Professional Documents

Culture Documents

Monthly Monitoring Report May

Uploaded by

Brainard ConcordiaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monthly Monitoring Report May

Uploaded by

Brainard ConcordiaCopyright:

Available Formats

WATER TREATMENT PLANT

PROCESS OPERATION REPORT

BUTUAN CITY 30MLD BULK

WATER PROJECT

MAY 2017

ECO-SYSTEM TECHNOLOGIES INTERNATIONAL (ESTII), INC.

WTP MONITORING REPORT

30MLD Butuan Bulk Water Project

Sitio Iyao, Brgy. Anticala, Butuan City

Agusan Del Norte

Month Covered: MAY 2017

1.0 Plant Operational Status

1.1 Flow Monitoring Reports

The WTP processed a daily average of 28.72MLD of raw water. Peak flow

recorded for this period was 29.83MLD.

Maximum

Plant Total monthly

Ave Daily Flow Daily Flow

Capacity flow

Recorded

MLD MLD MLD Million Liters

Current 25.00 28.72 29.83 890.39

Previous 25.00 28.62 31.94 858.62

The WTP produced a daily average of 26.03MLD of treated water. Peak flow

recorded for this period was 27.36MLD.

Maximum

Plant Total monthly

Ave Daily Flow Daily Flow

Capacity flow

Recorded

MLD MLD MLD Million Liters

Current 25.00 26.03 27.36 806.85

Previous 25.00 25.86 30.71 775.69

Due to the absence of the Filter Membrane #1, the plant is not able to utilize its

full capacity which is 30 MLD. A single filter membrane tank has a flow rate capacity of 5

MLD, giving the plant to have a capacity of 25 MLD using the 5 available filter membrane

tanks. A little bit overloading on the filter membrane is observe but for a specific influent

turbidity only which is below 10 NTU. No overloading for the sedimentation basin since it

was designed to contain 30MLD.

Taguibo Aquatic Solutions Corporation 1|Page

1.2 Process Equipment Monitoring

Equipment monitoring status:

Name of Equipment Status

BACKWASH EQUIPMENTS

Air Scour Blower 1 Operational

Air Scour Blower 2 Operational

Backwash Pump 1 Not yet installed

Backwash Pump 2 Not yet installed

Backwash Pump 3 Operational

Backwash Pump 4 Operational

Sludge Pump 1 Operational/Stand-by

Sludge Pump 2 Operational/Stand-by

DOSING SYSTEM

NaOH Dosing Pump 1 Operational/Stand-by

NaOH Dosing Pump 2 Operational/Stand-by

PAC Dosing Pump 1 Operational

PAC Dosing Pump 2 Operational

Polymer Dosing Pump 1 Disconnected

Polymer Dosing Pump 2 Operational/Stand-by

NaOH Mixer 1 Operational/Stand-by

NaOH Mixer 2 Operational/Stand-by

PAC Mixer 1 Operational

PAC Mixer 2 Operational

Polymer Mixer 1 Stirrer Removed

Polymer Mixer 2 Operational/Stand-by

SLUDGE COLLECTION MOTORS

Drive Motor 1 Operational

Drive Motor 2 Operational

FILTER MEMBRANE VALVES

Inlet Valve (1-6) Operational

Filtrate Valve (2-6) Operational

BW Filtrate Valve (2-6) Operational

Air Scour Valve (1-6) Operational

Wastewater Valve (1-6) Operational

Note:

1. Backwash pump 1 and 2, Filtrate Valve 1 and BW Filtrate Valve 1 were not yet installed

due to the absence of CLEAR WATER BASIN 1.

2. Polymer Tank 2 is currently used as the tank for Chlorine Dioxide.

3. All equipment are operational.

4. All equipment needs to be checked by technician to determine undetected problems that

may arise sooner that can upset proper operation of the plant.

Taguibo Aquatic Solutions Corporation 2|Page

2.0 PROCESS OPERATIONAL STATUS

a. Static Mixer

- PAC solution is dosed before the first static mixer.

b. Dosing System

- PAC Tank 2 needs cleaning to remove unwanted stuffs inside that may cause dosing

pump clogging.

- PAC Tank 1 was cleaned. (May 4)

- Dosing Pump 1 and 2 were opened for possible clogging. Pieces of plastics were

found. (May 3)

c. Flocculation Basin

- No algae growth can be seen in the flocculation basin since the water is moving

constantly in the basin.

d. Sedimentation Basin 1

- Algae can be seen in the walls of Sedimentation tank 1.

- Plate Settlers were cleaned daily due to extensive algae growth.

- Sludge Collector Settings is adjusted from 8 hours cycle to 12 hours cycle when the

influent turbidity reading is 1-10 NTU.

e. Sedimentation Basin 2

- Algae can be seen in the walls of Sedimentation tank 1.

- Plate Settlers were cleaned daily due to extensive algae growth.

- Sludge Collector Settings is adjusted from 8 hours cycle to 12 hours cycle when the

influent turbidity reading is 1-10 NTU.

f. Sludge Collector

- Uninterruptible Power Supply was installed in the control panel. (May 22)

g. Filter Membrane Tank 1

- On standby because of unavailability of the channel connecting to the clear water

basin.

- Cement and stone particles needs to be removed from the anthracite due to

construction of the slope protection.

h. Filter Membrane Tank 2

- Algae growing constantly in the trough and walls of the tank were cleaned weekly.

i. Filter Membrane Tank 3

- Algae growing constantly in the trough and walls of the tank were cleaned weekly.

j. Filter Membrane Tank 4

- Algae growing constantly in the trough and walls of the tank were cleaned weekly.

k. Filter Membrane Tank 5

- Algae growing constantly in the trough and walls of the tank were cleaned weekly.

l. Filter Membrane Tank 6

- Algae growing constantly in the trough and walls of the tank were cleaned weekly.

m. Clear Water Basin

- Status of the inside of the clear water cannot be determined due to the cover placed.

Taguibo Aquatic Solutions Corporation 3|Page

2.1 INFLUENT AND EFFLUENT QUALITY MONITORING

Effluent sample was analyzed last _____________. Water analysis was

conducted by Butuan City Water District.

WATER ANALYSIS: PHYSICAL AND CHEMICAL

*PNSDW Maximum

Parameters Level (mg/L) or Result Method

Characteristics

PHYSICAL

Odor Unobjectionable Sensory

o

Temperature C Conductimetric

Color Apparent 10 Color units

APHA Platinum-Cobalt

True 5 Color units

Turbidity 5 NTU** Turbidimetric

CHEMICAL

6.5 – 8.5

pH 5-7 undergo RO or Glass electrode

distillation process

Salinity _ ppt Conductimetric

Specific Conductance _ µS/cm Conductimetric

Total Suspended Solids _ mg/L Photometric

500 mg/L

Total Dissolved Solids <10 undergo RO or Conductimetric

distillation process

Iron 1.0 mg/L Ferrover

Sulfate 250 mg/L Sulfaver4

Chloride 250 mg/L Argentometric

Copper 1.0 mg/L Bicinconinate

Fluoride 1.0 mg/L SPADNS

Nitrate 50 mg/L Cadmium Reduction

Alkalinity _ mg/L Titration/Methyl orange

Bicarbonates _ mg/L Titration

Carbonates _ mg/L Titration

Total Hardness 300 mg/L EDTA Titration

Magnesium (as CaCO3) _ mg/L Calculation

Calcium (as CaCO3) _ mg/L EDTA Titration

Taguibo Aquatic Solutions Corporation 4|Page

Influent and effluent sample was analyzed hourly for turbidity reading, having 24

sets of testing per day. These tests were performed in the site. Seven sampling points

was set; raw water, water leaving the sedimentation tank #1 and #2, clear water basin,

manhole #1, #2 and #3. Turbidity testing was done by the operator’s assistant using the

2100Q portable turbidimeter.

For complete influent and effluent turbidity reading please check file name:

Daily Turbidity Reading of Raw and Treated Water (May 2017)

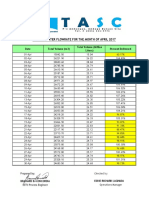

2.2 INFLUENT AND EFFLUENT FLOWRATE READING

Influent flow rate reading was being measured by float method. A bottle was

dropped in flowing water and measured the time it travelled a certain distance. This type

of measurement has a low accuracy since many factor is involved that may oppose or

cause the bottle to move fast or vice versa.

Effluent flow rate reading was measured by a TFP Clamp-on ultrasonic flowmeter.

Total volume delivered was displayed in this flowmeter in terms of cubic meter.

Flowmeter transducers were clamped on a 1100m pipe between manhole 1 and manhole

2.

For complete influent flowrate reading please check file name:

Raw Water Flowrate (May 2017)

For complete effluent flowrate reading please check file name:

Treated Water Flowrate (May 2017)

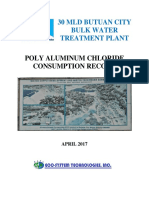

2.3 CHEMICAL USAGE MONITORING

A total of 265.5 bags (6637.5 kg) of Poly Aluminum Chloride were used for the

month of April. Poly Aluminum Chloride was the only coagulant used for the month since

the experienced turbidity was only low. The highest turbidity reading for the month

was 310NTU while the lowest was 1.67NTU.

For complete chemical usage monitoring please check file name:

PolyAluminum Chloride Consumption Record

Taguibo Aquatic Solutions Corporation 5|Page

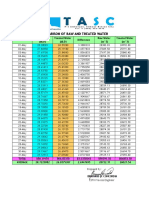

3.0 COMPARISON OF RAW AND TREATED WATER

COMPARISON OF RAW AND TREATED WATER

Raw Water Treated Water Raw Water Treated Water

Date Difference

(MLD) (MLD) (m^3/d) (m^3/d)

01-May 28.38083 24.99280 3.3880333 28380.83 24992.80

02-May 27.84958 25.19180 2.6577833 27849.58 25191.80

03-May 27.69708 25.84040 1.8566833 27697.08 25840.40

04-May 28.05435 25.00380 3.0505478 28054.35 25003.80

05-May 28.16875 25.43970 2.7290500 28168.75 25439.70

06-May 29.44870 26.06250 3.3861957 29448.70 26062.50

07-May 28.61413 25.81890 2.7952250 28614.13 25818.90

08-May 28.53750 25.06690 3.4706000 28537.50 25066.90

09-May 27.65438 25.24830 2.4060750 27654.38 25248.30

10-May 29.05125 26.10980 2.9414500 29051.25 26109.80

11-May 29.83271 27.36360 2.4691083 29832.71 27363.60

12-May 28.53913 26.89030 1.6488304 28539.13 26890.30

13-May 28.68021 24.61460 4.0656083 28680.21 24614.60

14-May 28.57179 26.45100 2.1207917 28571.79 26451.00

15-May 28.76667 26.86180 1.9048667 28766.67 26861.80

16-May 28.77458 24.70710 4.0674833 28774.58 24707.10

17-May 28.70292 25.73630 2.9666167 28702.92 25736.30

18-May 28.78958 26.18100 2.6085833 28789.58 26181.00

19-May 29.08500 26.52200 2.5630000 29085.00 26522.00

20-May 29.01458 26.90480 2.1097833 29014.58 26904.80

21-May 28.64375 26.14610 2.4976500 28643.75 26146.10

22-May 28.33375 24.67290 3.6608500 28333.75 24672.90

23-May 28.22708 25.50780 2.7192833 28227.08 25507.80

24-May 28.87438 26.10120 2.7731750 28874.38 26101.20

25-May 29.42750 26.91530 2.5122000 29427.50 26915.30

26-May 29.10042 26.67790 2.4225167 29100.42 26677.90

27-May 29.05563 26.45610 2.5995250 29055.63 26456.10

28-May 29.14392 26.76860 2.3753167 29143.92 26768.60

29-May 29.04563 26.85030 2.1953250 29045.63 26850.30

30-May 29.19667 26.69470 2.5019667 29196.67 26694.70

31-May 29.12913 27.05540 2.0737304 29129.13 27055.40

TOTAL 890.39155 806.85370 83.5378543 890391.55 806853.70

AVERAGE 28.7223082 26.0275387 2.6947695 28722.31 26027.54

Taguibo Aquatic Solutions Corporation 6|Page

COMPARISON OF RAW AND TREATED WATER

FOR THE MONTH OF MAY

30

25

20

15

10

Raw Water (MLD) Treated Water (MLD)

The water treatment facility averaged a daily influent flowrate of 28.72MLD and a

daily effluent flowrate of 26.03MLD for the month of April. A total of 83.54 million liters of

wastewater was disposed this month due to backwashing and removal of sludge in the

sedimentation tank, averaging a daily disposal of 2.69 million liters of wastewater.

Therefore, to attain a 25MLD daily production, a flowrate of 2-3MLD should be added to the

flowrate.

Prepared by: Checked by:

ENGR. BRAINARD B. CONCORDIA KHRISTIAN JOHN SAAVEDRA

ESTII Process Engineer Assistant Operations Manager

Noted by:

EDDIE RICHARD LAGNADA

Operation Manager

Taguibo Aquatic Solutions Corporation 7|Page

You might also like

- FlowDocument62 pagesFlowbapita roy100% (1)

- The Study of The Design of Production Systems of Purified Water For The Pharmaceutical IndustryDocument19 pagesThe Study of The Design of Production Systems of Purified Water For The Pharmaceutical IndustryAndreaVargasNo ratings yet

- Operation & Maintenance Manual - Sewage Treatment PlantDocument147 pagesOperation & Maintenance Manual - Sewage Treatment PlanthashemiteNo ratings yet

- Engineers Report - YclDocument3 pagesEngineers Report - YclAngela Emanuelle V. Estil88% (8)

- Calculating Water SuppliesDocument71 pagesCalculating Water SuppliesΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥ100% (1)

- ETP Operation Manual.Document68 pagesETP Operation Manual.Faisal Sr. Executive100% (1)

- Centrifugal Pump Data SheetDocument4 pagesCentrifugal Pump Data SheetJohnNo ratings yet

- Lact UnitDocument9 pagesLact UnitBolarinwaNo ratings yet

- Update Operation ManualDocument67 pagesUpdate Operation ManualFaisal Sr. ExecutiveNo ratings yet

- Client Name: XXX: Standard Operating ProcedureDocument6 pagesClient Name: XXX: Standard Operating ProcedureEra Enviro Solitions100% (2)

- Abhishek Project FileDocument40 pagesAbhishek Project FileAbhishek JayantNo ratings yet

- Operators Training Module - PresentationDocument62 pagesOperators Training Module - Presentationdiana bunagan100% (1)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Package Bumhan Water Co.Document40 pagesPackage Bumhan Water Co.ReyNo ratings yet

- Plant ReportDocument5 pagesPlant ReportAli Hassan RazaNo ratings yet

- Operation and Maintenance of Urban Sewage System in Puducherry (Cpet 711 Summer Training)Document24 pagesOperation and Maintenance of Urban Sewage System in Puducherry (Cpet 711 Summer Training)md adimNo ratings yet

- URS - Tanauan Factory WWTP Upgrade PDFDocument23 pagesURS - Tanauan Factory WWTP Upgrade PDFVer AmorosoNo ratings yet

- Liquid Flowmeters: Reynolds NumbersDocument12 pagesLiquid Flowmeters: Reynolds NumbersAsaithambi DorairajNo ratings yet

- O & M - Pidilite EtpDocument51 pagesO & M - Pidilite EtpOmkar BharankarNo ratings yet

- STP Design Report - IndiqubeDocument20 pagesSTP Design Report - IndiqubeRajkishore NayakNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- 07 Apr 2019 1431276907G6O3U69Annexure-ETPproposalDocument8 pages07 Apr 2019 1431276907G6O3U69Annexure-ETPproposalSUN AQUATECHNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar BharankarNo ratings yet

- BS 7965-2013.part1Document12 pagesBS 7965-2013.part1penjualgasNo ratings yet

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 pagesOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNo ratings yet

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridDocument9 pagesTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerNo ratings yet

- O & M - Kalpataru STP MBBRDocument43 pagesO & M - Kalpataru STP MBBROmkar Bharankar100% (2)

- Technical Proposal RO PT Sarana Tirta Utama 28072021Document11 pagesTechnical Proposal RO PT Sarana Tirta Utama 28072021Budi Iswahyudi100% (1)

- Techno Feasibility Report LAIL 1 PDFDocument28 pagesTechno Feasibility Report LAIL 1 PDFGarad MadhukarNo ratings yet

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Problems PDFDocument9 pagesProblems PDFEduarGelvezNo ratings yet

- Technical Specification SWRO 4x2500cmdDocument23 pagesTechnical Specification SWRO 4x2500cmdJeyakumar Arumugam100% (2)

- Equipment List and CalculationDocument25 pagesEquipment List and CalculationAzman Bin Kadir100% (1)

- Functional Design ReportDocument94 pagesFunctional Design Reportrlowe55No ratings yet

- PFD FileDocument11 pagesPFD FileNaveen MahawarNo ratings yet

- SWTP Operation ManualDocument131 pagesSWTP Operation ManualKASHIFNo ratings yet

- STP Presentation - SBRDocument51 pagesSTP Presentation - SBRNoriel LunaNo ratings yet

- Effluent & Sewage Treatment Plant 110 KLD: Operation ManualDocument10 pagesEffluent & Sewage Treatment Plant 110 KLD: Operation ManualBinod DavisNo ratings yet

- 1-FSS Code - Fire Safety SystemsDocument73 pages1-FSS Code - Fire Safety SystemsMôncèf Bôudlàl100% (3)

- Techno-Commercial Offer For 600 KLD STP MBBRDocument9 pagesTechno-Commercial Offer For 600 KLD STP MBBRTech MongerNo ratings yet

- Monthly Monitoring Report AprilDocument8 pagesMonthly Monitoring Report AprilBrainard ConcordiaNo ratings yet

- Techno Commercial Offer For 120 KLD MBBR Based STP - Option 2 Civil Tank - 02.09.2023-2Document18 pagesTechno Commercial Offer For 120 KLD MBBR Based STP - Option 2 Civil Tank - 02.09.2023-2Saiful SaifNo ratings yet

- مرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقDocument20 pagesمرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقHesham ElshazelyNo ratings yet

- NHT Amine Degrease Procedure Rev2Document29 pagesNHT Amine Degrease Procedure Rev2raj kumarNo ratings yet

- Doc-20240327-Wa0029 240329 163445Document14 pagesDoc-20240327-Wa0029 240329 163445rakshithnayak678No ratings yet

- Ablandador Manual-Hankscraft-Runxin PDFDocument37 pagesAblandador Manual-Hankscraft-Runxin PDFgonzaloagustin84No ratings yet

- Puritainer Wastewater System Description - 200207 PDFDocument6 pagesPuritainer Wastewater System Description - 200207 PDFUghojor ElohoNo ratings yet

- Chemical Program Administration ManualDocument8 pagesChemical Program Administration ManualsudyNo ratings yet

- Welcome To Trainig Programme of Water Tretment, Ro & Chem. DosingDocument22 pagesWelcome To Trainig Programme of Water Tretment, Ro & Chem. Dosingsandeep_jiNo ratings yet

- Engineers's Report AlvieraDocument11 pagesEngineers's Report AlvieraMarco Paolo MagayNo ratings yet

- Assignmnet 3-CPE675-Sept20-Feb21Document5 pagesAssignmnet 3-CPE675-Sept20-Feb21NAJIHANo ratings yet

- Kelani Right Bank Water Treatment Plant Sri LankaDocument11 pagesKelani Right Bank Water Treatment Plant Sri LankaSudeepa SumanasekaraNo ratings yet

- Misr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantDocument29 pagesMisr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantmohamedqadiNo ratings yet

- Month Report-Dec 2021Document22 pagesMonth Report-Dec 2021Ahmed AdelNo ratings yet

- Back Wash RecycleDocument2 pagesBack Wash RecycleMSAJJIMALNo ratings yet

- Tri Con Presentation2013Document29 pagesTri Con Presentation2013Jim TsikasNo ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- Ojt StudiesDocument10 pagesOjt StudiesJochebel MenesesNo ratings yet

- 3000 LTR RO PLANT ISI PLANT R KDocument17 pages3000 LTR RO PLANT ISI PLANT R KVidya SinghNo ratings yet

- Feed Water System: Chanar Energy Limited Tandlianwala FaisalabadDocument11 pagesFeed Water System: Chanar Energy Limited Tandlianwala FaisalabadMuhammadTayyabNo ratings yet

- Biological Treatment Checklist - Suspended Growth - Activated Sludge, Oxidation DitchesDocument13 pagesBiological Treatment Checklist - Suspended Growth - Activated Sludge, Oxidation DitchesRonald Cario SeguinNo ratings yet

- Water Production ProposalDocument10 pagesWater Production ProposaltgistjasonNo ratings yet

- Water Treatment Plant - UPG - Specs.Document4 pagesWater Treatment Plant - UPG - Specs.ashokjj26No ratings yet

- INDUSTRIALPOLLUTIONCONTROLDocument17 pagesINDUSTRIALPOLLUTIONCONTROLRaijo PhilipNo ratings yet

- Energies: Designing Control Strategies of Aeration System in Biological WWTPDocument17 pagesEnergies: Designing Control Strategies of Aeration System in Biological WWTPLouie SerranoNo ratings yet

- U D C 3 5 0 0 A P P L I C A T I o N N o T eDocument4 pagesU D C 3 5 0 0 A P P L I C A T I o N N o T earjun232No ratings yet

- ENVIROZONE - IETS Design - Discription-ThiruDocument11 pagesENVIROZONE - IETS Design - Discription-ThiruNor Rashida HishamNo ratings yet

- CA-1500 SM #2 Hydraulic&MechDocument24 pagesCA-1500 SM #2 Hydraulic&Mechjakab.m.atilaNo ratings yet

- Environmental Biz - Vietnam Market Overview - November 2021Document26 pagesEnvironmental Biz - Vietnam Market Overview - November 2021ngocmai30397No ratings yet

- Daily Turbidity Reading of Raw and Treated Water (May 2017)Document32 pagesDaily Turbidity Reading of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Monthly Monitoring Report MayDocument8 pagesMonthly Monitoring Report MayBrainard ConcordiaNo ratings yet

- Daily Turbidity Reading of Raw and Treated Water (May 2017)Document32 pagesDaily Turbidity Reading of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Comparison of Raw and Treated Water (May 2017)Document2 pagesComparison of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Comparison by Graph of Raw and Treated Water (May 2017)Document2 pagesComparison by Graph of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Manhole 3 Turbidity Reading - MAYDocument1 pageManhole 3 Turbidity Reading - MAYBrainard ConcordiaNo ratings yet

- PolyAluminum Chloride Consumption Record (April 2017)Document3 pagesPolyAluminum Chloride Consumption Record (April 2017)Brainard ConcordiaNo ratings yet

- Comparison of Raw and Treated Water (May 2017)Document2 pagesComparison of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Comparison by Graph of Raw and Treated Water (May 2017)Document2 pagesComparison by Graph of Raw and Treated Water (May 2017)Brainard ConcordiaNo ratings yet

- Treated Water Flowrate Reading (April 2017)Document1 pageTreated Water Flowrate Reading (April 2017)Brainard ConcordiaNo ratings yet

- Treated Water Production and Delivery (April 2017)Document4 pagesTreated Water Production and Delivery (April 2017)Brainard ConcordiaNo ratings yet

- Guidelines For Engineering Reports FOR Wastewater Projects: Oklahoma Funding Agency Coordinating TeamDocument24 pagesGuidelines For Engineering Reports FOR Wastewater Projects: Oklahoma Funding Agency Coordinating Teamjherson gravidesNo ratings yet

- Manhole 3 Turbidity Reading - MAYDocument1 pageManhole 3 Turbidity Reading - MAYBrainard ConcordiaNo ratings yet

- Raw Water Flowrate Reading (April 2017)Document1 pageRaw Water Flowrate Reading (April 2017)Brainard ConcordiaNo ratings yet

- SwitchDocument1 pageSwitchBrainard ConcordiaNo ratings yet

- Treated Water Production and Delivery (April 2017)Document4 pagesTreated Water Production and Delivery (April 2017)Brainard ConcordiaNo ratings yet

- PolyAluminum Chloride Consumption Record (April 2017)Document3 pagesPolyAluminum Chloride Consumption Record (April 2017)Brainard ConcordiaNo ratings yet

- Raw Water Flowrate Reading (April 2017)Document1 pageRaw Water Flowrate Reading (April 2017)Brainard ConcordiaNo ratings yet

- Global Excellence Local ExpertiseDocument16 pagesGlobal Excellence Local ExpertiseAllan YdiaNo ratings yet

- 1720E Turbidimeter Low Range, Analysis Sys-User ManualDocument39 pages1720E Turbidimeter Low Range, Analysis Sys-User ManualVinc PanNo ratings yet

- Butuan 30 MLD Dosing Chart - EditedDocument3 pagesButuan 30 MLD Dosing Chart - EditedBrainard ConcordiaNo ratings yet

- Treated Water Flowrate Reading (April 2017)Document1 pageTreated Water Flowrate Reading (April 2017)Brainard ConcordiaNo ratings yet

- 1720E Turbidimeter Low Range, Analysis Sys-User ManualDocument39 pages1720E Turbidimeter Low Range, Analysis Sys-User ManualVinc PanNo ratings yet

- Guidelines For Engineering Reports FOR Wastewater Projects: Oklahoma Funding Agency Coordinating TeamDocument24 pagesGuidelines For Engineering Reports FOR Wastewater Projects: Oklahoma Funding Agency Coordinating Teamjherson gravidesNo ratings yet

- Florence Hall Sewage Treatment ReportDocument8 pagesFlorence Hall Sewage Treatment ReportFarman Ali KhaskheliNo ratings yet

- Drawing 1Document1 pageDrawing 1Brainard ConcordiaNo ratings yet

- Verma 2017Document14 pagesVerma 2017Bernardo MacaraNo ratings yet

- B2800 Flow Monitor: Programming & Installation Manual Simplified VersionDocument20 pagesB2800 Flow Monitor: Programming & Installation Manual Simplified VersionRicardo SeguraNo ratings yet

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesDocument2 pagesMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesFabian Solano100% (1)

- Hunter Catalog EMDocument264 pagesHunter Catalog EMEng. EsraaNo ratings yet

- Dwyer Rma 32 SSV Flow Meter DatasheetDocument2 pagesDwyer Rma 32 SSV Flow Meter DatasheetPedro PeñaNo ratings yet

- Performance Degradation and Wearing of Electrical Submersible PumpDocument18 pagesPerformance Degradation and Wearing of Electrical Submersible PumpCamilo CajiaoNo ratings yet

- WLA Handbook 3rd Edition - v2 - Web - PLT-EXE PDFDocument115 pagesWLA Handbook 3rd Edition - v2 - Web - PLT-EXE PDFFernanda Medrano MirelesNo ratings yet

- Manuals E PDFDocument5 pagesManuals E PDFjamesrickynNo ratings yet

- Flow ComputerDocument625 pagesFlow ComputersuhailfarhaanNo ratings yet

- VAV Terminal Units: Type LVCDocument16 pagesVAV Terminal Units: Type LVCNikosNo ratings yet

- Grey Water Treatment and Simultaneous Surfactant Recovery Using UF and RO ProcessDocument13 pagesGrey Water Treatment and Simultaneous Surfactant Recovery Using UF and RO ProcessVishal Kumar VermaNo ratings yet

- Gas Holdup in Flotation ColoumnDocument18 pagesGas Holdup in Flotation ColoumnMochamad Kamal IhsanNo ratings yet

- Grounding RingDocument2 pagesGrounding Ringoadipphone7031No ratings yet

- TK20 - Revised Assignment 2 - Excel SizingDocument387 pagesTK20 - Revised Assignment 2 - Excel SizingMuhammad AzharNo ratings yet

- Gas Flow - Pressure RestrictionDocument10 pagesGas Flow - Pressure RestrictionJovicin RadovanNo ratings yet

- Caudalimetro Ultrasonico Kobold DucDocument10 pagesCaudalimetro Ultrasonico Kobold DucBase SistemasNo ratings yet

- Series Ec900 Oxygen Analyzers Operator'S Instruction Manual: (Covers MK3 USB Models)Document51 pagesSeries Ec900 Oxygen Analyzers Operator'S Instruction Manual: (Covers MK3 USB Models)primoNo ratings yet

- Volume 5dDocument387 pagesVolume 5dFabian GuzmanNo ratings yet

- + Basics of DPTsDocument3 pages+ Basics of DPTsCyrix.OneNo ratings yet

- Instrumentação - Vazão - VAFDocument8 pagesInstrumentação - Vazão - VAFCarlinhos da BelinhaNo ratings yet