Professional Documents

Culture Documents

Fertigation

Uploaded by

Deepak MewarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fertigation

Uploaded by

Deepak MewarCopyright:

Available Formats

WATER POWERED DOSING TECHNOLOGY

fertigation and

chemigation

The objectives of fertigation are to

Water

control water quantities and added

nutrients necessary for optimum

growth of crops.

powered

Dosatron offers a constant injection

ratio and uniform and proportional

volumetric

injection, adding flexibility to simple

or automated systems, so that the

proportional

producer can very easily take action

whenever he considers it necessary. dosing

Advantages

of the fertigation

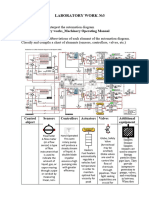

■ Significantly better agronomic Total bypass installations

efficiency by simultaneous

supply of water and minerals.

■ Small but numerous appli- Principle of centralized installation (automated or not)

cations of nutrients to

best satisfy the different Sector solenoid Pressure

needs of crops. Sand valves reducers

■ Limitation of "leaching" filter

Tank

due to small but frequent Timer

additions of nutrients. Drip

system

■ Application of nutrient 300 micron

solutions through the filter

irrigation system, provi-

ding homogenous distri- Solenoid valve

bution in the different

parcels. Solenoid valve Non-return

■ Thus, minerals reach the valve

heart of the root system, and A B

crop needs can be satisfied

immediately at all stages. Mixer Mixer

80 to 120

■ Savings of water, pro- micron filter

ducts and labor.

■ Automation

possibilities. Stock Stock

solution solution

300 tank A tank B

micron

filter

Spraying Timer

nozzle

Connector Stock solution Solenoid valve

to water drum

circuit

Principle of

mobile Spray boom

installation

Timer

Sand

filter 80 to 120

micron filter Sector solenoid

Tank valves Drip

system

Solenoid

300 valve Non-

Advantages micron return

filter valve

of Dosatron

■ Hydraulic, no elec- Non-

tricity required Timer return

■ Precise: Dosing pro- valve Pressure

Mixer

portional to the water reducers

flow passing through the Stock solution tank

Dosatron

■ Unlike other systems, proportional Sector solenoid

dosing provides uniform distribu- Solenoid valves

tion of the products over the valve

entire sector(s).

■ Dosing and treatments can be Solenoid Drip tape

changed at any time without valve

changing the programming of 80 to

the entire irrigation or control Mixer

120 micron

system. filter

■ Ease of use and maintenance. Principle of Pressure

■ Flexibility and speed of use decentralized reducers

(fixed or mobile). installation Stock solution tank

(automated or not)

How to choose

your Dosatron

Software for

The choice of the Dosatron essentially depends on the preparation of the stock solution

required irrigation flow.

Example from water soluble or liquid fertilizers

Software for fertigation is available in the form of Excel spreadsheets.

Basic principle for preparation of the stock solution (from water soluble fertilizers):

1st sector:

3000 2 l/h drippers

Fertigation water or

Irrigation sub-concentration

Non- water

return 2nd sector: %

Manual valve 1000 2 l/h drippers

valves

Final concentration or daughter solution in grams/liter

3rd sector:

2000 2 l/h drippers 0,5 0,75 1 1.25 1.50 1.75 2 2.5 3 4 5

0.2 250 Fertilizer weight in grams to be placed

0.4 125 188 250 in a receptacle and topped up to 1 liter

0.6 83 125 167 208 (thus the fertilizer density is ignored)

Adjustment %

1. Calculation 0.8 63 94 125 156 188 219

of the required irrigation flow 1.0 50 75 100 125 150 175 200 250

Minimum irrigation flow: 1.2 42 63 83 104 125 146 167 208 250

Multiply the number of drippers (or sprinklers or 1.4 36 54 71 89 107 125 143 179 214

nozzles) in the smallest sector by their unit flow: 1 liter 1.6 31 47 63 78 94 109 125 156 188 250

1 000 x 2 l/h 1.8 28 42 56 70 83 97 111 139 167 222

Note: this solution preparation example

= 2 000 l/h = 2 m3/h is given for guidance only, and we cannot 2.0 25 38 50 63 75 88 100 125 150 200 250

be responsible for it. Please call your

chemical supplier for further information.

Maximum irrigation flow:

Multiply the total number of drippers in all sectors by

their unit flow:

3 000 + 1 000 + 2 000 Recommendations: The level in the stock solution tank must never be

higher than the Dosatron (risk of siphoning).

= 6 000 x 2 l/h

= 12 000 l/h = 12 m3/h ■ Standards and regulations in force in the country For acid dosing, it is preferable to move the acid

must be respected during installation and use on drum away from the Dosatron and put a cover on

the drinking water network. the drum.

2. Choice of the Dosatron ■ The installation must comprise a disconnector or a

Its minimum flow non-return valve upstream the injection system to Note: If the weight of acid in the stock solution is

Its minimum flow capacity must be equal to or less prevent from any pollution of the water source. more than 6% and up to 10%, choose a PVDF

than the required irrigation flow in the smallest sector. ■ Install a 300-micron filter upstream the Dosatron, model (see option on page 4).

depending on the water quality.

E.g.: Sector 2: 2 m3/h

Possibilities: Note: the built-in filter in some models is no more

D 45: 100 l/h to 4.5 m3/h than a final safety device, and it must never be used

D 8 R: 500 l/h to 8 m3/h to replace the filter upstream.

D 20 S: 1 m3/h to 20 m3/h ■ For assemblies in parallel, a single stock solution

tank should be used to supply the various Dosatrons.

Its maximum flow ■ Never use an inlet T at the intake to draw in two

Possibilities: different solutions.

1°For simultaneous fertigation of all sectors: ■ The motor is lubricated by water, never apply grea-

Maximum required irrigation flow, se to the motor.

namely ≥ 12 m3/h:

the required Dosatron is the D 20 S, up to 20 m3/h For protection against water hammer, it is recom-

mended that:

2°For fertigation, one sector at a time:

Required irrigation flow in the largest sector, ■ Slowly opening and closing solenoid valves should

be used.

namely 3 000 x 2 l/h = 6 000 l/h, namely ≥ 6 m3/h: ■ If a Dosatron is used to supply several sectors, acti-

The required Dosatron in the D8R up to 8 m3/h vate the solenoid valves simultaneously (close one

sector and open another sector at the same time).

Note: it is preferable to choose a Dosatron with a ■ Start irrigation first, and start fertilization (total

maximum flow capacity higher than the required bypass installation) only once the whole irrigation

irrigation flow in order to optimize its life. system is full of water (after a few minutes).

fertigation and chemigation

Operating principle Recommended models* Vacuum

breaker

Installed directly in the water supply line, the

Dosatron operates by using the flow of water as the

3 NEW

m3/h Operating water flow:

power source. The water activates the Dosatron,

which takes up the required percentage of concentra-

10 l/h to 3 m3/h

te directly from the container and injects it into the ref. - injection rate:

water. D3 GL 2 - 0.2 to 2 %

D3 GL 5 - 0.5 to 5 %

Inside the Dosatron, the concentrate is mixed with D3 GL 10 - 1 to 10 %

the water, and the water pressure forces the solution

downstream. The dose of concentrate will be directly The vacuum breaker at the outlet

proportional to the volume of water entering the prevents the solution tank from

Dosatron, regardless of variations in flow or pressure, uncontrolled suction when the irri-

which may occur in the main line. 4.5 gation network is not under pressure.

It must be installed before the

m3/h Operating water flow: Dosatron is put into operation.

100 l/h to 4.5 m3/h

ref. - injection rate: Pest-control option

D 45 RE 1.5 - 0.2 to 1.5 %

D 45 RE 3 - 0.5 to 3 %

Motor 8

piston m3/h Operating water flow:

500 l/h to 8 m3/h

ref. - injection rate:

D 8 R - 0.2 to 2 %

Solution D 8 R 150 - 1 to 5 %

water + %

additive

*Special seals and PVDF housing for

highly concentrated acids and other

Clear aggressive concentrates.

irrigation

water 20 Other Dosatron

m3/h Operating water flow:

1 m3/h to 20 m3/h applications

Dosing Dosing ref. - injection rate: ■ Pest-control *

piston adjustment (%) D 20 S - 0.2 to 2 % ■ Maintenance of networks and

irrigation systems

■ Acidification*

■ Soil disinfection

Concentrated ■ Post-harvest treatment

product intake ■ Conservation and disinfection

*WARNING: Please call your dealer for dosing of corrosive of cut flowers

products before use, in order to confirm compatibility with ■ ...

the Dosatron.

A wide range of dosing units

combined with a broad choice of

options (high flow, micro dosage,

highly chemical resistant mate-

rials...) means that we can

address all your needs.

CUSTOMER SERVICE - SERVICE CLIENTÈLE

FA/C2-21- IRRIGATION D3- GB/09/08

Crédit photo de couverture : Vakblad voor de Bloemisterij

This document does not form a contractual engagement

on the part of Dosatron International and is for information

only. Dosatron International reserves the right to alter

product specification or appearance without prior

notice. © DOSATRON INTERNATIONAL S.A.S. 2004

DOSATRON INTERNATIONAL S.A.S.

Rue Pascal - B.P. 6 - 33370 TRESSES (BORDEAUX) - FRANCE

Tel. 33 (0)5 57 97 11 11 - Fax. 33 (0)5 57 97 11 29 / 33 (0)5 57 97 10 85

e.mail : info@dosatron.com - http://www.dosatron.com

You might also like

- Interceptors Tech Data PDFDocument3 pagesInterceptors Tech Data PDFXAVIER RUBIONo ratings yet

- Brochure PTM-600 EnglishDocument8 pagesBrochure PTM-600 EnglishGiorgioNo ratings yet

- Client Name: XXX: Standard Operating ProcedureDocument6 pagesClient Name: XXX: Standard Operating ProcedureEra Enviro Solitions100% (2)

- NPR100 Ratio Controller Model RCWDocument4 pagesNPR100 Ratio Controller Model RCWDaniel Carmona AriasNo ratings yet

- Venturi Injectors Principle Operation and Installation NetafimDocument4 pagesVenturi Injectors Principle Operation and Installation NetafimRizzdaron TikingNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- ITT and The Cycle of Water: Wastewater SolutionsDocument3 pagesITT and The Cycle of Water: Wastewater SolutionsManoj SinghNo ratings yet

- Water Injection Systems Solutions BRDocument8 pagesWater Injection Systems Solutions BRBrahim BenabdallahNo ratings yet

- Removal 1Document6 pagesRemoval 1Amoghasakti AbinawaNo ratings yet

- Centra R 60 120 Spec Sheet Litr38761 05Document2 pagesCentra R 60 120 Spec Sheet Litr38761 05Sergio RodríguezNo ratings yet

- Water Treatment System - Thermogenics Mexico OTSG PDFDocument15 pagesWater Treatment System - Thermogenics Mexico OTSG PDFAnonymous 6meMTlNo ratings yet

- Water Flow MSMTDocument2 pagesWater Flow MSMTkrbabu1969No ratings yet

- Ossm-Osso IIsec 2.01Document19 pagesOssm-Osso IIsec 2.01Dhenny FarialNo ratings yet

- Flowmaster Reservoir Level Sensor and Overflow Prevention SystemDocument4 pagesFlowmaster Reservoir Level Sensor and Overflow Prevention SystemВиталий КозловскийNo ratings yet

- MBR Design Guidebook - 2007Document71 pagesMBR Design Guidebook - 2007juan pedrazaNo ratings yet

- Ratio Controllers: Model RCTDocument4 pagesRatio Controllers: Model RCTWilly DinataNo ratings yet

- B HighHead IS115-ADocument2 pagesB HighHead IS115-AJOHNNY CALERONo ratings yet

- Main Plant Kamimine Plant: DistributorDocument5 pagesMain Plant Kamimine Plant: DistributorsmendozaNo ratings yet

- NPR080 Ratio Controller Model RCTDocument4 pagesNPR080 Ratio Controller Model RCTJorge VelasquezNo ratings yet

- Band 6 en Planungshinweise Amacan DataDocument58 pagesBand 6 en Planungshinweise Amacan DatavctrnuevoNo ratings yet

- Pumps in Potentiometry: Safe and Convenient Transportation of Liquids of All KindsDocument4 pagesPumps in Potentiometry: Safe and Convenient Transportation of Liquids of All KindsRamirez FrancisNo ratings yet

- Corn ManualDocument58 pagesCorn ManualOana CorduneanuNo ratings yet

- System Integrated Water Softener: On-Demand Steam SolutionsDocument4 pagesSystem Integrated Water Softener: On-Demand Steam SolutionsvgdbrifNo ratings yet

- Data Sheet: Micromist® Suppression SystemDocument2 pagesData Sheet: Micromist® Suppression SystemProingmeca CANo ratings yet

- SERIES 7000 Paste Slakers: Fully Automated Lime Slaking SystemsDocument4 pagesSERIES 7000 Paste Slakers: Fully Automated Lime Slaking Systemssoumyarm942No ratings yet

- Tacmina Motor SXDA1Document12 pagesTacmina Motor SXDA1arisqi wahyuNo ratings yet

- National Foam ManualDocument4 pagesNational Foam ManualRiky AyalaNo ratings yet

- Bro Water Efficient SystemsDocument16 pagesBro Water Efficient SystemsmountainoasisNo ratings yet

- SE - Series - Brochure (ROV OCC)Document4 pagesSE - Series - Brochure (ROV OCC)Gabo Montaño MendozaNo ratings yet

- Micron: Environmentally Friendly Media FilterDocument4 pagesMicron: Environmentally Friendly Media Filterethan8888No ratings yet

- Understanding Mobile Hydraulics.: Simple Hydraulic SystemDocument12 pagesUnderstanding Mobile Hydraulics.: Simple Hydraulic SystemSumeet GuptaNo ratings yet

- Dust Collector Circuit: Service Training Manual CM 760/780Document8 pagesDust Collector Circuit: Service Training Manual CM 760/780victor laraNo ratings yet

- 53C - FsaDocument5 pages53C - FsaSulaiman Kadher KNo ratings yet

- Aquabiome: Mechanical and Biological FiltrationDocument4 pagesAquabiome: Mechanical and Biological FiltrationJosse RuizNo ratings yet

- Inundación de Polímero para Mejorar La Eficiencia Del Barrido Volumétrico en Los Procesos de Inyección de AguaDocument20 pagesInundación de Polímero para Mejorar La Eficiencia Del Barrido Volumétrico en Los Procesos de Inyección de AguaRicardoNo ratings yet

- Pcm-Lagoa Series Brochure - English2Document6 pagesPcm-Lagoa Series Brochure - English2Hafid NaufalNo ratings yet

- Monthly Monitoring Report MayDocument8 pagesMonthly Monitoring Report MayBrainard ConcordiaNo ratings yet

- Water Treatment Catalogue 2017 Europe, Middle East, AfricaDocument150 pagesWater Treatment Catalogue 2017 Europe, Middle East, AfricaThiện Lương MinhNo ratings yet

- Filtral UVC: Underwater Filter With UVC and Filter PumpDocument2 pagesFiltral UVC: Underwater Filter With UVC and Filter PumpDebora MaryantiNo ratings yet

- Filtral UVCDocument2 pagesFiltral UVCdebora maryantiNo ratings yet

- EOR Water Injection PDFDocument35 pagesEOR Water Injection PDFLulut Fitra Fala100% (1)

- MTC 1000 SpecDocument2 pagesMTC 1000 SpecJuan José Tovar PérezNo ratings yet

- Jet Filter GBDocument6 pagesJet Filter GBBrian WebbNo ratings yet

- 321 - Дудник ЛР№3Document8 pages321 - Дудник ЛР№3Роман ДудникNo ratings yet

- Centriquip - 2002 - BrochureDocument5 pagesCentriquip - 2002 - BrochureCentrifugal SeparatorNo ratings yet

- AutoCAD PID 2011 Features and BenefitsDocument5 pagesAutoCAD PID 2011 Features and BenefitsIfeanyi Ezemonye-AgwuegboNo ratings yet

- GSD SERIES Belt ThickennerDocument16 pagesGSD SERIES Belt ThickennerSid Esterico SestosoNo ratings yet

- Brochure - MBR 20 - 80 - HMIDocument2 pagesBrochure - MBR 20 - 80 - HMIkoen irawanNo ratings yet

- Tensiómetros Jet Fill Soilmoisture® 2011Document7 pagesTensiómetros Jet Fill Soilmoisture® 2011linaNo ratings yet

- Filtro de Linea de Agua DuraDocument3 pagesFiltro de Linea de Agua Duradéborah_rosalesNo ratings yet

- Lalpir Thermal Power Plant Internship ReportDocument38 pagesLalpir Thermal Power Plant Internship ReportKhawaja Muhammad MoinNo ratings yet

- Risonic ModularDocument12 pagesRisonic Modularabsolutvacio82No ratings yet

- 50at Fliter Catalog and User ManualDocument8 pages50at Fliter Catalog and User ManualGustavo CardenasNo ratings yet

- Mfm220 - 2" FP Manifold Flowmeter: This Is A Self-Calibrating FlowmeterDocument9 pagesMfm220 - 2" FP Manifold Flowmeter: This Is A Self-Calibrating FlowmeterMarcelo GonçalvesNo ratings yet

- Sugar Evap 2020 07 10 enDocument2 pagesSugar Evap 2020 07 10 enkrbabu1969No ratings yet

- Water Treatment Plant, C11Document10 pagesWater Treatment Plant, C11Saksopheaktra PhoNo ratings yet

- Vacuum Tumbler SystemDocument2 pagesVacuum Tumbler SystemJANE JACOBSNo ratings yet

- Applications/Processing Guide: How To Use This Section The Resistive ElementDocument8 pagesApplications/Processing Guide: How To Use This Section The Resistive ElementCarlosAgustoPinedaSanchezNo ratings yet

- FHT ProfileDocument18 pagesFHT ProfileDeepak MewarNo ratings yet

- ApomixisDocument42 pagesApomixisDeepak MewarNo ratings yet

- What Is in Your GardenDocument7 pagesWhat Is in Your GardenfloanfloanNo ratings yet

- PHT in HorticultureDocument57 pagesPHT in HorticultureDeepak MewarNo ratings yet

- Role of Biotechnology in Production of Fruit CropsDocument12 pagesRole of Biotechnology in Production of Fruit CropsDeepak MewarNo ratings yet

- FAO Report On Mountain AgricultureDocument322 pagesFAO Report On Mountain AgricultureDeepak MewarNo ratings yet

- Integrated Farming SystemsDocument22 pagesIntegrated Farming SystemsDeepak MewarNo ratings yet

- Integrated Farming SystemsDocument22 pagesIntegrated Farming SystemsDeepak MewarNo ratings yet

- FAO Report On Mountain AgricultureDocument322 pagesFAO Report On Mountain AgricultureDeepak MewarNo ratings yet

- Integrated Farming SystemsDocument22 pagesIntegrated Farming SystemsDeepak MewarNo ratings yet

- Integrated Farming SystemsDocument22 pagesIntegrated Farming SystemsDeepak MewarNo ratings yet

- Course code:-FSC-506 Course Title:-Prodn Tech of Subtropical and Temperate Crop Credit Hour:-3 (2+1)Document44 pagesCourse code:-FSC-506 Course Title:-Prodn Tech of Subtropical and Temperate Crop Credit Hour:-3 (2+1)Deepak MewarNo ratings yet

- Seed and Fruit DevelopmentDocument6 pagesSeed and Fruit DevelopmentDeepak MewarNo ratings yet

- Answers/ Solutions For Assignment QuestionsDocument2 pagesAnswers/ Solutions For Assignment QuestionsMUBASHSHAR SULTANNo ratings yet

- Faculty of Civil and Environmental Engineering Water Resource and Environmental Engineering Department Environmental Engineering Lab Short ReportDocument11 pagesFaculty of Civil and Environmental Engineering Water Resource and Environmental Engineering Department Environmental Engineering Lab Short ReportKhinwah Siew82% (11)

- Ra 8749Document66 pagesRa 8749Belle Blances75% (4)

- Bo de Thi HK2 Tieng Anh 9 KeyDocument18 pagesBo de Thi HK2 Tieng Anh 9 KeyNganNo ratings yet

- Tdu Presentation EngDocument18 pagesTdu Presentation EngDJ WALET100% (1)

- MSDS ApsDocument8 pagesMSDS ApsShifa Anindya HartonoNo ratings yet

- Safety Data Sheet: Triple Superphosphate, Granular 0-46-0Document24 pagesSafety Data Sheet: Triple Superphosphate, Granular 0-46-0energy efficiencyNo ratings yet

- Cape Chemistry Module 3Document7 pagesCape Chemistry Module 3Giselle Williams-VachéNo ratings yet

- Community Immersion Activity PlanDocument4 pagesCommunity Immersion Activity PlanAG DANONo ratings yet

- Marine Oil Spill TezDocument53 pagesMarine Oil Spill Tezhalit canNo ratings yet

- 2022 Exp 8 TEMPLATE Hydraulic Fracking and Ground Water PollutionDocument11 pages2022 Exp 8 TEMPLATE Hydraulic Fracking and Ground Water PollutionKarabo Kaytee DhlaminiNo ratings yet

- Study of Storm and Sewer Drains For Rajarhat (Ward No 4) in West Bengal Using Sewergems SoftwareDocument47 pagesStudy of Storm and Sewer Drains For Rajarhat (Ward No 4) in West Bengal Using Sewergems SoftwareRuben Dario Posada BNo ratings yet

- Cot 1 - Health 6 Q3Document18 pagesCot 1 - Health 6 Q3ALJEAN VERA MARIE SAMSONNo ratings yet

- Trail+smelter+cae+-+usa+v +canadaDocument5 pagesTrail+smelter+cae+-+usa+v +canadaPrakher DubeyNo ratings yet

- Format For Field Technical Report (2017) For Certified Professional in Sewage Treatment Plant OperationsDocument25 pagesFormat For Field Technical Report (2017) For Certified Professional in Sewage Treatment Plant OperationsyogapostNo ratings yet

- Tony Lamb - Make Your Own Water FilterDocument9 pagesTony Lamb - Make Your Own Water FilterSmart KiddNo ratings yet

- Stone CrusherDocument5 pagesStone CrusherAnkitSinghaiNo ratings yet

- Food and Energy Security - 2017 - Carvalho - Pesticides Environment and Food SafetyDocument13 pagesFood and Energy Security - 2017 - Carvalho - Pesticides Environment and Food SafetyMarcos SolimanNo ratings yet

- Air PollutionDocument22 pagesAir PollutionSaba waseemNo ratings yet

- 8dd8 P2 Program Food MFG Final PublicDocument19 pages8dd8 P2 Program Food MFG Final PublicNemanja RadonjicNo ratings yet

- WRO SW5m3+Document4 pagesWRO SW5m3+Onie Hammamz Oyl100% (1)

- Qs Spot For EVT711 N EVT714 (Air)Document6 pagesQs Spot For EVT711 N EVT714 (Air)ratna_aqilahNo ratings yet

- Roof Drainage DesignDocument22 pagesRoof Drainage Designruwanpura50% (2)

- E E I M 3: Nvironmental Ngineering OduleDocument54 pagesE E I M 3: Nvironmental Ngineering OduleirshadNo ratings yet

- Wastemanagement 161028065024Document80 pagesWastemanagement 161028065024Atharva MansabdarNo ratings yet

- Living in The IT Era HandoutsDocument36 pagesLiving in The IT Era HandoutsAlexis RiveraNo ratings yet

- Plumbing Layout: General NotesDocument1 pagePlumbing Layout: General NotesMiiNo ratings yet

- Chapter 2 SolutionsDocument41 pagesChapter 2 SolutionsbrayanNo ratings yet

- Safety Data Sheet: Armohib 31Document12 pagesSafety Data Sheet: Armohib 31Dr. Pushkar ShuklaNo ratings yet

- Service Bulletin No1 - Filter Proper Operation & Screen PreservationDocument6 pagesService Bulletin No1 - Filter Proper Operation & Screen Preservationkillm3plzNo ratings yet