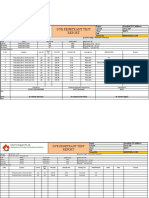

LINTEC KUALA LUMPUR SDN BHD

Tape Measure Inspection Log

Master Equipment Calibration S/N : MBP6064

Indicate Pass or Fail on Push and Pull Measurement

Temp. Inside Outside Inspected

Examine for

ID Tag No Model # Measurement Measurement 6" Push Date

(Deg c) Damage

Accuracy Accuracy by

MT001 RD Tape 22 Nil Pass N/A Pass 19/09/23 Amy (Tech)

MT002 RD Tape 22 Nil Pass N/A Pass 19/09/23 Amy (Tech)

MT002 RD Tape 22 Nil Pass N/A Pass 19/09/23 Amy (Tech)

MT004 RD Tape 22 Nil Pass N/A Pass 19/09/23 Amy (Tech)

verified By:

Rizal

Date:21/09/2023

LINTEC KUALA LUMPUR SDN BHD

Steel Ruler Measure Inspection Log

Master Equipment Calibration S/N : MBP6065

Indicate Pass or Fail on Push and Pull Measurement

Temp.(Deg Examine for Gradation Lines Inspected

ID Tag No Model # Flatness Straight Edge Date

c) Damage Consistency by

RSS001 SF Steel Ruler 22 Nil Pass Clear & OK Pass 19/09/23 Amy (Tech)

RSS002 SF Steel Ruler 22 Nil Pass Clear & OK Pass 19/09/23 Amy (Tech)

verified By:

Rizal

Date:21/09/2023

�Steel Measuring Tape Calibration

Step 1: Tools Needed:

1. The retractable steel tape measure you want to calibrate. This may be a new tape measure you want to check for accuracy or an old, accurate.

well used tape measure you suspect is not accurate.

2. A straight measuring ruler. This should be a trusted ruler with fine, engraved lines for markings. A framing square or tri-square would be good.

Increments of 1/16 inch or better is needed. A printed, promotional yard stick is not a good choice, since it will have wide marking lines.

3. Two pair of pliers. These can be basic slip joint pliers, needle nose pliers or locking type pliers. They do not need to be identical types.

Step 2: Examine for Damage

1) Carefully examine the hook end of the tape measure. Do you need to clean dirt and gunk? Is the tape cracked at the rivets attaching the hook?

If the tape is damaged, calibration may not improve accuracy and the useful life of the tape may be over.

Step 3: Check Inside Measurement Accuracy

1) Check the tape accuracy with inside measurement. Press the outside against a surface while

the ruler is also pushed against the same surface. Observe the difference between the 1 inch mark

for the tape measure and the ruler.Use 'Magnifying Glass' to check gradation line accuracy.

2) If the 1 inch marks are aligned, the tape is accurate for inside measurements.

3) If the 1 inch marks are not perfectly aligned, write down the TAPE measurement at

the 1 inch mark of the ruler. Mark this measurement with INSIDE.

Step 4: Check Outside Measurement Accuracy

1) Next place the hook of the tape measure over the end of the ruler. Carefully position the hook so

the end of the tape hook is extended the maximum distance from the tape.

2) Observe the difference between the 1 inch mark of the tape measure and the 1 inch mark of the ruler.

3) If the marks are perfectly aligned, the tape measure is accurate for outside measurements.

4) If there is a difference, write down the TAPE measurement at the 1 inch mark of the ruler.

Mark this measurement with OUTSIDE.

�** If both inside and outside accuracy checks are aligned with the ruler, then the tape measure hook does not need adjustment.

Your tape measure is accurate and can be used with confidence!

�Step 5: Determine How to Adjust the Hook

1) Gather your notes from your initial checks for inside and outside accuracy.

Remember these measurements were read on the TAPE at the 1 inch mark of the ruler.

*INSIDE CHECK~ If the tape measurement is GREATER THAN the ruler on inside check,

then the tape hook is too long and must be bent toward the tape.

If the tape measurement is LESS THAN the ruler on inside check,

the tape hook is too short and the hook must be bent out from the tape.

The amount of the measurement difference from 1 inch is the amount the hook need to bend.

*OUTSIDE CHECK~ If the tape measurement is GREATER THAN the ruler on outside check,

the tape hook is too short and needs to be bent toward the tape.

If the tape measurement is LESS THAN the ruler on the outside check,

the tape hook is too short and must be bent out from the tape.

The measurement difference form 1 inch on the ruler is the amount the hook tab needs to be bent.

If the inside check and outside checks indicate opposite tab adjustments, you will not be able to calibrate the tape measure.

If you have any doubts about your initial inside and outside checks, repeat the process.

�Step 6: Adjusting the Hook

1) Grip the tape hook at the rivet area with one of the pliers.

2) Grip the hook tab with the second pliers. Be careful to hold the rivet end

stationary and only bend the hook tab.

3) Do not damage the end of the flexible tape.

4) Make very small adjustments and then retest for accuracy as noted in the steps below.

5) If you fear you may damage the marks on the tape,wrap a couple turns of electrical tape around

the tape measure to protect the marks.

Step 7: Repeat Inside Accuracy Check

Repeat Step 3 to confirm you have adjusted the hook tab as needed for inside measurements.

Step 8: Repeat Outside Accuracy Check

Repeat Step 4 to confirm you have adjusted the hook tab as needed for outside measurement accuracy.

Step 9: Adjust the Hook Again If Needed

If you have not adjusted the hook correctly to pass the latest accuracy check, repeat Step 6 again.

Try to make very small adjustments to the hook tab.

Step 10: Check Inside Accuracy Again

Repeat Step 3 to confirm you have adjusted the hook tab as needed for accuracy.

Step 11: Recheck Outside Accuracy

Repeat Step 4 again to confirm you have adjusted the hook tab as needed

1) If the inside and outside tests are both correct, you have completed the calibration process!

2) You can now make measurements with assurance you will have accuracy on both inside and outside measurements.

3) If repeated adjustments cannot make the tape accurate for both inside and outside measurement,

the tape may be beyond calibration !! Marked this tape with permanent marker & disposed it.