Professional Documents

Culture Documents

05 Process Datasheet Annexure-P

Uploaded by

pdilgnfcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 Process Datasheet Annexure-P

Uploaded by

pdilgnfcCopyright:

Available Formats

GNFC LTD. PROCESS DATASHEET FOR NEW DOUBLE WALL DRAWING NO.

:

BHARUCH DOUBLE INTEGRITY AMMONIA STORAGE TANK ANNEXURE - P

D&C. DEPT. ( TAG NO. D-1003AM1 )

GENERAL

Plant Ammonia

Location Section-1000, Ammonia storage tank area

Equipment Anhydrous Ammonia Storage Tank

Tank Type Vertical Double Wall Double Integrity with Suspended Deck & Dome Roof

Capacity 10,000 MT

Inner Tank Inside Diameter 35,000 mm

Inner Tank Height 16,000 mm (Hold)(This is estimated value. The exact value will be as design by the contractor)

Outer Tank Inside Diameter 36,530 mm (Hold)(This is estimated value. The exact value will be as design by the contractor)

Outer Tank Height 15,200 mm (Hold)(This is estimated value. The exact value will be as design by the contractor)

Corrosion Allowance

a) Shell & Bottom Plate (Inner & Outer Tank) 1.5 mm

b) Roof & Deck 1.5 mm

Material of Construction

a) Inner Tank SA 537 CLASS 1

b) Outer Tank SA 537 CLASS 1

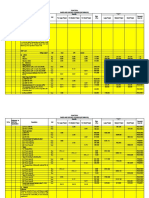

PROCESS DATA

Stream TP-1 TP-2 TP-4 TP-5

Fluid Amm IN Amm OUT Amm OUT Amm IN

Phase Liquid Liquid Vapour Vapour

Parameter Unit

For balance process streams please refer

Flow Rate (Normal) Kg / Hr 10,000 9,646 438 84

Annexure-P2.

Flow Rate (Maximum) Kg / Hr 58,000 57,150 1,750 900

Density Kg / M^3 682.60 682.60 0.77 0.77

Viscosity cP 0.25 0.25 0.01 0.01

OPERATING CONDITIONS FOR INNER AND OUTER TANK

Operating Temperature °C -34

Min./Max. Operating Temperature °C -35 / Ambient

Operating Pressure mm WC g 800

Min./Max. Operating Pressure -50 mm of WC / Max Liquid Head + 0.2 Barg

Max. Evaporation Loss % 0.05 wt% of total quantity in 24 hrs.

NOTES:

1 All instruments shall be included in the scope of supply of tank vendor as shown in schematic drawing at Annexure - P1.

2 The new Liquid Ammonia Storage Tank shall be integrated with the existing liquid ammonia storage tank D-1003B

and existing handling system by vendor.

3 The existing Ammonia Boil-Off Compressors (3 Nos.), Transfer Pumps and all the existing facilities including the flare

system with PCV & N2 purging system etc. shall be utilized for operation of this new tank.

4 Existing Ammonia Boil-Off Compressors will take care of Boil-off vapour from new tank D-1003AM1 of capacity

10,000 MT & as well as from existing tank D-1003B of capacity 10,000 MT.

5 For details of interlock system refer P&I Diagram (Drg. No. P&ID / D&C / P / 1000 / 227).

6 For piping tapping points (TP), Nozzle Number, Line Number & Process Parameters refer Annexure - P2.

7 All elevations, references is to be considered from the bottom of the inner tank.

8 Orientation of all nozzles is to be decided suitably by the vendor considering the existing tank D-1003B for smooth

and safe operation.

ORDER

ISSUED

ENQUIRY X

FOR

BUDGETARY OFFER 0 30 June 2020 SRSE(GSD) CM(PJK) GM(RJH)

SCHEME NO.: S - 500836 REV. DATE PREP. BY CHK. BY APPD. BY

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Process Calculation-Rev0Document15 pagesProcess Calculation-Rev0kkkhattabbbNo ratings yet

- K6V02_BOP_M2_A-IADocument19 pagesK6V02_BOP_M2_A-IAkeen2seeuNo ratings yet

- Technical OfferDocument10 pagesTechnical OfferNishantNo ratings yet

- Digitally signed wet dust extraction system design reportDocument17 pagesDigitally signed wet dust extraction system design reportmathan_aeNo ratings yet

- Technical Specifications For RAW Mill-KILN BAG HOUSE SectionDocument3 pagesTechnical Specifications For RAW Mill-KILN BAG HOUSE SectionRajmohan KushwahaNo ratings yet

- Surface Tension PMD Tank For On Orbit Fluid TransferDocument18 pagesSurface Tension PMD Tank For On Orbit Fluid TransferSteve SmothNo ratings yet

- Data Sheet For DP Flow Transmitter - JBF Manglore PTA PlantDocument3 pagesData Sheet For DP Flow Transmitter - JBF Manglore PTA Plantmayukhguha1988No ratings yet

- Ore DescriptionDocument5 pagesOre DescriptionAlejandro Bartolo YañezNo ratings yet

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanNo ratings yet

- 9452 SamsungDocument13 pages9452 SamsungEdward José Chacín R.No ratings yet

- Greenesol HPH Safety Valve Data SheetDocument11 pagesGreenesol HPH Safety Valve Data SheetRavi YadavNo ratings yet

- J K PharmaDocument5 pagesJ K PharmaRAMKRUSHNANo ratings yet

- BlowerDocument2 pagesBlowerRohit Jangid100% (1)

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- Measure rectangular duct flow with aerodynamic foilDocument6 pagesMeasure rectangular duct flow with aerodynamic foilvaisakp777No ratings yet

- Tank Calculation PDFDocument3 pagesTank Calculation PDFAlvin SmithNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- HFY-3800-0000-MEC-PD-0005 - 0 - Tanks Hydro Test (Leak Test) Procedure CODE ADocument19 pagesHFY-3800-0000-MEC-PD-0005 - 0 - Tanks Hydro Test (Leak Test) Procedure CODE Aامجد عباس حاجم بريديNo ratings yet

- 5.4.1. Appendix D - Rig Technical SpecificationsDocument126 pages5.4.1. Appendix D - Rig Technical SpecificationsMathias Onosemuode100% (1)

- 1000 Liter Ion Exchange GalleriaDocument5 pages1000 Liter Ion Exchange GalleriaBiswajit SahooNo ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- Calculation-Option-1Document1 pageCalculation-Option-1JOSEPH ESCOBARNo ratings yet

- Orifice Size Calc For Gas PressureDocument2 pagesOrifice Size Calc For Gas PressureHyejune ParkNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDocument26 pagesWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- 15MW Steam Turbine Installation and Operation ManualDocument83 pages15MW Steam Turbine Installation and Operation ManualMohammed MuzzamilNo ratings yet

- Service & Operating Manual: Ii 2 GD CDocument10 pagesService & Operating Manual: Ii 2 GD CRAHMAT ARIFINNo ratings yet

- D-1309 Sizing Calc Sht1Document1 pageD-1309 Sizing Calc Sht1NKNo ratings yet

- API 620 Ammonia Storage Tank Capacities and DesignDocument89 pagesAPI 620 Ammonia Storage Tank Capacities and DesignHamid Mansouri100% (5)

- Page 493 of 635Document30 pagesPage 493 of 635Sugadev SinghNo ratings yet

- Sizing FLO 5WBB 20231104T101703Z003Document6 pagesSizing FLO 5WBB 20231104T101703Z003mkfe2005No ratings yet

- Milling Rate Formate 2019 SDBDocument3 pagesMilling Rate Formate 2019 SDBpraveen kumar sainiNo ratings yet

- Eth - 7000024824 - Hvac BoqDocument28 pagesEth - 7000024824 - Hvac Boqmohammedansin1No ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- MC-001-DS-M-007-140 DS For Water Sump Pump Rev ADocument4 pagesMC-001-DS-M-007-140 DS For Water Sump Pump Rev AHeldiyan RamdhanNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- Technical Specification For Termonorte 93MW DFPPDocument23 pagesTechnical Specification For Termonorte 93MW DFPPandersonNo ratings yet

- Rah 563 Ce Heating Element 35 Non Enamelled 1566626618Document4 pagesRah 563 Ce Heating Element 35 Non Enamelled 1566626618Senthil KumarNo ratings yet

- SGGP Reference No: P0116-TAK-P01-0200-01Document6 pagesSGGP Reference No: P0116-TAK-P01-0200-01Jabel Oil Services Technical DPTNo ratings yet

- Sizing FLO 8X5B 20230620T094030Z030Document2 pagesSizing FLO 8X5B 20230620T094030Z030amilasriNo ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- 01 8768 Fe 61021Document1 page01 8768 Fe 61021mohammadtm90No ratings yet

- TCP Documents CommentedDocument64 pagesTCP Documents CommentedVartika UpretyNo ratings yet

- Part BDocument1,080 pagesPart BgovindharajaluNo ratings yet

- Condensate Storage Tank Design OverviewDocument44 pagesCondensate Storage Tank Design OverviewkpsahuNo ratings yet

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 pagesPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNo ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- KS Pulp Creator Final Quotation Air CompressorDocument4 pagesKS Pulp Creator Final Quotation Air Compressoratul guptaNo ratings yet

- N1 2Document7 pagesN1 2Vik KarNo ratings yet

- General Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)Document6 pagesGeneral Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)dee balkondaNo ratings yet

- m43 Aux. BoilerDocument657 pagesm43 Aux. BoilerPavel PaskarNo ratings yet

- Voith IPC Medium-pressure internal gear pumps technical data sheetDocument20 pagesVoith IPC Medium-pressure internal gear pumps technical data sheetNutrición SaludableNo ratings yet

- Technical Specification for Heavy Duty DampersDocument6 pagesTechnical Specification for Heavy Duty Dampersprth valveNo ratings yet

- TSL Design Basis Report r0Document6 pagesTSL Design Basis Report r0apcd electrothermNo ratings yet

- Data Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Document10 pagesData Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Vinícius Toni MartinsNo ratings yet

- Rig DesginDocument25 pagesRig DesginImam PranadipaNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Fatigue Life of Double Angle Tension MembersDocument10 pagesFatigue Life of Double Angle Tension MembersalbertoxinaNo ratings yet

- Copeland Selection Software PDFDocument2 pagesCopeland Selection Software PDFHonka VoxNo ratings yet

- Wiley, Plasticity of Metals Experiments Models Computation (1999) (3527277285)Document427 pagesWiley, Plasticity of Metals Experiments Models Computation (1999) (3527277285)Mosaad RagabNo ratings yet

- Heat Capacity at Constant PressureDocument5 pagesHeat Capacity at Constant PressureOsama GamalNo ratings yet

- Dehumidification Equipment Advance ASHRAE Journal PDFDocument6 pagesDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloNo ratings yet

- Earthquake Design of Tied-Back Retaining WallDocument15 pagesEarthquake Design of Tied-Back Retaining WallEverson BoyDayz PetersNo ratings yet

- Mnemonic Diagrams For Thermodynamic Systems: James M. PhillipsDocument2 pagesMnemonic Diagrams For Thermodynamic Systems: James M. PhillipsErnita SsntNo ratings yet

- External Static Pressure Calculation: Hvac 3/27 M.M 4 June 2014 MA/CAL/3Document3 pagesExternal Static Pressure Calculation: Hvac 3/27 M.M 4 June 2014 MA/CAL/3Engr.MmosaadNo ratings yet

- Samsung 2019 Product Reference Guide PDFDocument36 pagesSamsung 2019 Product Reference Guide PDFdanielNo ratings yet

- Sand Dgremoval Handling Cleaning PDFDocument28 pagesSand Dgremoval Handling Cleaning PDFTrịnh Đức Hạnh100% (2)

- Shear Strength of Soils ExplainedDocument6 pagesShear Strength of Soils Explainedicemage1991No ratings yet

- TMC To CumecsDocument2 pagesTMC To CumecsNaveen NagisettiNo ratings yet

- CH - 2.1 Gravity DamDocument55 pagesCH - 2.1 Gravity DamzelalemniguseNo ratings yet

- Module 1 AxialCompressorDocument25 pagesModule 1 AxialCompressorPreetam BezbaruaNo ratings yet

- Cracks in Immature ConcreteDocument2 pagesCracks in Immature ConcreterasikamalNo ratings yet

- PhysicsDocument4 pagesPhysicsDexter the DoubledmintNo ratings yet

- AERO 4402 FinalDocument16 pagesAERO 4402 FinalminyounNo ratings yet

- Rheology - Coconut Handbook Chapter 10Document12 pagesRheology - Coconut Handbook Chapter 10kellyNo ratings yet

- Variable Wavespeed Modelling in LiquidsDocument8 pagesVariable Wavespeed Modelling in LiquidsmanojmoryeNo ratings yet

- EM39Document48 pagesEM39jeremypollardNo ratings yet

- Jet Impingement CoolingDocument9 pagesJet Impingement CoolingDanish AbbasNo ratings yet

- Reaction Forces and Equilibrium in LiftsDocument8 pagesReaction Forces and Equilibrium in LiftsDean MillarNo ratings yet

- Design of Face Mounted BracketDocument4 pagesDesign of Face Mounted Bracketvishal tomarNo ratings yet

- Atmospheric Water Generator - ReportDocument38 pagesAtmospheric Water Generator - ReportArif AliNo ratings yet

- Conclusion: Every System Has Advantages and DisadvantagesDocument1 pageConclusion: Every System Has Advantages and DisadvantagesOAV DaikinNo ratings yet

- Design of Crane Girder for TG BayDocument31 pagesDesign of Crane Girder for TG BaygvlanushaNo ratings yet

- From Modern Thermodynamics To How Nature Works 2812 OriginalDocument7 pagesFrom Modern Thermodynamics To How Nature Works 2812 OriginalEdison BittencourtNo ratings yet

- Isentropic ExponentDocument2 pagesIsentropic ExponentAlf OtherspaceNo ratings yet

- 30GXDocument14 pages30GXlijoNo ratings yet

- HSC Physics 1st Year Units 1-3 NotesDocument5 pagesHSC Physics 1st Year Units 1-3 Notesvvn natrajNo ratings yet