Professional Documents

Culture Documents

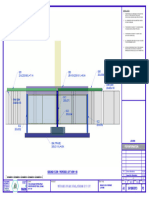

RA - Frampton Boston

RA - Frampton Boston

Uploaded by

filancheshitCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA - Frampton Boston

RA - Frampton Boston

Uploaded by

filancheshitCopyright:

Available Formats

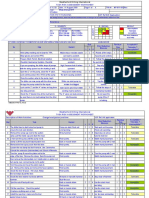

DEMOLITION

RISK ASSESSMENTS

Ultimate Demolition and Construction Service Limited Page 1 of 38

Demolition Risk Assessments

Job Name Job Number Client Details Address Date

Frampton Factory PRI-000-282 Irwin Project Management West End Road, Frampton, Boston, PE20 1BT 11/05/2022

Ultimate Demolition and Construction Service Limited Page 2 of 38

Operation: Work at height Persons at risk: Operatives, employees, 3rd parties. RA 01

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Collapse of All scaffolds are to be erected by competent scaffolders (CISRS). All scaffolds are to

work platform. comply with current regulations. All scaffolds are to adhere to the system of weekly

inspections by a trained competent inspector. All scaffolds are to be visually inspected

4 4 16 4 1 4

by a supervisor before putting operatives to work. All operatives are to visually

inspect the scaffold before commencing work. Trestles if used must be in good

condition, sited on firm level ground and secured where possible.

Falls from All work at height where personnel are exposed to a fall where an injury can occur

height/ Serious must have edge protection in place. If handrails are missing to allow work access,

injury safety harnesses, nets must be in place. Harnesses/ nets must be of an approved

4 4 16 type, checked by the user prior to use and attached to a secure anchor point. All 4 1 4

works at height must be adequately supervised. Ensure adequate information,

instruction and training. Trestles must have edge protection in place where a fall can

occur leading to an injury.

Materials/ tools Keep all tools and materials away from the scaffold edge. Store items so they cannot

falling/ Head 4 4 16 fall or be kicked over the edge. Where necessary use signs and physical barriers to 4 1 4

injury. protect areas below works at height. Be vigilant at all times.

Slips, Trips, Remove off cuts, scrap, waste etc, good housekeeping and cable management.

Falls 4 3 12 clean any spillages, Grit if ice or clear build up of snow. 4 1 4

Access/ Egress. Adequate safe access and egress must be provided and maintained, all ladders to be

4 4 16 4 1 4

tied off.

Adequate Suitable lighting to be provided when natural light is insufficient.

4 3 12 4 1 4

lighting.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 3 of 38

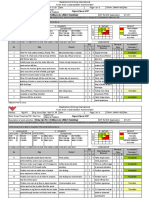

Operation: Fire risk assessment Persons at risk: Employees, 3rd parties RA 06

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Accumulation of All personnel to keep their work areas tidy, free from excessive combustible material. All

flammable 4 4 16 bins are to be emptied daily. 4 1 4

materials

Poor storage of Flammable materials e.g. files etc to be kept to a minimum in the workplace. Should be

4 3 12 4 1 4

materials stored away in filing cabinets/ cupboards. Flammables stored away from main work areas.

Smoking Smoking is only permitted in designated areas. Non-combustible receptacles supplied for

4 5 20 cigarette ends in designated smoking areas. 4 1 4

LPG cylinder These are stored in designated compounds 2 meters away from boundary fence with

4 3 12 4 1 4

storage warning notices prominently displayed.

Security of Site boundaries are secure with all round CCTV. Entry points to main site are locked at

premises/ arson 4 5 20 night. Regular fire inspections out of work hours. 4 1 4

prevention

Access/ egress All stairways, corridors, walkways and work areas to have safe access/ egress at all times.

blocked 4 4 16 Fire exits will not be blocked. All vehicles to be parked in the designated areas only. 4 1 4

Missing persons All personnel must report to reception when they are out of office. All visitors and

4 4 16 4 1 4

contractors to sign in & out at reception.

Ineffective All areas have fire warden to clear and account for personnel. Fire Action signs prominently

evacuation 4 5 20 displayed throughout site. 6 monthly fire drills in place. 4 1 4

Fire protection Portable fire extinguishers located throughout office building for fire fighting if safe to do so.

inadequate 4 5 20 Equipment checked regularly by in house competent person. 4 1 4

Electrical Electrical equipment is to be free from obvious defect, and readily identified with a current

equipment faulty 4 5 20 test examination certificate. Sockets are not to be overloaded. 4 1 4

or overloaded

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 4 of 38

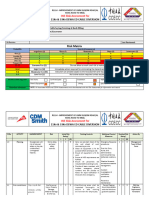

Operation: Materials storage on site Persons at risk: Employees, 3rd parties RA 07

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Falling Follow manufacturer’s guidance with respect to storage and stacking.

materials Palletised materials should not be stacked more than two pallets high.

Cylindrical materials e.g. pipes, should be wedged and not stacked.

4 4 16 Site/Yard Supervisor should regularly inspect stock piles and storage areas 4 1 4

to check their safety.

Material storage areas should be secured in order to prevent unauthorised

access, especially during out of hours.

Environmental Secure storage should be provided for hazardous substances and

contamination 3 3 9 unauthorised access prevented. 3 1 3

Trays or bunds to be provided where containment may be necessary.

Hazardous Ensure assessments are available on site.

substances Drums and containers should be clearly marked, stored in purpose made

3 3 9 3 1 3

containers and away from ignition, heat sources and incompatible

materials.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 5 of 38

Operation: Storage and use of highly flammable liquids Persons at risk: Employees, 3rd parties RA 09

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Explosion/fire Only keep the minimum quantity of highly flammable liquids on site. They should

be stored in a secure, fire resistant, well ventilated store. This must be

adequately signed both as a deterrent but also to provide information on the

liquids that are stored there. A no smoking area must be enforced. Highly

4 5 20 flammable liquids must only be kept in suitable, labelled containers. Whenever 4 1 4

highly flammable liquids are present, no means of ignition will be allowed and the

area will be kept clear of other combustible materials. Any substances, which can

react with one another should be stored separately with adequate ventilation

throughout.

Spillage Adequate bunds must be in place 110% of the capacity of the largest vessel to

prevent leakage and allow the effective use of extinguishants.

3 3 9 All spillages must be cleared as soon as they occur, see relevant COSHH 4 1 4

assessment for specific measures needed when clearing spillages. Spill kits to be

readily available.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 6 of 38

Operation: Slinging of loads Persons at risk: Employees, 3rd parties RA 10

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Falling objects Operation should be planned to minimise the risk to personnel and equipment.

Never sling loads over personnel, vehicles or cabins. Ensure any equipment that

4 4 16 is used to sling loads is maintained and checked regularly and that relevant test 4 1 4

certificates are readily available. Only trained operatives are to use any

equipment involved in the slinging process.

Trapping by Ensure that lifting appliance has firm, level base. Never sling sharp edges. Use

load 4 4 16 tail ropes to steady and guide loads. All personnel associated with the slinging 4 1 4

process to wear appropriate PPE.

Electrocution Plan Safe System of Work in vicinity of O/H cables, see relevant risk assessment

for this activity.

4 4 16 4 1 4

Obtain data on loads in advance, and obtain compatible lifting equipment.

Damage to All defects to equipment must be reported using the established procedure and

equipment equipment taken out of use immediately.

4 4 16 4 1 4

Suspend work if adverse weather affects safety.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 7 of 38

Operation: Use of lifting equipment Persons at risk: Employees, 3rd parties RA 11

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Falling objects Prior to work commencing a safe system of work to be produced by the person in

control of the operations. A lift plan is to be produced by a competent appointed

person for operations involving mobile cranes. Only lifting equipment complying

4 4 16 4 1 4

with statutory requirements, marked with SWL, holds current test and thorough

examination certification and inspected will be used. Only trained personnel will

be involved in the lifting operation.

Crushing All site personnel will be made aware of the lifting operation taking place and the

injuries 4 3 12 areas of the site this will affect. An appropriate exclusion zone must be formed 4 1 4

and all non-essential personnel will be excluded from the area.

Electrocution No lifting operations will take place when there are overhead power cables

present, without the consultation of the local electricity board. Undertaking of

work close to or below such lines should be carefully considered and avoided

4 3 12 where possible. Contact the electricity company to agree diversion of supply, safe 4 1 4

working distances or any other safety precautions. Highly visible barriers and

solid goalposts should be erected at the set safe distance, which will be

determined in accordance with electricity company and GS6 requirements.

Damage to Ensure machines and equipment’s capabilities are not exceeded - only trained

4 3 12 4 1 4

equipment personnel will operate plant.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 8 of 38

Operation: Lifting operations Persons at risk: Employees, 3rd parties RA 12

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Lighting Lighting should be adequate to enable good vision. If extra lighting is required use

4 4 16 4 1 4

110volt only. Installation of junction boxes to be done by trained certified electrician.

Collision with Routes to be planned in advance and, crane to be escorted to place of operations by

other vehicles trained competent banksman. Overhead cables to be protected by safe distances as set

structures or 4 3 12 by service provider. Underground services to be established. Where distance between 4 1 4

overhead cables counter balance and the nearest fixed structure is less than 600mm, gap will be cordoned

off.

Loss of load All lifting equipment to be adequate for the load with up to date test certificates. Slingers

to visibly inspect before use. All slingers and banksmen to be trained, certified and

4 3 12 4 1 4

competent. All areas affected by the operation will be cordoned off to prevent

unauthorised personnel from entering.

Overturning/crush The crane/ excavator must have all relevant test certificates. The driver must be trained,

injuries certified and competent. (Personnel in charge of operations to check before

4 3 12 commencement of work) Crane/ excavator to be sited on firm level ground adequate for 4 1 4

the task. No lifts to be done without the outriggers extended and the pads placed beneath

them.

Operator errors In cases where the driver’s visibility is restricted, competent banksmen must be placed in

caused by poor 4 3 12 full view to direct operations or radios provided. 4 1 4

visibility.

Adverse weather In adverse weather conditions LOLER regulations will apply. Cranes will not be operated in

4 3 12 4 1 4

conditions wind speeds in excess of manufacturer’s specifications.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 9 of 38

Operation: Use of cut off saw Persons at risk: Employees, 3rd parties RA 13

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Entanglement/ Only authorised, trained and competent personnel are to operate the saw. Before operating

contact with 3 5 15 the saw ensure that all the guards are in the correct position. Do not wear loose clothing, 3 1 3

moving parts including gloves.

Material ejection Guard must be in position to prevent ejection of material. Eye protection must be worn.

3 5 15 3 1 3

Electrocution Only trained personnel are to carry out maintenance operations with the power supply

4 4 16 isolated. A current, valid test for electrical safety must be in place, carried out by a competent 4 1 4

person.

Uncontrolled start Saws are to be isolated when not in use.

3 3 9 3 1 3

up

Equipment failure 3 3 9 Check equipment before use and report any defects to your supervisor immediately. 3 1 3

Blocked access/ Safe access and egress to and from the saw must be maintained at all times, with floors kept

egress 3 4 12 clean and free of slip/trip hazards. 3 1 3

Cuts The correct PPE must be worn at all times including gloves whilst handling off cuts. Know who

3 4 12 your first aiders are. 3 1 3

Hazardous Before use all operatives must have read, understood and signed the COSHH assessment.

substances 3 3 9 Cutting lubricants must be stored in the COSHH stores, not in the work area. 3 1 3

Slips, trips, falls Ensure adequate lighting is available. Keep the work area clear of debris, storing off cuts

3 4 12 neatly and away from walkways. 3 1 3

Fire Carbon dioxide or dry powder extinguishers to be available. Do not use water or foam on

4 4 16 electrical equipment. Ensure sparks during cutting are directed in a safe direction. 4 1 4

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 10 of 38

Manual handling (generic) for unfamiliar

Operation: Persons at risk: Employees, 3rd parties RA 15

tasks a specific assessment may be required

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Lifting/ pulling/ Use mechanical aids where possible i.e. pallet truck, rollers, hoists etc. If this is not

pushing heavy necessary or practicable, and the load is within your capabilities, plan the lift, lift the load

loads. 3 4 12 with your back straight and your knees bent looking straight ahead, taking the strain on 3 1 3

your legs. If the load is too heavy or awkward seek assistance- Do not attempt to lift it on

your own.

Slips/ trips/ Plan your route, move any obstacles. Ensure safe access and egress to and from all work

falls. 3 4 12 areas and adequate lighting. Maintain high standards of housekeeping. 3 1 3

Cuts from sharp Wear gloves for manual handling operations to protect hands.

edges. 3 4 12 3 1 3

Trapped fingers Always try to keep hands away from load edges especially in tight areas and use handles

& hands. 3 4 12 where provided. 3 1 3

Sprains & Avoid twisting, stooping, reaching and carrying long distances.

3 4 12 3 1 3

strains.

Muscular/ Ensure an even floor and sufficient rest/ recovery time. Maintain a good posture, if the

skeletal task is repetitive a separate risk assessment may be required.

3 4 12 3 1 3

disorders.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 11 of 38

Operation: Use of hand tools Persons at risk: Employees, 3rd parties RA 16

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Sprains & Always use the correct tool for the task in hand. During repetitive work (hammering,

3 3 9 3 1 3

strains. sawing) share the task or take regular breaks to do alternative work.

Flying particles. Safety glasses/ face shield to be worn when using hand tools. Screens must be used to

3 3 9 3 1 3

protect other personnel.

Lacerations. Ensure sharp edges of tools are protected when stored or carried. Always keep hands

3 5 15 behind the cutting edge. Wear suitable PPE where required. 3 1 3

Falling from All hand tools used at a height where there is a risk of them falling must be securely

height. 4 4 16 stored. With adequate protection installed to prevent materials falling. 4 1 4

Slips, trips & After use all hand tools must be correctly stored away.

falls. 3 3 9 3 1 3

Noise. Ear protection is to be worn where required, display signage to warn other personnel in

3 4 12 the vicinity. 3 1 3

Injuries from When using hand tools ensure there is adequate lighting to enable the task to be done

insufficient 3 3 9 safely. 3 1 3

lighting.

Injury from Only well maintained tools that conform to British Standards to be used. Prior to use

damaged 3 5 15 check all tools for wear and damage. Any worn or damaged equipment must be returned 3 1 3

equipment. to the stores.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 12 of 38

Operation: Use of portable electrical equipment Persons at risk: Employees, 3rd parties RA 18

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Operator error Only competent personnel are to use electrical equipment.

4 3 12 4 1 4

Electrocution Only equipment with a current PAT test is to be used. Before use check the

equipment for damage. If unsure about the safety of electrical equipment do not

4 4 16 use it. Only competent persons are to repair faulty electrical equipment. 4 1 4

Never stand on damp or wet surfaces when using electrical equipment and keep

electrical equipment clean and dry.

Slips, trips & Run all cables in a tidy manner so they are not a trip hazard. Ensure they are not

falls 3 3 9 over stretched, exposed to sharp edges or susceptible to damage from hot work 3 1 3

or traffic. After use disconnect tools and cables and store correctly.

Flying particles Safety glasses/ face visor to be worn where risk of flying particles. Screens where

3 4 12 required to protect other personnel. 3 1 3

Noise Most processes generate noise so hearing protection may be required. Signage

3 5 15 will warn other personnel in the vicinity to wear hearing protection. 3 1 3

Vibration When using vibrating electrical equipment take regular breaks form the task to do

3 4 12 alternative work, and keep your hands warm. Report any problems immediately 3 1 3

to the safety department.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 13 of 38

Operation: Disposal of waste materials Persons at risk: Employees, 3rd parties RA 19

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Fires Skips to be provided and kept in secure locations. Build up of waste to be

removed regularly. Waste fires not to be permitted on sites. Suitable

4 3 12 4 1 4

extinguishers to be available depending on type of waste.

Toxins/ Manufacturer’s and local authorities’ waste disposal instructions to be applied.

contamination Disposal to be dealt with by registered waste carriers and transfer notes

required. Containers to clearly identify types of waste they contain. See

4 3 12 relevant COSHH assessment for storage and disposal requirements. Asbestos 4 1 4

waste to be stored in accordance with requirements outlined within safe

systems of work and method statements.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 14 of 38

Operation: Work Near/Under Overhead Power Lines Persons at risk: Employees, 3rd parties RA 21

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Striking of Undertaking of work close to or below such lines should be carefully considered

overhead lines. and avoided where possible. Contact the electricity company to agree diversion of

supply, safe working distances or any other safety precautions.

Highly visibility barriers and solid goalposts should be erected at the set safe

distance, which will be determined in accordance with electricity company and

GS6 requirements.

Height restrictors (set in accordance with electricity company advice) should be in

4 4 16 4 1 4

place on all plant working in direct proximity to lines. Ground directly under

power lines should be inspected to guarantee that surface has no hidden

gradients or gullies which in effect could render the height restrictors ineffective

and increase the likelihood of plant coming into contact with the lines. All

personnel to be briefed on these requirements within the method statement for

the works.

All services to be assumed live.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 15 of 38

Operation: Work near existing underground services Persons at risk: Employees, 3rd parties RA 22

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Striking of Obtain details of underground services from statutory undertakers and site

underground owners. Follow guidance detailed in HSG47.

services – Always use Cable Avoidance Tool to confirm the location of and trace any

flooding, services, marking the ground and relevant drawings accordingly.

electrocution, Look for obvious signs of underground services e.g. valve covers or patching

explosion, fire. of the road surface.

Trial holes to be hand dug to confirm location. Lines of services to be

4 5 20 4 1 4

marked using paint or wooden pegs. Earthwork support to take into account

the positions of nearby services. All services to be assumed live. If

services are struck stop work immediately and contact relevant utilities

company.

When backfilling excavations containing existing services, extreme care will

be taken to ensure voids beneath the services are not created, and the

service is not shifted off line during backfilling.

Explosion Ensure that all confined spaces are ventilated and no naked flames are near

4 5 20 when identifying existing services. No Smoking. Ensure all equipment is 4 1 4

intrinsically safe.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 16 of 38

Operation: Public safety Persons at risk: Employees, 3rd parties RA 26

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Struck by plant Pedestrians to be made aware of plant entering and leaving the site and whilst crossing all

pedestrian areas. Ensure plant is not in danger of knocking down barriers onto pedestrian

4 4 16 areas. Ensure reverse alarms, lights and beacons are in working order. Ensure traffic 4 1 4

management is appropriate to deal with members of the public. Any concerns about the

safety of public or other site operatives stop work & report to supervisor.

Traffic accidents Ensure safety exclusion zone from traffic (Road and Street works Act) is in place. Access/

Egress to be signed and controlled by banksman. Rotating beacons to be used on all

4 4 16 4 1 4

vehicles. Hi-vis jackets/vests to be worn at all times. If not satisfied with traffic

management stop work and report to immediately to supervisor.

Struck by Ensure all materials are stacked and safely secured away from areas where pedestrians

4 4 16 4 1 4

materials may enter.

Noise When working in built up areas always use equipment and plant with consideration for

3 5 15 residents living in the area. 3 1 3

Dust 3 5 15 Use water spray to damp surface down. 3 1 3

Injury to Members of public will not be allowed to enter the workshop area. Ensure work area is

trespassers 4 4 16 securely protected with signage warning of all hazards. All plant to be immobilised when 4 1 4

left unattended. Flammable and dangerous substances securely stored.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 17 of 38

Operation: Transport safety on site Persons at risk: Employees, 3rd parties RA 27

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Struck by plant Separate vehicle routes and pedestrian routes and where possible provide

footways. Ensure all traffic routes, and offloading points are adequately signed.

Ensure system is in place to ensure that all delivery drivers report to site before

4 4 16 4 1 4

entering. Control vehicles/plant using designated banksman. Ensure banksman

and driver use agreed and recognised signs. Banksman must always wear high

visibility jacket.

Reversing Minimise the need for reversing operations. Keep personnel clear of areas where

vehicles need to reverse. Provide markings to guide drivers. Ensure that

banksman is used when reversing. Ensure rotating beacons, reverse alarms and

4 4 16 4 1 4

reverse cameras are used and are all in working order.

Vehicles Ensure traffic areas are firm and level. Drivers should drive with care and

overturning 4 4 16 attention. Visible warnings/barriers must be used near hazards (e.g. 4 1 4

excavations).

Struck by Designate an area for offloading and keep personnel clear. Ensure there are no

falling 4 4 16 objects, which may fall from the equipment onto those working below. 4 1 4

materials.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 18 of 38

Operation: Dust Persons at risk: Employees, 3rd parties RA 30

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Production of Work areas will be kept free from excessive dust by regular cleaning. Areas

dust where excessive dust production is foreseeable will be kept clear of personnel

until airborne levels settle. Personnel will wear suitable respiratory protection

at all times in these areas. Covers will be in place on equipment to prevent

4 4 16 4 1 4

emissions of dust. Where possible areas that are to be cleaned will be

dampened prior to cleaning to reduce the levels of dust being spread into the

air. Measures to reduce the amount of dust produced during all stages of the

graining process should be implemented.

Eye irritation Ensure all operatives who are working in areas prone to dust must wear eye

3 5 15 3 2 6

protection.

Inhalation of When there are still high levels of dust present Respiratory Protective

dust Equipment must be used. RPE will be carefully selected and used in

consultation with the supplier/manufacturer. Unless selected carefully it is

unlikely to be effective in providing the appropriate protection. Use natural

4 5 20 4 1 4

ventilation where possible to reduce the amounts of dust, ensure that this

ventilation does not produce a build up of dust in another area. Ensure

systems installed to protect operatives from dust such as filtration systems in

cabs are maintained and full working order.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 19 of 38

Operation: Vermin Persons at risk: Employees, 3rd parties RA 31

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Leptospirosis Pest control contractor to be called to rid area of rodents as far as possible.

(Weils Disease) All operatives must maintain good levels of personal hygiene.

Operatives must never touch dead animals.

If feeling flu like symptoms with severe headaches/sickness to report to G.P.

immediately and inform of the fact that you have worked in a vermin

contaminated area.

4 3 12 4 1 4

All operatives to be instructed in the symptoms of Leptospirosis and issued with

Leptospirosis cards.

This can be best achieved by showing Leptospirosis COSSH Assessment to

medical staff.

Bitten Disinfect area of wound immediately, apply dressing and seek immediate medical

4 3 12 attention. See Leptospirosis COSHH Assessment. 4 1 4

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 20 of 38

Operation: Loading/Unloading of plant and machinery Persons at risk: Employees, 3rd parties RA 34

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Overturn whilst Ensure area is cleared of non-essential personnel. Area for approach, loading and

loading/ 4 4 16 unloading to be level and well consolidated. Competent banksman to be 4 1 4

unloading appointed. Only trained and competent operatives to load/unload.

Overturn whilst Driver to report to supervisor before vehicle enters site. Driver to ensure the

entering/ 4 3 12 route on site is well consolidated and level. 4 1 4

leaving site

Load Driver to ensure load is evenly distributed and adequately secured with tested

inadequately chains. Any damaged chains to be reported immediately and removed from

4 4 16 4 1 4

secured service. Prior to leaving site all loose items must be secured and any mud/debris

that could be a hazard to other vehicles removed.

Vehicle Defects Driver should check vehicle/trailer for defects prior to all journeys. All defects to

4 4 16 4 1 4

vehicles/trailers to be reported to supervisor.

Driver fatigue/ Drivers will not exceed the recommended driving hours at any time. Stop journey

illness/ injury 4 4 16 and report to depot if you experience fatigue, distress or are involved in an 4 1 4

accident.

Vehicle defects All defects to vehicles/trailers to be reported to supervisor. Driver should check

4 4 16 4 1 4

for defects prior to all journeys.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 21 of 38

Operation: Protection to third parties Persons at risk: Third parties RA 35

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Injury to visitors Excellent standards of housekeeping to be maintained - all floors to be clear of potential slip and

(delivery drivers, trip hazards.

customers etc) or Visitors should be informed upon arrival of the arrangements in place for emergency evacuation,

other 3rd parties. the associated assembly points and the location of welfare and first aid facilities and no-go areas.

No visitor to the premises should be permitted to access any area of the premises out of the offices

3 3 9 3 1 3

unescorted - where potentially hazardous operations take place such as forklift operations, shelf

stacking overhead etc. In such areas visitors should only be escorted by employees who are

familiar with the operations taking place so these can be avoided.

Access should not be permitted where any maintenance or other such works are taking place.

Fragile roof signs to be displayed on all buildings if fragile roof lights exist.

Injury/harm to Prior to commencing works, whether at a clients premises or other, a competence assessment must

contractors be carried out to ensure the contractor possesses adequate skills, training and relevant experience

working on clients to carry out the works. It must also be ensured that adequate insurances are held, that an

behalf adequate safe system of work will be employed and suitable and sufficient risk assessments are in

4 3 12 place for the works to be carried out, and that sufficient resources of time have been allowed for to 4 1 4

carry out the work safely and equipment is provided to carry out the works in accordance with the

above. This must all be assessed and approved prior to works commencing.

For major works the contractor should be researched for any previous health and safety

prosecutions or enforcement notices and accident statistics requested.

Injury to When employees visit another premises it should be ensured that any site or other safety

customers 3 3 9 rules/exclusion zones in place are adhered to and any potentially unsafe situations are reported 3 1 3

immediately.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 22 of 38

Operation: Mobile elevated work platform operations Persons at risk: Operatives, employees RA 39

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Overturning It is essential to only use the M.E.W.P. on firm, well-maintained and level ground.

4 5 20 4 1 4

Structural failure. Platform to be thoroughly examined by a competent person at least once every six months. Pre-use

4 3 12 4 1 4

checks to be carried out before use. The S.W.L. of the platform must not be exceeded.

Working at height. Operatives must use double lanyard if they need to leave, enter or over reach from the platform

while it is elevated. One lanyard at least must be attached at all times. Initial correct positioning

4 4 16 4 1 4

should prevent personnel having to lean out of platform.

Safety harnesses should be worn attached to anchor points in basket.

Operator error Only personnel who are trained, competent, certified and authorised are to operate the M.E.W.P.

3 3 9 The M.E.W.P should only be moved with the working platform elevated if safe to do so. When 3 1 3

elevated the transmission must be in placed in neutral.

Work area- falling Warning barriers, and signage should be positioned around the platform working area where there

objects. is any possibility of other vehicles or pedestrians coming into close proximity, or of objects falling

4 3 12 4 1 4

from the platform. If necessary other adjacent operations/ activities may have to stop. Equipment

and materials must be stored securely at all times.

Crushing/ Be aware of overhead hazards and electrical cables, which may cause injury to operatives. No work

4 3 12 4 1 4

trapping. is to occur within 30 metres of overhead power lines.

Overloading. The Safe Working Load of the work platform must never be exceeded and clearly marked on the

4 3 12 platform. Only tools required for the task in hand are to be stored on or lifted in the elevated 4 1 4

platform.

Overhead cables Do not operate a mobile elevated work platform where overhead power cables are without

4 3 12 4 1 4

contacting the apparatus owner prior to works commencing.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 23 of 38

Operation: Using substances hazardous to health Persons at risk: Employees, 3rd parties RA 40

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Operator error Know what the substance is and what it does before using. Read the COSHH assessment

4 3 12 and sign the briefing sheet before taking any substance from the COSHH stores. 4 1 4

Information and instructions detailed in the COSHH assessment must be followed.

Contact with skin Wear the correct PPE as indicated by the COSHH assessment. Any contamination must be

4 3 12 cleaned up immediately and any contaminated clothing removed and laundered before 4 1 4

re-use.

Contact with If substances need to be decanted or moved do so in a controlled manner. Any contact

eyes 3 5 15 with the eye must be rectified immediately. Never store hazardous substances above 3 1 3

head height.

Inhalation If natural ventilation is insufficient use local exhaust ventilation or respiratory protective

3 4 12 3 2 6

equipment as required. Ensure other persons are not effected by emissions.

Ingestion Do not drink or eat any hazardous substances. Never eat or drink when using hazardous

4 5 20 substances and after use always follow good hygiene practices. 4 1 4

Spillage 4 3 12 Ensure spill clean up equipment is readily available. Always replace the lid after use. 4 1 4

Explosion/ fire Do not mix substances together. Never smoke when using substances. Always have a

4 5 20 suitable extinguishing media available. Keep flammable materials away from hot work 4 1 4

areas. Store materials correctly in accordance with the COSHH assessment.

Environmental Prevent hazardous substances entering drains or watercourses. Spills to be contained

damage 4 4 16 cleared and disposed of in accordance with relevant COSHH assessment. 4 1 4

3rd party contact. 4 3 12 After use all substances must be returned to the COSHH stores. 4 1 4

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 24 of 38

Operation: Re-fuelling of plant Persons at risk: Employees, 3rd parties RA 41

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Contact with See COSHH Assessment.

diesel 3 3 9 3 1 3

Leakage/ spills Ensure that all diesel tanks are bunded to prevent diesel leaking. Any leakage

should be contained and prevented from spreading to other parts of the site. Use

4 3 12 spill kits provided. In the event of major spillage Environmental Agency to be 4 1 4

contacted immediately. Delivery of fuel only to commence when hose is correctly

placed into fuel tank. Personnel must remain with hose whilst delivering fuel

Fire All sources of ignition should be completely removed from the area of work.

Provide fire extinguishers. Ensure that all exits are clearly marked and clear of

any obstacles. Provide copy of emergency fire drill in the workshop. All engines to

4 3 12 4 1 4

be turned off when refuelling is in process. Ensure that all flammable liquids are

securely stored separately and clearly labelled with appropriate signage- No

Smoking etc. No hot work to be carried out within 10 metres of fuel store.

Fumes. If working indoors or in confined spaces ensure that there is adequate ventilation

4 3 12 to disperse any fumes, this can also disperse vapours, which may become ignited. 4 1 4

Contact with High visibility clothing must be worn when re-fuelling to alert others of your

4 3 12 4 1 4

other vehicles presence at the fuel pumps.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 25 of 38

Operation: Working with white asbestos cement sheeting Persons at risk: Employees, 3rd parties RA 43

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Injury through All personnel to be adequately trained CAR 2012 Reg 10. Minimum number of

asbestos persons to be present. Disposable overalls fitted with hood to be worn, boots

inhalation without laces and disposable particulate respirator (FFP3) to be worn.

If other asbestos is discovered work to cease immediately, area made secure until

4 5 20 4 1 4

status of ACM is ascertained.

Asbestos waste must be placed in a secure purpose designed container/skip and

disposed of at a suitably licensed facility. Waste transfer note needed for

quantities over 5 litres in volume.

Third party Form an exclusion zone around the working area i.e locked doors and display

injury warning signage. Where possible surfaces within the segregated area should be

4 5 20 4 1 4

covered and sealed using polythene sheeting and duct tape.

Drilled ACM to be sealed using sealant once complete.

Creation of Where possible hand tools should be used to drill the ACM, or power tool on

excessive dust lowest setting. Material to be wetted to reduce/eliminate dust creation. Where

4 5 20 4 1 4

asbestos cement sheeting is to be dismantled this should be carried out carefully

by removing fixings and never broken up.

Insufficient Segregated area to be cleaned using a wet rag. Disposable overalls, cleaning

decontamination 4 5 20 rags and disposable particulate respirator (FFP3) to be disposed of in an asbestos 4 1 4

waste container.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 26 of 38

Operation: Visitors to site Persons at risk: Employees, 3rd parties RA 44

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Injury to visitor Hard hats and high visibility garments are mandatory PPE items at all times.

Safety footwear is only required where ground conditions dictate, otherwise

sensible footwear shall be adequate.

4 3 12 Adequate first aid trained persons and equipment must be readily available at all 4 1 4

times. During the induction the visitor and where relevant their escort must be

instructed in the procedure for contacting first aiders.

Insufficient All visitors to site must receive an induction prior to entering any site areas.

hazard During the induction process the Site Manager shall ascertain the visitor’s level of

awareness construction site experience – unless considerable experience is held the visitor

4 3 12 will not be allowed on site without a dedicated escort, designated by the Site 4 1 4

Manager. Visitors not to enter potentially hazardous areas i.e. near tele-handler

operations – safest route to be taken wherever possible.

Fire Adequate fire fighting equipment to be situated to necessitate means of escape

4 3 12 within buildings. 4 1 4

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 27 of 38

Operation: Driving company cars & vans Persons at risk: Employees, 3rd parties RA 45

Re-assessment

HAZARD Assessment CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Competency & All drivers must be current licence holders and authorised for the class of vehicle that they are driving. All

Reliability drivers and passengers must wear their seat belts.

4 5 20 4 1 4

Ensure that the vehicle (and trailer) is in sound mechanical condition, including tyres, brakes, steering and

lights. (Regular servicing).

The driver must be physically fit to drive and not under the influence of alcohol or drugs. (Prescribed or

Fitness to drive otherwise). On long journeys, regular breaks must be taken to avoid drowsiness. A break of at least 15 minutes

4 5 20 4 1 4

must be taken after each 2-hour driving period. The maximum recommended driving distance within a working

day should not exceed 350 miles.

Road and Weather Drive at a safe speed giving due respect to weather and traffic conditions.

4 4 16 4 1 4

conditions. Do not exceed speed limits. Use dipped headlights in inclement weather.

Traffic conditions 4 4 16 Always take account of high volumes of traffic, keep a safe distance, stay calm in a traffic jam. Be courteous; do 4 1 4

not get involved with road rage. Remember, it’s more important to arrive late than not to arrive at all.

In the event of a breakdown, ensure the vehicle is parked in a safe place. Use hazard-warning lights, contact

Breakdowns 4 4 16 Plant breakdown service and wait in a safe place for assistance.

4 1 4

Distractions DO NOT use hand held mobile telephones whilst driving. Keep your attention on the road. Do not rubber neck at

4 5 20 incidents on other carriageways. Smoking is prohibited in company vehicles. 4 1 4

Re-fuelling 4 5 20 Ensure sufficient fuel is in the vehicle. When refuelling observe the safety instructions posted on forecourts. DO 4 1 4

NOT SMOKE. Avoid spillage of fuel. Wash off any skin contamination.

Only company trailers to be towed by company vehicles unless written confirmation obtained. Ensure trailer

Towing correctly connected (hitch, emergency line brake, lights). Do not exceed the maximum towing weight of the

vehicle. Ensure lights are working & correct number plate clearly displayed. Loads to be secured. Adhere to

4 5 20 4 1 4

towing speed limits for road used (30mph on all roads with street lighting unless signed otherwise, 50mph on

single carriageways unless signed otherwise, 60mph on dual carriageways & motorways- Do not travel in the

right-hand lane of motorway, with 3 lanes or more, if you are towing.)

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1 20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk 20345 EN397 EN361

SNR26

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 28 of 38

Operation: Working in Hot Climate Persons at risk: Employees, 3rd parties RA 52

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Sunburn, Ensure that operatives keep their tops on while working, maintaining a barrier

Blistering, Skin between the sun and the skin. Wear a hat that covers the ears and the back of

Ageing, Skin the neck. Stay in the shade during breaks or lunch time. Use a high factor sun

4 4 16 2 3 6

Cancer. screen of at least SPF15 on any exposed skin, applying frequently as required.

Check the skin regularly looking for unusual moles or spots. Reduce the amount

of time spent in the sun by job rotation or introducing more frequent breaks.

Insufficient All operatives/visitors to site must receive an induction, toolbox talk, and be

training briefed about the dangers of Ultra Violet Radiation, the symptoms of heat stroke

4 4 16 and how to identify them, and the appropriate actions required. All personnel are 3 2 6

to know who and where the First Aider is on site, and are to report any symptoms

immediately.

Dehydration All personnel are to ensure that they drink plenty of water when working in the

sun. Water or drinking stations are to be provided for use by all operatives, and

4 3 12 4 1 4

where possible these are to be located in the shade. Alcohol is not to be

consumed on site or during breaks.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 29 of 38

Operation: Loading And Unloading Vehicles Persons at risk: Employees, 3rd parties RA 53

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Lifting/ pulling/ Use mechanical aids where possible i.e. pallet truck, rollers, hoists etc. If this is not necessary or

pushing heavy practicable, and the load is within your capabilities, lift the load with your back straight and your

loads. knees bent looking straight ahead, taking the strain on your legs. If the load is too heavy or

3 4 12 awkward seek assistance- Do not attempt to lift it on your own. 3 1 3

All personnel to receive manual Handling training. The supplier is to ensure loads are delivered in

the suggested amounts acorn has provided them with. If not the load is to be returned and not

attempted to be moved without mechanical means.

Slips/ trips/ falls. Plan your route, move any obstacles. Ensure safe access and egress to and from all work areas and

adequate lighting. Maintain high standards of housekeeping. The vehicle bed is to be kept clear of

used discarded packing. The operative that is unloading from the vehicle bed is to remain at least

3 4 12 3 1 3

.5 m from the edge of the vehicle bed ideally a hand rail should be fitted across the tailgate to avoid

falls. If this is not practical the persons on the ground are to ensure the person on the vehicle bed

keeps his distance from the edge.

Cuts from sharp Wear gloves for manual handling operations to protect hands. The operatives on the ground are to

edges. 3 4 12 keep their eyes focused on the materials as they are unloaded to avoid turning into the load or it 3 1 3

striking their head or eye’s.

Trapped fingers & Always try to keep hands away from load edges especially in tight areas and use handles

hands. 3 4 12 where provided. When possible the load should always be taken from the top, this will 3 1 3

rely on the correct loading and sequence of delivery by the supplier.

Sprains & strains. Avoid twisting, stooping, reaching and carrying long distances.

3 4 12 3 1 3

Muscular/ skeletal Ensure an even floor and sufficient rest/ recovery time. Maintain a good posture, if the task is

disorders. 3 4 12 repetitive a separate risk assessment may be required. 3 1 3

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 30 of 38

Operation: Protection from Asbestos exposure Persons at risk: Employees, 3rd parties RA 55

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Injury through Consult clients asbestos register/management plan, check with responsible person.

asbestos All personnel to be asbestos awareness trained (CAR 2012 Reg 10).

inhalation Work area is to be checked by supervisor competent person, and confirmation that

asbestos will not be disturbed before any works commence.

No asbestos work to be carried out by Newell operatives.

Minimum number of persons to be present. Disposable overalls fitted with hood to be

4 5 20 4 1 4

worn, boots without laces and disposable particulate respirator (FFP3) to be worn.

If other asbestos is discovered work to cease immediately, operatives in the work area

are to remain in vicinity for decontamination if required and until status of potential ACM

is ascertained. Asbestos waste must be placed in a secure purpose designed

container/skip and disposed of at a suitably licensed facility. Waste transfer note needed

for quantities over 5 litres in volume.

Third party injury Form an exclusion zone around the working area i.e locked doors and display warning

4 5 20 signage. Where possible surfaces within the segregated area should be covered and 4 1 4

sealed using polythene sheeting and duct tape.

Creation of Where possible hand tools should be used to drill the ACM (licensed Contractor), or power

excessive dust 4 5 20 tool on lowest setting. Material to be wetted to reduce/eliminate dust creation LEV /Vac. 4 1 4

Insufficient Segregated area to be cleaned using a wet rag. Hooded Disposable overalls, cleaning

decontamination 4 5 20 rags and disposable particulate respirator (FFP3) to be disposed of in an asbestos waste 4 1 4

container.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 31 of 38

Operation: Waste Management Persons at risk: Employees, 3rd parties RA 58

HAZARD Assessment CONTROL MEASURES TO REDUCE THE RISK Re-assessment

S L R S L R

Reduction of All waste will be kept to a minimum by pre-planning and recycling

4 4 16 4 1 4

waste

Energy All electrical equipment will be switched off when not in use.

conservation 4 5 20 All plant and equipment will be turned off when not in use. 4 1 4

Heat conservation within buildings will be monitored and optimum savings achieved

The segregation An assessment of waste materials will be carried out in order to identify all re-usable or

of re-usable and recyclable waste. This will then be segregated accordingly. Separate storage for paper,

recyclable cardboard, wood, metal and waste oils for recycling should be utilised. All such waste will

materials be re-used on site where possible, or sent for recycling via a licensed waste contractor.

4 5 20 4 1 4

Licensed waste contractor will transfer only materials that are suitable for landfill to a

licensed landfill site.

All contaminated waste, chemical waste and sewage will be disposed of as special waste

via a licensed waste contractor

Compliance with Only selected licensed waste contractors will be appointed to remove any waste products

duty of care, from site to licensed tips. All such contractors will be audited to ensure compliance with

including the duty of care requirements. All such transfers shall be fully documented with waste

4 4 16 4 1 4

maintenance of transfer slips. These slips shall be kept on file for inspection, and record of transfer of

the necessary duty of care to the license holder

records

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3

B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 32 of 38

Operation: Excavators used for lifting Persons at risk: Employees, 3rd parties RA 60

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Dropping of Excavator to be used as a crane must be designed for the purpose and fitted with

load sling attachments and check valves. A current test certificate or certificate of

exemption must be held for the excavator. No load greater than the SWL shall be

4 4 16 lifted. SWL will be clearly marked on the excavator and a table of SWL’s (at different 4 1 4

radius) will be clearly visible to the operator. Slinging of loads shall only be carried

out by a competent person. Loads must not be slewed over personnel, vehicles,

cabins or huts.

Boom striking No lifting operations will take place when there are overhead power cables present -

O/H cables see RA29. Undertaking of work close to or below such lines should be carefully

4 4 16 considered and avoided where possible. Contact the electricity company to agree 4 1 4

diversion of supply, safe working distances or any other safety precautions as

detailed within GS6.

Persons struck No person shall stand or work within operating radius of machine. A banksman shall

by boom or be used for all lifting operations. Operation of machines shall be by competent

4 4 16 persons only. Operatives working adjacent to excavators will wear head protection 4 1 4

other part of

machine and high visibility clothing.

Overturning SWL of machine shall not be exceeded. Machine to be operated on firm/level base,

4 3 12 and lifts carried out with boom parallel to machine tracks/wheels. Lifting operations 4 1 4

to be supervised by a competent person to ensure stability of load/machine.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 33 of 38

Operation: Emergency Planning Persons at risk: Employees, 3rd parties RA 63

HAZARD Assessment CONTROL MEASURES TO REDUCE THE RISK Re-assessment

S L R S L R

Fire procedure Procedure to be in place for evacuating the site, provide as much information as possible with

regard to substances, which are or could become involved. Only attempt to fight the fire if you are

4 5 20 4 1 4

trained, competent and it is safe to do so. DO NOT TAKE PERSONAL RISKS. Should the evacuation

alarm be sounded report to the designated muster point for a roll call.

Spillage control On discovering a spillage or leakage identify the nature of the substance. If spillage material is

hazardous ensure other parties are aware and removed to a safe distance. If in doubt treat the

substance as hazardous. If necessary raise the alarm in accordance with site procedure. Attempt to

4 5 20 4 1 4

contain the spillage/ leakage if safe to do so. Prevent spillage/ leakage entering watercourses.

Clear up spillage/ leakage with suitable materials and dispose of in accordance with COSHH data/

site procedures in order to prevent contamination.

Actions to be taken In the event of an emergency situation a designated person must take control to ensure the safety

in emergency of all personnel, and the following actions take place. If safe to do so attempt to minimise the

situations 4 5 20 hazard and control the situation. Ensure site emergency alarms are activated and relevant 4 1 4

authorities have been informed (if required). If local or site evacuation is required all personnel to

attend pre-arranged muster points for a roll call to take place.

Emergency drill Emergency drill practices should take place periodically and be assessed by competent observers

practices 4 4 16 who will record the outcomes of such drills and implement any necessary improvements required to 4 1 4

ensure that an emergency procedures can be safely and effectively carried out.

Emergency Data to be available in an emergency situation includes:- Up to date attendance record, COSHH records for

equipment and substances, Detailed site plans of how, where, and what quantity substances are stored, Emergency telephone

data 4 4 16 contact numbers, Drainage plans. Equipment could include:- Fire fighting equipment, spillage control material, 4 1 4

specialised PPE, emergency deluge showers, breathing apparatus (This will be site or area specific and be

appropriate to the hazard).

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 34 of 38

Operation: Pollution Prevention & Control Persons at risk: Employees, 3rd parties RA 64

HAZARD Assessment CONTROL MEASURES TO REDUCE THE RISK Re-assessment

S L R S L R

Discharges to Identify substances and possible environmental impact that may ensue any unplanned release. Where possible

water 4 5 20 substitute substance and ensure correct handling, storage, use and disposal, in accordance with Manufacturers 4 1 4

Safety Data Sheet. (MSDS). No substances shall be directly discharged into watercourses, including drains.

Ground Ground contamination must be prevented by using bunded storage, drip trays under static plant and ensuring all

contamination mobile plant is regularly inspected for leaks. Contaminated land may need to excavated in order to prevent

washing of substances into ground water system. Contaminated spoil must be disposed of in accordance with

4 5 20 4 1 4

local waste regulations. Drip trays need to be emptied regularly into a suitable receptacle so that correct

disposal of contents can be controlled. Suitable materials for spillage control must be utilised and disposed of in

accordance with waste regulations

Releases to There will be no incineration of any waste material on any site. Minimising the frequency and duration of vehicle

atmosphere movements will reduce vehicle emissions. All vehicles and plant, will be well maintained and turned off when not

in use. Where operations produce significant emissions, Local Exhaust Ventilation will be used to filter out

noxious substances, in line with COSHH regulations. Work activities where dust could be produced need to be

4 5 20 eliminated or controlled. Methods include vacuuming instead of sweeping, placing waste dust in sealed

4 1 4

containers, dust suppression i.e. damping down and filters on extractors. The release of chemical vapours must

be minimised. Container lids should be fitted at all times when not in use, if the vapour is present when using

the substance ensure sufficient local exhaust ventilation is provided.

Noise Noise is created in most processes and therefore must be controlled and reduced to the lowest practicable level.

To ascertain this, causes, and levels of the noise have to be identified, usually by noise and risk assessment.

4 4 16 Once determined alternative processes and or control measures need to be implemented. If substitution of a 4 1 4

process not possible, use: Plant fitted with silencers and vibration dampers, Sound proof screens/ barriers

around noisy work, Control working hours, Monitor, re-assess and improve where possible.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K

2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 35 of 38

Excavators Persons at risk: Employees, 3rd parties RA 67

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

People being A signaller/ banksman should be provided in a safe position to direct excavator operation and any

struck by pedestrian movements. Only licensed personnel should operate plant vehicles. Use of

plant/boom beacons on plant is imperative when in operation to increase the visibility of the excavator and

4 4 16 4 1 4

awareness of site personnel to the operation at hand. All personnel to wear high visibility clothing.

Excavators should be equipped with adequate visibility aids to ensure drivers can see areas where

people may be at risk from the operation of the machine.

Striking of Undertaking of excavation work close to or below such lines should be carefully considered and

overhead lines avoided where possible. Contact the electricity company to agree diversion of supply, safe working

distances or any other safety precautions. Highly visible barriers and solid goalposts should be

erected at the set safe distance, which will be determined in accordance with electricity company

4 4 16 and GS6 requirements. Height restrictors (set in accordance with electricity company advice) should 4 1 4

be in place on all plant working in direct proximity to lines. Ground directly under power lines should

be inspected to guarantee that surface has no hidden gradients or gullies which in effect could

render the height restrictors ineffective and increase the likelihood of plant coming into contact with

the lines.

Falling objects Do not allow persons to stand/ work within operating radius or under loads, ensure this by creating

4 3 12 an exclusion zone around the plant. Ensure security of bucket or other attachments prior to use. 4 1 4

Plant overturning Operate with wheels/tracks at 90 deg to the workface. Ensure operations on gradients do not cause

4 3 12 loss of stability. Do not undercut and cause overhangs. Ensure that excavation inspection has taken 4 1 4

place before work is carried out.

Plant falling into Where vehicles are excavating use stop blocks to prevent plant from over-running and entering the

excavation 4 3 12 excavation area. Excavation site should be highly visible and the edges should be fenced off 4 1 4

appropriately. This reduces this risk of plant entering the excavation.

Contact when When slewing in a confined area the selection of plant with minimal tail swing is preferred.

slewing Machine 4 3 12 Clearance of over 0.5m needs to be maintained between any part of the machine, particularly the 4 1 4

ballast weight, and the nearest obstruction.

Likelihood→ Likely Probable Possible Unlikely Very unlikely KEY: S = Severity

EN149 EN166 EN388 ENISO

Severity (5) (4) (3) (2) (1) L= Likelihood

FFP3 B-N-K 2-1-2-1

20471

Death (4) 20 16 12 8 4 R= Risk rating

Major Injury (3) 15 12 9 6 3 High risk ENISO

EN352

Minor Injury (2) 10 8 6 4 2 Medium risk

SNR26

20345 EN397 EN361

No Injury (1) 5 4 3 2 1 Low risk S1P

Ultimate Demolition and Construction Service Limited Page 36 of 38

Operation: DEMOLITION /DISMANTLING Persons at risk: Operatives, employees, 3rd parties. RA 69

Assessment Re-assessment

HAZARD CONTROL MEASURES TO REDUCE THE RISK

S L R S L R

Demolition Only competent (CCDO) demolition personnel experienced in the type of demolition to be

Operative error 4 4 16 4 1 4

undertaken are to plan and carry out these works (. A written plan following BS6187)

Use of Excavator A signaller/ banksman should be provided in a safe position to direct excavator operation and any