Professional Documents

Culture Documents

EMX¦11¦E¦H-------EN¦DC¦004-en-A-HRSG Guarantees (T212B4; Appendix 4)

Uploaded by

RichardLemusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EMX¦11¦E¦H-------EN¦DC¦004-en-A-HRSG Guarantees (T212B4; Appendix 4)

Uploaded by

RichardLemusCopyright:

Available Formats

HRSG Guarantees (T212B4; Appendix 4)

EVM II

EVM Energía del Valle de Mexico II

Combined Cycle Power Plant

Cross checked

Department Name Date Signature

Revision History

Rev. Revision Date Created by Checked by Approved by Brief Description

Description current Revision

Owner Contractor

General Electric (Switzerland) GmbH

GE Power Systems Inc.

GE Global Services GmbH

Replaces Customer Code Project Document Code

EMX/11/E/H-------EN/DC/004

Responsible Created by Checked by Approved by Format

GS-EM U. Saur U. Spannenberger G. Mouttouvengattaroyal DIN A4

Document Type Document Status

DC Released

GE POWER Document Title Identification Number

Gas Power Systems HRSG Guarantees (T212B4; 1GP006589

Rev. Date Lang. Sheet

Appendix 4) A 23.06.2017 en 1/7

GBM Gas Master Doc Temp (ZZZ)

GE CLASS II (INTERNAL NON-CRITICAL)

© COPYRIGHT 2017 General Electric Company

All rights reserved. The information herein is Proprietary and Technically Exclusive content that is solely owned by General Electric Company

and/or its affiliates. Thus, it is being provided with the explicit expectation of restricted and privileged use. All recipients of this information

shall be deemed to have agreed not to make duplications, reproductions of any nature by any means, modifications, disclosures, or use any

portion of this material; except as is expressly authorized in writing by the General Electric Company, and/or its legitimate affiliates.

g GE Power EVM II Spec. No. T212B4

The HRSG design point is Case Number 1 of Appendix B17 of the

HRSG performance specification.

Tests to demonstrate the guaranteed performance shall be

conducted in accordance with the Thermal Performance Test

Procedure, Appendix B7.

The following performance shall be guaranteed for these HRSG

Requested Guarantees Vendor Guarantees

Case numbers of Appendix B17.

1 2 1 2

GE will verify the HRSG heat transfer surface areas and the HRSG

supplier shall only use designs and surface areas which have

been approved by GE.

The energy output in the high pressure steam shall not be less

than:10^6 kJ/hr 1010,60 1267,90

The energy output in the high pressure steam, plus the

superheated intermediate pressure steam shall not be less

than:10^6 kJ/hr 1083,10 1310,90

The energy output in the high pressure steam, plus the

superheated and saturated intermediate pressure steam shall

not be less than:10^6 kJ/hr 1083,10 1310,90

The energy output in the high pressure steam, plus the

superheated and saturated intermediate pressure steam, plus

the low pressure steam shall not be less than:10^6 kJ/hr 1203,20 1407,20

The energy output in the intermediate pressure economizer

discharge water export shall not be less than:10^6 kJ/hr 27,20 26,50

The total HRSG energy output shall not be less than:10^6 kJ/hr 1230,40 1433,70

Duct burner fuel consumption shall not exceed: 10^6 kJ/hr, LHV 0,00 186,50

Steam temperature at the discharge of the high pressure

superheater shall be no hotter than 586.4 °C to no colder than5.6

°C below the value shown in this table: 578,9 575,4

Steam temperature at the discharge of the reheater shall be no

hotter than 580 °C to no colder than 5.6°C below the value

shown in this table: 580,0 576,1

Steam temperature at the discharge of the intermediate

pressure superheater shall be: +5.6 °C/ -0 °C 312,8 328,6

Water temperature at the discharge of the intermediate

pressure economizer shall be: +2.8 °C/ -0 °C 242,5 253,2

Steam temperature at the discharge of the low pressure

superheater shall be: +5.6 °C/ -5.6 °C 311,3 323,4

The static pressure loss from the HRSG inlet flange to the HRSG

stack discharge shall be less than : mm H2O (@15°C) 333,2 340,1

The reheater plus piping pressure drop is defined as the steam

pressure drop from the balance of plant cold reheat piping

terminal point with the HRSG to the balance of plant hot reheat

piping terminal point with the HRSG. This pressure drop shall

also include the reheater, and attemperator.

This pressure drop shall not exceed: bar 1,86 2,27

Steam energy output guarantees are based on the NET steam

flow delivered to the steam turbine. Drum pegging steam flows

are NOT included in these guarantees.

Class I GE Information Page 2 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

g GE Power EVM II Spec. No. T212B4

The HRSG design point is Case Number 1 of Appendix B17 of the

HRSG performance specification.

Tests to demonstrate the guaranteed performance shall be

conducted in accordance with the Thermal Performance Test

Procedure, Appendix B7.

The following performance shall be guaranteed for these HRSG

Requested Guarantees Vendor Guarantees

Case numbers of Appendix B17.

1 2 1 2

The energy guarantees use steam properties from ASME's '1997

Formulation for Industrial Use'.

Steam Energy output is calculated as follows:

High Pressure:

HP Steam Energy = HP discharge flow x (HP discharge enthalpy -

HPBFW enthalpy -HPBFW pump enthalpy rise - IPBFW pump

enthalpy rise - Normalized LP Economizer Enthalpy Rise) + HP

drum blowdown flow x (HP drum liquid enthalpy - HPBFW

enthalpy - HPBFW pump enthalpy rise - IPBFW pump enthalpy

rise - Normalized LP Economizer Enthalpy Rise) + (Reheater inlet

flow - IP discharge flow )*(Reheater discharge enthalpy -

Reheater Inlet Steam Enthalpy before mixing with Intermediate

Pressure Steam])

HPBFW enthalpy, kJ/kg = 155,7 165,0

Pump enthalpy rise from IP discharge to HP pressure of

combined pump, kJ/kg = 30,0 30,1

HP drum liquid enthalpy, kJ/kg = 1550,3 1583,6

Pump enthalpy rise from suction to IP discharge pressure of

combined pump kJ/kg = 7,0 7,0

Superheated Intermediate Pressure:

IP Superheated Steam Energy = (IP superheater discharge flow +

Reheater Attemperation Flow) x (Reheater discharge enthalpy -

IPBFW enthalpy -IPBFW pump enthalpy rise - Normalized LP

Economizer Enthalpy Rise) + IP Drum blowdown x (IP Drum Liquid

Enthalpy- IPBFW enthalpy - IP BFW pump enthalpy rise -

Normalized LP Economizer Enthalpy Rise)

IPBFW enthalpy, kJ/kg = 155,7 165,0

IPBFW pump enthalpy rise, kJ/kg = 7,0 7,0

IP drum liquid enthalpy, kJ/kg = 1049,7 1101,5

Saturated Intermediate Pressure:

IP Saturated Steam Energy = (IP drum saturated steam flow to

auxiliary header) x (IP Drum Steam Enthalpy- IPBFW enthalpy - IP

BFW pump enthalpy rise - Normalized LP Economizer Enthalpy

Rise)

IPBFW enthalpy, kJ/kg = 155,7 165,0

IPBFW pump enthalpy rise, kJ/kg = 7,0 7,0

IP drum steam enthalpy, kJ/kg = 2801,8 2798,4

Low Pressure:

Class I GE Information Page 3 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

g GE Power EVM II Spec. No. T212B4

The HRSG design point is Case Number 1 of Appendix B17 of the

HRSG performance specification.

Tests to demonstrate the guaranteed performance shall be

conducted in accordance with the Thermal Performance Test

Procedure, Appendix B7.

The following performance shall be guaranteed for these HRSG

Requested Guarantees Vendor Guarantees

Case numbers of Appendix B17.

1 2 1 2

LP Steam Energy = LP discharge flow x (LP discharge enthalpy -

LPBFW enthalpy - Normalized LP Economizer Enthalpy Rise) + LP

Drum Blowdown Flow x (LP Drum Liquid Enthalpy- LPBFW

enthalpy - Normalized LP Economizer Enthalpy Rise)

LPBFW enthalpy, kJ/kg = 155,7 165,0

LP Liquid Drum Enthalpy, kJ/kg = 640,5 651,3

Normalized LP Econ recirculation enthalpy rise = (flow through

LP economizer recirculation pump * enthalpy rise through

recirculation pump) / Boiler feedwater to HRSG before

recirulation, kJ/kg of net flow through LP economizer =

0,12 0,11

Water Energy output is calculated as follows:

Intermediate Pressure Economizer Water

IP Water Energy = IP Water Export flow x (IP Economizer

discharge enthalpy - IPFW enthalpy - IPBFW pump enthalpy rise -

Normalized LP Economizer Enthalpy Rise)

IPFW enthalpy, kJ/kg = 155,7 165,0

IPBFW pump enthalpy rise, kJ/kg = 7,0 7,0

Class I GE Information Page 4 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

g GE Power EVM II Spec. No. T212B4

HRSG Emissions Guarantee -

Contents are to be provided by

Environmental Engineer.

HRSG Emissions Guarantee

Notes:

The duct burner will only burn natural gas and will only operated when the gas turbine is at base load and is burning natural gas.

System Conditions

Parameter Units 1 2

GT Fuel NA Gas Gas

DB Fuel NA None Gas

Duct Burner Status NA Off On

GT Load % base load MECL to Baseload Baseload

Duct Burner Heat Consumption, HHV

Duct Burner Heat Consumption, LHV Refer to Equipment General Technical Requirements document (EMX/00/E/001b---

GT Fuel Sulfur 000/GS/500) for the fuel analysis.

DB Fuel Sulfur

Minimum ambient dry bulb temperature °C -10 -10

Maximum ambient dry bulb temperature °C 35 35

NOx GT ppmvd@5%O2 70,0 70,0

CO GT ppmvd@5%O2 350,0 350,0

Emissions Guarantees Required From The HRSG

Parameter Units 1 2

NOx HRSG Stack ppmvd@5%O2 70 70

CO HRSG Stack ppmvd@5%O2 350 350

Class I GE Information Page 5 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

g GE Power EVM II Spec. No. T212B4

HRSG Steam

Purity

Guarantees

For HRSG Steam purity requirements refer to Water Chemistry Water Steam Cycle (EMX/00/E/003b---010/GS/001)

Class I GE Information Page 6 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

g GE Power EVM II Spec. No. T212B4

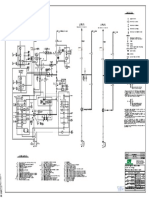

Appendix B4, HRSG Acoustic Guarantees

Refer to the Noise concept (ELA/00/M/----------/DO/100) for the HRSG noise guarantee requirements.

1M

FIGURE B4-1A

Stack Aperture

reading taken at

this point.

1M

S2

Stack Aperture

1- Steam vent and stack noise will be measured

reading taken at

at 1 meter from the rim of the stack/vent this point.

aperture (90 deg from stack axis)

S2

S1

T1 T2 B1 B2

S

1

T1 T B1 B2

Class I GE Information Page 7 of 7

Copyright 2017, GE Company Date: 23-Jun-2017 Rev. -

EMX/11/E/H-------EN/DC/004 and its Affiliates By : U. Saur

You might also like

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- EMX¦11¦E¦H-------EN¦DC¦003-en-A-HRSG Performance Equations (T212B3; Appendix B3)Document5 pagesEMX¦11¦E¦H-------EN¦DC¦003-en-A-HRSG Performance Equations (T212B3; Appendix B3)RichardLemusNo ratings yet

- EMX¦00¦E¦005b---009¦GS¦004-en-A-Requirements for Low Voltage DC MotorsDocument6 pagesEMX¦00¦E¦005b---009¦GS¦004-en-A-Requirements for Low Voltage DC MotorsRichardLemusNo ratings yet

- 22BMJ 045 FEA 03 - Rev 0 - 23.07.05Document14 pages22BMJ 045 FEA 03 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- SCA Technical Spec GE Frame 9E S Rev1 9e SpecificationDocument144 pagesSCA Technical Spec GE Frame 9E S Rev1 9e Specificationzhangj5100% (2)

- EMX¦00¦E¦005b---009¦GS¦002-en-A-Low Voltage AC Motors - Technical RequirementsDocument15 pagesEMX¦00¦E¦005b---009¦GS¦002-en-A-Low Voltage AC Motors - Technical RequirementsRichardLemusNo ratings yet

- Scope of Supply GEF9Document144 pagesScope of Supply GEF9Her Phy ToNo ratings yet

- 22BMJ 045 FEA 09 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 09 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- 22BMJ 045 FEA 05 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 05 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- 22BMJ 045 FEA 07 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 07 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- HRSG PDFDocument248 pagesHRSG PDFHema Nandh100% (1)

- EMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical RequirementsDocument13 pagesEMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical RequirementsRichardLemusNo ratings yet

- 22BMJ 045 FEA 08 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 08 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- SMBI - IN.FI12 REV02 Motor Insulation Resistance Test ReportDocument3 pagesSMBI - IN.FI12 REV02 Motor Insulation Resistance Test Reporteugene mejidana100% (1)

- 22BMJ 045 FEA 01 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 01 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- EMX - 00 - E - 001b - 001 - DO - 003-A - En-Plant Start-Up and Shutdown CurvesDocument7 pagesEMX - 00 - E - 001b - 001 - DO - 003-A - En-Plant Start-Up and Shutdown CurvesRichardLemusNo ratings yet

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- EMX¦00¦E¦001b---004¦GS¦001-en-A-Supply and control voltage levelsDocument6 pagesEMX¦00¦E¦001b---004¦GS¦001-en-A-Supply and control voltage levelsRichardLemusNo ratings yet

- Dfds CompressorDocument54 pagesDfds CompressorRahul Dev GoswamiNo ratings yet

- Technical Spec GE Frame 9E'S - Rev1Document144 pagesTechnical Spec GE Frame 9E'S - Rev1Alaa Zora - OnlineNo ratings yet

- RV Sizing SampleDocument13 pagesRV Sizing SampleDin Aizu0% (1)

- EMX¦00¦E¦005b---007¦GS¦001-en-A-General Technical Requirements for Electrical EquipmentDocument29 pagesEMX¦00¦E¦005b---007¦GS¦001-en-A-General Technical Requirements for Electrical EquipmentRichardLemusNo ratings yet

- AnnexB Energy Audit ReportDocument25 pagesAnnexB Energy Audit ReportJ-R MERLIN CabatoNo ratings yet

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 pagesWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- GE Challenge Problem Statement 2009Document11 pagesGE Challenge Problem Statement 2009looserlooserNo ratings yet

- Thermal Performance ReviewDocument17 pagesThermal Performance Reviewshameer_sanju1049No ratings yet

- YG-420/9.8-M1 Type CFB Steam Boiler Protection SpecificationDocument7 pagesYG-420/9.8-M1 Type CFB Steam Boiler Protection SpecificationYuliadi YunusNo ratings yet

- FGSSDocument4 pagesFGSSYoon SDNo ratings yet

- SDFFFDocument28 pagesSDFFFahem budi setiawanNo ratings yet

- QCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCDocument20 pagesQCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCTrần TùngNo ratings yet

- Green Mark For Non-Residential Buildings: Appendix B2: Verification Information SheetDocument6 pagesGreen Mark For Non-Residential Buildings: Appendix B2: Verification Information SheetPhúc Lộc NguyễnNo ratings yet

- DH PEP PPS PR 001 Process DescriptionDocument6 pagesDH PEP PPS PR 001 Process Descriptionfadli arsyadaNo ratings yet

- Heat Treatment ManualDocument29 pagesHeat Treatment ManualAlexis Williams100% (1)

- SDS-01-M-01 Heavy Fuel Oil HeaterDocument2 pagesSDS-01-M-01 Heavy Fuel Oil HeaterAJAY1381No ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- GE expands compressor facilityDocument2 pagesGE expands compressor facilityJavier PalaciosNo ratings yet

- 7.2 Installation Qualification Protocol For Air Handling UnitDocument37 pages7.2 Installation Qualification Protocol For Air Handling UnitTanveer Ahmed Quadri100% (1)

- Measuring Efficiency in Modern Gas Turbine Power StationsDocument14 pagesMeasuring Efficiency in Modern Gas Turbine Power StationsjparmarNo ratings yet

- 13UP0911RE Technical ProposalDocument388 pages13UP0911RE Technical ProposalAlfonso Perez100% (2)

- GEK 116403 PG 7121 Estimating Gas Turbine PerformanceDocument54 pagesGEK 116403 PG 7121 Estimating Gas Turbine PerformanceAbdelaziz EldeebNo ratings yet

- CFM56 5B SB Rev 72-0907 TSN.01 R 20200228Document7 pagesCFM56 5B SB Rev 72-0907 TSN.01 R 20200228Irfan05No ratings yet

- CahdezDocument29 pagesCahdezcoyana9652No ratings yet

- A HRSG System DescriptionDocument25 pagesA HRSG System Descriptionکالرو تحریک اتحادNo ratings yet

- Load Specification For The Foundation of The Wind Turbine Generator SystemsDocument26 pagesLoad Specification For The Foundation of The Wind Turbine Generator SystemsIvo LozićNo ratings yet

- RDJ GM 620 047 - (En)Document14 pagesRDJ GM 620 047 - (En)fouad kerkarNo ratings yet

- Nong Son 1 x 30 MW Thermal Power Plant C&I DesignDocument13 pagesNong Son 1 x 30 MW Thermal Power Plant C&I DesignMạnh CườngNo ratings yet

- Eoi HRSG Scope FinalDocument4 pagesEoi HRSG Scope Finalgo2ashokkumardutta2505No ratings yet

- Bock Compressor HG$ PDFDocument32 pagesBock Compressor HG$ PDFAbdel Fattah Hussein AhmedNo ratings yet

- GE 9HA Gas Turbine PDFDocument4 pagesGE 9HA Gas Turbine PDFAlfian Muhammad RezaNo ratings yet

- Psib 20120531aDocument1 pagePsib 20120531aLéandre Ettekri NdriNo ratings yet

- Specification for 2 KG CO2 Fire ExtinguisherDocument5 pagesSpecification for 2 KG CO2 Fire ExtinguisherDharmavir SinghNo ratings yet

- 9e PDFDocument12 pages9e PDFgayani100% (1)

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Sandra Elizabeth Palacios Carbajal 2022.03.08 09:53:03 - 06'00'Document1 pageSandra Elizabeth Palacios Carbajal 2022.03.08 09:53:03 - 06'00'RichardLemusNo ratings yet

- EMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical Requirements-1GP006414AT03-enDocument5 pagesEMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical Requirements-1GP006414AT03-enRichardLemusNo ratings yet

- EMX¦00¦E¦005b---007¦GS¦001-en-A-General Technical Requirements for Electrical EquipmentDocument29 pagesEMX¦00¦E¦005b---007¦GS¦001-en-A-General Technical Requirements for Electrical EquipmentRichardLemusNo ratings yet

- EMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical RequirementsDocument13 pagesEMX¦00¦E¦005b---009¦GS¦003-en-A-Medium Voltage AC Motors, Technical RequirementsRichardLemusNo ratings yet

- 01.02 - Pearl Electric - Company Catalog - ENGDocument8 pages01.02 - Pearl Electric - Company Catalog - ENGRichardLemusNo ratings yet

- Cable and wire diagram layoutDocument1 pageCable and wire diagram layoutRichardLemusNo ratings yet

- 4 LI CHD 38 11 PN DIE OB 004 H1de1 R-BDocument1 page4 LI CHD 38 11 PN DIE OB 004 H1de1 R-BRichardLemusNo ratings yet

- 5 LI CHD 38 11 PN DIE OB 005 H1de1 R-BDocument1 page5 LI CHD 38 11 PN DIE OB 005 H1de1 R-BRichardLemusNo ratings yet

- MGC Moser-Glaser Reference Letter, North AmericaDocument4 pagesMGC Moser-Glaser Reference Letter, North AmericaRichardLemusNo ratings yet

- Taikai 145kV GIS CatalogueDocument2 pagesTaikai 145kV GIS CatalogueRichardLemusNo ratings yet

- Project 22-EPM-QT-063 Electrical Panel DetailDocument3 pagesProject 22-EPM-QT-063 Electrical Panel DetailRichardLemusNo ratings yet

- EMX - 11 - G - MKA - GA71 - DS - 003-B - en-GENERATOR ELECTRICAL DATADocument17 pagesEMX - 11 - G - MKA - GA71 - DS - 003-B - en-GENERATOR ELECTRICAL DATARichardLemusNo ratings yet

- Sergio Corinca Rea Cibrian 2022.03.07 18:04:21 - 06'00': Juan Carlos Perez Sanchez 2022.03.07 18:18:37 - 06'00'Document1 pageSergio Corinca Rea Cibrian 2022.03.07 18:04:21 - 06'00': Juan Carlos Perez Sanchez 2022.03.07 18:18:37 - 06'00'RichardLemusNo ratings yet

- Previews 1873959 PreDocument12 pagesPreviews 1873959 PreWebster K. Huaynoca AcericoNo ratings yet

- EMX-00-E-001b - 001-DO-004-en-A-Design Concept - Plant Load ControlDocument7 pagesEMX-00-E-001b - 001-DO-004-en-A-Design Concept - Plant Load ControlRichardLemusNo ratings yet

- 21.82.06 - GEK103801 - F - For GE LSB'sDocument6 pages21.82.06 - GEK103801 - F - For GE LSB'sRichardLemusNo ratings yet

- EMX - 00 - 008b - 007 - TP - 001-A - En-Grid CodeTest Procedure Plant CapabilityDocument56 pagesEMX - 00 - 008b - 007 - TP - 001-A - En-Grid CodeTest Procedure Plant CapabilityRichardLemusNo ratings yet

- EMX - 11 - G - MB - EN - GS - 016 - En-Gas Turbine Functional Description, 7HA.02Document21 pagesEMX - 11 - G - MB - EN - GS - 016 - En-Gas Turbine Functional Description, 7HA.02RichardLemus100% (2)

- EMX - 00 - E - UBB - EP52 - EA - 010-C - en-E-Room Equipment ArrangementDocument24 pagesEMX - 00 - E - UBB - EP52 - EA - 010-C - en-E-Room Equipment ArrangementRichardLemusNo ratings yet

- EMX - 00 - G - 06a - 001 - EP - 001-A - En-Project Specific Site Erection Inspection and Test Program (ITP) Gas Turbine (GT) and Generator (GTG)Document8 pagesEMX - 00 - G - 06a - 001 - EP - 001-A - En-Project Specific Site Erection Inspection and Test Program (ITP) Gas Turbine (GT) and Generator (GTG)RichardLemusNo ratings yet

- EMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsDocument235 pagesEMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsRichardLemusNo ratings yet

- EMX - 00 - E - 001b - 004 - SD - 001-D - En-Overall Single Line DiagramDocument6 pagesEMX - 00 - E - 001b - 004 - SD - 001-D - En-Overall Single Line DiagramRichardLemus0% (1)

- EMX - 00 - E - 001b - 001 - DO - 003-A - En-Plant Start-Up and Shutdown CurvesDocument7 pagesEMX - 00 - E - 001b - 001 - DO - 003-A - En-Plant Start-Up and Shutdown CurvesRichardLemusNo ratings yet

- ADMO Brochure ENU PDFDocument12 pagesADMO Brochure ENU PDFRichardLemusNo ratings yet

- EMXÂ 00Â - Â 150b - 002Â CMÂ 001-En - Commissioning Manual For IPS 1154163 EVM2 - 299574 PDFDocument464 pagesEMXÂ 00Â - Â 150b - 002Â CMÂ 001-En - Commissioning Manual For IPS 1154163 EVM2 - 299574 PDFRichardLemusNo ratings yet

- EMX - 00 - E - 006b - 003 - GA - 001-D - En-Central Control Room Layout PDFDocument1 pageEMX - 00 - E - 006b - 003 - GA - 001-D - En-Central Control Room Layout PDFRichardLemusNo ratings yet

- ADMO Brochure NERC Edition ENU PDFDocument12 pagesADMO Brochure NERC Edition ENU PDFRichardLemusNo ratings yet

- EMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsDocument235 pagesEMX 00 E 122b - ET99 CL 003-en-A-Acid Cleaning Procedure and Supporting DocumentsRichardLemusNo ratings yet

- TRACE 700 - Users ManualDocument468 pagesTRACE 700 - Users Manualantmang100% (3)

- Dokumen - Tips Uniflair Brex1612a 2812a Technical DataDocument24 pagesDokumen - Tips Uniflair Brex1612a 2812a Technical DataJim JonesjrNo ratings yet

- 13415Document94 pages13415Prakash WarrierNo ratings yet

- Horizontal Accumulator Sizing GuideDocument14 pagesHorizontal Accumulator Sizing GuideHoàngViệtAnhNo ratings yet

- Factors for installing a 5 MW solar PV power plantDocument94 pagesFactors for installing a 5 MW solar PV power plantDeepakNo ratings yet

- Industrial Visit TO Kothagudem Thermal Power PlantDocument23 pagesIndustrial Visit TO Kothagudem Thermal Power PlantAbhishek NarayanaNo ratings yet

- Encircle The Letter That Represents The Best Answer To The Questions Given Below. Erasures May Invalidate Your AnswerDocument6 pagesEncircle The Letter That Represents The Best Answer To The Questions Given Below. Erasures May Invalidate Your AnswerAlexia VargasNo ratings yet

- Daikin LXE10A PDFDocument162 pagesDaikin LXE10A PDFTama MaliNo ratings yet

- Blue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualDocument123 pagesBlue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualAwdhesh Singh Bhadoriya71% (35)

- PIPE Reviewer LooksfamDocument15 pagesPIPE Reviewer LooksfamRichelle Valerie BastroNo ratings yet

- Boiler Tube Failure Causes and LocationsDocument17 pagesBoiler Tube Failure Causes and LocationsAshwani Dogra100% (1)

- Hmel CFBC Operating ParameterDocument6 pagesHmel CFBC Operating ParameterAnonymous qT80dF24dNo ratings yet

- 10 Power Plant Operation Vol V PDFDocument133 pages10 Power Plant Operation Vol V PDFmira100% (1)

- Eco-I Module AssemblyDocument3 pagesEco-I Module AssemblyPriyank ModasiyaNo ratings yet

- Hanbell Spec Sheet RC2-230B PDFDocument1 pageHanbell Spec Sheet RC2-230B PDFDaniel Naoe FestinNo ratings yet

- Attachment 4 - HRSG General ProcedureDocument6 pagesAttachment 4 - HRSG General ProcedureRicky JayaNo ratings yet

- Power Plant FamiliarizationDocument33 pagesPower Plant FamiliarizationAnand Kumar100% (1)

- SMARDT Catalogue TW ClassWaterCooled-En PRINTDocument12 pagesSMARDT Catalogue TW ClassWaterCooled-En PRINTBrunoWelter0% (1)

- ECBC 2017 Compliance Requirements (40Document30 pagesECBC 2017 Compliance Requirements (40Anand_HvacNo ratings yet

- Training Session4 - Heat Recovery Steam GeneratorsDocument34 pagesTraining Session4 - Heat Recovery Steam GeneratorsarianaseriNo ratings yet

- RT SVP07E en Programming GuideDocument157 pagesRT SVP07E en Programming Guidemarcp22No ratings yet

- AC Bard Wall MountedS3502Document24 pagesAC Bard Wall MountedS3502Ricardo Dardon100% (1)

- S11-936 Rev 2Document80 pagesS11-936 Rev 2Salomón BolañosNo ratings yet

- Boiler EmergenciesDocument5 pagesBoiler Emergenciesshantanu_scribdNo ratings yet

- ASHRAE Terminology - Complete ListDocument297 pagesASHRAE Terminology - Complete Listwado11No ratings yet

- Chiller CarrierDocument70 pagesChiller CarrierJavier OmarNo ratings yet

- Trane - Education MaterialsDocument14 pagesTrane - Education MaterialsFawaaz KhurwolahNo ratings yet

- Thermal Fluid Systems 4Document10 pagesThermal Fluid Systems 4Boogi Andika TamamiNo ratings yet

- HPAC Combining DOAS & VRFDocument12 pagesHPAC Combining DOAS & VRFZoidberg12No ratings yet

- Boiler Engneer Examination Procedure PDFDocument7 pagesBoiler Engneer Examination Procedure PDFArkadev GhoshNo ratings yet