Professional Documents

Culture Documents

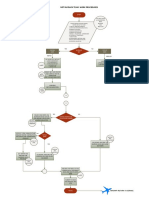

Uflex Diagram

Uploaded by

prashantkpjkanpurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uflex Diagram

Uploaded by

prashantkpjkanpurCopyright:

Available Formats

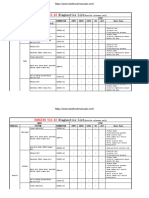

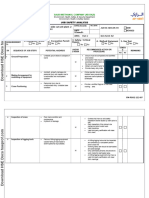

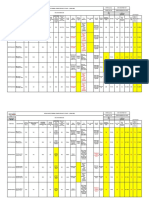

Kaizen No.

- 0054 Result : Productivity improvement, Manpower

Deptt.: -Assembly (Assy) saving, Space saving, Energy saving, Two MAR'11

fixtures eliminated

Theme : Manpower Saving & Productivity improvement Process : Body insert assy + Terminal insertion + Greasing

1. Manpower, Man-hour

Before Improvement After Improvement Saving

√

( Photo or Explanation Drawing ) ( Photo or Explanation Drawing ) 2. Physical Distribution

(Transporting distance)

√

WORK FLOW BODY TERMINAL GREASING 3. Space saving √

Body insert

INSERT ASSY. (3)

Assy Punch 4. Commanisation,

ASSY (2) √

(1) unification

Terminal Assy

Punch 5. Weight reduction

6. Energy Saving √

7. Yield

8. Quality improvement √

9. 5S √

GREASING

Auto 10. Cost Reduction √

Greasing

11. Safety √

12. Horizontal Application √

13. Others

Three processes is done at separate stations by three Three processes merge into single process with auto

operators 1) ejection and transported to next process by single Cost Saving /year- Rs. 215820/-

Body Insert Assy. operator & station

2) Terminal Assy. Date of

26-03-2011

3) Greasing Implementation

WHY-WHY ANALYSIS HORIZONTAL DEPLOYMENT

1) S01062-000 DLS(Batch Marking & Body Insert assy.) Production

Delivery Failure Line Capacity Constraint Suggested by

Deptt

(Customer Demand Increased) More Man Power used 2) Plan made for S02001 BLS(Stamping & Caulcking)

Quality

BENEFITS:- PRODUCTIVITY IMPROVED & TWO MAN POWER SAVED Approved By

(Manager)

You might also like

- HSE Training MatrixDocument1 pageHSE Training Matrixragil86% (7)

- Gasp Polarimeter Gasp-Cs Polarimeter Lcd-Gasp Polarimeter Video-GASP System Instruction ManualDocument29 pagesGasp Polarimeter Gasp-Cs Polarimeter Lcd-Gasp Polarimeter Video-GASP System Instruction ManualAlex Pelinco Apaza100% (1)

- Advanced Femap Training - A4Document25 pagesAdvanced Femap Training - A4Vikas HNo ratings yet

- DPWH Atlas As of January 2022Document10 pagesDPWH Atlas As of January 2022Cathy EnriquezNo ratings yet

- Intervention/decommissioningDocument15 pagesIntervention/decommissioningAnonymous ZO1piE3VNo ratings yet

- Training CalanderDocument2 pagesTraining CalanderMahendra KakdeNo ratings yet

- CA Inter Costing Charts by CA Kriti GoelDocument19 pagesCA Inter Costing Charts by CA Kriti GoelCA Manoj Kumar SabatNo ratings yet

- FMT - Qa.014 Capa FormatDocument2 pagesFMT - Qa.014 Capa Formatnishantpriya1104No ratings yet

- Oltp Vs Datawarehouse DSSDocument2 pagesOltp Vs Datawarehouse DSSriteshkumar2kNo ratings yet

- ANSYS v14 Rotordynamics Intro - Workshop 2B Critical Speed Map (2013)Document31 pagesANSYS v14 Rotordynamics Intro - Workshop 2B Critical Speed Map (2013)LarryLevon88100% (1)

- Improvement KaizenDocument11 pagesImprovement KaizenAnkurNo ratings yet

- Fifo Board - Rack "A" Example: Item Name: 0044 Needle Bearing SAP Code: B-NB-X050-0044-N0Document12 pagesFifo Board - Rack "A" Example: Item Name: 0044 Needle Bearing SAP Code: B-NB-X050-0044-N0Anonymous tv3qpx250% (2)

- Improvement KaizenDocument11 pagesImprovement KaizenAnkur DhirNo ratings yet

- Hmi CNG SpecDocument15 pagesHmi CNG SpecSantosh MordeNo ratings yet

- AWS Security ServicesDocument11 pagesAWS Security ServicesjayNo ratings yet

- Research GapDocument7 pagesResearch GapYant HArdy WaeNo ratings yet

- Commercial Note PDFDocument17 pagesCommercial Note PDFNguyễn Trần NamNo ratings yet

- Latest ILC 4 Year PlanDocument5 pagesLatest ILC 4 Year PlanARNAB GHOSHNo ratings yet

- SAMPLE Safety Training Plan 2023Document1 pageSAMPLE Safety Training Plan 2023Yusnor YunusNo ratings yet

- Action Plan 2020Document1 pageAction Plan 2020donaldNo ratings yet

- Hse Selasa 27 Daily ReportDocument1 pageHse Selasa 27 Daily Reporthse bsjNo ratings yet

- Zhonghua SpecialDocument1 pageZhonghua SpecialProsto VetahaNo ratings yet

- Hro PTWDocument1 pageHro PTWMami MohantyNo ratings yet

- Please Attached For Con: Project Name Location: ....... Floor Carpark Area: Date: Daswin Office Tower ProjectDocument4 pagesPlease Attached For Con: Project Name Location: ....... Floor Carpark Area: Date: Daswin Office Tower ProjectWahyu Rohmad DiantoNo ratings yet

- Draft Buy Back NDT ProsesDocument1 pageDraft Buy Back NDT ProsesScotNo ratings yet

- Hse Selasa 27 Daily ReportDocument1 pageHse Selasa 27 Daily Reporthse bsj100% (1)

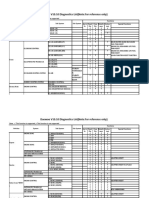

- Hongyan V10.63 Diagnostics List PDFDocument4 pagesHongyan V10.63 Diagnostics List PDFlaynurlanNo ratings yet

- Hro PTW R1Document1 pageHro PTW R1JISHNU EHSNo ratings yet

- Most Expected Topics - JEE April 2023 PDFDocument7 pagesMost Expected Topics - JEE April 2023 PDFrajNo ratings yet

- JSA For Column Lifting& ErectionDocument20 pagesJSA For Column Lifting& ErectionVennila RangithNo ratings yet

- Six Sigma Project FBUDocument7 pagesSix Sigma Project FBUvikashbhartiNo ratings yet

- March 09Document4 pagesMarch 09Kaliyamoorthy SamiayyaNo ratings yet

- 4.18.1 Mandatory Protocol Checklist For External EmbellishmentDocument1 page4.18.1 Mandatory Protocol Checklist For External EmbellishmentTrang NguyễnNo ratings yet

- Kulhawy (1991) Fiftreen+ Years of Model Foundation Testing in Large Chambers-185-195Document11 pagesKulhawy (1991) Fiftreen+ Years of Model Foundation Testing in Large Chambers-185-195Cesar Felipe Jimenez SantiagoNo ratings yet

- IJSER1553Document4 pagesIJSER1553Kyriakos MichalakiNo ratings yet

- Tbina GQCC RofDocument2 pagesTbina GQCC RofasepssoriesNo ratings yet

- Solid Slab Bridge Design Example 39 2015 - 8Document1 pageSolid Slab Bridge Design Example 39 2015 - 8Hamlity SaintataNo ratings yet

- QFD TesisDocument1 pageQFD TesisGabriel VazquezNo ratings yet

- Application of Optimization Techniques To Weight Reduction of Automobile BodiesDocument6 pagesApplication of Optimization Techniques To Weight Reduction of Automobile BodiesTibebu MerideNo ratings yet

- Borealis Po-Blown-Film-ApplicationsDocument4 pagesBorealis Po-Blown-Film-ApplicationsHafiani HichamNo ratings yet

- Pul F PHRD 2010 1 Matrik PelatihanDocument1 pagePul F PHRD 2010 1 Matrik PelatihanTraining BBSNo ratings yet

- 4 - BhattiAcademy - Com - Physics - 6. Scohlar SeriesDocument19 pages4 - BhattiAcademy - Com - Physics - 6. Scohlar SeriesBabar AliNo ratings yet

- Swift Brand Brochure PDFDocument12 pagesSwift Brand Brochure PDFChiquita WhiteNo ratings yet

- Designing of Chain Drive Mechanism 4 Selection of Flat BeltsDocument1 pageDesigning of Chain Drive Mechanism 4 Selection of Flat BeltsAbhishekNo ratings yet

- Ucs Crushed SandDocument1 pageUcs Crushed SandMohammed SalhinNo ratings yet

- Standard Muster List: NYK SMS Manual (Rev:2020/01/01)Document2 pagesStandard Muster List: NYK SMS Manual (Rev:2020/01/01)Cleanard HidalgoNo ratings yet

- Fuel Savings: A300/A310 Family Symposium A300/A310 Family Symposium A300/A310 Family SymposiumDocument27 pagesFuel Savings: A300/A310 Family Symposium A300/A310 Family Symposium A300/A310 Family SymposiumLbrito01No ratings yet

- This Study Resource Was: Friction Inquiry LabDocument7 pagesThis Study Resource Was: Friction Inquiry LabLilithNo ratings yet

- Intern Presentation1 DahaitsuDocument19 pagesIntern Presentation1 DahaitsuIqmal HalimNo ratings yet

- Daewoo V10.10 Diagnostics List (Note:For Reference Only)Document9 pagesDaewoo V10.10 Diagnostics List (Note:For Reference Only)Ismael ZerpaNo ratings yet

- Steel DesignDocument29 pagesSteel Designinayat_abbasNo ratings yet

- 1.1 Design WeaknessDocument8 pages1.1 Design Weaknesssherif mahmoudNo ratings yet

- Catálogo Geral Sobre Soluções KaeserDocument21 pagesCatálogo Geral Sobre Soluções KaeserEriton CavalcantiNo ratings yet

- ESC ComparisonDocument1 pageESC Comparisoncathy058No ratings yet

- Stone Panels Technical InformationDocument2 pagesStone Panels Technical Informationnumber_25No ratings yet

- Gravity Field Reduction and Correction (C08) : Library - Help - Top - Back - TopDocument32 pagesGravity Field Reduction and Correction (C08) : Library - Help - Top - Back - TopIca VianisyaNo ratings yet

- Analisis Process Fix Plant (Jaw Crusher) 16.03.24Document3 pagesAnalisis Process Fix Plant (Jaw Crusher) 16.03.24arbino sinagaNo ratings yet

- Module 2 Tension MembersDocument9 pagesModule 2 Tension MembersAbren DaysoNo ratings yet

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilNo ratings yet

- Lab Test Request FOR CBH1Document1 pageLab Test Request FOR CBH1Lee Jia QingNo ratings yet

- Salahaddin University College of Engineering Geomatics DepartmentDocument6 pagesSalahaddin University College of Engineering Geomatics DepartmentDaneal SofiNo ratings yet

- LBWE Message MCEX 140 With Extract Structure ChangeDocument2 pagesLBWE Message MCEX 140 With Extract Structure ChangeDeri PermanaNo ratings yet

- 2013 - Dimyadi - Automated Building Code Compliance Checking - Where Is It atDocument15 pages2013 - Dimyadi - Automated Building Code Compliance Checking - Where Is It atVicente MedianoNo ratings yet

- Tascam DM 24 Manual de UsuarioDocument12 pagesTascam DM 24 Manual de UsuarioZharick Aponte100% (1)

- AZ104 - Documentos AdicionalesDocument14 pagesAZ104 - Documentos AdicionalesWalter CampalNo ratings yet

- Meganet VME-ManPack JammerDocument15 pagesMeganet VME-ManPack JammerMeganet CorporationNo ratings yet

- Electronic Mainternance 1981Document180 pagesElectronic Mainternance 1981Hoa Nguyen VanNo ratings yet

- CleanCool2010 MeetTheUKCleantechCompanies FinalFeb23Document211 pagesCleanCool2010 MeetTheUKCleantechCompanies FinalFeb23tonychaoNo ratings yet

- Practical Examples Using Dachcz RegulationsDocument11 pagesPractical Examples Using Dachcz RegulationsrvasilevaNo ratings yet

- Agilent Haim SDocument54 pagesAgilent Haim Ssepe999No ratings yet

- SEW AC Motors 2009 PDFDocument496 pagesSEW AC Motors 2009 PDFwickedness100% (1)

- TP48400B-N20A1 - L20A1 - N20B1 - TP48600B-N20A1 Engineer ManualDocument79 pagesTP48400B-N20A1 - L20A1 - N20B1 - TP48600B-N20A1 Engineer ManualWhite KingNo ratings yet

- Iim Indore'S: Integrated Program in Business Analytics (IPBA)Document8 pagesIim Indore'S: Integrated Program in Business Analytics (IPBA)Ankit PandaNo ratings yet

- Unit 4Document77 pagesUnit 4baidnirvana8No ratings yet

- SuperMax Receiver Biss EnglishDocument7 pagesSuperMax Receiver Biss EnglishStelios ZoitNo ratings yet

- Radiometric Correction and Calibration of SAR ImagesDocument7 pagesRadiometric Correction and Calibration of SAR ImagesSimone MeschinoNo ratings yet

- Communication Material On Antenna Product Switch To 4.3-10 ConnectorDocument12 pagesCommunication Material On Antenna Product Switch To 4.3-10 ConnectorZoheir KacimiNo ratings yet

- Application of OR in Fashion IndustryDocument7 pagesApplication of OR in Fashion IndustryManali ThakkarNo ratings yet

- Engineering ProfessionDocument45 pagesEngineering ProfessionUpender DhullNo ratings yet

- PSP0 Process Script Purpose Entry Criteria: - PSP0 Project Plan Summary FormDocument16 pagesPSP0 Process Script Purpose Entry Criteria: - PSP0 Project Plan Summary FormDaniela Rodriguez ZavalaNo ratings yet

- PR100 Portable ReceiverDocument30 pagesPR100 Portable ReceiverHassan Daud100% (1)

- Smart Cities and Big DataDocument14 pagesSmart Cities and Big DataLeonardo SeubeNo ratings yet

- TSC NSC SeriesDocument32 pagesTSC NSC Seriesmoh shoNo ratings yet

- Microsoft Excel: Superviser: Nahla Name of Student: Yusif Natiq JalalDocument10 pagesMicrosoft Excel: Superviser: Nahla Name of Student: Yusif Natiq Jalalayad nuhNo ratings yet

- ECSS-E-33-11A - Explosive Systems and DevicesDocument64 pagesECSS-E-33-11A - Explosive Systems and DevicessebamonsuNo ratings yet

- SOP-11355 Immune Cell Serum Replacement (ICSR) ThawingDocument3 pagesSOP-11355 Immune Cell Serum Replacement (ICSR) ThawingAlejandro LlccNo ratings yet

- Tiny Electret Microphone Pre-Amplifier Using OPA172: FeaturesDocument1 pageTiny Electret Microphone Pre-Amplifier Using OPA172: FeaturesvermdocamitNo ratings yet

- Time Series-171KDocument190 pagesTime Series-171KGowtham KumarNo ratings yet