Professional Documents

Culture Documents

Sizing 2x50% Adequacy

Uploaded by

Sagaya Raj YCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing 2x50% Adequacy

Uploaded by

Sagaya Raj YCopyright:

Available Formats

FOSTER WHEELER ENERGY LIMITED

SUBJECT Nitrogen Receiver Sizing SHEET

PROJECT Jafurah REV DATE ORIGINATOR CHECKER APPROVER

CONTRACT NO. JO / EWO 10-17537-0001 O1 23-May-22 SY VA YM

LOCATION Saudi Arabia

CALC NO. 502385-8110-CA-889103-25

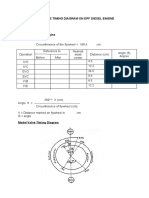

INSTRUMENT AIR RECEIVER SIZING

Vessel Item Number: 889-D-3501A/B

Service: Nitrogen Receiver

Calculation Case: Design

Flowrate for sizing Select

Select Unit

Unit of

of Flow

Flow

REFERENCE

Design Flowrate ( C ) = 9608.00 kg / hr Total Nitrogen Demand

7431.93 Nm³ / hr Unit Conversion

Design Basis

Supply time ( t ) = 2.0 minutes Note 1, SAES-J-901 Page 9, section 5.7.1

Air Supply Temperature = 48.9 oC 889-A-JN-821950_REV A- BEDD

Initial Receiver Pressure ( P1) = 6.9 bar g 889-A-JN-821950_REV A- BEDD

Final Receiver Pressure ( P2) = 4.8 bar g 889-A-JN-821950_REV A- BEDD

Pressure at Normal Conditions ( p ) = 1.01325 bar a

NOTE: Formula for sizing taken from FW Italiana Offsites Manual for Instrument and Plant Air

Receiver Volume Required( V ) = t x C x p m³ Based on air temp = 0 oC

60 x (P1 - P2)

= 121.35 m³

Corrected Receiver Volume Required = 143.09 m³ Based on air supply temperature = 48.9 °C

Number of Receivers = 2

Volume of each Receiver = 71.55 m³

Calculated Dimensions of each Receiver (based on L/D ratio of 4) User Input Size if required

Receiver Target Length/Diameter Ratio 4.0 Diameter 2820 mm

(Note: L/D typically between 3 & 5)

tan - tan 11480 mm

Diameter 2800 mm

Actual Volume (cylinder) 71.7 m³

tan - tan 11700 mm

Actual Volume (incl. ends) 77.5 m³

Volume of Receiver (cylindrical section only) 72.0 m³

Actual L / D 4.1

Volume of Receiver (incl. 2:1 elliptical ends) 77.8 m³

Actual Supply Time (Cylinder) 2.0 mins

Actual L / D 4.2

Actual Supply Time (Incl. Ends)) 2.2 mins

Note (1) : P1=100psig & P2=70 psig is considered.

Note (2) :

Note (3) :

Version 3.04 Rev Date: Aug-14 Printed on: 3/25/2024 8:05

Filename & path: 'file:///conversion/tmp/activity_task_scratch/738611128.xlsx'#$Calculation

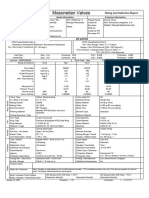

FOSTER WHEELER ENERGY LIMITED VESSEL PROCESS SPECIFICATION

CUSTOMERS NAME: PROJECT No:

LOCATION: Saudi Arabia UNIT No:

SERVICE: Nitrogen Receiver ITEM No: No. REQD:

DOCUMENT CAT.-CLASS 1

REV A DOCUMENT No.

DATE 04-10-2019 SHEET 1 OF 3

ORIG. BY DOCUMENT SEQUENCE No.

APP. BY

N2

N4 Wet Air N5

N2

Dry Air

M1

N6

N7

N1 A

N7

B

N3

?????? mm

Instructions: (Note that these will not appear on your print-out).

1. Select air out nozzle N2 as required. Delete unwanted nozzle N2.

2. Delete text "Dry air" and text "Wet air".

3. Delete any other nozzles not required.

4. Renumber nozzles as necessary.

5. Enter vessel dimensions in mm.

Note that the sketch can be copied into Zyqad.

NOTE 1. LLL TO BE AT LEAST 200mm ABOVE BTM TAN LINE.

NOTE 2. SEE SEPARATE DATA SHEET FOR NOZZLE CHART, DESIGN DATA ETC.

ITEM No. SHEET 1 OF 3

FWEL.2068/1 Rev.6 BASE : Vessel Datasheet.xls

FOSTER WHEELER ENERGY LIMITED VESSEL PROCESS SPECIFICATION

CUSTOMERS NAME: PROJECT No: #NULL!

LOCATION: Saudi Arabia UNIT No: #NULL!

SERVICE: Nitrogen Receiver ITEM No: #NULL! No. REQD: #NULL!

DOCUMENT CAT.-CLASS 1

REV #NULL! #NULL! #NULL! #NULL! DOCUMENT No. #NULL!

DATE #NULL! #NULL! #NULL! #NULL! SHEET 2 OF #NULL!

ORIG. BY #NULL! #NULL! #NULL! #NULL! DOCUMENT SEQUENCE No. #NULL!

APP. BY #NULL! #NULL! #NULL! #NULL!

NOZZLE CHART

CONN SIZE SERVICE REMARKS No. Design Pressure(1) Top/Bottom: / barg

No. mm REQD. Design Temp. Top/Bottom: / °C

Operating Pressure Top/Bottom: / barg

Operating Temp. Top/Bottom: / °C

Vac. design condition: barg @ °C

Steamout Conditions:(2) °C @ barg

Short term maximum temperature of °C for

hrs Coincident pressure barg

Minimum temperature °C @ barg

Pressure/Temperature Cycling:

Stress Relieved: (Process Reasons)

Insulation: (4)

Fireproofing:

PED Fluid Type/ State: /

MATERIALS

Shell: Corr. Allowance: mm

Shell Lining/Cladding: Thickness mm

Boot: Corr. Allowance: mm

Boot Lining: Thickness mm

Internals: Corr. Allowance: mm

Others:

GENERAL NOTES: OPERATING TEMPERATURE PROFILE (columns only)

(1) Design pressure excludes static head of liquid- Vessel Group to Tray No. °C

calculate. Maximum operating liquid level = m

Operating liquid SG =

(2) Steam out details by Vessel Group.

(3) Number & size of instrument connections to be confirmed by Instrument Group. TANK VENTING DATA

(4) Personnel protection & winterisation (if required) by Engineering. Blanketing (tanks only):

(5) Special relief requirements: Max. inbreathing rate m³/h

Max. outbreathing rate m³/h MW kg/kmol

Emergency relief

flow kg/h

MW kg/kmol

Relieving temperature: °C

Max. relieving pressure: barg

Fluid:

ITEM No. #NULL! SHEET 2 OF ###

FWEL.2068/2 Rev.6 BASE : Vessel Datasheet.xls

You might also like

- Breaking Into Software Defined Radio: Presented by Kelly AlbrinkDocument40 pagesBreaking Into Software Defined Radio: Presented by Kelly AlbrinkChris Guarin100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Air Receiver SizingDocument7 pagesAir Receiver SizingKong Lingwei0% (2)

- HUD Settlement Statement - 221-1993Document4 pagesHUD Settlement Statement - 221-1993Paul GombergNo ratings yet

- 1000TR Entravac Centrifugal Chiller Product ReportDocument2 pages1000TR Entravac Centrifugal Chiller Product ReportEdwin CalpitoNo ratings yet

- Design of Collector Subsoil Drainage SystemDocument2 pagesDesign of Collector Subsoil Drainage Systemeric bargasNo ratings yet

- Safety Critical Equipment and Spare Parts Guidance PDFDocument23 pagesSafety Critical Equipment and Spare Parts Guidance PDFΑλέξης Κριτσωτάκης100% (1)

- Process Data Sheet For Main Air Compressor Rev00Document4 pagesProcess Data Sheet For Main Air Compressor Rev00mahan moradiNo ratings yet

- User Guide Varicent IcmDocument380 pagesUser Guide Varicent IcmSharad Sharma100% (3)

- Liquid - Gas Phase SizingDocument12 pagesLiquid - Gas Phase Sizingeke23No ratings yet

- Data Sheet For DP Flow Transmitter - JBF Manglore PTA PlantDocument3 pagesData Sheet For DP Flow Transmitter - JBF Manglore PTA Plantmayukhguha1988No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- Identification of Safety Critical Equipment (SCE) : GuideDocument28 pagesIdentification of Safety Critical Equipment (SCE) : Guidemoustafa100% (1)

- Pump NPSH CalculationDocument18 pagesPump NPSH CalculationDarwinNo ratings yet

- Chiller Product Report Design Conditions PDFDocument2 pagesChiller Product Report Design Conditions PDFSiddharth JainNo ratings yet

- Rotary Dryer SizingDocument3 pagesRotary Dryer Sizingadil shidiq100% (1)

- Data Kalibrasi Injection Pump Forklift MitsubishiDocument3 pagesData Kalibrasi Injection Pump Forklift Mitsubishinarama100% (1)

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- MO-MM Sist Espuma Helipuerto WILHELMSENDocument54 pagesMO-MM Sist Espuma Helipuerto WILHELMSENArturo suzan arvizuNo ratings yet

- Proyek Mini LPG Plant Lapangan JataDocument6 pagesProyek Mini LPG Plant Lapangan JataDIANTORONo ratings yet

- PLN CNG Process CalculationDocument14 pagesPLN CNG Process CalculationViqiNo ratings yet

- Tunisia - Country Profile: 1 Background 2 2 Population 2Document18 pagesTunisia - Country Profile: 1 Background 2 2 Population 2stand4xNo ratings yet

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- Feasibility Study Pengebangan Stasiun LCNG Untuk Kendaraan Bermotor Di Jawa Barat ProcessDocument15 pagesFeasibility Study Pengebangan Stasiun LCNG Untuk Kendaraan Bermotor Di Jawa Barat ProcessAgus SupriadiNo ratings yet

- WC Centravac Centrifugal Chiller Product ReportDocument2 pagesWC Centravac Centrifugal Chiller Product ReportAbdul MNo ratings yet

- Data Sheet-Bandar - Dayyer - BACDocument1 pageData Sheet-Bandar - Dayyer - BACmeisamNo ratings yet

- Measure rectangular duct flow with aerodynamic foilDocument6 pagesMeasure rectangular duct flow with aerodynamic foilvaisakp777No ratings yet

- 358051-PRO-RP-4000 Rev.a Verification & Recommendation Report, AshourDocument12 pages358051-PRO-RP-4000 Rev.a Verification & Recommendation Report, AshourMuhammad KhaleelNo ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- Data Sheet-Bandar - Dayyer - MACDocument1 pageData Sheet-Bandar - Dayyer - MACmeisamNo ratings yet

- Pump Duty Points - DesDocument8 pagesPump Duty Points - DesMaqsood NishatNo ratings yet

- Technical Data Sheet: Customer: Ref.Document1 pageTechnical Data Sheet: Customer: Ref.Mohamad ItaniNo ratings yet

- Centrifugal PumpsDocument7 pagesCentrifugal PumpsNhutNo ratings yet

- 05 Process Datasheet Annexure-PDocument1 page05 Process Datasheet Annexure-PpdilgnfcNo ratings yet

- 3031 PDFDocument4 pages3031 PDFMihai-Eugen Popa100% (1)

- 104780-3031 Test PlanDocument4 pages104780-3031 Test PlanMihai-Eugen PopaNo ratings yet

- Technical Data Sheet for UEA-01,02 CentrífugoDocument13 pagesTechnical Data Sheet for UEA-01,02 Centrífugocarmen hernandezNo ratings yet

- CRTAG - CRTAG-1 - Product ReportDocument2 pagesCRTAG - CRTAG-1 - Product ReportMohammed EmamNo ratings yet

- MC-001-DS-M-007-140 DS For Water Sump Pump Rev ADocument4 pagesMC-001-DS-M-007-140 DS For Water Sump Pump Rev AHeldiyan RamdhanNo ratings yet

- Specification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitDocument4 pagesSpecification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitAvinash ShuklaNo ratings yet

- Attachment-4 - Compressed Air Balance CalculationDocument4 pagesAttachment-4 - Compressed Air Balance CalculationdhamuNo ratings yet

- Water Sump Pump Data SheetDocument2 pagesWater Sump Pump Data Sheetadrian bargasNo ratings yet

- Appendix IIDocument834 pagesAppendix IIjvfcvNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Muhammed Ali CangürNo ratings yet

- Air System Sizing Summary For ITR 87-AHUDocument10 pagesAir System Sizing Summary For ITR 87-AHUvictor.s100% (1)

- 1100tr-Design - Water Cooled ChillerDocument2 pages1100tr-Design - Water Cooled ChillerRamNo ratings yet

- MC Fe-88115spiDocument1 pageMC Fe-88115spigallegos70No ratings yet

- Air Cooled Condenser Test Procedure (2)Document10 pagesAir Cooled Condenser Test Procedure (2)RajarshiNo ratings yet

- Ac001 D6000 15 MTD D XXX0009 CDocument2 pagesAc001 D6000 15 MTD D XXX0009 Cessaessa1980No ratings yet

- Configure/Setup of 04/27/2017 15:44:21.347 8800D Rev. 2Document4 pagesConfigure/Setup of 04/27/2017 15:44:21.347 8800D Rev. 2Liviu CretuNo ratings yet

- 15SV2GG4F60: Operating DataDocument4 pages15SV2GG4F60: Operating DatajtorerocNo ratings yet

- Ejercicio Ácido Cítrico - EERDocument10 pagesEjercicio Ácido Cítrico - EERLali SalcedoNo ratings yet

- RTHD - RTHD AFD 87-99 - Consolidated Customer PackageDocument13 pagesRTHD - RTHD AFD 87-99 - Consolidated Customer Packageimecc ingenieriaNo ratings yet

- Jenbacher Combustion Air CoolingDocument10 pagesJenbacher Combustion Air CoolingAli AbbasiNo ratings yet

- DPF Vertical Diesel EngineDocument9 pagesDPF Vertical Diesel Engine19M231 - N KARENNo ratings yet

- DJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1Document6 pagesDJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1DIANTORONo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- SESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Document65 pagesSESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Quyet PhungNo ratings yet

- MN-176323-24 (2)Document3 pagesMN-176323-24 (2)nawaz.ahmed.spnutra.comNo ratings yet

- Technical Specs for 5-Unit Air Cooler SystemDocument9 pagesTechnical Specs for 5-Unit Air Cooler SystemSladjan UgrenovicNo ratings yet

- ERTAF - ERTAF-2 maco-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 maco-2 - Product ReportKaran GnaniNo ratings yet

- CenTraVac Centrifugal Chiller Product Report - Cap.450TRDocument2 pagesCenTraVac Centrifugal Chiller Product Report - Cap.450TRWahyu HarisantoNo ratings yet

- Sales Report CEFTDocument3 pagesSales Report CEFTHemant Singh RajpootNo ratings yet

- Roxar - 20092851 IDSDocument4 pagesRoxar - 20092851 IDSDidik WahyudiNo ratings yet

- PG Regulations 2017 ANNA UniversityDocument17 pagesPG Regulations 2017 ANNA UniversityMurali Krishnan SelvarajaNo ratings yet

- PG Regulations 2017 ANNA UniversityDocument17 pagesPG Regulations 2017 ANNA UniversityMurali Krishnan SelvarajaNo ratings yet

- Pipe Fitting LossesDocument4 pagesPipe Fitting LossesSafeNo ratings yet

- Natural Gas ViscosityDocument2 pagesNatural Gas ViscositySagaya Raj YNo ratings yet

- VBA Codes For PRD Sizing As Per API 520 (Part 1)Document7 pagesVBA Codes For PRD Sizing As Per API 520 (Part 1)Sagaya Raj YNo ratings yet

- Macquarie Capital Cover LetterDocument1 pageMacquarie Capital Cover LetterDylan AdrianNo ratings yet

- Audprob 9Document2 pagesAudprob 9lovely abinalNo ratings yet

- Nucor at A Crossroads: Group-2, Section - BDocument8 pagesNucor at A Crossroads: Group-2, Section - BHimanshiNo ratings yet

- Certif Icate of Motor Insurance: MmencementDocument2 pagesCertif Icate of Motor Insurance: MmencementSarfraz ZahoorNo ratings yet

- Prepare Level 2 Achievement Test 5 17-20Document2 pagesPrepare Level 2 Achievement Test 5 17-20mggaes75% (4)

- bài tập ôn MA1Document34 pagesbài tập ôn MA1Thái DươngNo ratings yet

- Washing Machine ManualDocument15 pagesWashing Machine ManualtauseefNo ratings yet

- Abortion Guide: Types, Causes and TreatmentDocument46 pagesAbortion Guide: Types, Causes and TreatmentNikhil TyagiNo ratings yet

- Topics in English SyntaxDocument131 pagesTopics in English SyntaxPro GamerNo ratings yet

- Ahu KitDocument37 pagesAhu KitLaurentiu LapusescuNo ratings yet

- CRM Assignment FrankfinnDocument4 pagesCRM Assignment FrankfinnJyoti Choudhary60% (5)

- Job DescriptionDocument4 pagesJob Descriptionnafis hasnayenNo ratings yet

- Linear Equations and Functions Financial PlansDocument3 pagesLinear Equations and Functions Financial PlansEmelyn AbucayNo ratings yet

- Coa - Resolution No. 2017-023 Dtd.12.21.2017 - Intosai Sai Qms Cert.Document2 pagesCoa - Resolution No. 2017-023 Dtd.12.21.2017 - Intosai Sai Qms Cert.Anie Guiling-Hadji GaffarNo ratings yet

- Code: Final Exam in English: Grade 8Document7 pagesCode: Final Exam in English: Grade 8Luka EradzeNo ratings yet

- GW - Energy Storage Solutions - Brochure-ENDocument24 pagesGW - Energy Storage Solutions - Brochure-ENjhtdtNo ratings yet

- Jig and Fixture Design AnnaDocument22 pagesJig and Fixture Design AnnaZemariyam BizuayehuNo ratings yet

- Logical Ability QuestionsDocument23 pagesLogical Ability Questionsjaya pavanNo ratings yet

- Plummer Blocks 2500-E LowresDocument66 pagesPlummer Blocks 2500-E LowresChintamani VeerrajuNo ratings yet

- Diease LossDocument10 pagesDiease LossGeetha EconomistNo ratings yet

- Common Phrasal VerbsDocument2 pagesCommon Phrasal VerbsOscar LasprillaNo ratings yet

- Roll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHDocument3 pagesRoll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHBeenish MirzaNo ratings yet

- 9A01709 Advanced Structural Analysis PDFDocument8 pages9A01709 Advanced Structural Analysis PDFReddy Kiran KDNo ratings yet

- The Best Chicken Quesadillas - Mel's Kitchen Cafe 4Document1 pageThe Best Chicken Quesadillas - Mel's Kitchen Cafe 4Yun LiuNo ratings yet

- Beam 3 Design and AnalysisDocument5 pagesBeam 3 Design and AnalysisCelsoRapiNo ratings yet

- CriticalAppraisalWorksheetTherapy EffectSizeDocument2 pagesCriticalAppraisalWorksheetTherapy EffectSizeFitriArdiningsihNo ratings yet