocument1 pageQC 64256-1 Ring Spacer Inspection ReportSenthil KumarNo ratings yet

- Inspection Report: Khodiyar Spring IndustriesDocument1 pageInspection Report: Khodiyar Spring IndustriesVinay KumarNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Galvanizing Coating Thickness ReportsDocument3 pagesGalvanizing Coating Thickness Reportsm.aliNo ratings yet

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammarNo ratings yet

- Norm Cıvata inspection certificateDocument3 pagesNorm Cıvata inspection certificateömer cılızNo ratings yet

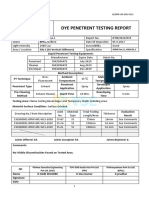

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- PDIR B0Y46408Document1 pagePDIR B0Y46408Shankar JadhavNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Krishna Indu: Standard Deviation MethodDocument17 pagesKrishna Indu: Standard Deviation MethodDisha ShahNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- INSPECTION REPORT DETAILS CYLINDER DIMENSIONSDocument1 pageINSPECTION REPORT DETAILS CYLINDER DIMENSIONSAgni DuttaNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingDocument2 pagesMonth Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingJatin SharmaNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Edo Model 1Document4 pagesEdo Model 1PotirnichiNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Pdi Report: JN Engg Works DATE: 1/8/18Document32 pagesPdi Report: JN Engg Works DATE: 1/8/18Anil kumarNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- CORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTDocument4 pagesCORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTArun Prasad100% (1)

- TEST REPORT FINDINGSDocument1 pageTEST REPORT FINDINGSAbhinav SinghNo ratings yet

- Concrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_6_20170228Document1 pageConcrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_6_20170228hbduzitNo ratings yet

- Test PackDocument17 pagesTest PackMuhammad Bilal Arif100% (3)

- Inspection Report: 0M-84150C Assy Suction Pipe To Coil C223C4-3-1Document1 pageInspection Report: 0M-84150C Assy Suction Pipe To Coil C223C4-3-1NAGRAJNo ratings yet

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785Document9 pagesAshirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785mohd shirazNo ratings yet

- Inspection ReportDocument1 pageInspection Reportharrydev27No ratings yet

- TM 215461 SRTDocument3 pagesTM 215461 SRTömer cılızNo ratings yet

- Lobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportDocument2 pagesLobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportvipanNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Spool HT EPCMD 2 QM00 FMT PP 028 - 01Document1 pageSpool HT EPCMD 2 QM00 FMT PP 028 - 01Muthu AlaguRajNo ratings yet

- Nepal Rubber and Engineering Pvt. LTD: Vertical Load Test ReportDocument8 pagesNepal Rubber and Engineering Pvt. LTD: Vertical Load Test ReportAankil SharmaNo ratings yet

- 2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXDocument1 page2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXSonali AhirwarNo ratings yet

- Inspection Report and Leak Test FormatDocument2 pagesInspection Report and Leak Test Formatmujahed_muhammedNo ratings yet

- Work order for painting 96 pipesDocument1 pageWork order for painting 96 pipesAlfian ImaduddinNo ratings yet

- Inspection Report: 875-4547 Gasket C223C6-1-1Document1 pageInspection Report: 875-4547 Gasket C223C6-1-1NAGRAJNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Layout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Document3 pagesLayout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Fortune FireNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- RM Mechanical Report 28.1 MMDocument1 pageRM Mechanical Report 28.1 MMBHUSHANNo ratings yet

- Mendez-Ejercicio 3Document14 pagesMendez-Ejercicio 3Dennis MendezNo ratings yet

- Top Cover - Casting Final Insp ReportDocument1 pageTop Cover - Casting Final Insp ReportEURO CAST ENGINEERING EURO CAST ENGINEERINGNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- FM-07 Quality Report - ExtrusionDocument1 pageFM-07 Quality Report - ExtrusionMATTHEW MUNGAINo ratings yet

- Rubber InspectionDocument1 pageRubber InspectionShalin mishraNo ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- Concrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_7_20170331Document1 pageConcrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_7_20170331hbduzitNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- SJP - Safety Audit Checklist (T2 Vendor) - R1Document11 pagesSJP - Safety Audit Checklist (T2 Vendor) - R1Manoharar RNo ratings yet

- Powder Caoting Defects and ActionsDocument8 pagesPowder Caoting Defects and ActionsManoharar RNo ratings yet

- Customer Specific Requirements ChecklitDocument1 pageCustomer Specific Requirements ChecklitManoharar RNo ratings yet

- Rane Part PPAP Audit MOMDocument4 pagesRane Part PPAP Audit MOMManoharar RNo ratings yet

- Inspection Report Filter Bracket Step 21SK119 1Document2 pagesInspection Report Filter Bracket Step 21SK119 1Manoharar RNo ratings yet

- 05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsDocument75 pages05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsManoharar RNo ratings yet

- 07 Control PlanDocument5 pages07 Control PlanManoharar RNo ratings yet

- Audit ObservationDocument8 pagesAudit ObservationManoharar RNo ratings yet

- Audit ChecklistDocument18 pagesAudit ChecklistManoharar RNo ratings yet

- Rane Part PPAP Audit MOMDocument4 pagesRane Part PPAP Audit MOMManoharar RNo ratings yet

- Best Rubber Prodcuts Internal Audit Observation SheetDocument1 pageBest Rubber Prodcuts Internal Audit Observation SheetManoharar RNo ratings yet

- Audit ObservationDocument8 pagesAudit ObservationManoharar RNo ratings yet

- 05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsDocument75 pages05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsManoharar RNo ratings yet

- 07 Control PlanDocument5 pages07 Control PlanManoharar RNo ratings yet

- I, Handle Bar N360 Rejection Data - SKB-SEP - 2022Document7 pagesI, Handle Bar N360 Rejection Data - SKB-SEP - 2022Manoharar RNo ratings yet

- Customer Specific Requirements ChecklitDocument1 pageCustomer Specific Requirements ChecklitManoharar RNo ratings yet

- Visitor Gate Pass Template for AJAY FORGINGDocument2 pagesVisitor Gate Pass Template for AJAY FORGINGManoharar R0% (1)

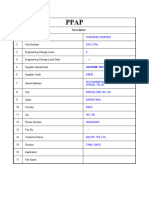

- Part Submission WarrantDocument1 pagePart Submission WarrantManoharar RNo ratings yet

- CT-01 - 09Document1 pageCT-01 - 09Manoharar RNo ratings yet

- RM Third Party Plan-2019Document1 pageRM Third Party Plan-2019Manoharar RNo ratings yet

- Electrochem Technologies India Pvt. LTD.,: Phone # + 91 44 26520024 / + 91 44 26520064 Fax # + 91 44 26520064 E MailDocument1 pageElectrochem Technologies India Pvt. LTD.,: Phone # + 91 44 26520024 / + 91 44 26520064 Fax # + 91 44 26520064 E MailManoharar RNo ratings yet

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Fmea PDFDocument5 pagesFmea PDFManoharar RNo ratings yet

- Oct.-14 - Oee DetailsDocument132 pagesOct.-14 - Oee DetailsManoharar RNo ratings yet

- Fmea PDFDocument5 pagesFmea PDFManoharar RNo ratings yet

- Calibration History CardDocument2 pagesCalibration History CardManoharar RNo ratings yet

- Fmea PDFDocument5 pagesFmea PDFManoharar RNo ratings yet

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- Geometry QuotesDocument2 pagesGeometry Quotesalecksander2005No ratings yet

- LA36300 Circuit Breaker Data SheetDocument2 pagesLA36300 Circuit Breaker Data SheetALEJANDRO DOMINGUEZNo ratings yet

- Lecture 9: Exploration and Exploitation: David SilverDocument47 pagesLecture 9: Exploration and Exploitation: David Silver司向辉No ratings yet

- 1.master Techniques in Surgery - Esophageal Surgery, 1E (2014)Document456 pages1.master Techniques in Surgery - Esophageal Surgery, 1E (2014)Raul Micu ChisNo ratings yet

- Privilege Speech of Hon. Rex Sarabia, Member of The Sangguniang Panlungsod NG Iloilo Delivered On June 7, 2023 During The Regular Session of The Sangguniang Panlungsod NG IloiloDocument4 pagesPrivilege Speech of Hon. Rex Sarabia, Member of The Sangguniang Panlungsod NG Iloilo Delivered On June 7, 2023 During The Regular Session of The Sangguniang Panlungsod NG IloiloSelurongNo ratings yet

- PublicLifeUrbanJustice Gehl 2016-1Document119 pagesPublicLifeUrbanJustice Gehl 2016-1bronsteijnNo ratings yet

- Cbse & Ntse: MathematicsDocument397 pagesCbse & Ntse: MathematicsAbhinav BNo ratings yet

- Flammability Characteristics of Common Gases and LiquidsDocument1 pageFlammability Characteristics of Common Gases and LiquidsNeme VasquesNo ratings yet

- Jaguar Land-Rover: A Customer Centric OrganizationDocument15 pagesJaguar Land-Rover: A Customer Centric OrganizationAnmol Shukla100% (1)

- Skies of Arcadia - Lists (Cham, Moonfish, Discoveries)Document9 pagesSkies of Arcadia - Lists (Cham, Moonfish, Discoveries)123142asdadNo ratings yet

- BFV WeightDocument8 pagesBFV WeightBhargav PatelNo ratings yet

- Quiz 2 AnswersDocument6 pagesQuiz 2 Answerselliott.rillstoneNo ratings yet

- Module 6 PDFDocument10 pagesModule 6 PDFTazbir AntuNo ratings yet

- How To Do Chromatography With Candy and Coffee FiltersDocument4 pagesHow To Do Chromatography With Candy and Coffee FiltersSuharti HartiNo ratings yet

- 986.33 Mesofilos Aerobios-PetrifilmDocument1 page986.33 Mesofilos Aerobios-PetrifilmBleidy NieblesNo ratings yet

- Profession Jokes - DoctorsDocument10 pagesProfession Jokes - DoctorssagararlaNo ratings yet

- Electric Tool Parts List: Air Compressor 2007 - 04 - 02 Model EC 119 (E3)Document3 pagesElectric Tool Parts List: Air Compressor 2007 - 04 - 02 Model EC 119 (E3)Ivan GallegosNo ratings yet

- DC TC 600 L, 01.00, enDocument61 pagesDC TC 600 L, 01.00, enDarkNo ratings yet

- The Wall Street Journal - 24-11-2021Document30 pagesThe Wall Street Journal - 24-11-2021Samuel GiovanelliNo ratings yet

- Ce6101 Problem Sheet 3Document4 pagesCe6101 Problem Sheet 3HT BinhNo ratings yet

- Internship ReportDocument33 pagesInternship Reportstreamingmedia786No ratings yet

- Menu Shamrock BarDocument1 pageMenu Shamrock BarCantyaNo ratings yet

- 3d Printing Thesis StatementDocument5 pages3d Printing Thesis Statementoabfziiig100% (2)

- Port EquipmentsDocument21 pagesPort EquipmentsNeha Motwani100% (2)

- Cengel FTFS 6e ISM CH 13Document83 pagesCengel FTFS 6e ISM CH 13Duck FernandoNo ratings yet

- (Ebook - PDF - Hack) Advanced Hardware HackingDocument20 pages(Ebook - PDF - Hack) Advanced Hardware HackingogmpsqjuNo ratings yet

- Inscription of Preah Vihear Temple of Cambodia For World HeritageDocument131 pagesInscription of Preah Vihear Temple of Cambodia For World HeritageChourn ChamroeurnNo ratings yet

- Unit Ii, Lesson 4: Qualitative Research in Different Areas of KnowledgeDocument6 pagesUnit Ii, Lesson 4: Qualitative Research in Different Areas of KnowledgeJessy RoseNo ratings yet

- Cambridge IGCSE™: Geography 0460/41 October/November 2020Document9 pagesCambridge IGCSE™: Geography 0460/41 October/November 2020RutendoNo ratings yet

- Module 2: Hematopoiesis I. General Principles of HematopoiesisDocument13 pagesModule 2: Hematopoiesis I. General Principles of HematopoiesisJane JapoleNo ratings yet