Professional Documents

Culture Documents

Design of A Shaft

Uploaded by

Siddiqui RanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of A Shaft

Uploaded by

Siddiqui RanaCopyright:

Available Formats

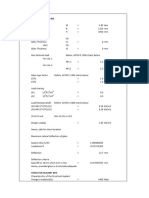

ESR 1.

25 Lakh litres x 10 m

Design Of Shaft

Empty Full

1 Inner dia of shaft 5 m

2 Thickness of shaft 0.15 m

3 Outer dia of shaft 5.3 m

4 Centeral dia of Shaft 5.15 m

5 Fck = 30 N/mm2

6 Fy = 415 N/mm2

7 Modulus of Elasticity = E = 27386.1 N/mm2

8 Total weight of shaft+ Container+ water = W = 1681 2934 kN

9 Total Overturning Moment = M = 2799 3883 kN-m

10 Base shear V = 197 266 kN

Area of shaft = 2.42565 2.426 m2

Moment of Inertia of shaft = I = 8.1 8.1 m4

Section modulus of shaft = Z = 3.039 3.039 m3

Minimum thickness of shaft as per IS 11682 = t min = 150 mm

t min = 150+( ( D - 6000) / 120 )

< 150 mm OK

Permissible buckling stress σb

σb = =0.2 x E x ts x /(Od+Id)/2)/2 314.48 N/mm2

Permissible Buckling Comp. strength of concrete σc =

σc = 0.25 x 0.85 x fck /(1+(fck/σb)) 5.82 N/mm2

Permissible direct comp. stress = 5.82 N/mm2

Permissible bending compresion stress = 8.5 N/mm2

Permissible bending tension stress = 2.125 N/mm2

Area of Shaft required = Total Weight / σc 0.504 m2

Max Comp Stress = (P/A) + (M/Z) 1.6144 2.48739 N/mm2 OK

Min Comp. Stress = (P/A) - (M/Z) -0.2281 -0.0684 N/mm2 OK

25% stress 0.4036 0.6218 OK

Direct comp stress = 0.6932 1.2095 N/mm2 OK

Bending comp stress = 0.9212 1.27789 N/mm2 OK

Ratio (Direct comp stress/Per Dir. comp stress) 0.208

Ratio of (Bending comp stress/Per Bending comp stress) 0.15034

sum= 0.358

Shear stress 0.109 N/mm2

Per. shear stress for min. or no tension steel 0.190 N/mm2

As/clause B.5.2.2 factor for compression member 1.500

Permissible shear stress = 0.19*1.5= 0.285 N/mm2

For EQ force 33% increase may be given at the

engineers' discretion = 0.285 N/mm2 O.K.

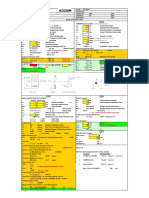

ESR 1.25 Lac x 10 m

VERTICAL STEEL

Minimum % of steel required = 0.25

Ast = 6064.13 mm2

Use 10 mm diameter = 77.7452 no. of bars

Total Steel required in mm2 = 375 mm2 / m

Total Steel required on each face in mm2 = 187.5 mm2 / m / face

Provide 10 mm diameter bar at 300 C/C

Max. permisible spacing = 2 x thickness of shaft (Max. 300)= 300 mm OK

Area of steel provided (vertical steel) = 262 mm2 / m/face OK

Bending Tension / m =bt = 10258 N/m

Vertical Steel to meet bending tension = bt / (230*1.33) = 34 mm2

Vertical steel Provided /m = 523.333 mm2

OK

HORIZONTAL STEEL

Minimum % of steel required = 0.2

Total Steel required in mm2 = 300 mm2 / m

Minimum Horizontal steel as per code / m = 400 mm2 / m

Total Steel required on each face in mm2 = 200 mm2 / m / face

Provide 8 mm diameter bar at 150 C/C

Maximum permisible spacing = 150 mm OK

Area of steel provided (horizontal steel) = 334.93 mm2 / m/face OK

Horizontal steel Provided /m = 669.867 mm2

OK

Summary

dia spacing Ast Provided mm2 (2 faces)

Vertical steel at each face 10 300 523.333

Horizontal steel at each face 8 150 669.867

Internal diameter 5m

Thickness of the wall 150 mm

ESR 1.25 Lac x 10 m

You might also like

- Slab DesignDocument6 pagesSlab DesignmadhuNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- One Way Slab Design: 1. Calculation of LoadDocument6 pagesOne Way Slab Design: 1. Calculation of LoadSaugat ThapaNo ratings yet

- Cantilever Slab Beam Design For TorsionDocument17 pagesCantilever Slab Beam Design For TorsionNikhil100% (1)

- Steel Staircase DesignDocument6 pagesSteel Staircase DesignMario FeghaliNo ratings yet

- Cantlver SlabDocument8 pagesCantlver SlabsheikNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Share Wall Design As Per Is 456Document2 pagesShare Wall Design As Per Is 456Sanjay RokkaNo ratings yet

- Design of Valve-chamber-Vc - 08 & 12-13-04-23Document26 pagesDesign of Valve-chamber-Vc - 08 & 12-13-04-23desilcharpdmcNo ratings yet

- 3-Stress Check - Rectangular AbutDocument6 pages3-Stress Check - Rectangular Abutsanjay vermaNo ratings yet

- Structural Cals For UCWDocument11 pagesStructural Cals For UCWShubham SoniNo ratings yet

- Design of One Way Slab (Continuous) : Given DataDocument3 pagesDesign of One Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Design ExamplesDocument42 pagesDesign ExamplesARSENo ratings yet

- Slab & BeamDocument34 pagesSlab & BeamVishruth JainNo ratings yet

- Butterfly Valve Chamber Design - 300 - 700mm DIDocument6 pagesButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Beam Design (SSB)Document6 pagesBeam Design (SSB)Er Sai KiranNo ratings yet

- Ohsr - 17 - 20 - HealthDocument10 pagesOhsr - 17 - 20 - HealthPrashant GargNo ratings yet

- Deck Member Design - AshuDocument11 pagesDeck Member Design - Ashurehan7421No ratings yet

- Super PassageDocument5 pagesSuper PassageSamir Rawat0% (1)

- Structural Design and Drawing of Clarifloculator Chiragaon 10MLDDocument4 pagesStructural Design and Drawing of Clarifloculator Chiragaon 10MLDShashank0% (1)

- Design of 200m3 TankDocument4 pagesDesign of 200m3 TankMiko AbiNo ratings yet

- Design of Built-Up Column: Section UsedDocument6 pagesDesign of Built-Up Column: Section UsedKrishna KumarNo ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- StaicaseDocument4 pagesStaicaseAlex MachariaNo ratings yet

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Bending Strength CheckDocument2 pagesBending Strength CheckwaquarstrNo ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- Two Way SLabDocument22 pagesTwo Way SLabDevesh GuptaNo ratings yet

- Design of Pad Footings BS 8110Document4 pagesDesign of Pad Footings BS 8110thanigai veluNo ratings yet

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Document3 pagesDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Water Tank - Is 3370-Sludge TankDocument4 pagesWater Tank - Is 3370-Sludge TankDhayalan PalanisamyNo ratings yet

- Slab Thickness : 0.92 KN 8.825kN/mDocument6 pagesSlab Thickness : 0.92 KN 8.825kN/mhamza hanifNo ratings yet

- Stud-Bolts Connection - 650x650Document10 pagesStud-Bolts Connection - 650x650Ammar Ayub0% (1)

- SlabDocument6 pagesSlabBishal ShresthaNo ratings yet

- Cantilever Beam 450x600Document27 pagesCantilever Beam 450x600Shivaranjan HJNo ratings yet

- Design of Cantilever Slab As Per Is 456 - 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 - 2000Sanjay RokkaNo ratings yet

- Rough SL TH CalDocument53 pagesRough SL TH CalAnkita PalNo ratings yet

- Sludge ThicknerDocument28 pagesSludge ThicknerAnkita PalNo ratings yet

- Design of Slab. S1: Between Grid 18 and 19 First Floor: Provide #10 at 150 MM C/C at Bottom Along Short SpanDocument3 pagesDesign of Slab. S1: Between Grid 18 and 19 First Floor: Provide #10 at 150 MM C/C at Bottom Along Short SpanPrashant PatilNo ratings yet

- Beam DesignDocument18 pagesBeam DesignBuddhiraj kadelNo ratings yet

- Design of Pile Cap: X Y XYDocument2 pagesDesign of Pile Cap: X Y XYvoilNo ratings yet

- Cantilever Slab DesignDocument2 pagesCantilever Slab Designsibu_bhusalNo ratings yet

- 2 Way Slab DesignDocument6 pages2 Way Slab DesignAditya singhNo ratings yet

- Design Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415Document5 pagesDesign Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415swapan.boseNo ratings yet

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Water Tank - Is 3370-MBBR Tank - 1 & 2Document4 pagesWater Tank - Is 3370-MBBR Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Design of Cantilever Slab As Per IS 456 2000Document2 pagesDesign of Cantilever Slab As Per IS 456 2000Ram LangheNo ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- Singly Reinforcrd BeamDocument2 pagesSingly Reinforcrd BeamLikith Gowda MNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- 3) Corbel DesignDocument10 pages3) Corbel Designp_ignatiusNo ratings yet

- Roof Slab of Guard RoomDocument3 pagesRoof Slab of Guard RoomAditya KumarNo ratings yet

- Combi 30 EngDocument2 pagesCombi 30 EngSiddiqui RanaNo ratings yet

- Uniform Grid SpacingDocument1 pageUniform Grid SpacingSiddiqui RanaNo ratings yet

- Steps To Do Sample ProjectDocument1 pageSteps To Do Sample ProjectSiddiqui RanaNo ratings yet

- Default FolderDocument5 pagesDefault FolderSiddiqui RanaNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- Read Me!Document1 pageRead Me!Siddiqui RanaNo ratings yet

- Wind Loadn CalculationDocument1 pageWind Loadn CalculationSiddiqui RanaNo ratings yet

- Dubai Municipality G 1 G 4 G 12 Exams MCQs 1690895684Document20 pagesDubai Municipality G 1 G 4 G 12 Exams MCQs 1690895684osama75% (8)

- Aramco Comment Excel SheetDocument1 pageAramco Comment Excel SheetSiddiqui RanaNo ratings yet

- Fabric Form FindDocument1 pageFabric Form FindSiddiqui RanaNo ratings yet

- Foundation DesignDocument1 pageFoundation DesignSiddiqui RanaNo ratings yet

- Load Calculation HDPE Fabric Car Parking ShadesDocument1 pageLoad Calculation HDPE Fabric Car Parking ShadesSiddiqui Rana100% (1)

- NDN Membrane SoftwareDocument11 pagesNDN Membrane SoftwareShaikh Muhammad AteeqNo ratings yet

- Tq114a eDocument10 pagesTq114a eShaikh Muhammad AteeqNo ratings yet

- RCC81 Foundation PadsDocument23 pagesRCC81 Foundation PadsSiddiqui RanaNo ratings yet

- 06 Story StiffnessDocument2 pages06 Story StiffnessDigvijay GiraseNo ratings yet

- Soil Resources Inventory For Land Use PlanningDocument9 pagesSoil Resources Inventory For Land Use PlanningmehNo ratings yet

- Iaph LNG Bunker Checklist Bunker Station To Ship Final v3.6 Incl GuidelinesDocument26 pagesIaph LNG Bunker Checklist Bunker Station To Ship Final v3.6 Incl Guidelines서창빈No ratings yet

- 07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PDocument65 pages07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PjedossousNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaJohny Iskandar Arsyad NstNo ratings yet

- AD GT3000 Catalogue en 12-07 CDocument52 pagesAD GT3000 Catalogue en 12-07 CMohamed AlkharashyNo ratings yet

- Pharmacology SamplexDocument12 pagesPharmacology SamplexLiezel Dejumo BartolataNo ratings yet

- Manila Revenue Code, As Amended (Ordinance No. 7988)Document121 pagesManila Revenue Code, As Amended (Ordinance No. 7988)Charles Augustine AlbañoNo ratings yet

- UHF and 5 Gigahertz (60 MM) SHF ISM Radio BandsDocument3 pagesUHF and 5 Gigahertz (60 MM) SHF ISM Radio BandsAnandhu cNo ratings yet

- Presentation RAB Jalan Dan Jembatan PT. GUNUNG TANGINDocument9 pagesPresentation RAB Jalan Dan Jembatan PT. GUNUNG TANGINMuhammad Rabbil AlbadriNo ratings yet

- Rofecoxib Inhibits Heterotopic Ossification AfterDocument146 pagesRofecoxib Inhibits Heterotopic Ossification AfterHaqqi IslamiNo ratings yet

- Journal of Experimental Biology and Agricultural Sciences: Anitha KC, Rajeshwari YB, Prasanna SB and Shilpa Shree JDocument5 pagesJournal of Experimental Biology and Agricultural Sciences: Anitha KC, Rajeshwari YB, Prasanna SB and Shilpa Shree Jkristel amadaNo ratings yet

- 8-Unit, Low-Saturation Driver: Package Dimensions ApplicationsDocument4 pages8-Unit, Low-Saturation Driver: Package Dimensions ApplicationsTestronicpartsNo ratings yet

- Type VBPDF: Pilot Operated Check ValvesDocument3 pagesType VBPDF: Pilot Operated Check ValvesAslam ShaikhNo ratings yet

- EarlyDocument59 pagesEarlyjrtlimNo ratings yet

- The Hidden Word Is: The CluesDocument2 pagesThe Hidden Word Is: The CluesИра НикулочкинаNo ratings yet

- Technical Specifications For LT/HT, XLPE Insulated Aluminium/Copper CablesDocument49 pagesTechnical Specifications For LT/HT, XLPE Insulated Aluminium/Copper CablesAjay KumarNo ratings yet

- Natal Chart ReportDocument23 pagesNatal Chart ReportEvelyn WilsonNo ratings yet

- Echo SounderDocument2 pagesEcho SounderDimas AnggaNo ratings yet

- GG IFA CPCC FV V5 2 enDocument151 pagesGG IFA CPCC FV V5 2 enNys Del Tropico SaNo ratings yet

- DimensionsDocument103 pagesDimensionslaurariton100% (1)

- 10th PET POW EM 2023 24Document6 pages10th PET POW EM 2023 24rpradeepa160No ratings yet

- Anatomy-Head and NeckDocument94 pagesAnatomy-Head and NeckXahid IqbalNo ratings yet

- Commercial Galvanic Cells: BatteriesDocument9 pagesCommercial Galvanic Cells: BatteriesKamalpreet SinghNo ratings yet

- Critical Planning Issues in MTODocument2 pagesCritical Planning Issues in MTOAzhar QadriNo ratings yet

- Soundarya Lahari Translation in EnglishDocument50 pagesSoundarya Lahari Translation in EnglishRanganatha Gowda100% (1)

- Weapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)Document1 pageWeapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)John SmithNo ratings yet

- Tank Vessel Overflow Line SizingDocument4 pagesTank Vessel Overflow Line SizingSteve Wan100% (1)

- Start Up Slug Catcher and Train 1Document43 pagesStart Up Slug Catcher and Train 1Larbi HammounNo ratings yet

- Berk-2009-Journal of Forensic SciencesDocument9 pagesBerk-2009-Journal of Forensic SciencesClaudio NovaesNo ratings yet