Professional Documents

Culture Documents

HSCM BRL ITP 002 Fire Installation Works

Uploaded by

Habib BagciCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSCM BRL ITP 002 Fire Installation Works

Uploaded by

Habib BagciCopyright:

Available Formats

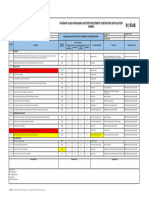

#VALUE!

HUNGARY GLASSPACKAGING FACTORY

INSPECTION, CONTROL AND TEST PLAN (ITP)

Methot Of Statement Fire Installation Works MOS Document No BM-MOS-PLN-003

Document No HSCM-BRL-ITP-002 Rev.No

Date 3/1/2024 Rev.Date

ACTION GENARAL DOCUMENTS

TEST

S.No ACTİVİTY

FREQUENCY

RESPONSIBLE

S.C C CL REFERENCE DOCUMENT ACCEPTANCE CRİTERİA STATUS GENERAL NOTES

PARTY

1 DOCUMENTATION

1.1 Contractor drawings. 100% W Contract,PQP,Approved Drawing,Project Specification DIN Standards,NFPA,,Project specification,MOS QCI

1.2 Verify calibration of inspection, measuring and test equipment. 100% W Project Specification,Manufacturer Recommendation,PQP DIN Standards,NFPA,,Project specification,MOS QCI

2 MATERIALS

Approved Drawing,Manufacturer,Instruction,

DIN Standards,NFPA,,Project specification,MOS,Material

2.1 Control of pipes and insulation products to be used. 100% W Approved,Material Submittal,Purchase Order,Project QCI A

Submittal

Specification

Project Specification,Manufacturer DIN Standards,NFPA,,Project specification,MOS,Material

2.2 Pipe Fitting Equipment (Bolt, DObel, Rod, Profile, Clip). 100% W QCI A

Recommendation,Material Submittal Submittal

Project Specification,Manufacturer DIN Standards,NFPA,,Project specification,MOS,Material

2.3 Fire Equipments (Fire Pump, Fire Cabinet, Zone Valves, Compressor, Valves). 100% W QCI A

Recommendation,Material Submittal Submittal

3 INSTALLATİON

3.1 Pipe Installation as per approved drawings. 100% W DIN Standards,NFPA,,Approved Drawing DIN Standards,NFPA,,Project specification,MOS QCI

3.2 Valve and Accessory Assembly Control. 100% W Approved Drawing.PQP,DIN Standards,NFPA, DIN Standards,NFPA,,Project specification,MOS QCI

DIN Standards,NFPA,,Project specification,Approved

3.3 Hangers and support installation support spacing,ducting route,reinforcement & hangers. 100% S DIN Standards,NFPA,,Project specification,MOS QCI

Drawing.MOS

DIN Standards,NFPA,,Project specification.MOS,Material

3.4 Pipe Paint material are conforming to the project specification. 100% W DIN Standards,NFPA,,Project specification,MOS QCI A

Submittal

DIN Standards,NFPA,,Project specification.MOS,Material

3.5 Fittings, Threaded Branch and Clamp Compliance Control. 100% W DIN Standards,NFPA,,Project specification,MOS QCI A

Submittal

DIN Standards,NFPA,,Project specification.MOS,Material

3.6 Pipe Internal Cleanliness Control with Flushing Application. 100% W DIN Standards,NFPA,,Project specification,MOS QCI A

Submittal

DIN Standards,NFPA,,Project specification.MOS,Material

3.7 Sprinkler Installation Control Suitable for Intended Use. 100% W DIN Standards,NFPA,,Project specification,MOS QCI A

Submittal

4 EQUIPMENT INSTALLATİON

4.1 Fire Equipments (Fire Pump, Fire Cabinet, Zone Valves, Compressor, Valves) Check as per Approved Drawing. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

4.2 Dilatation Expansion Joint Installation Control. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

4.3 Equipment Foundation Location Check as per Approved Drawing. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

4.4 Verify unit Installation is as per approved Drawing, Check Vibration pad Place Beneath the Package Equipment installation. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

4.5 Fire Cabinet Model, Sheet Thickness, Lock, Paint Color etc. Compliance Check. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

4.6 Fire Brigade Connection Nozzles, Cabinet Internal Sets (Tube and Hose) Assembly Control. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

5 FINAL INSPECTION

5.1 Check Orientation & Level is per IFC Drawing.Check Condensate Drain System is as per approved drawing. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

5.2 Check for leak test for pipe installation. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

5.3 Control of Tightness Tests of Pipes (Hydrostatic Test, 1.5 times the operating pressure 24 hours). 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

5.3 Conducting Operational Tests, Complete Commissioning of the Entire System and Labeling. 100% W Approved Drawing.PQP,Project specification DIN Standards,NFPA,,Project specification,MOS QCI

S.No Action Definitions Codes GENERAL NOTES

1 Sub-Contractor S.C

2 Contractor C

3 Clıent CL

4 Inspectıon / Test I

5 Document Issued/Report Revıew R

6 Surveılance S

7 Hold Poınt (Notification Required And Presence Mandatory) H

8 Wıtness (Notification Required But Presence Not Mandatory) W

S.No Statüs Definitions Codes

1 Approved A

2 Awaiting Approval A.A

3 Verbal Approval V.A

4 No Presentation N.P

5 Rejected R

You might also like

- HSCM-BRL-ITP-004 Sanitary İnstallation WorksDocument1 pageHSCM-BRL-ITP-004 Sanitary İnstallation WorksHabib BagciNo ratings yet

- HSCM-BRL-ITP-003 Heating and Cooling Installation WorksDocument1 pageHSCM-BRL-ITP-003 Heating and Cooling Installation WorksHabib BagciNo ratings yet

- HSCM BRL ITP 001 Ventılatıon Installatıon WorksDocument1 pageHSCM BRL ITP 001 Ventılatıon Installatıon WorksHabib BagciNo ratings yet

- Inspection and Test Plan (ITP) - Civil WorksDocument1 pageInspection and Test Plan (ITP) - Civil WorksNaveen GladsonNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Inspection Test Plan For Erection of Tower CraneDocument5 pagesInspection Test Plan For Erection of Tower CraneMarco AragonesNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Itp Piping Rev 0Document2 pagesItp Piping Rev 0Angel Rebollo100% (1)

- Itp Jib Crane Rev.1Document1 pageItp Jib Crane Rev.1Roger MahilumNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Inspection and Test Plan Ventılatıon Installatıon Works 21 MarchDocument1 pageInspection and Test Plan Ventılatıon Installatıon Works 21 MarchHabib BagciNo ratings yet

- Industrial Water Pump 6600-P-02BDocument25 pagesIndustrial Water Pump 6600-P-02BJp RaoNo ratings yet

- PGC Q q2 RP 001 W Rfi Besi Rebar1Document4 pagesPGC Q q2 RP 001 W Rfi Besi Rebar1MacrhyMath AllaydruzztNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- ITP-Refrac 03B001&02B001-1Document2 pagesITP-Refrac 03B001&02B001-1มิตร อันมา100% (2)

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

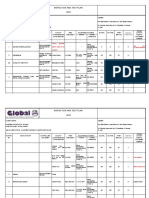

- Inspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Document4 pagesInspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Ubed KudachiNo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- Process Map Project Construction Reporting Requirements: in Amenas Gas ProjectDocument2 pagesProcess Map Project Construction Reporting Requirements: in Amenas Gas ProjectChiheb KaanicheNo ratings yet

- 6143-MAR-EU-1029 - R0 (1) Approved MAR For Terminal Lug & Cable Accessories (Speedwell)Document55 pages6143-MAR-EU-1029 - R0 (1) Approved MAR For Terminal Lug & Cable Accessories (Speedwell)NAVANEETHNo ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- 2.7 Inspection Test PlanDocument53 pages2.7 Inspection Test PlanLeo FirstsonNo ratings yet

- Civil FQP 22.11.22Document5 pagesCivil FQP 22.11.22Sankha Subhra JashNo ratings yet

- ITP Tempo BridgeDocument2 pagesITP Tempo BridgeSam GalangNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- PT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone TestDocument1 pagePT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone TestRangga GautamaNo ratings yet

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

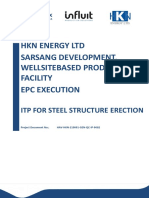

- HKN Energy LTD Sarsang Development, Wellsitebased Production Facility Epc ExecutionDocument4 pagesHKN Energy LTD Sarsang Development, Wellsitebased Production Facility Epc ExecutionDelil OzanNo ratings yet

- 8-1 Din R0Document2 pages8-1 Din R0Kingston RivingtonNo ratings yet

- l5 Dza FMT 068 Rev 01 Rapport CND UtDocument2 pagesl5 Dza FMT 068 Rev 01 Rapport CND Utzakaria khaledNo ratings yet

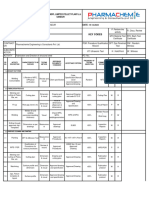

- Inspection and Test Plan Fire Installation WorksDocument1 pageInspection and Test Plan Fire Installation WorksHabib BagciNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- ITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1Document5 pagesITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1amirskbkbk0% (1)

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- ITP For BLOCKWORKDocument4 pagesITP For BLOCKWORKimkashifsaleemNo ratings yet

- ROKA-RDNLGENA000-CIV-CAL-PHR-2001-00 Job Mix Formula Design For CTB (Cement-Treated Base) ApplicationDocument35 pagesROKA-RDNLGENA000-CIV-CAL-PHR-2001-00 Job Mix Formula Design For CTB (Cement-Treated Base) ApplicationLucky Cahya PermanaNo ratings yet

- Inspection and Test Plan For Waterproofing WorksDocument8 pagesInspection and Test Plan For Waterproofing WorksResearcherNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- Rfi Log 24.12.2020Document67 pagesRfi Log 24.12.2020Deepu CNo ratings yet

- Power Transformer Test Format 1ZTR 131300Document35 pagesPower Transformer Test Format 1ZTR 131300Ahmed Badr100% (1)

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Icl Condensate TrapDocument5 pagesIcl Condensate TrapAlberto CamposNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- ITP Inspection and Testing Plan For Above Ground Water Supply PipesDocument1 pageITP Inspection and Testing Plan For Above Ground Water Supply Pipessarmad spectrumNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- ITP Fire Hydrant Installation Testing CommissioningDocument1 pageITP Fire Hydrant Installation Testing CommissioningAmie GTunedNo ratings yet

- R03 C03B01 Mag MTS Ci 0006 - 01Document26 pagesR03 C03B01 Mag MTS Ci 0006 - 01Syed AliNo ratings yet

- ITP For Testing & Commissioning SwitchgearDocument1 pageITP For Testing & Commissioning SwitchgearguspriyNo ratings yet

- Itp - Refrigerant Pipe & Ac Split InstallationDocument9 pagesItp - Refrigerant Pipe & Ac Split InstallationGultom Juliana LiliesNo ratings yet

- Itp Installation of 11kv HV Switchgear Rev.00Document2 pagesItp Installation of 11kv HV Switchgear Rev.00syed fazluddin100% (1)

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- SATIP-A-000-01 Rev 7Document1 pageSATIP-A-000-01 Rev 7Zuhaib KhanNo ratings yet

- ITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1Document10 pagesITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1amirskbkbkNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- JISKOOT 210 SD Probe Rev 4Document49 pagesJISKOOT 210 SD Probe Rev 4ray mojicaNo ratings yet

- Demo Junit Test: Introduction To Software TestingDocument21 pagesDemo Junit Test: Introduction To Software TestingNguyên HưngNo ratings yet

- Scheme of Work: Cambridge IGCSE / Cambridge IGCSE (9-1) Computer Science 0478 / 0984Document39 pagesScheme of Work: Cambridge IGCSE / Cambridge IGCSE (9-1) Computer Science 0478 / 0984Syed Ashar80% (10)

- WFT101353 Weatherford Valves - CatalogoDocument13 pagesWFT101353 Weatherford Valves - Catalogoandres peraltaNo ratings yet

- GA and ANNDocument17 pagesGA and ANNini benNo ratings yet

- Chapter 5 - The Expenditure Cycle Purchasing To Cash DisbursementsDocument3 pagesChapter 5 - The Expenditure Cycle Purchasing To Cash DisbursementsHads LunaNo ratings yet

- Zenith 913 Manual Book PDFDocument190 pagesZenith 913 Manual Book PDFArvin Bhurtun71% (7)

- BCA 605 Practical File CompletedDocument15 pagesBCA 605 Practical File CompletedEr Niraj SinghNo ratings yet

- DC-6 Service ManualDocument179 pagesDC-6 Service ManualJairo ManzanedaNo ratings yet

- We're Programming Your Future: Melsec MedocDocument8 pagesWe're Programming Your Future: Melsec MedocSlawaNo ratings yet

- Linux Command Line Cheat SheetDocument21 pagesLinux Command Line Cheat SheetbelopezpNo ratings yet

- Getting Started With The MERN StackDocument11 pagesGetting Started With The MERN StackSunee100% (1)

- 40-Ipl32l-Pwg1xg China Psu PDFDocument3 pages40-Ipl32l-Pwg1xg China Psu PDFotavio jose sbarainiNo ratings yet

- IGCC-OPM-QUA-FMT-0097 Rev.0 - INSPECTION OF ELECTRICAL CABLES AFTER INSTALLATION, GLANDING ADocument1 pageIGCC-OPM-QUA-FMT-0097 Rev.0 - INSPECTION OF ELECTRICAL CABLES AFTER INSTALLATION, GLANDING AAhmedNo ratings yet

- Ankit Bhardwaj ResumeDocument2 pagesAnkit Bhardwaj ResumearpitdagreatNo ratings yet

- DAYTONA HPI AC-InFR-SF UK2301167-1 Interfabrics BS5852 Pt1 1979 CertificateDocument4 pagesDAYTONA HPI AC-InFR-SF UK2301167-1 Interfabrics BS5852 Pt1 1979 Certificateandy.maldiniNo ratings yet

- Rashid Jamal's Resume: Full NameDocument3 pagesRashid Jamal's Resume: Full Namerasheed17No ratings yet

- Sales Order & Pricelist Jobs - Id (Promo Februari 2021)Document1 pageSales Order & Pricelist Jobs - Id (Promo Februari 2021)Asriadi KPF SemarangNo ratings yet

- Web Technology Assignment OneDocument4 pagesWeb Technology Assignment OneAlemgena YeshuNo ratings yet

- Home Theater LG DH4220S C/ DVD Player 330W RMS - 5.1 Canais, Conexão HDMI e USB, KaraokêDocument1 pageHome Theater LG DH4220S C/ DVD Player 330W RMS - 5.1 Canais, Conexão HDMI e USB, KaraokêTiara RoweNo ratings yet

- Physics 5054: MCM Nkana Secondary School End of Topic Test 1Document10 pagesPhysics 5054: MCM Nkana Secondary School End of Topic Test 1Jedediah PhiriNo ratings yet

- Instant Download Strategic Market Management 11th Edition Aaker Solutions Manual PDF Full ChapterDocument7 pagesInstant Download Strategic Market Management 11th Edition Aaker Solutions Manual PDF Full Chapteramityleightonwfp9z100% (6)

- Twenty: 20.1 Try Yourself Create OSM Based Vector FilesDocument10 pagesTwenty: 20.1 Try Yourself Create OSM Based Vector Filesສີສຸວັນ ດວງມະນີNo ratings yet

- 18ec42 Module 5 (SB Bkit)Document151 pages18ec42 Module 5 (SB Bkit)sharanbasappaNo ratings yet

- PEST Analysis: Technological FactorsDocument2 pagesPEST Analysis: Technological FactorsM Jawad AliNo ratings yet

- 785C - Apx LineasDocument43 pages785C - Apx LineasChema VenegasNo ratings yet

- Get File From Url PDFDocument24 pagesGet File From Url PDFluqmanNo ratings yet

- Kennvood DMF9020 SMDocument29 pagesKennvood DMF9020 SMbetmenn45No ratings yet

- Type of Fixture Maximum Allowable Flow RateDocument3 pagesType of Fixture Maximum Allowable Flow RateChinadevudu GandiNo ratings yet

- MS837 Brochure RevBDocument1 pageMS837 Brochure RevBevelinpirajanNo ratings yet