Professional Documents

Culture Documents

Drilling Rig Components

Drilling Rig Components

Uploaded by

Dr.Amir Sadeghi0 ratings0% found this document useful (0 votes)

7 views62 pagesThis document lists and defines various components that make up an oil and gas drilling rig. Some of the key components described include the crown block and traveling block which guide the drilling line, the mast which supports the derrick, drill pipe which rotates the drill bit, blowout preventers which control well pressures, mud pumps which circulate drilling fluid, shale shakers which separate cuttings from the fluid, and the drawworks which hoist and lower the drill string. In total, 52 different parts that make up the full drilling rig are defined.

Original Description:

Drilling-Rig-Components locked

Original Title

Drilling-Rig-Components

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document lists and defines various components that make up an oil and gas drilling rig. Some of the key components described include the crown block and traveling block which guide the drilling line, the mast which supports the derrick, drill pipe which rotates the drill bit, blowout preventers which control well pressures, mud pumps which circulate drilling fluid, shale shakers which separate cuttings from the fluid, and the drawworks which hoist and lower the drill string. In total, 52 different parts that make up the full drilling rig are defined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views62 pagesDrilling Rig Components

Drilling Rig Components

Uploaded by

Dr.Amir SadeghiThis document lists and defines various components that make up an oil and gas drilling rig. Some of the key components described include the crown block and traveling block which guide the drilling line, the mast which supports the derrick, drill pipe which rotates the drill bit, blowout preventers which control well pressures, mud pumps which circulate drilling fluid, shale shakers which separate cuttings from the fluid, and the drawworks which hoist and lower the drill string. In total, 52 different parts that make up the full drilling rig are defined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 62

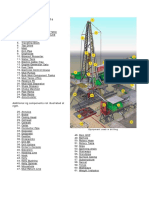

1.

Crown Block and Water Table

2. Catline Boom and Hoist Line

3. Drilling Line

4. Monkeyboard

5. Traveling Block

6. Top Drive

7. Mast

8. Drill Pipe

9. Doghouse

10. Blowout Preventer

11. Water Tank

12. Electric Cable Tray

13. Engine Generator Sets

14. Fuel Tank

15. Electrical Control House

16. Mud Pumps

17. Bulk Mud Component Tanks

18. Mud Tanks (Pits)

19. Reserve Pit

20. Mud-Gas Separator

21. Shale Shakers

22. Choke Manifold

23. Pipe Ramp

24. Pipe Racks

25. Accumulator

1- Crown Block and Water Table

An assembly of sheaves or pulleys mounted on

beams at the top of the derrick. The drilling line

is run over the sheaves down to the hoisting

drum.

2- Catline Boom and Hoist Line

A structural framework erected near the top of

the derrick for lifting material.

3- Drilling Line

A wire rope hoisting line, reeved on sheaves of

the crown block and traveling block (in effect a

block and tackle). Its primary purpose is to hoist

or lower drill pipe or casing from or into a well.

Also, a wire rope used to support the drilling

tools.

4- Monkeyboard

The derrickman's working platform. Double

board, tribble board, fourable board; a monkey

board located at a height in the derrick or mast

equal to two, three, or four lengths of pipe

respectively.

5- Traveling Block

An arrangement of pulleys or sheaves through

which drilling cable is reeved, which moves up or

down in the derrick or mast.

6- Top Drive

The top drive rotates the drill string end bit

without the use of a kelly and rotary table. The

top drive is operated from a control console on

the rig floor

7- Mast

A portable derrick capable of being erected as a

unit, as distinguished from a standard derrick,

which cannot be raised to a working position as a

unit.

8- Drill Pipe

The heavy seamless tubing used to rotate the bit

and circulate the drilling fluid. Joints of pipe 30

feet long are coupled together with tool joints.

9- Doghouse

A small enclosure on the rig floor used as an

office for the driller or as a storehouse for small

objects. Also, any small building used as an

office or for storage.

10- Blowout Preventer

A large valve, usually installed above the ram

preventers, that forms a seal in the annular

space between the pipe and well bore or, if no

pipe is present, on the well bore itself

11- Water Tank

Is used to store water that is used for mud mixing,

cementing, and rig cleaning.

12- Electric Cable Tray

Supports the heavy electrical cables that feed the power

from the control panel to the rig motors

13- Engine Generator Sets

A diesel, Liquefied Petroleum Gas (LPG), natural gas,

or gasoline engine, along with a mechanical

transmission and generator for producing power for the

drilling rig. Newer rigs use electric generators to power

electric motors on the other parts of the rig.

14- Fuel Tanks

Fuel storage tanks for the power generating system.

15- Electric House

On diesel electric rigs, powerful diesel engines drive

large electric generators. The generators produce

electricity that flows through cables to electric switches

and control equipment enclosed in a control cabinet or

panel. Electricity is fed to electric motors via the panel.

16- Mud Pump

A large reciprocating pump used to circulate the mud

(drilling fluid) on a drilling rig.

17- Bulk Mud Components in Storage

Hopper type tanks for storage of drilling fluid

components.

18- Mud Pits

A series of open tanks, usually made of steel plates,

through which the drilling mud is cycled to allow sand

and sediments to settle out. Additives are mixed with the

mud in the pit, and the fluid is temporarily stored there

before being pumped back into the well. Mud pit

compartments are also called shaker pits, settling pits,

and suction pits, depending on their main purpose.

19- Reserve Pits

A mud pit in which a supply of drilling fluid has

been stored. Also, a waste pit, usually an

excavated, earthen-walled pit. It may be lined

with plastic to prevent soil contamination.

20- Mud Gas Separator

A device that removes gas from the mud coming

out of a well when a kick is being circulated out.

21- Shale Shaker

A series of trays with sieves or screens that vibrate to

remove cuttings from circulating fluid in rotary drilling

operations. The size of the openings in the sieve is

selected to match the size of the solids in the drilling

fluid and the anticipated size of cuttings. Also called a

shaker.

22- Choke Manifold

The arrangement of piping and special valves,

called chokes, through which drilling mud is

circulated when the blowout preventers are

closed to control the pressures encountered

during a kick.

23- Pipe Ramp

An angled ramp for dragging drill pipe up to the

drilling platform or bringing pipe down off the

drill platform.

24- Pipe Racks

A horizontal support for tubular goods.

25- Accumulator

The storage device for nitrogen pressurized

hydraulic fluid, which is used in operating the

blowout preventers.

26- Annulus

The space around a pipe in a well bore, the outer

wall of which may be the wall of either the bore

hole or the casing; sometimes termed the

annular space.

27- Brake

The braking device on the drawworks to stop a

load being lifted.

28- Casing Head

A heavy, flanged steel fitting connected to the

first string of casing. It provides a housing for

slips and packing assemblies, allows suspension

of intermediate and production strings of casing,

and supplies the means for the annulus to be

sealed off. Also called a spool.

29- Cathead

A spool-shaped attachment on a winch around

which rope for hoisting and pulling is wound.

30- Catwalk

The ramp at the side of the drilling rig where

pipe is laid to be lifted to the derrick floor by the

catline or by an air hoist.

31-Cellar

A pit in the ground to provide additional height

between the rig floor and the well head to

accommodate the installation of blowout

preventers, ratholes, mouseholes, and so forth.

It also collects drainage water and other fluids

for disposal.

32- Conductor Pipe

The largest diameter casing and the topmost

length of casing. It is relatively short and

encases the topmost string of casing.

33- Degasser

The equipment used to remove unwanted gas

from a liquid, especially from drilling fluid.

34- Desander

A centrifugal device for removing sand from

drilling fluid to prevent abrasion of the pumps. It

may be operated mechanically or by a fast-

moving stream of fluid inside a special cone-

shaped vessel, in which case it is sometimes

called a hydrocyclone.

35- Desilter

A centrifugal device, similar to a desander, used

to remove very fine particles, or silt, from drilling

fluid. This keeps the amount of solids in the fluid

to the lowest possible level.

36- Drawworks

The hoisting mechanism on a drilling rig. It is

essentially a large winch that spools off or takes

in the drilling line and thus raises or lowers the

drill stem and bit

37- Drill Bit

The cutting or boring element used in drilling oil

and gas wells. Most bits used in rotary drilling

are roller-cone bits. The bit consists of the

cutting elements and the circulating element.

The circulating element permits the passage of

drilling fluid and uses the hydraulic force of the

fluid stream to improve drilling rates.

38- Drill Collar

A heavy, thick-walled tube, usually steel, used

between the drill pipe and the bit in the drill

stem. It is used to put weight on the bit so that

the bit can drill.

39- Drillers Console

The control panel, located on the platform,

where the driller controls drilling operations.

40- Elevators

A set of clamps that grips a stand, or column, of

casing, tubing, drill pipe, or sucker rods, so the

stand can be raised or lowered into the hole.

41- Hoisting Line

A wire rope used in hoisting operations. Must

conform to the API standards for its intended

uses.

42- Hook

A large, hook-shaped device from which the

elevator bails or the swivel is suspended. It is

designed to carry maximum loads ranging from

100 to 650 tons and turns on bearings in its

supporting housing.

43- Kelly

The heavy square or hexagonal steel member

suspended from the swivel through the rotary

table. It is connected to the topmost joint of drill

pipe to turn the drill stem as the rotary table

turns.

44- Kelly Bushing

A device fitted to the rotary table through which

the kelly passes. It is the means by which the

torque of the rotary table is transmitted to the

kelly and to the drill stem. Also called the drive

bushing.

45- Kelly Spinner

A device for spinning the drill pipe. Replaces the

spinning chain.

46- Mousehole

Shallow bores under the rig floor, usually lined

with pipe, in which joints of drill pipe are

temporarily suspended for later connection to

the drill string.

47- Mud Return Line

A trough or pipe, placed between the surface

connections at the well bore and the shale

shaker. Drilling mud flows through it upon its

return to the surface from the hole.

48- Ram Blowout Preventer

A blowout preventer that uses rams to seal off

pressure on a hole that is with or without pipe. It

is also called a ram preventer. Ram-type

preventers have interchangeable ram blocks to

accommodate different O.D. drill pipe, casing, or

tubing.

49- Rathole

A hole in the rig floor 30 to 35 feet deep, lined

with casing that projects above the floor. The

kelly is placed in the rathole when hoisting

operations are in progress.

50- Rotary Hose

The hose on a rotary drilling rig that conducts

the drilling fluid from the mud pump and

standpipe to the swivel and kelly; also called the

mud hose or the kelly hose.

51- Rotary Table

The principal component of a rotary, or rotary

machine, used to turn the drill stem and support

the drilling assembly. It has a beveled gear

arrangement to create the rotational motion and

an opening into which bushings are fitted to

drive and support the drilling assembly.

Note the pipe spinner (in red) on the side of the

swivel.

52- Slips

Wedge-shaped pieces of metal with teeth or

other gripping elements that are used to prevent

pipe from slipping down into the hole or to hold

pipe in place. Rotary slips fit around the drill pipe

and wedge against the master bushing to

support the pipe. Power slips are pneumatically

or hydraulically actuated devices that allow the

crew to dispense with the manual handling of

slips when making a connection. Packers and

other down hole equipment are secured in

position by slips that engage the pipe by action

directed at the surface.

53- Spinning Chain

A relatively short length of chain attached to the tong

pull chain on the manual tongs used to make up drill

pipe. The spinning chain is attached to the pull chain so

that a crew member can wrap the spinning chain

several times around the tool joint box of a joint of drill

pipe suspended in the rotary table. After crew members

stab the pin of another tool joint into the box end, one

of them then grasps the end of the spinning chain and

with a rapid upward motion of the wrist "throws the

spinning chain"—that is, causes it to unwrap from the

box and coil upward onto the body of the joint stabbed

into the box. The driller then actuates the makeup

cathead to pull the chain off of the pipe body, which

causes the pipe to spin and thus the pin threads to spin

into the box.

54- Stairways

Stairs leading from one level to another.

Protected with handrails.

55- Standpipe

A vertical pipe rising along the side of the derrick

or mast. It joins the discharge line leading from

the mud pump to the rotary hose and through

which mud is pumped going into the hole.

56- Surface Casing

Usually the first casing to be run in a well. This is

done after spudding-in so a blowout preventer

can be installed before drilling is started.

57- Substructure

The foundation on which the derrick or mast and

usually the drawworks sit; contains space for

storage and well control equipment.

58- Swivel

A rotary tool that is hung from the rotary hook

and traveling block to suspend and permit free

rotation of the drill stem. It also provides a

connection for the rotary hose and a passageway

for the flow of drilling fluid into the drill stem.

59- Tongs

The large wrenches used for turning when

making up or breaking out drill pipe, casing,

tubing, or other pipe; variously called casing

tongs, rotary tongs, and so forth according to

the specific use. Power tongs are pneumatically

or hydraulically operated tools that spin the pipe

up and, in some instances, apply the final

makeup torque.

60- Walkways

An area cleared for moving through by personnel

and protected with a handrail.

61- Weight Indicator

A device for measuring the weight of the drill

string. Monthly calibration to calculated drill

string weight is required by API.

You might also like

- Completions Company. Baker Oil ToolsDocument32 pagesCompletions Company. Baker Oil ToolsHamid Reza BabaeiNo ratings yet

- Crane SafetyDocument166 pagesCrane Safetymordidomi100% (2)

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Rig ComponentsDocument114 pagesRig ComponentskumoziNo ratings yet

- Jaybee Energy Pvt. LTD Presentation-23 July OIl India PresentationDocument62 pagesJaybee Energy Pvt. LTD Presentation-23 July OIl India PresentationMadhuryya BhuyanNo ratings yet

- Checklist of Mast and SubstructureDocument8 pagesChecklist of Mast and SubstructureKachur Aleksey100% (1)

- AC-0049 Well Design RulesDocument5 pagesAC-0049 Well Design RulesairlinemembershipNo ratings yet

- QC 006 Rig Inspection WorkshopDocument132 pagesQC 006 Rig Inspection WorkshopYacine Flyacinegazza100% (2)

- Lecture #2 Pee3321 Rig Systems Wellbore Elements and VolumesDocument25 pagesLecture #2 Pee3321 Rig Systems Wellbore Elements and Volumesحيدر بادي - Haider Badi100% (1)

- Lecture2 Hoisting SystemDocument26 pagesLecture2 Hoisting SystemART BAJALAN100% (3)

- ZaneGrey Well Completion Report - Basic Data Rev B GovDocument1,018 pagesZaneGrey Well Completion Report - Basic Data Rev B GovHtetAungMoeNo ratings yet

- Rig Components 101Document90 pagesRig Components 101irrosel4650100% (1)

- L2-Well CirculationDocument33 pagesL2-Well CirculationManish SoniNo ratings yet

- TDS1000AInstallationManual 03May28AbridgedDocument20 pagesTDS1000AInstallationManual 03May28Abridgedbwd104No ratings yet

- DerrickDocument17 pagesDerrickNigin Parambath100% (4)

- IADC DDR Codes 2 13 2019Document4 pagesIADC DDR Codes 2 13 2019txcrudeNo ratings yet

- BOP Test Rig 51 #2Document9 pagesBOP Test Rig 51 #2Sohaib TahirNo ratings yet

- DPT1-01-Rig Sizing and Selection (New)Document65 pagesDPT1-01-Rig Sizing and Selection (New)Brahim Letaief100% (1)

- Heavy Lift PDFDocument78 pagesHeavy Lift PDFmaersk01100% (5)

- Rotary Rig ComponentsDocument32 pagesRotary Rig ComponentsFahad Paracha50% (2)

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMarcio Nascimento BezerraNo ratings yet

- 2.0 Components of Drilling RigDocument81 pages2.0 Components of Drilling RigConnor Whiltshire100% (1)

- Drilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFDocument10 pagesDrilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFAmine MimoNo ratings yet

- Drilling NotesDocument137 pagesDrilling NotesmohammedNo ratings yet

- Drilling Fluids, Drill String, CirculatingDocument10 pagesDrilling Fluids, Drill String, CirculatingBianca Quiroga AndiaNo ratings yet

- 5M54C DC Duri0726120190423prf01Document26 pages5M54C DC Duri0726120190423prf01Ryan SinagaNo ratings yet

- XJ550 Workover RigDocument11 pagesXJ550 Workover RigWanmi MANo ratings yet

- Rig-Less Intervention Course - Mod. 7 Workover TechniquesDocument121 pagesRig-Less Intervention Course - Mod. 7 Workover TechniquesnaoufelgcNo ratings yet

- Basic Drilling EngineeringDocument26 pagesBasic Drilling Engineeringgfaux03No ratings yet

- Crawler Crane Technical Manual: ApprovedDocument20 pagesCrawler Crane Technical Manual: Approvedkartik kumarNo ratings yet

- Well Surface Equipment: Presented By: Submitted ToDocument17 pagesWell Surface Equipment: Presented By: Submitted ToShaykh AlthamasNo ratings yet

- Rig ComponentsDocument59 pagesRig ComponentsMuhammad Nabil Ezra100% (3)

- Hoisting System (Sistema de Elevacion)Document8 pagesHoisting System (Sistema de Elevacion)Ferna DiazNo ratings yet

- U6 - Economic Optimization of Unconventional ReservoirsDocument92 pagesU6 - Economic Optimization of Unconventional ReservoirsWoodoo OodoowNo ratings yet

- Rig IMI Specific Remove Drilling Line On The Drawworks DrumDocument8 pagesRig IMI Specific Remove Drilling Line On The Drawworks Drumsaysamajo100% (1)

- Standard Format Equipment List Land Drilling Units (Land Rigs)Document51 pagesStandard Format Equipment List Land Drilling Units (Land Rigs)Shofwan Hilal100% (1)

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- UH Final Presentation 1 - Sept 9, 2013 - PrintingDocument68 pagesUH Final Presentation 1 - Sept 9, 2013 - PrintingTauqeer IqbalNo ratings yet

- Drilling Rig ComponentsDocument61 pagesDrilling Rig ComponentsRichard Arnold SimbolonNo ratings yet

- Eq52648 0001 1383079116633Document6 pagesEq52648 0001 1383079116633tungbk9100% (2)

- Career On Drilling RigDocument12 pagesCareer On Drilling RigAhmed BalochNo ratings yet

- RR - UnrepDocument2 pagesRR - UnrepRAJESH GANESANNo ratings yet

- Drilling and Testing of An HPHT Deep Gas Prospect From An Existing Well: Case HistoryDocument8 pagesDrilling and Testing of An HPHT Deep Gas Prospect From An Existing Well: Case HistoryAhmed GharbiNo ratings yet

- Introduction To Onshore DrillingDocument41 pagesIntroduction To Onshore DrillingSu Chong Guang50% (4)

- Global Reporting System User Manual GRS-Rig V4.0: TitleDocument161 pagesGlobal Reporting System User Manual GRS-Rig V4.0: Titlevikrant911No ratings yet

- Specs ZJ 30 2Document1 pageSpecs ZJ 30 2fatehul alamNo ratings yet

- Drilling EquipmentDocument86 pagesDrilling EquipmentIqbal AfriansyahNo ratings yet

- Drilling Rig Components PDFDocument61 pagesDrilling Rig Components PDFzerocool2k0% (1)

- Coiled Tubing Dual Action Hydraulic JarDocument13 pagesCoiled Tubing Dual Action Hydraulic JarAhmedNo ratings yet

- Triplex Pump Part 1 PDFDocument30 pagesTriplex Pump Part 1 PDFvenkysaranNo ratings yet

- Drilling Rig ComponentsDocument18 pagesDrilling Rig ComponentsIsmail A. IsmailNo ratings yet

- Cargo Handling PortDocument29 pagesCargo Handling PortHarry PasaribuNo ratings yet

- Tech Drilling CoilTubingDocument45 pagesTech Drilling CoilTubingLawNo ratings yet

- Blann Presentation - Continuous Flow Gas Lift DesignDocument59 pagesBlann Presentation - Continuous Flow Gas Lift DesignNigel Ramkhalawan100% (1)

- Rig Components PDFDocument19 pagesRig Components PDFBalant AxNo ratings yet

- 01-Section 02 Drilling Fluids Functions PDFDocument11 pages01-Section 02 Drilling Fluids Functions PDFLazharNo ratings yet

- TTM 2000 RezeoDocument403 pagesTTM 2000 RezeoFlo FloNo ratings yet

- Unit 1 4th Topic Oil Rig SystemDocument14 pagesUnit 1 4th Topic Oil Rig SystemUmaNo ratings yet

- Drilling Rig ComponentsDocument27 pagesDrilling Rig ComponentsBasit KhanNo ratings yet

- Class Problems: Esp Design and Analysis Gabor Takacs, PHD InstructorDocument38 pagesClass Problems: Esp Design and Analysis Gabor Takacs, PHD Instructoralexis_viteriNo ratings yet

- Pre-Spud Checklist # 4Document2 pagesPre-Spud Checklist # 4Yougchu LuanNo ratings yet

- Training ManualDocument295 pagesTraining ManualVictorNo ratings yet

- Www.petroleumbook.comDocument8 pagesWww.petroleumbook.comShakeel AhmedNo ratings yet

- Cementing 1 PDFDocument30 pagesCementing 1 PDFShafeeq ChappuNo ratings yet

- Noble CorporationDocument25 pagesNoble CorporationFahmi Tamimi El MahmudNo ratings yet

- Rig Specification Rev1Document15 pagesRig Specification Rev1ImanNo ratings yet

- Sec 3 Well ServicingDocument38 pagesSec 3 Well ServicingWilliam EvansNo ratings yet

- Chapter 11Document21 pagesChapter 11m90abdelwahabNo ratings yet

- 02 WH & XTreeDocument47 pages02 WH & XTreeilkerkozturkNo ratings yet

- Lesson 10 Flow Mudcap Snub Closed Systems1Document50 pagesLesson 10 Flow Mudcap Snub Closed Systems1Heris SitompulNo ratings yet

- Well CompletionDocument22 pagesWell CompletionRobot100% (1)

- Drilling Process BasicsDocument18 pagesDrilling Process BasicsBudiman50% (2)

- Wireline Jar - Hydraulic: Slickline ToolsDocument1 pageWireline Jar - Hydraulic: Slickline ToolsFranklin NavarroNo ratings yet

- Equipo de PerforacionDocument21 pagesEquipo de PerforacionJoanna Guio0% (1)

- Terex Digger Derrick Operators Manual 1Document20 pagesTerex Digger Derrick Operators Manual 1Israel SotoNo ratings yet

- The Rotary Rig and Its ComponentsDocument11 pagesThe Rotary Rig and Its ComponentsAnonymous ReUt4WnNo ratings yet

- UniDocument21 pagesUnisparda94No ratings yet

- QUY650操作手册 第一章Document13 pagesQUY650操作手册 第一章मुकेश कुमार झाNo ratings yet

- Derrick Oisd STD 190 ModifiedDocument33 pagesDerrick Oisd STD 190 ModifiedBenny TranNo ratings yet

- Rigging Requirements For Personnel Platforms Cranes and Derricks Used in ConstructionDocument20 pagesRigging Requirements For Personnel Platforms Cranes and Derricks Used in ConstructionRafael Mallqui ANo ratings yet

- Navsea S9 84-Ac-Mmo-010/lst-1í79 CLDocument306 pagesNavsea S9 84-Ac-Mmo-010/lst-1í79 CLfrancisco xavier palma ramirezNo ratings yet

- TMS 860Document8 pagesTMS 860Saheb PalNo ratings yet

- Zoomlion Crawler Cranes Spec 83a2ecDocument32 pagesZoomlion Crawler Cranes Spec 83a2echamza bayramNo ratings yet

- Live Saving Rules PresentationDocument19 pagesLive Saving Rules PresentationDie HArdNo ratings yet

- 89 Gas and Oilfield Safety Inspection ChecklistDocument14 pages89 Gas and Oilfield Safety Inspection Checklistdilip matalNo ratings yet

- Ifr em I, 1 U3Document7 pagesIfr em I, 1 U3Marian MunteanuNo ratings yet

- Calculus of A Single Variable Early Transcendental Functions 6th Edition Larson Test BankDocument36 pagesCalculus of A Single Variable Early Transcendental Functions 6th Edition Larson Test Bankcapsicum.imprison0fwm100% (29)

- Register of Ship Lifting Appliance and Cargo Handling GearDocument2 pagesRegister of Ship Lifting Appliance and Cargo Handling GearRohit SinghNo ratings yet

- Preparation For Leaving and Entering All Crew Hands All Hands Lash, Tie, Bind, and Buckle Secure, Batten, Make SureDocument38 pagesPreparation For Leaving and Entering All Crew Hands All Hands Lash, Tie, Bind, and Buckle Secure, Batten, Make SureАлександр ВасенинNo ratings yet