Professional Documents

Culture Documents

Mahagenco: Data Sheet For Mechanical and Process Equipments & Accessories of Post-Water Treatment Plant

Uploaded by

keen2seeuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mahagenco: Data Sheet For Mechanical and Process Equipments & Accessories of Post-Water Treatment Plant

Uploaded by

keen2seeuCopyright:

Available Formats

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

SPECIFICATION – M2

APPENDIX-I

DATA SHEET FOR MECHANICAL AND PROCESS

EQUIPMENTS & ACCESSORIES OF POST- WATER TREATMENT PLANT

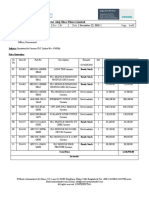

DM PLANT

I) DM Plant shall consist of three (3) chains, each chain of net capacity 100 m3/hr for

meeting the DM water requirement of each unit and one (1) common standby chain.

Net throughput between regeneration for each chain is 1500cu.m.

II) Design Raw water analysis refer Appendix II.

III) Design treated water analysis refer Appendix III.

IV) The Detail specification sheets for equipment is indicated below :

1.0 D.M PLANT FEED PUMPS

i) Number : Three (3) nos. (2 W & 1 SB) one for each chain and

one common standby

ii) Service : To supply filtered water to D.M. Plant.

iii) Duty : Continuous, suitable for parallel operation.

iv) Type : Vertical wet pit centrifugal.

v) Capacity and head : 115 Cu.m/hr (rated), without (-)ve tolerance, TDH

minimum 50 mWC. (To be finalized by bidder,

considering C=120 in Hazen Williams Equation for

calculating pipe friction loss, bidder shall work out

the pump head considering pressure required at DM

plant inlet, frictional drop in piping and static head

involved).

vi) Location : On the filtered water storage tank

vii) Lubrication : Self water lubricated

viii) Rated Speed : 1500 RPM (Maximum)

ix) Range of Operation : From safe minimum flow to 120% of rated capacity

x) Noise Level : 85 dB(A) (at a distance of 1.5 m from the outer

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 1

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

(Pump Motor Set) surface of motor)

xi) Impeller Type : Closed/ Semi-open

xii) Depth of pump sump

invert level from opera-

ting floor level : 4.0 m

xiii) Testing and Inspection :

a) Material Test

required for : Casing, Impeller, Shaft and Shaft sleeve

b) Hydrotest pressure

duration and pro-

cedure : As per IS-5120

c) Dynamic Balancing

Test : Required

d) Performance Test :

o Testing Standard : Hydraulic Institute Standard

o Test to be done : Head-capacity Curve, BHP-

for determining Capacity Curve and Efficiency -

Capacity Curve

o Test to be

Carried out : On all pumps at rated speed

o Testing for : Yes

satisfactory

running of pump

at site required

xiv) Material of Construction

a) Suction Bell & Casing : Cast Iron conforming to IS-210, FG-260

b) Impeller : Bronze as per IS-318 Gr LTB -6

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 2

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

c) Wear rings : Bronze as per IS-318 Gr-LTB-6

d) Shaft : Hardened carbon steel conforming to BS-970, EN-8

or better

e) Shaft sleeve : Stainless Steel AISI-410 (Hardened)

f) Line shaft bearing : Cutless rubber backed by Bronze

g) Column Pipe and : Fabricated Carbon steel as per IS-2062 Gr.A

Delivery Pipe

h) Stuffing box : Cast Iron as per IS-210, FG-260

i) Stuffing box

packing : Graphitized Asbestos

j) Base plate : Fabricated steel as per IS-2062 Gr-A

k) Nuts and Bolts

under wetted

condition : SS-304

xv) Instrument

a) Pressure gauge : Yes, at discharge side of each pump.

b) Pressure switch : Yes, at common pump discharge header for "low &

high" header pressure alarm and interlock for

individual chain.

xvi) Special feature : One low level and one very low level switch shall be

provided with the Filtered Water Storage Tank. The

Bidder shall provide necessary interlock for the

pumps with the level switches as per the flow

diagrams.

While selecting the motor for pump, 15% (minimum)

margin over BkW of pump at rated duty point shall

be taken and standard motor with next higher kW

rating available shall be selected. This shall in no

way be less than maximum power required by pump.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 3

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

2.0 ACTIVATED CARBON FILTERS

I) Type : Vertical, cylindrical with dished ends.

ii) Number of unit : Three (3) nos.

iii) a) Design flow per

unit (Net) : 100 Cu.m/hr.

b) Maximum flow per

unit (Net) under

overloading

condition : 120 Cu.m/hr.

iv) Design surface flow rate : Not more than 15 Cu.m/sq.m/hr.

at maximum flow

v) Fill : Activated carbon dechlorination grade (activated

carbon bed depth not less than 1200 mm).

a) Carbon content : Not less than 90%

b) Moisture content : 5% (maximum)

c) Total surface area : Not less than 850 Sq.m/gm

d) Bulk density : Not less than 400 kg/Cu.m

e) Particle density,

wetted in water : 1.3 - 1.4 gm/c.c.

f) Mean particle length : 2.2 – 2.4 mm

g) Uniformity

co-efficient : 1.9 or less

h) Mean particle

diameter : 0.6 – 0.8 mm

i) Iodine number : Minimum 850

j) Ash : 7% (maximum)

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 4

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

vi) Supporting material : Graded gravel (minimum depth 300 mm)

vii) a) Shell material : Carbon Steel as per IS-2062 Gr-A

b) Dished ends : Boiler quality steel as per IS- 2002 Gr. 1

viii) Internal & External painting : Required as per specification No. M0

ix) Manhole (500 mm dia.) : Two (2) in each vessel (minimum)

x) Handhole (150 mm dia.) : One (1) in each vessel for taking out filter media.

xi) Guaranteed effluent : Turbidity shall be nil. Free residual chlorine content

shall be nil.

xii) Backwash water source : By reversible flow

xiii) Inlet flow rate indicator

a) Type : Rotameter

b) Number : One/Unit

xiv) Pressure gauge

a) Location : Inlet of unit

b) Number : One per unit

xv) Differential pressure

indicator and switch

a) Number : One per unit

b) Location : Across the bed and carbon trap

c) Alarm : On panel, with interlock

xvi) Interconnection of : Outlet of the activated carbon filters shall be

Activated Carbon interconnected with isolation valve so that any of

Filters the carbon filters can be used for any stream.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 5

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

3.0 CATION UNITS

i) Type : Compact layered bed of Strongly acidic & Weakly

acidic cation resin

ii) Number of unit : Three (3) nos.

iii) a) Design flow per

unit (Net) : 100 Cu.m/hr.

b) Maximum flow per

unit (Net) under

overloading

condition : 120 Cu.m/hr.

iv) Total water treated/ : 1500 Cu.m (considering 10% margin on resin

unit between two exchange capacity)

successive regene-

rations (Net) : 1650 Cu.m (guaranteed) (without considering 10%

margin on resin exchange capacity)

v) Design surface flow : Not more than 40 Cu.m/Sq.m/hr.

rate at maximum flow.

vi) Regeneration time : 2 hours/ exchanger

vii) Regeneration interval : 15 hours

viii) a) Shell material : Carbon Steel as per IS-2062 Gr-A

b) Dished ends : Boiler quality steel as per IS- 2002, Gr. 1

ix) Shell lining (internal)

a) Material : Natural rubber

b) Thickness : 4.5 mm in three (3) layers

x) External painting : Required as per Specification No. M0

xi) Manhole (Davit type) : Two (2) in each vessel (minimum)

(500 mm dia.)

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 6

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

xii) Sight windows : Two (2) in each vessel (minimum)

xiii) Handhole (150 mm dia.) : One (1) in each vessel for taking out the

ion-exchange resin.

xiv) Resin Weakly Acidic Cation Strongly Acidic Cation

(WAC) (SAC)

a) Type : Weakly acidic polyacrylic resin Strongly acidic polystyrene

with di-vinyl benzene cross- resin with di-vinyl benzene

linking and with carboxylic cross linking and with sulphonic

acid functional group. acid functional group.

b) Regeneration : Counter current regeneration by 30% HCl (IS-265 -

Technical grade).

c) Resin Transfer System : Hydro-pneumatic resin transfer to Resin transfer

vessel.

d) Special feature : Suitable connections at the top and bottom of each

exchanger for hydro-pneumatic resin transfer.

Connection of respective unit with main resin

transfer line shall be achieved through flexible

reinforced coupling. All exchanger units shall be

provided with necessary valving arrangement for the

removal and charging of resin to and from the resin

transfer vessel.

xv) Flow Indicator

a) Location : Inlet of unit

b) Number : One/Unit

c) Type : Rotameter

xvi) Flow Integrator and Indicator

a) Location and Type : Outlet of unit, integrator electronic type with digital

LED display and manual reset type, indicator

analogue type. (Refer Instrumentation specification).

b) Number : One/Unit

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 7

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

c) Whether panel mounted : Yes, with local flow indication facility.

d) Alarm : On panel, with interlock

e) Transmitter : DP Type

xvii) Pressure Gauge (Diaphragm

Seal Type)

a) Location : Inlet of each unit

b) Number : One/Unit

xviii) Sodium Ion Analyser/ Recorder

a) Sampling point : Outlet of each Cation Exchanger unit

b) Number : One analyser, with analyser output recorder and

automatic stream selection facility.

c) Whether panel mounted : Analyser to be housed in a separate cubicle.

d) Alarm & Indication : At panel with LED digital display facility and interlock

& necessary contacts.

xix) Interconnection of

Cation Exchanger Units : The outlet of Cation Exchanger Units shall be

interconnected with isolation valves so that any

of the exchangers can be used for any stream.

4.0 DEGASSER SYSTEM

i) Degasser Tower

a) Number required : Three (3) nos. (each mounted on individual

degasser sump).

b) Type : Forced draft type

c) Design flow rate

per tower (net) : 100 Cu.m/hr.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 8

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

d) Maximum and minimum

capacity : 120% and 20% of normal capacity

e) Fill material : Polypropylene

f) CO2 content in

effluent : Not more than 5 ppm as CO2

g) External painting : Required as per specification No. M0

h) Shell material : Carbon steel as per IS-2062

i) Rubber lining : Natural rubber - 4.5 mm thick in 3 layers

j) Degasser air : Suitably extended to avoid acid

discharge duct water dripping on nearby buildings and vessels.

ii) Degassed Water Storage

Tank

a) Number required : Three (3) nos.

b) Material : Carbon Steel with rubber lining (natural rubber - 4.5

mm) in 3 layers.

c) Useful capacity : 100 Cu.m (size : 4200 mm dia. x 8000 mm LOS).

of each tank

d) Level indicator : Minimum three/tank, gauge glass (Reflex type) with

overlap.

e) High, low and very

low level switches

per tank : Three for alarm and interlock.

f) Staircase, platform

with handrails : Required

g) Manhole (Davit type) : Two (2) nos. 500 NB size for each tank

iii) Level Indicator-cum-

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 9

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

Controller

a) Type : Level indicator-cum-controller (panel mounted) with

analogue level display facility.

b) Number : One/tank

c) Transmitter : One for each controller, D/P type.

d) Auto-manual facility : Position indication, with set-point, measured value,

Required deviation.

e) Control Valve

1. Number : Two (2) nos. globe type

2. Body : SS-316

3. Plug & stem : SS-316

4. Seat : SS-316

5. Actuator : Pneumatic Diaphragm

iv) Air Blowers

a) Number : Six (6) nos. [two (1 Working & 1 Standby) for each degasser

tower]

b) Type : Centrifugal

c) Duty : Continuous

d) Capacity each : 100% requirement of one tower

e) Material of

Construction : Casing and Impeller - Cast Iron/ Steel.

f) Suction Air Filter : Required for each blower

g) Pressure gauge/

manometer : One per blower with pressure snubber

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 10

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

v) Degasser tower inlet

flow indicator : Required, one/tower

5.0 DEGASSED WATER PUMPS

i) Number : Three (3) nos. (one for each chain)

ii) Service : To supply degassed water to DM water storage tanks

through Anion Exchangers and Mixed Bed Exchangers

iii) Type : Horizontal, centrifugal

iv) Location : Indoor

v) Duty : Continuous, suitable for parallel

operation

vi) Capacity and head : 115 Cu.m/hr (rated) no (-) ve tolerance, TDH 25 mWC. To be

finalized by bidder..(Considering C=120 in Hazen Willams

Equation for calculating pipe friction loss)

vii) Rated speed : 1500 RPM (Maximum)

viii) Permissible tolerance

in rated capacity (%) : As per IS-5120

ix) Permissible tolerance

in efficiency at rated

capacity (%) : As per IS-5120

x) Range of operation : As per IS-5120

xi) Noise Level (Pump motor : 85 dB (A) (at a distance of 1.5 m

set) from the outer surface of motor)

xii) Design Standard : IS-5120

xiii) Impeller type : Closed

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 11

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

xiv) Casing type : End suction top discharge

xv) Testing and Inspection :

a) Material Test : Casing, Impeller, Shaft and

Required for Shaft Sleeve

b) Hydrotest Pressure, : As per IS-5120

duration and pro-

cedure

c) Dynamic Balancing

test : Required

d) Performance Test :

o Testing Standard : Hydraulic Institute Standard

o Test to be done : Head-capacity curve, BHP-

for determining Capacity Curve, Efficiency- Capacity Curve

o Test to be

carried out : All pumps at rated speed

o Testing for : Yes

satisfactory

running of pump

at site required

xvi) Material of construction :

a) Casing, impeller,

stuffing box : SS conforming to AISI-316

b) Shaft and shaft

sleeve : SS-316

c) Wear rings : SS-316

d) Packing seal : Mechanical type

e) Common base plate : Fabricated steel as per IS-2062, epoxy painted

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 12

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

xvii) Special Feature : While selecting the motor for pump, 15% (minimum) margin over

BKW of pump at rated duty point shall be taken and standard

motor with next higher KW rating available shall be selected.

This shall in no way be less than maximum power required by

pump.

xviii) Pressure gauge : One for each pump discharge with diaphragm seal.

xix) Pressure switch : Yes, at pump discharge header for "low" pressure alarm and "high"

pressure alarm and interlock.

6.0 ANION UNITS

i) Type : Compact layered bed of Weakly basic and Strongly basic

anion resin

ii) Number of unit : Three (3) nos.

iii) a) Design flow per : 100 Cu.m/hr

unit (Net)

b) Maximum flow per

unit (Net) under

overloading

condition : 120 Cu.m/hr

c) CO2 content to

be Considered for

design at inlet : 10 PPM as CO2

iv) Total water treated/ : 1500 Cu.m (considering 10% margin on resin exchange capacity)

unit between two

consecutive regenera-

tions (Net)

: 1650 Cu.m (Guaranteed without considering 10% margin on resin

exchange capacity)

v) Design surface flow

rate : Not more than 40 Cu.m/Sq.m/hr.

vi) Regeneration time : 2 hours/ exchanger

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 13

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

vii) Regeneration interval : 15 hours

viii) a) Shell material : Carbon Steel as per IS-2062

b) Dished ends : Carbon Steel As per IS-2002, Gr.1

ix) Shell Lining

a) Material : Natural Rubber

b) Thickness : 4.5 mm in 3 layers

x) External Painting : Required as per specification M0

xi) Manholes (Davit type) : Two (2) in each vessel - (Min.)

(500 mm dia.)

xii) Sight windows : Two (2) in each vessel - (Min.)

xiii) Handhole : One in each vessel for resin removal

(150 mm dia.)

xiv) Resin Weakly Basic Strongly Basic

(WBA) (SBA)

a) Type : High capcity macroporous High capacity polystyrene

polystyrene resin with resin with DBV cross

DBV cross linking with linking with quaternary

tertiary amine functional ammonium functional

group having weak base group

capacity not less than 80%

b) Regeneration : Counter current regeneration by sodium hydroxide (IS-252 - Technical

Grade).

c) Resin Transfer System : Hydro-pneumatic Resin transfer to resin transfer vessel.

d) Special feature : Suitable connection at the top and bottom of each exchanger unit

for hydro-pneumatic resin transfer. Connection of respective unit

with main resin transfer line shall be achieved through flexible

reinforced coupling. All exchanger units shall be provided with

necessary valving arrangement for the removal and charging of

resin to and from the resin transfer vessel.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 14

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

xv) Flow indicator

a) Location : Inlet of Unit

b) Number : One/Unit

c) Type : Rotameter

xvi) Flow Integrator and

Indicator

a) Location and

type : Outlet of unit, integrator electronic type with digital LED display and

manual reset type, indicator analogue type. (Refer instrumentation

specification)

b) Number : One/Unit

c) Whether panel

mounted : Yes, with local flow indication facility.

d) Alarm : Panel mounted, with interlock

e) Transmitter : DP Transmitter type

xvii) Pressure Gauge

(Diaphragm Seal Type)

a) Location : Inlet of unit

b) Number : One/Unit ........

c) Seal : Diaphragm Seal ...

xviii) Conductivity Monitor

complete with cell

a) Sampling point : Service outlet and rinsing line for each unit

b) Number : Two (2)per unit

c) Indicator : Required at panel with LED digital display

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 15

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

d) Alarm & Interlock : Required at panel

e) Local indication : Required with analogue digital display

Standby conductivity monitor with cell shall be provided for each sampling point.

xix) Interconnection of Anion : The outlet of the anion exchanger units shall be

Exchanger Units interconnected with isolation valve so that any

of the anion units can be used for any stream.

7.0 MIXED BED UNITS OF DM PLANT

i) Type : Vertical, cylindrical with dished ends.

ii) Number of unit : Three (3) nos.

iii) a) Design flow per

unit (Net) : 100 Cu.m/hr

b) Maximum flow per

unit (Net) under

overloading

condition : 120 Cu.m/hr.

iv) Total water treated/ : 10,500 Cu.m

unit between two (Considering 10% margin on

consecutive regene- resin exchange capacity)

ration (net)

: 11,550 Cu.m (guaranteed) (without considering 10%

deration on exchange capacity)

v) Design surface flow : Not more than 60 Cu.m/Sq.m/hr.

rate at maximum flow

vi) Regeneration time : 2 hours/ exchanger

vii) Regeneration interval : 105 hours

viii) a) Shell material : Carbon Steel as per IS-2062

b) Dished ends : Carbon Steel as per IS-2002 Gr.1

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 16

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

ix) Internal Lining

a) Material : Natural rubber

b) Thickness : 4.5 mm in three layers

x) External Painting : Required as per Specification M0.

xi) Manhole (Davit Type) : Two (2) per vessel (minimum)

(500 mm dia.)

xii) Sight windows : Three (3) per vessel

xiii) Handhole : One(1) per vessel for resin removal.

(150 mm dia.)

xiv) Resins

a) Type : Strongly acidic cation and strongly basic type-I anion.

b) Regeneration : By HCl & NaOH (Technical Grade)

c) Resin Transfer System : Hydroneumatic Resin transfer to

resin transfer vessel.

d) Special feature : Suitable connections at the top and bottom of each exchanger

unit for hydropneumatic resin transfer. Connection of respective

unit with main resin transfer line shall be achieved through flexible

reinforced coupling. All exchanger units shall be provided with

necessary valving arrangement for the removal and charging of

resin to and from the resin transfer vessel.

xv) Flow Indicator

a) Location : Inlet of unit

b) Number : One/Unit

c) Type : Rotameter

xvi) Flow Integrator and

Indicating Recorder

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 17

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

a) Location and Type : Outlet of unit, integrator electronic type with digital LED display

and manual reset type, recorder continuous analogue type. With

indication (Refer instrumentation specification)

b) Number : One/Unit

c) Whether panel

mounted : Yes, with local flow indication facility.

d) Alarm : Panel mounted, with interlock

xvii) Pressure Gauge

(Diaphragm Seal Type)

a) Location : Inlet and outlet of unit

b) Number : Two/Unit

c) Seal : Diaphragm seal

xviii) Conductivity monitor

complete with cell

a) Sampling : Service Outlet and rinsing line for each unit

b) Number : Two (2) per unit

c) Indication, alarm

and interlock : Required on panel, with LED digital display.

d) Recorders : Required for service line

e) Local indication : Required with analogue digital display

Standby conductivity monitor with cell shall be provided for each sampling point.

xix) Silica Analyser/ Recorder

a) Sampling point : Outlet of each MB unit

b) Number : One analyser, with analyser output recorder and

automatic stream selection facility.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 18

MAHAGENCO

Maharashtra State Power Generation Co. Ltd.,

c) Whether panel mounted : Analyser to be housed in a separate cubicle.

d) Alarm & Indication : At panel with LED digital display facility and interlock & necessary

contacts.

xx) pH Recorder

a) Sampling points : Outlet of each MB unit

b) Number : One per unit with pen recorder along with indication facility.

c) Alarm indication : At panel with high and low pH and recorder alarm along the

interlock with contacts

d) Local indication : Required

Standby pH element shall be provided.

xxi) Air Blowers

a) Number : Three (3), one will run to meet the resin mixing operation and air

agitation in MB unit for each chain, if necessary, for the

neutralising pit, the third one shall remain as common standby.

b) Type : Rotary twin lobe oil free type

c) Duty : Intermittent

d) Capacity and head : As required considering 20% margin over required flow.

e) Pressure gauge : One per blower

f) Location : Indoor

g) Material of : Casing and Impeller - cast construction iron/steel

h) Suction Air Filter, : Required for each blower

Silencer at suction

and Discharge,

Relief Valve, Anti-

vibration Pad, etc.

Bhusawal TPS Expansion Project Volume – II – M2 Page No.

2 x 500 MW, Balance of Plant Package Appendix- I AI - 19

You might also like

- Hyundai SL760Document203 pagesHyundai SL760Anonymous yjK3peI7100% (3)

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- P3 Past Papers Model AnswersDocument211 pagesP3 Past Papers Model AnswersEyad UsamaNo ratings yet

- 10P01 1a e 604 R00 - HCSD - Pump - MotorDocument17 pages10P01 1a e 604 R00 - HCSD - Pump - Motorsuleman247No ratings yet

- Summit HPS BrochureDocument8 pagesSummit HPS BrochureOswaldo ChiaNo ratings yet

- Condensate StorageTank - R0 - 24march 2022Document44 pagesCondensate StorageTank - R0 - 24march 2022kpsahuNo ratings yet

- JUnit 5 User GuideDocument90 pagesJUnit 5 User GuideaawaakNo ratings yet

- Pearson R CorrelationDocument2 pagesPearson R CorrelationAira VillarinNo ratings yet

- 20m3 25m3 50m3 60m3 75m3 Elevated Water Reservoirs BoQDocument232 pages20m3 25m3 50m3 60m3 75m3 Elevated Water Reservoirs BoQKim Ryan Pomar100% (1)

- PVElite Design GuidelinesDocument7 pagesPVElite Design Guidelinesndrarly100% (2)

- 1000HP SpecificationDocument107 pages1000HP SpecificationAl Manar Petroleum100% (1)

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanNo ratings yet

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemNo ratings yet

- Oil Tender Part 3Document40 pagesOil Tender Part 3Dhrubajyoti SonowalNo ratings yet

- 19.auxiliary Trafo GTPDocument11 pages19.auxiliary Trafo GTPAnkit VishwakarmaNo ratings yet

- Hitachi Vehicle CardDocument44 pagesHitachi Vehicle CardKieran RyanNo ratings yet

- Part BDocument1,080 pagesPart BgovindharajaluNo ratings yet

- 05 Process Datasheet Annexure-PDocument1 page05 Process Datasheet Annexure-PpdilgnfcNo ratings yet

- Turbine Efficiency Data Annexure - 3Document10 pagesTurbine Efficiency Data Annexure - 3parthdhar10No ratings yet

- Mahagenco: Maharashtra State Power Generation Co. LTD.Document34 pagesMahagenco: Maharashtra State Power Generation Co. LTD.keen2seeuNo ratings yet

- 33kv sf6 Breaker GTPDocument100 pages33kv sf6 Breaker GTPaaditya singhNo ratings yet

- 100-900mec-1st-Mq-4 80449Document55 pages100-900mec-1st-Mq-4 80449احمد شوقي عمارNo ratings yet

- A) A) B) B) C) C)Document6 pagesA) A) B) B) C) C)kamal kuttyNo ratings yet

- Technical Spec Ification Ac System Sg-Package Part-4Document105 pagesTechnical Spec Ification Ac System Sg-Package Part-4Arul SankaranNo ratings yet

- AmrutDocument46 pagesAmrutJitendraHatwarNo ratings yet

- Sewer Pump Stations and AppurtenancesDocument9 pagesSewer Pump Stations and AppurtenancesMussa ElbarraniNo ratings yet

- 07 Vol III C Mechanical DatasheetDocument12 pages07 Vol III C Mechanical DatasheetDhaval ParmarNo ratings yet

- 1 Technical Spec Ification Ac System SG Package Part 3 1467452730Document104 pages1 Technical Spec Ification Ac System SG Package Part 3 1467452730Ahmed NasserNo ratings yet

- SpecDocument5 pagesSpecsrik11No ratings yet

- Purandhar Report (T)Document74 pagesPurandhar Report (T)saishankarlNo ratings yet

- Employer Requirement - NPS.sampleDocument11 pagesEmployer Requirement - NPS.sampleJurutera Perunding FRM Sdn. Bhd.No ratings yet

- MS9 21 September 2010Document18 pagesMS9 21 September 2010abdullah sahibNo ratings yet

- Format of Pumping MachineryDocument20 pagesFormat of Pumping Machineryshaman chauhanNo ratings yet

- Technical Specification - IDTDocument14 pagesTechnical Specification - IDTgaurav mevadaNo ratings yet

- Tspart Asub Section IVDocument15 pagesTspart Asub Section IVkumar sandeepNo ratings yet

- SL No Parameter Description: Specification Data Sheet For 1000 M /H Pultruded FRP Cooling TowerDocument6 pagesSL No Parameter Description: Specification Data Sheet For 1000 M /H Pultruded FRP Cooling TowerANIMESH JAINNo ratings yet

- 06 Vol III C Mechanical Works SpecificationDocument54 pages06 Vol III C Mechanical Works SpecificationDhaval ParmarNo ratings yet

- Fixed Displacement Bent Axis Motor: Advantages Design FeaturesDocument2 pagesFixed Displacement Bent Axis Motor: Advantages Design FeaturesAdiyatma DjatnikaNo ratings yet

- Scope of Work For EOI and Tech Specs of RigDocument20 pagesScope of Work For EOI and Tech Specs of RigDimple SinghNo ratings yet

- 20 - M - DATA Bajaj High MastDocument2 pages20 - M - DATA Bajaj High Mastrohit1980No ratings yet

- Flygt A-C Series: WCXH Axial Flow PumpsDocument4 pagesFlygt A-C Series: WCXH Axial Flow PumpsKrrishNo ratings yet

- 11kV CT & PTDocument6 pages11kV CT & PTSanjeev RajputNo ratings yet

- Technical Details Mobile High Pressure CompressorDocument8 pagesTechnical Details Mobile High Pressure CompressorpinkNo ratings yet

- Safety Valve's Noise LevelDocument2 pagesSafety Valve's Noise Levelaravind grandhiNo ratings yet

- Technical Specification For Sea Water Booster Pump For ChlorinatorDocument4 pagesTechnical Specification For Sea Water Booster Pump For ChlorinatorzulfikarNo ratings yet

- Chapter-7 Turbine and Governing SpecificationsDocument24 pagesChapter-7 Turbine and Governing Specificationshangmann169No ratings yet

- School of Energy, Geosciences, Infrastructure & Society Institute of Petroleum EngineeringDocument8 pagesSchool of Energy, Geosciences, Infrastructure & Society Institute of Petroleum EngineeringTamkin TamrazliNo ratings yet

- 1000 LPH Water Purifier PlantDocument5 pages1000 LPH Water Purifier Plantsheik FareethNo ratings yet

- File 70516Document6 pagesFile 70516Arturo Valles TerrazasNo ratings yet

- Specification of 11KV MUDocument16 pagesSpecification of 11KV MUPaatala Raagamlo Jeevitha SaagaramNo ratings yet

- Technical System Pumps Specifications of Equipment For Each WWTPDocument13 pagesTechnical System Pumps Specifications of Equipment For Each WWTPBimal DeyNo ratings yet

- Quiz Ecm 3me41Document2 pagesQuiz Ecm 3me41MikNo ratings yet

- Airwasher Boq.Document1 pageAirwasher Boq.Nitesh SinghNo ratings yet

- 0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISDocument36 pages0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISBebilson MansinghNo ratings yet

- Vol 4Document216 pagesVol 4Dharmendra SharmaNo ratings yet

- QuestionnaireDocument2 pagesQuestionnairenmapeshawarNo ratings yet

- BlowerDocument2 pagesBlowerRohit Jangid100% (1)

- 153b PDFDocument15 pages153b PDFSoumya RanjanNo ratings yet

- Technical SpecificationDocument9 pagesTechnical SpecificationDesign JRMSNo ratings yet

- 10.over Head Tanks (F22,23,24)Document41 pages10.over Head Tanks (F22,23,24)M ShahidNo ratings yet

- LTR STS To CCC - C-Scheme CWR PumpsDocument6 pagesLTR STS To CCC - C-Scheme CWR PumpsRajesh GangwalNo ratings yet

- 2UEB000487 v1 Drive On GeneratorDocument19 pages2UEB000487 v1 Drive On GeneratorSherifNo ratings yet

- Section 1: Scope of Work Sheet - 14 of 37: CH 1: Steam GeneratorDocument7 pagesSection 1: Scope of Work Sheet - 14 of 37: CH 1: Steam GeneratorMohammad AdilNo ratings yet

- TCP Documents CommentedDocument64 pagesTCP Documents CommentedVartika UpretyNo ratings yet

- CAPACITOR BANK - Rev 2Document9 pagesCAPACITOR BANK - Rev 2saratNo ratings yet

- Installation of Equipment in The Electric Room (SS-AD)Document8 pagesInstallation of Equipment in The Electric Room (SS-AD)Addin Galih PrakosoNo ratings yet

- MahagencoDocument16 pagesMahagencokeen2seeuNo ratings yet

- Mahagenco: Design Raw Water AnalysisDocument2 pagesMahagenco: Design Raw Water Analysiskeen2seeuNo ratings yet

- Mahagenco: Specification No. M2 Post Water Treatment PlantDocument18 pagesMahagenco: Specification No. M2 Post Water Treatment Plantkeen2seeuNo ratings yet

- K6V02 Bop M6aDocument17 pagesK6V02 Bop M6akeen2seeuNo ratings yet

- Mahagenco: Specification No. M2Document6 pagesMahagenco: Specification No. M2keen2seeuNo ratings yet

- Annexure-II-A MechDocument6 pagesAnnexure-II-A Mechkeen2seeuNo ratings yet

- Coal SamplingDocument14 pagesCoal Samplingkeen2seeuNo ratings yet

- BG For Bid SecurityDocument4 pagesBG For Bid Securitykeen2seeuNo ratings yet

- 123Document3 pages123Phoebe AradoNo ratings yet

- Inverter 2 chiềuDocument2 pagesInverter 2 chiềuKhánh Nguyễn MinhNo ratings yet

- AP8 Q4 Ip9 V.02Document7 pagesAP8 Q4 Ip9 V.02nikka suitadoNo ratings yet

- The University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDocument5 pagesThe University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDavid Adeyinka RamgobinNo ratings yet

- My BaboogDocument1 pageMy BaboogMaral Habeshian VieiraNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- CE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Document6 pagesCE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Angelice Alliah De la CruzNo ratings yet

- English For Academic and Professional Purposes - ExamDocument3 pagesEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoNo ratings yet

- Blackberry: Terms of Use Find Out MoreDocument21 pagesBlackberry: Terms of Use Find Out MoreSonu SarswatNo ratings yet

- Topic One ProcurementDocument35 pagesTopic One ProcurementSaid Sabri KibwanaNo ratings yet

- Banking Ombudsman 58Document4 pagesBanking Ombudsman 58Sahil GauravNo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- Regulasi KampenDocument81 pagesRegulasi KampenIrWaN Dompu100% (2)

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- KK AggarwalDocument412 pagesKK AggarwalEnrico Miguel AquinoNo ratings yet

- Pyramid Type Plate Bending MachineDocument10 pagesPyramid Type Plate Bending MachineAswin JosephNo ratings yet

- MLX90614Document44 pagesMLX90614ehsan1985No ratings yet

- Bridge Over BrahmaputraDocument38 pagesBridge Over BrahmaputraRahul DevNo ratings yet

- Names of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: KindergartenDocument4 pagesNames of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: Kindergartenapi-428128701No ratings yet

- "Tell Me and I Forget, Teach Me and I May Remember, Involve MeDocument1 page"Tell Me and I Forget, Teach Me and I May Remember, Involve MeBesufkad Yalew YihunNo ratings yet

- Plan Lectie Clasa 5 D HaineDocument5 pagesPlan Lectie Clasa 5 D HaineCristina GrapinoiuNo ratings yet

- Diverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesDocument2 pagesDiverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesleonNo ratings yet

- Atomberg Gorilla FanDocument12 pagesAtomberg Gorilla FanjothamNo ratings yet