Professional Documents

Culture Documents

7306 131090

Uploaded by

nextomegagenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7306 131090

Uploaded by

nextomegagenCopyright:

Available Formats

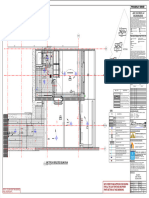

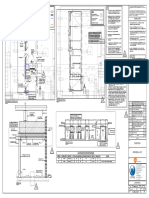

The contractor is responsible for checking dimensions, tolerances and references.

Waterproofing Key Any discrepancy to be verified with the Architect before proceeding with the works.

Where an item is covered by drawings to different scales the larger scale drawing

Note 1: Installation of all gas and hydrocarbon vapour resistant is to be worked to.

membranes to meet BS8485:2015. Manufacturers to confirm.

Manufacturer standard detail package required. Do not scale drawing. Figured dimensions to be worked to in all cases.

All basement waterproofing to be NHBC CH5.4 compliant and is subject

to specialist detailed design by a CSSW accredited waterproofing design

CDM REGULATIONS 2015. All current drawings and specifications for the

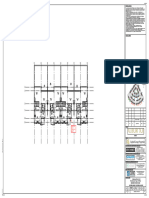

INTERNAL EXTERNAL INTERNAL EXTERNAL INTERNAL EXTERNAL

surveyor. Refer to structural engineer's drawings and specifications for project must be read in conjunction with the Designer's Hazard and Environment

further information. Assessment Record

Note 2: All waterproofing systems above ground described below form

GL All intellectual property rights reserved.

GL the basis of PRP design. Any substitutions should be agreed only once

alternative supplier has given written confirmation that all details and

415 EW 01 415 EW 01 performance criteria can be achieved.

Below ground gas and waterproofing solution to Structural engineer

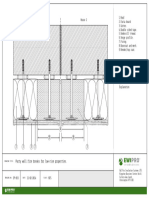

30 100 12 171 103 30 100 12 120 51 103 specification and design to meet RSA report findings and

recommendations.

415 EW 01

WL-In 07

30 100 12 120 DPC-FL 05 Vapour barrier / separating layer min. thickness 0.12mm

(500 gauge). Visqueen Vapour Barrier or similar approved.

Lapped and taped as per manufacturer's instructions.

WL-Ms 01

1-EN-St 26 DPC-FL 01

WL-In 03 WL-Ms 01 LN-W 01 Visqueen Zedex CPT High Performance DPC/DPC Tray.

Stop ends as required by NHBC.

DPC-W 04 WL-Ms 01

DPC-W 04 1-EN-St 26

DPC-W 04 DPC-FL 33 Loose laid DPM membrane. Visqueen High Performance

WL-In 03 DPM or similar approved. Substrate preparation, laps and

LN-W 01

joints to manufacturers details and specification.

LN-W 01

WL-St 03

LN-W 02 LN-W 02

WL-St 03 DPC-W 04 Vapour control layer min. thickness 0.12 mm (500 gauge).

Visqueen Vapour Barrier or similar approved. Lapped and

LN-W 03 LN-W 03 taped as per manufacturer's instructions.

FL-IS 28

DPC-W 02 EPDM fixed/sealed to window/door frame packer and

20

LN-W 17 WL-In 07

150

LN-W 17 bonded to the face of substrate on all 4 sides of window

1-EN-St 26 frames. Installed in accordance with maufacturers details.

Finishes Zone Finishes Zone WL-In 03

1-EN-St 26

36 F07

WL-Pt 02 LN-W 02 DPC-RF 01

18

46 F06

DPC-FL 01 FL-Fn 02 LN-W 03 Two layer bituminous waterproofing membrane. BAUDER

DPC-FL 31 Total Roof or similar.

20

DPC-FL 01

Finishes Zone DPC-RF 03

150

28

36 F07

Structural waterproofing. Bauder Hotmelt or similar over

36

WL-Ms 01 Bauder Polymer Primer.

WL-Mac 06

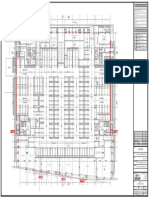

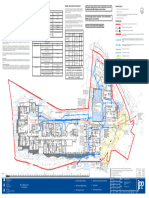

DPC-FL 09 Key Plan

WL-Mac 20 Vapour barrier layer. Part of Bauder warm roof system.

170

1-EN-St 21 GENERAL NOTES

250

250

Typical information subject to installation design & recommendations

1-EN-St 19

including review by all relevant Consultants & Sub-Contractors:

WL-In 07 · Precast RC units at ground floor construction

Keynote Legend

17

· External windows / Doors / Garages / louvre's etc.

· Ventilation duct / pipe requirements, locations & distribution.

15 15

Connection to Key Value Keynote Text · District Heating & other incoming services

Typical Information to propriety Supplier / manufacturer typical

443

Metek details

120

installation details & instructions subject to review as noted above:

1-EN-St 26 1-EN-St 19 Ancon MDC or similar approved masonry support system · Single Ply Roofing

LN-W 17 to Structural Engineer's details. · Roof tiles, including Dry Verge/Ridge details etc.

LN-W 17 WL-In 07 1-EN-St 21 Metek composite slab · Cavity Barriers

WL-In 10 1-EN-St 26 25/14 Ancon Channel fixed to Metsec SFS studs.Tie · Fire Barriers

LN-W 17 specification & spacing to SE details. · Solar Panels

212

LN-C 01 · Render Systems

284 C01

8935 FL-Fn 02 Polypipe Overlay Lite UFHS

· Timber Cladding

LN-W 05 FL-IS 28 Acoustic flanking strip. Yelofon ES5-60 or similar · Insulation Products

214 C03

8860 approved. · Sealants / Mastic & Movement Joint products

LN-C 01 Plasterboard fitted to British Gypsum MF system or equal · Light pipes

LN-W 17 approved · Velux 'Type' roof lights.

Window head LN-W 01 Plasterboard lining with skim coat. Refer to Principal · Roof cowls

787.5 Constructions

LN-W 02 MDF Skirting, size & profile as ERs The above items noted are not exhaustive & may include other products &

WL-Mac 16 systems

LN-W 03 Flexible sealant set behind skirting at base of

plasterboard where applicable

LN-W 05 Gyproc sealant to maintain acoustic performance and air KEY DRAWING REFERENCES

LN-W 17 tightness.

LN-C 01 LN-W 17 Intumescent acoustic sealant. Rockwool Firepro or Title of Drawing Series Drawing Series No's

LN-W 05 similar. To maintain fire rating of the lining Plot Location Plan 3050

WL-In 03 Mineral wool insulation. Rockwool Flexi or similar Gridline Setting-Out 3010

LN-W 05 LN-W 01 approved. Building Co-Ordinates 3015

Str Setting-Out 4000

LN-W 01 WL-In 07 Kingspan TW55 insulation. Thickness as required U GA Plans 4100

DPC-W 04 Value. Joints and exposed edges taped and sealed as per Elevations 4200

415 EW01 manufacturers recomendations. Cores 4400

WL-In 10 Mineral wool batt. Rockwool Cavity Batt or similar. Dwelling Plans 4500

WL-Mac 06 Weep hole in brickwork @ 450mm c/c, minimum 2 per Strategies 5000

opening (proprietary type with insect mesh/limited hole External Wall Types 6000

sizes as per NHBC requirements). Internal Wall Types 6020

Floor Types 6030

WL-Mac 16 Proprietary brick slip soffit system, Ancon Nexus or similar

Roof Types 6040

approved. Support frame to Structural Engineer's details.

Detail Studies 6100

WL-Mac 20 Cavity barrier. Rockwool SP120 or similar approved.Fitted Sub-structure Details 6200

to manufacturers specification. Opening Details 6300

WL-Ms 01 103mm facing brickwork above dpc laid stretcher bond in Envelope Details 6400

1:1:6 cement:lime:sand mortar - refer to elevations for Roof Details 6500

type Internal Wall Details 6600

WL-Pt 02 18mm WBP exterior grade plywood plate Door & Window Types 7000

Internal Doors 7050

Typical Slab Edge at Separating Floor (Metek Composite Slab) Typical Slab Edge Non Compartment Floor (Metek Joist) Slab Edge with Brick Support (Metek Joist) WL-St 03 12mm cement particle sheathing board. Joints taped and

1 1:5 2 1:5 3 1 : 10

sealed to comply with NHBC requirements. Alternatively

use full length breather membrane.

Bathroom Types

Timber Stairs

8000

8100

MATERIAL REFERENCES

Brickwork

EW 01a Facing Brick - Mirato Mixture (Light)

EW 01b Facing Brick - Cinder Coal (Dark)

All details to be compliant with Acredited Construction Details for Part L

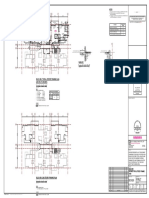

INCOMING SERVICES THROUGH METEK

Where horizontal service runs penertate Metek party wall the apeture is to

be set out from the door S/O as indicated below:

Underside of

250mm from Metek Concrete

Incoming Service

U.S of Metek Deck

'Letterbox'

Concrete

Deck

To match door S/O CONCRETE

Door S/O

Underside of Fire

250mm from Lining on Metek

Incoming Service

U.S of Lining Joists

'Letterbox'

on Metek

Joists

To match door S/O

JOISTED

Door S/O

Please refer to DRG. AA6546-6670 'Fire Stopping Details'

D 10.04.2018 Brick Soffit Updated SG SG

C 05.03.2018 Construction Issue BE SG

B 01.12.2017 General amendments. TK SG

A 13.10.2017 Issued for Brickwork / Blockwork Tender Package TK SG

- 15.09.2017 First Issue TK SG

Rev Date Description Dwn Ckd

Chobham Farm Zone 2

2C-Vertical Envelope Details Sh1

AA6546-6405 REV D

CONSTRUCTION

Drawn Author Checked Checker Date 09/01/17 Scale @ A1 As

indicated

prp-co.uk

London

020 7653 1200

You might also like

- Reinforced Walls Design ManualDocument17 pagesReinforced Walls Design ManualNANA ADDONo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- SVC Specifications For Civil WorksDocument33 pagesSVC Specifications For Civil WorksFarooq BhuttaNo ratings yet

- 2022-09-01 5F MAIN OFFICE - STEPS FOR MEZZANINE - CommentsDocument2 pages2022-09-01 5F MAIN OFFICE - STEPS FOR MEZZANINE - CommentsParamanathan SubramaniamNo ratings yet

- Floor Plan and Roof PlanDocument1 pageFloor Plan and Roof PlanAnotida Tuna ManganyeNo ratings yet

- Qa QC PlanDocument20 pagesQa QC PlanfelipeNo ratings yet

- Structural DrawingsDocument1 pageStructural DrawingserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- TSC TQL Cfe BTB 001Document1 pageTSC TQL Cfe BTB 001Abigail De VeraNo ratings yet

- Reaffirmed 2004Document11 pagesReaffirmed 2004krixotNo ratings yet

- Timboon Housing Estate PlansDocument17 pagesTimboon Housing Estate PlansKyra GillespieNo ratings yet

- Church PresDocument69 pagesChurch Presfelix sowah-laryeaNo ratings yet

- AP20.CAP02.2.4 WS 4PL 100 101 Layout1Document1 pageAP20.CAP02.2.4 WS 4PL 100 101 Layout1m.elleithyNo ratings yet

- CCDC NTL Ar Una1 RCP 01Document1 pageCCDC NTL Ar Una1 RCP 01ericka.mir401No ratings yet

- Manhole Type B and Inspection ChamberDocument1 pageManhole Type B and Inspection ChamberComofco GibraltarNo ratings yet

- Building Jali Detail-Layout1Document1 pageBuilding Jali Detail-Layout1SUMIT SHARMA100% (1)

- Warehouse DrawingsDocument6 pagesWarehouse DrawingsnokoNo ratings yet

- First FloorDocument1 pageFirst FloorNurul SyahirahNo ratings yet

- Gambar Concrete PoleDocument1 pageGambar Concrete PolerifkynetNo ratings yet

- Gambar Concrete Pole PDFDocument1 pageGambar Concrete Pole PDFrifkynetNo ratings yet

- 2020-11-15 RFI 13 Switch Socket Installation Details (3) Dated 14-12-2020Document4 pages2020-11-15 RFI 13 Switch Socket Installation Details (3) Dated 14-12-2020zafrikhan875No ratings yet

- AVK Check-Valves BrochureDocument32 pagesAVK Check-Valves BrochureHadi SofyanNo ratings yet

- Atk GLW XX DR Ew 000007Document1 pageAtk GLW XX DR Ew 000007BEN BENNo ratings yet

- Royale Option 3Document1 pageRoyale Option 3Edmore MukotsanjeraNo ratings yet

- Structural Drawings 10 Kenny CT - 20240308 StructureDocument5 pagesStructural Drawings 10 Kenny CT - 20240308 StructuretigzzlopesNo ratings yet

- Specs 1Document1 pageSpecs 1mohammedpetiwalaNo ratings yet

- QC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Document1 pageQC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Moosa RizwanNo ratings yet

- 17 1197 Column LayoutDocument1 page17 1197 Column LayoutKeise AliNo ratings yet

- BA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesDocument1 pageBA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesAditya HegdeNo ratings yet

- Submission: Block B8 - Typical Storey Framing Plan (3Rd To 5Th Storey)Document1 pageSubmission: Block B8 - Typical Storey Framing Plan (3Rd To 5Th Storey)fade2black11No ratings yet

- 3RD Storey Wall Layout Part CDocument1 page3RD Storey Wall Layout Part CDhrubajyoti BordoloiNo ratings yet

- GC ST 09 RevisedDocument1 pageGC ST 09 Revisedmhazarath murariNo ratings yet

- King Khalid International Airport Kkia: SubmittalsDocument49 pagesKing Khalid International Airport Kkia: SubmittalsDILSHAD AHEMADNo ratings yet

- Uci Mce Stru D S-20.6Document1 pageUci Mce Stru D S-20.6Thanh Đạt NguyễnNo ratings yet

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G77-501P6 - Drainage LayoutDocument1 page9946Z - 0657-SP-SL-PL-C-G77-501P6 - Drainage Layoutjmdavies.isNo ratings yet

- 1.2 Method of Statement For Ducting WorksDocument5 pages1.2 Method of Statement For Ducting WorksburakNo ratings yet

- Structural GilbaneDocument11 pagesStructural Gilbanejh50000No ratings yet

- KIL2189 - 200 - 0001 - REV08 - Proposed LayoutDocument1 pageKIL2189 - 200 - 0001 - REV08 - Proposed LayoutNiemNo ratings yet

- Exist/ New Asphalt Road & Rig Road Crossing Details Table-1Document1 pageExist/ New Asphalt Road & Rig Road Crossing Details Table-1Er Md AamirNo ratings yet

- Dimmer System Control SchematicDocument2 pagesDimmer System Control SchematicCheah ChenNo ratings yet

- Contract CheckListDocument2 pagesContract CheckListFatmah El WardagyNo ratings yet

- FS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- A B C D E F G: Ground Floor PlanDocument1 pageA B C D E F G: Ground Floor PlanNPCC MawsynramNo ratings yet

- Laxcon Developments: Cardiff 029 2052 8140 London 0207 138 3560 Wrexham 01978 357 887 WWW - Lawray.co - UkDocument1 pageLaxcon Developments: Cardiff 029 2052 8140 London 0207 138 3560 Wrexham 01978 357 887 WWW - Lawray.co - Ukrajen raghwaniNo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- EVPD - Full - Exposed Floors - KingpsanDocument1 pageEVPD - Full - Exposed Floors - Kingpsandeboline mitraNo ratings yet

- 05 First FloorDocument1 page05 First FloorAbu Baker DajahNo ratings yet

- Floor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining LobbyDocument1 pageFloor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining Lobbyamadi4bizNo ratings yet

- Concrete Paving Airfield PosterDocument1 pageConcrete Paving Airfield PosterdavidhmoloneyNo ratings yet

- Gerald NM BLACKDocument1 pageGerald NM BLACKgeraldnguma8No ratings yet

- Combivert: Instruction ManualDocument36 pagesCombivert: Instruction Manualruisengo100% (1)

- Van Eden House Plan - Catchment AreaDocument1 pageVan Eden House Plan - Catchment Areadalubuhlencube12345No ratings yet

- G B F E D: 2Nd Flr. Water Line LaytoutDocument1 pageG B F E D: 2Nd Flr. Water Line LaytoutDavie MolateNo ratings yet

- St-Nerf-20 Basement Floor PlanDocument1 pageSt-Nerf-20 Basement Floor Planmhazarath murariNo ratings yet

- Parent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTDocument9 pagesParent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTmoneyphotocopyshopNo ratings yet

- Vivekanand Education Society's College of Architecture: NotesDocument1 pageVivekanand Education Society's College of Architecture: NotesKalpak SurveNo ratings yet

- Is 4241-1990 (R.a. 2020)Document6 pagesIs 4241-1990 (R.a. 2020)HARIOM INSTRU-LABSNo ratings yet

- Autos PoolDocument8 pagesAutos PoolPARASCADD Private LimitedNo ratings yet

- BRICK Book7Document167 pagesBRICK Book7nextomegagenNo ratings yet

- BRICK Book1Document73 pagesBRICK Book1nextomegagenNo ratings yet

- Vehicle Tracking GuidelineDocument32 pagesVehicle Tracking GuidelinenextomegagenNo ratings yet

- 25 - 24 06 14 - A5 Guide 05 14 WebDocument104 pages25 - 24 06 14 - A5 Guide 05 14 WebnextomegagenNo ratings yet

- Constructive Details Handbook Full FillDocument57 pagesConstructive Details Handbook Full Fillnico Dela RamaNo ratings yet

- External Product Information - Ggu Integra ElectricDocument9 pagesExternal Product Information - Ggu Integra ElectricnextomegagenNo ratings yet

- MVL - Planning Vs B.Regs - 1Document4 pagesMVL - Planning Vs B.Regs - 1nextomegagenNo ratings yet

- Guide Kingframe SFSDocument100 pagesGuide Kingframe SFSCommercial MarocNo ratings yet

- 2015 05891 Nmat-Typical Bay Study-1584101Document1 page2015 05891 Nmat-Typical Bay Study-1584101nextomegagenNo ratings yet

- 11 Extending Window Sill With Under Sill ProfileDocument1 page11 Extending Window Sill With Under Sill ProfilenextomegagenNo ratings yet

- 33 Party Wall Fire Breaks For Low Reise PropertiesDocument1 page33 Party Wall Fire Breaks For Low Reise PropertiesnextomegagenNo ratings yet

- Parking Standards - Annex B - Cycle Parking Design Details - Planning PortalDocument4 pagesParking Standards - Annex B - Cycle Parking Design Details - Planning PortalnextomegagenNo ratings yet

- UK MKT DOC The Brick Book 13th EditionDocument144 pagesUK MKT DOC The Brick Book 13th EditionPragati SinghalNo ratings yet

- Prediction of Adhesion and Wetting From Lewis Acid Base MeasurementsDocument6 pagesPrediction of Adhesion and Wetting From Lewis Acid Base MeasurementsGabriel MendivilNo ratings yet

- 1492Document15 pages1492_Anggyaa_No ratings yet

- Rapid StrataDocument2 pagesRapid StrataHansonNo ratings yet

- Design of Gabion Retaining Structure As PDFDocument22 pagesDesign of Gabion Retaining Structure As PDFAHSANNo ratings yet

- B 3Document5 pagesB 3manuel floresNo ratings yet

- Autoclave CatalogueDocument12 pagesAutoclave CataloguecristianoclemNo ratings yet

- Hvac Brochure - FinalDocument9 pagesHvac Brochure - FinalAmrut Prasade100% (1)

- Moeez Raza ReportDocument6 pagesMoeez Raza ReportMoeez RazaNo ratings yet

- CH 02Document25 pagesCH 02chaitanyacheggNo ratings yet

- Sama Wira Mulpha IndustiresDocument24 pagesSama Wira Mulpha Industireslbhock123No ratings yet

- Lakhmir Singh Manjit Kaur Class 7 Science 14th Chapter Electric Current and Its Effects SolutionsDocument4 pagesLakhmir Singh Manjit Kaur Class 7 Science 14th Chapter Electric Current and Its Effects SolutionsShaurya Maniktala0% (1)

- Review of The Application of Design Guideline Vdi 2230: Using Sr1 For PcsDocument16 pagesReview of The Application of Design Guideline Vdi 2230: Using Sr1 For PcsCunha Projetos de Cilindros HidráulicosNo ratings yet

- The Loads Acting On BridgesDocument21 pagesThe Loads Acting On BridgesdabalaNo ratings yet

- Double Glazing ManualDocument19 pagesDouble Glazing ManualullwnNo ratings yet

- 18 Quick Release Coupler Mod 5051Document6 pages18 Quick Release Coupler Mod 5051mmkattaNo ratings yet

- Ch-3 Compatibility ModeDocument143 pagesCh-3 Compatibility Modedreamgurl9011No ratings yet

- Robertshaw - Electrical ThermostatsDocument3 pagesRobertshaw - Electrical ThermostatsKhairul MuzafarNo ratings yet

- Building Techniques - WoodDocument86 pagesBuilding Techniques - WoodShaira Jane De MesaNo ratings yet

- 4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDocument1 page4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFHeri Fadli SinagaNo ratings yet

- Section Properties: Properties of Tata Structura (Rectangular Hollow Sections) YST 310 GradeDocument2 pagesSection Properties: Properties of Tata Structura (Rectangular Hollow Sections) YST 310 GradeSudipta Sarkar100% (1)

- InRoom Tech Data 31010 ApcDocument92 pagesInRoom Tech Data 31010 ApcRolandoNo ratings yet

- Brinell Hardness ReportDocument3 pagesBrinell Hardness Reportjaibalayya100% (1)

- WBS-Commercial Construction ProjectDocument2 pagesWBS-Commercial Construction ProjectM iqbalNo ratings yet

- Concrete Coating of Line Pipe PDFDocument19 pagesConcrete Coating of Line Pipe PDFZadeh Norman100% (1)

- Doors and Windows Details PDFDocument1 pageDoors and Windows Details PDFMark Anthony Capito AñosNo ratings yet

- PTT Price List PDFDocument3 pagesPTT Price List PDFMin Khant HtetNo ratings yet

- Foundation DesignDocument12 pagesFoundation DesignLuis AparcanaNo ratings yet

- Casting Brochure 1 PDFDocument12 pagesCasting Brochure 1 PDFAkshayNo ratings yet

- Lecture 1 Nano Macro BuehlerDocument66 pagesLecture 1 Nano Macro BuehlerVarun RavikumarNo ratings yet

- Bueco Clean Room AHUDocument26 pagesBueco Clean Room AHUHENRY100% (1)