Professional Documents

Culture Documents

69372

Uploaded by

hai LinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

69372

Uploaded by

hai LinCopyright:

Available Formats

SVEND HØYER A/S

MOTOR TEST CERTIFICATE

Allweiler AG Your order no. ..................... : xxxxxx

Project no............................ : xxxxxx

D-78301 Radolfzell Mark.................................... : xxxxxx

Motortype........................... : Y2E2 200 L1-2 Our order no........................ : xxxx

Mounting ............................. : B5 / V1, fixed bearing Date .................................... : 18-09-2006

Protection class................... : IP55 Certificate no....................... : xxx-xxxxx

Insulation class.................... : F/B

Duty cycle............................ : S1-100% Moment of inertia J (kgm) . : 0,124

Mass (kg) ............................ : 246 No load current (A).............. : 18,7

Starting torque d.o.l............. : x2,0 Temp. rise surface (K) ........ : 43,7

Starting current d.o.l. (A) ..... : 448 Temp. rise windings (K) ...... : 69,3

Cable Gland ........................ : 2 pcs. M50 x 1,5 Cable diameter (mm) .......... : Ø22-32

Starting time (sec.) .............. : 10 Noise (dBa) ......................... : 74

Frequency (Hz) .................. : 50 Frequency (Hz) .................. : 60

Output (kW)......................... : 30 Output (kW)......................... : 34,9

-1

Speed (min ) ...................... : C-CW - 2950 -1

Speed (min ) ...................... : C-CW - 3540

Voltage (Vac) ...................... : Δ/Y 400/690 Voltage (Vac) ...................... : Δ 440

Nominal current (A) ............. : 52,3/30,3 Nominal current (A)............. : 55,3

Power factor cos. Phi .......... : 4/4 load 0,90 Power factor cos. Phi .......... : 4/4 load 0,90

Efficiency (%) ...................... : 92,0 Efficiency (%) ...................... : 92,0

Anti condensation heating : Consumption (W) : 42 Voltage (V) : 230

Marine classification : Acc. to DNV standard Amb.temp. : 45o C

High voltage dielectric test between phases and earth during 1 min (Vac) ............ : 2000

Overload test during 15 seconds overload torque (%FLT) ..................................... : 160

Vibration severity according NEN/ISO 2373-1974 (half key)................................. : Class “N” or as specified below

Bearings DA/NDE .............. : 6312 C3 6312 C3

Special features .................. :

Motor serial numbers .......... : XXXXXXXX

Quotation / Offer No.

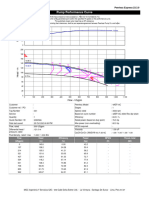

Charact. curves Jinling Shipyard

NAM 65-250/01 Proj ect ID

Hull JLZ9100415 / 416

Charact. curves acc. DIN EN ISO 9906 Class 2 Item: 016

Admissible minmum capacity 10 % * Q(opt) at continous operation Emergency Fire Pump

Rem arks:

Created by Date

Ev a Ruhl 2010-11-03

Power data ref erred to: Sea water

H

Q P

25,76 kW

Vis Temp Density rated Torque

69,5 Nm

Speed

1) 72,00 m³/h 75,00 m 0,8 mm²/s 32,0 °C 1,03 kg/dm³

2) 3540 1/min

NPSH-value without safety margins

Head

[m]

95 40% 50%

60%

90 66%

85 70%

80 Eff.

71,1%

75 75 m

1

70

65

69,5% 66%

60 69,4%

55 60%

Ø 220

50

45

40

Ø 203

Ø 200

35

30

Shaft power P2 Ø 220 (P2)

[kW]

50

40 ØØ200

203(P2)

(P2)

30

25,8 kW

20

10

NPSH-values Ø 220

[m]

12

ØØ200

203

4 3,56 m

Efficiency

[%]

60 Ø 22058,6 %

ØØ200

203

40

20

72 m³/h

0

0 20 40 60 80 100 120 140 160 180 200 220 [m³/h]

Flow

Version 2.0.3 Curve number: 065 01250 0129 Page 7

You might also like

- Product Information: X-Ray Tube D-054 D-054S D-054SB Stationary Anode X-Ray TubeDocument10 pagesProduct Information: X-Ray Tube D-054 D-054S D-054SB Stationary Anode X-Ray TubeWaheed MidoNo ratings yet

- X Ray Tube User ManualDocument14 pagesX Ray Tube User ManualRameshNo ratings yet

- WEG 3kW 2P B3 IE3 WIMES Data SheetDocument7 pagesWEG 3kW 2P B3 IE3 WIMES Data SheetA aaa AaaNo ratings yet

- WEG 132kW 315frame 2pole B5Document23 pagesWEG 132kW 315frame 2pole B5A aaa AaaNo ratings yet

- Mega Ohm Box 2022Document1 pageMega Ohm Box 2022SOURABH JAINNo ratings yet

- 6X52 - 7250kW - 85rpm - Low Load TuningDocument25 pages6X52 - 7250kW - 85rpm - Low Load TuningParis AndreadisNo ratings yet

- 6X52 - 7250kW - 85rpm - Delta Bypass TuningDocument25 pages6X52 - 7250kW - 85rpm - Delta Bypass TuningParis AndreadisNo ratings yet

- CMCR and Engine Operating Curves: Rating FieldDocument24 pagesCMCR and Engine Operating Curves: Rating FieldmanuNo ratings yet

- Product Information: Toshiba X-Ray Tube D-045Document6 pagesProduct Information: Toshiba X-Ray Tube D-045KamilNo ratings yet

- X Ray TubeDocument18 pagesX Ray TubeEduardo UrbanoNo ratings yet

- Product Information: Toshiba X-Ray Tube D-058 D-058R D-058S D-058SR D-058SB D-058SBRDocument12 pagesProduct Information: Toshiba X-Ray Tube D-058 D-058R D-058S D-058SR D-058SB D-058SBRKamilNo ratings yet

- FIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVDocument8 pagesFIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVCrysthian AspilcuetaNo ratings yet

- WEG 55kW 4P B3 IE3 WIMES Data SheetDocument7 pagesWEG 55kW 4P B3 IE3 WIMES Data SheetJoey seoNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument10 pagesData Sheet: Three Phase Induction Motor - Squirrel CageSergeiNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- P PG G - 1 12 2V V1 12 20 0: 12 Volt 120 A.HDocument2 pagesP PG G - 1 12 2V V1 12 20 0: 12 Volt 120 A.HJuan EsNo ratings yet

- Bateria CSB HRL12390W Equivalente HX400FRDocument2 pagesBateria CSB HRL12390W Equivalente HX400FRomarpatNo ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- Product Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube Assemblykhawar mukhtarNo ratings yet

- Product Information: Rotanode™ E7239X E7239FX E7239GXDocument10 pagesProduct Information: Rotanode™ E7239X E7239FX E7239GXWael Fuad AL-MaktariNo ratings yet

- CMCR and Engine Operating Curves: Rating FieldDocument17 pagesCMCR and Engine Operating Curves: Rating FieldmanuNo ratings yet

- Generator Type Eco 3-1Sn/4: Electrical CharacteristicsDocument5 pagesGenerator Type Eco 3-1Sn/4: Electrical CharacteristicsFaridh AmroullohNo ratings yet

- Toshiba PDFDocument22 pagesToshiba PDFSohail AhmedNo ratings yet

- Product Information: Rotanode™ E7255X E7255FX E7255GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7255X E7255FX E7255GX Rotating Anode X-Ray Tube Assemblykhawar mukhtarNo ratings yet

- P PG G - 1 12 2V V1 15 50 0: 12 Volt 153 A.HDocument2 pagesP PG G - 1 12 2V V1 15 50 0: 12 Volt 153 A.HJuan EsNo ratings yet

- FDC045954 2023Document19 pagesFDC045954 2023Sameh KhalidNo ratings yet

- Data Sheet D2848LE423 662@2300V8 900 2015 04 21Document3 pagesData Sheet D2848LE423 662@2300V8 900 2015 04 21alper zihnioluNo ratings yet

- Hanyoung Limit SwitchDocument3 pagesHanyoung Limit Switchfrans yama putraNo ratings yet

- Generator Type Ecp 3-1L/4: HZ V kVA KW kVA KW DSRDocument5 pagesGenerator Type Ecp 3-1L/4: HZ V kVA KW kVA KW DSRFaridh AmroullohNo ratings yet

- P PG G - 1 12 2V V2 20 00 0: 12 Volt 200 A.HDocument2 pagesP PG G - 1 12 2V V2 20 00 0: 12 Volt 200 A.HJuan EsNo ratings yet

- Product Information: Rotanode™ E7846Document7 pagesProduct Information: Rotanode™ E7846KamilNo ratings yet

- BPH 80 65SDocument2 pagesBPH 80 65SNicolae HincuNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data Sheethalil ibrahim soysalNo ratings yet

- Pe E7876x - 2018 11Document8 pagesPe E7876x - 2018 11aplicacionista.imagenesNo ratings yet

- Ecp3 1s4Document5 pagesEcp3 1s4plennyNo ratings yet

- Ap303 - Cooling Water PumpsDocument4 pagesAp303 - Cooling Water Pumpsminov minovitchNo ratings yet

- Transmission: Section 8A - ZF Marine Transmissions-HSW 63A, 63IV, 80ADocument10 pagesTransmission: Section 8A - ZF Marine Transmissions-HSW 63A, 63IV, 80AJorge SoberanoNo ratings yet

- WEG 15kW 2P B3 IE3 WIMES Data SheetDocument7 pagesWEG 15kW 2P B3 IE3 WIMES Data Sheetabel manuel chico oleceNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument10 pagesData Sheet: Three Phase Induction Motor - Squirrel CageSergeiNo ratings yet

- 6 Volt 210 A.H.: Long Service LifeDocument2 pages6 Volt 210 A.H.: Long Service LifeJuan EsNo ratings yet

- Alternators: 4 Pole RangeDocument20 pagesAlternators: 4 Pole RangeRobiNo ratings yet

- GE Energy: Gas Turbine (60Hz)Document2 pagesGE Energy: Gas Turbine (60Hz)Rolando Antonio Cuenca PironaNo ratings yet

- Mecc Alte Gen. 40 - VL4Document5 pagesMecc Alte Gen. 40 - VL4Mustafa A.WNo ratings yet

- Planta Panaven Modelo GMS22PX6SDocument6 pagesPlanta Panaven Modelo GMS22PX6Sfranklin velasco100% (1)

- CFM40S - CFM60S DatasheetDocument3 pagesCFM40S - CFM60S DatasheetmrahNo ratings yet

- K321-05041 A2 - Electrical Load AnalysisDocument4 pagesK321-05041 A2 - Electrical Load AnalysisJerome EugeneNo ratings yet

- Leroy Somer Alternator Products PDFDocument20 pagesLeroy Somer Alternator Products PDFfirdNo ratings yet

- ps-610 11 Feb 21Document2 pagesps-610 11 Feb 21api-170472102No ratings yet

- Pe-E7242x Tubo CannonDocument10 pagesPe-E7242x Tubo Cannonaplicacionista.imagenesNo ratings yet

- WEG WEEE Inverters User Manual 10005837622 en Es PTDocument143 pagesWEG WEEE Inverters User Manual 10005837622 en Es PTjhsimiaoNo ratings yet

- Astronergy CHSM6612P 3BB 40mm Frame 20151014Document2 pagesAstronergy CHSM6612P 3BB 40mm Frame 20151014J AANo ratings yet

- FXSQ PaveDocument43 pagesFXSQ PaveAntônio Mauricio Leal BritoNo ratings yet

- Edfmt391738a Fxmq-PaveDocument64 pagesEdfmt391738a Fxmq-PaveEduardo RodriguezNo ratings yet

- Technical Manual NP V15 PDFDocument20 pagesTechnical Manual NP V15 PDFAhmed El KadyNo ratings yet

- TABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseDocument23 pagesTABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseJuan Carlos Perez ParraNo ratings yet

- Raffino 2013 LSR BrochureDocument3 pagesRaffino 2013 LSR BrochureSteve LeibovitzNo ratings yet

- WPS250S in H S e PDocument6 pagesWPS250S in H S e PMuntasir MunirNo ratings yet

- Pressure Switch For Industrial Applications Model PSM-520Document5 pagesPressure Switch For Industrial Applications Model PSM-520MathiasNo ratings yet

- Technical Data Sheet 75EPM 90EPMDocument1 pageTechnical Data Sheet 75EPM 90EPMkwstdbjp5fNo ratings yet

- K 160 M Sileo: Centrifugal Circular Duct Fan 125WDocument9 pagesK 160 M Sileo: Centrifugal Circular Duct Fan 125WOscar Barres MoreiraNo ratings yet

- Iptc 14300 MSDocument10 pagesIptc 14300 MShade wantoNo ratings yet

- PSP Lab 4 Group 7 Section (A)Document4 pagesPSP Lab 4 Group 7 Section (A)Kazi ShahadatNo ratings yet

- Thermodynamics Sample ProblemDocument1 pageThermodynamics Sample ProblemNiel ReproponioNo ratings yet

- ABB RMU Product CatalogueDocument124 pagesABB RMU Product CatalogueBirendra Kumar JhaNo ratings yet

- Catalogo de RepuestosDocument2 pagesCatalogo de RepuestossebastianNo ratings yet

- XR200 X-Ray Source: Operator'S ManualDocument25 pagesXR200 X-Ray Source: Operator'S ManualEOD HOLDING UNITNo ratings yet

- Department of Mechanical EngineeringDocument7 pagesDepartment of Mechanical EngineeringMuhammad TanveerNo ratings yet

- Design of Cooling SystemDocument5 pagesDesign of Cooling Systemsameerpatel15770100% (1)

- In Service Inspection and Testing of Electrical Equipment The Insulation TestDocument3 pagesIn Service Inspection and Testing of Electrical Equipment The Insulation TestBalasoobramaniam CarooppunnenNo ratings yet

- 3516B Generator Set GZS00001-UP (SEBP3935 - 40) - SMCS CodeDocument5 pages3516B Generator Set GZS00001-UP (SEBP3935 - 40) - SMCS CodeMetisNo ratings yet

- Developing A Sustainable Air Hub in SingaporeDocument79 pagesDeveloping A Sustainable Air Hub in SingaporeMok Thye YeeNo ratings yet

- Determination of Closure Stress and Characterization of Natural Fractures With Micro-Fracturing Field DataDocument20 pagesDetermination of Closure Stress and Characterization of Natural Fractures With Micro-Fracturing Field DataCaio AlmeidaNo ratings yet

- Computation For VOCDocument3 pagesComputation For VOCBROADFIELD ENGINEERINGNo ratings yet

- Carbicrete ReportDocument33 pagesCarbicrete Reportelaine liNo ratings yet

- Shell Helix Ultra 5W-40: Performance, Features & BenefitsDocument2 pagesShell Helix Ultra 5W-40: Performance, Features & BenefitsMuhNo ratings yet

- PGDT c3 DiagnosticsDocument14 pagesPGDT c3 DiagnosticsHushanjiNo ratings yet

- Sent Tutorial 5 Prob OnlyDocument2 pagesSent Tutorial 5 Prob OnlyYu LoengNo ratings yet

- Drive - HpmontDocument148 pagesDrive - HpmontsmsobhanNo ratings yet

- Physics SL Paper 2 TZ1Document28 pagesPhysics SL Paper 2 TZ1믯차No ratings yet

- Eig SaratDocument51 pagesEig SaratTTIPLNo ratings yet

- Hopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Document2 pagesHopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Save Standard TimeNo ratings yet

- Mark Scheme (Results) January 2023Document19 pagesMark Scheme (Results) January 2023aamirudheen ali100% (1)

- RotatingDocument6 pagesRotatingFarooq Ahmed Amir ChaudhryNo ratings yet

- Hydraulic Question BankDocument10 pagesHydraulic Question BankTariq khosoNo ratings yet

- ItatoolsDocument12 pagesItatoolsZaika NatalyNo ratings yet

- 1 s2.0 S0360319912017181 MainDocument8 pages1 s2.0 S0360319912017181 MainNafees VakilNo ratings yet

- Datasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Document7 pagesDatasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Blendwerk AntikunstNo ratings yet

- Air Standard Assumptions:: EN560: Foundation For Energy TechnologyDocument5 pagesAir Standard Assumptions:: EN560: Foundation For Energy TechnologypoojaNo ratings yet

- Ifec22 Leibniz University HannoverDocument23 pagesIfec22 Leibniz University HannoverruanNo ratings yet