Professional Documents

Culture Documents

RDSO-SPEC-Tribo Meter-TMM-0001-2023

Uploaded by

Karthikeyan RajamanickamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RDSO-SPEC-Tribo Meter-TMM-0001-2023

Uploaded by

Karthikeyan RajamanickamCopyright:

Available Formats

161

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

RDSO Standard of

Rail Surface Friction Meter

(Document No.: IS/RDSO-TMM/0001:2023)

Track Machines & Monitoring Directorate

Research Designs and Standards Organization

Manak Nagar, Lucknow-226011

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 1 of 6

Prepared by: Checked by: Approved by:

162

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

1.0 Purpose-Indian Railway is a large network. Indian Railway track network has lots of curves

which are lubricated on Gauge face corner of outer rail by lubricants to avoid gauge face wear.

Track based Lubricators are being adopted by Indian Railway for lubrication.

2.0 Scope

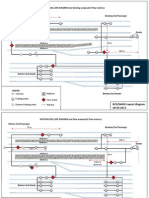

2.1 Purpose of this device to measure coefficient of friction (Dynamic) on the Gauge face Corner,

Gauge face & top of rail on curve section as well as straight section of the track.

2.2 Preference to make in India: Compliance of the instructions contained in Public procurement

(Preference to Make in India) order-2017 shall be ensured.

2.3 Definitions:

Gauge: The distance between the inside running (or gauge) faces of the two rails measured

between points 13-15 mm below the top of the rail head.

Gauge face corner: The single point in the gauge corner region, the tangent of which is at 45°

to the horizontal, with or without rail inclination.

Gauge face: The zone of the rail head facing the inside of the track. In the tighter curves the

gauge face may be worn due to contact with the wheel flange.

Top of Rail: The distance of rail crown (or rail head) is known as Top of rail.

3.0 Service Conditions-

3.1 System should be able to work under following service condition:

i) Ambient temperature: 0°c to 50°C

ii) Rail temperature: (-) 10°C to (+) 75°C

iii) Humidity: 40- 90%

iv) Rainfall: No

v) Atmospheric condition: Very Dusty, heavy fog

3.2 The system should be such that it does not affect the signaling system.

4.0 Functional requirement :

4.1 Device should be able to measure value of coefficient of friction (Dynamic) on the Gauge face

Corner, Gauge face & top of rail at desired location on curve section as well as straight section

of track.

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 2 of 6

Prepared by: Checked by: Approved by:

163

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

4.2 It should be able to work on BG track which is being generally used in Indian railway.

4.3 Device must be able to work under Indian environmental conditions.

4.4 It should be robust portable, lightweight & easy to operate so that one man can manage it.

4.5 It should work on rechargeable battery. Rechargeable battery should have sufficient capacity to

be able to work for at least 8hrs continuously without need for recharging.

4.6 This will be automatic digital type device that will give a value of friction (Dynamic) at desire

location on track.

4.7 It should containing a display screen that indicates the average value of coefficient of friction

(Dynamic) after minimum 50cm to maximum 3m distance during measurement and not the

instantaneous value. The device should save at least 100 readings and there should also be a

facility to transfer that reading to PC.

4.8 Data Transfer Module: This module is used for transferring data from Display Unit to

Personal Computer (PC) through USB/Pen drive/Bluetooth/mobile set. Data transferred in

Computer should create a file in ASCII format compatible to TMS software as given below:-

(i) Location record format: I,RRRR,DDDD,SSSS,SSSS where I is 1 for this type of record,

RRRR is name of Railway, DDDD is name of Division and SSSS,SSSS is name of the two

stations in between coefficient of friction measuring is being done.

(ii) Kilometer and curve record format: I,KKKK,CCCC where I is 2 for this type of record,

KKKK is kilometer post and CCCC is curve number reading where coefficient of friction

measuring is being done.

(iii) Coefficient of friction record format: I,DD/MM/YY,HH:MM,FF.FF,LLLLL,TP,TP

where I is 3 for this type of record, DD/MM/YY is date, month and year, HH:MM is

time, FF.FF is coefficient of friction in µ, LLLLL is the name of line and TP,TP is name

of the two electric poles in between coefficient of friction measuring is being done.

Thus file generated on PC will be in following format:-

1,RRRR,DDDD,SSSS,SSSS

2,KKKK,CCCC

3,01/01/23,16:26,02.25,LLLLL,TP,TP

(, stands for blank space)

This data can also be further accessed in EXCEL files. The supplier shall provide software on

Pen drive for both the functions. This module shall be designed in such a way that it can be

fitted easily in Display Unit and does not contain any power source or battery.

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 3 of 6

Prepared by: Checked by: Approved by:

164

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

4.9 The Device shall have menu based and user friendly man machine dialogue by using in-

built/detachable key board which enables:

Setting of date and time.

Setting of name of Railway, Division, from Station to Station upto 4 alphabets maximum.

Setting of Kilometer upto 4 numeric maximum.

Setting of Line name upto 5 alphanumeric maximum.

Setting of “from TP to TP” upto 2 numeric maximum each.

5.0 Technical Features:

i. Resolution 0.01

ii. Accuracy ± 0.02

iii. Measurement range (µ) 0.1-0.75

iv. Weight Light weight easy to carry by one man. (Maximum wt.

20kg)

v. Power Rechargeable battery

vi. Work on Curve & Straight section

vii. Measuring Area Gauge face, Gauge face corner & Top of Rail

(Details given in Annexure A)

6.0 Acceptance test

6.1 Visual test: The device shall be visually checked for defects like rough finishing, loose

fittings bend in frame etc.

6.2 The device should have all the technical features of para 5.0 of the Standard.

6.3 Repeatability test: Repeatability test shall be conducted on without lubricated rail at gauge

face. Repeatability test shall be conducted for atleast 5 nos. of reading at same point with

minimum 5 such locations out of which atleast two locations should be on curve of minimum

1.250. For same location, reading in different measurement should be within ± 0.02 of average

of the reading at the same point. Repeatability (or test–retest reliability) is described as the

variation in successive measurements.

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 4 of 6

Prepared by: Checked by: Approved by:

165

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

6.4 If the device fails in any acceptance test, it shall be rejected.

7.0 Marking And Packing:

Each device shall be legibly and indelibly marked with the following details:

(i) Name and trade mark/brand of the original manufacturer.

(ii) Serial no. of the device.

(iii) Make & Model

The device shall be packed in suitable box after covering with good quality material as per best

trade practice to avoid any damage during transshipment.

8.0 Details to be provided by Firms:

The following details shall be submitted by firms-

i. Description of working principal of the equipment/system.

ii. Working instruction manual

iii. Detailed description, function and weight of each unit of the equipment/system

iv. Technical literature, drawing and Standard of each unit of the equipment along with

details of relevant codes, if applicable.

v. Method of calibration of equipment and details methodology for validation of the

equipment/system.

9.0 Training and Commissioning:

9.1 Adequate training for operation and maintenance of the Rail Surface friction meter shall

be imparted to at Consignee’s end or at manufacturer’s premises as mutually agreed

between the manufacturer and the purchaser at the rate of one operator per Rail Surface

friction meter during supply which shall be treated as commissioning.

9.2 After the Rail Surface friction meter has been supplied at consignee premises, the supply

shall be considered as complete only after field training is provided by the supplier as

stated above.

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 5 of 6

Prepared by: Checked by: Approved by:

166

ISO 9001-2015 Document No.: IS/RDSO-TMM/0001:2023 Revision: 00 Date Effective From: 20.06.2023

1987272/2023/O/o PED/INFRA-1/RDSO

Document Title: RDSO Standard of Rail Surface Friction Meter

SSRE/SSE/JRE ARE/DTM/EDTM PED/INFRA-1 Page 6 of 6

Prepared by: Checked by: Approved by:

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- PCE Circular - Similar Nature of WorkDocument17 pagesPCE Circular - Similar Nature of WorkGyaneshwar Singh100% (2)

- Standard Practice For Quantifying Roughness of PavementsDocument4 pagesStandard Practice For Quantifying Roughness of PavementsManuel Enrique VásquezNo ratings yet

- Draft - 2 - Spec - 200 KMPH Loco PDFDocument69 pagesDraft - 2 - Spec - 200 KMPH Loco PDFABHISHEK KUMARNo ratings yet

- 38tmss06r0-Dynamic System MonitorDocument11 pages38tmss06r0-Dynamic System MonitorshabeerNo ratings yet

- Determining The Longitudinal Profile Roughness of Traveled Surfaces Using Automated ProfilersDocument8 pagesDetermining The Longitudinal Profile Roughness of Traveled Surfaces Using Automated ProfilersOkello StevenNo ratings yet

- Draft Specification of Lan Switch: Specification No. Rdso/Spn/Tc/83/2014 Revision 1.0Document27 pagesDraft Specification of Lan Switch: Specification No. Rdso/Spn/Tc/83/2014 Revision 1.0Anonymous MDkp0hnb3lNo ratings yet

- SDH Rdso 53 09Document12 pagesSDH Rdso 53 09GURNAYANNo ratings yet

- Ei Introduction To Otn 310317Document13 pagesEi Introduction To Otn 310317man_i_acNo ratings yet

- Falling Weight Deflectometer: EthodologyDocument4 pagesFalling Weight Deflectometer: EthodologyRajdev SinghNo ratings yet

- Specification of Off Track Tamper (India Gov)Document7 pagesSpecification of Off Track Tamper (India Gov)jasonNo ratings yet

- Spec 133 WAG7 RGB 09012018Document42 pagesSpec 133 WAG7 RGB 09012018essen999No ratings yet

- ETSI TR 101 983: Technical ReportDocument12 pagesETSI TR 101 983: Technical ReportNtsane MoleNo ratings yet

- IJIRAE:: Equalization & Channel Estimation of Block & Comb Type CodesDocument4 pagesIJIRAE:: Equalization & Channel Estimation of Block & Comb Type CodesIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- API For DDS Based MIL-STD-1553B Bus Simulator: September 2013Document8 pagesAPI For DDS Based MIL-STD-1553B Bus Simulator: September 2013sajid javidNo ratings yet

- Fo - QR Ehvj Jhfmax) 'Kqyd VKSJ Yksm Fu A KD Osq Fy, Vk¡Dm+Ksa DK Fofue LG KSXH Fof'Kf"VDocument23 pagesFo - QR Ehvj Jhfmax) 'Kqyd VKSJ Yksm Fu A KD Osq Fy, Vk¡Dm+Ksa DK Fofue LG KSXH Fof'Kf"VNikhil EkvachaneNo ratings yet

- Scanning With Sony Ericsson TEMS Devices - Technical PaperDocument13 pagesScanning With Sony Ericsson TEMS Devices - Technical PaperTaiba Asghar AwanNo ratings yet

- Measuring Pavement Macrotexture Properties Using The Circular Track MeterDocument5 pagesMeasuring Pavement Macrotexture Properties Using The Circular Track MeterDannyChaconNo ratings yet

- Telecom Hand Book IRICETDocument174 pagesTelecom Hand Book IRICETNeeraj Kumar MathuriyaNo ratings yet

- Code of Procedure of Ultrasonic Testing For WAP5 Loco Axle With Direct Drive To Drawing No. G34-300.00-81 in ServiceDocument27 pagesCode of Procedure of Ultrasonic Testing For WAP5 Loco Axle With Direct Drive To Drawing No. G34-300.00-81 in ServiceSarita ForgingNo ratings yet

- 06 Ijetmr17 A08 58Document7 pages06 Ijetmr17 A08 58sathya2040No ratings yet

- IADC Daily Drilling Report RevADocument8 pagesIADC Daily Drilling Report RevAtxcrudeNo ratings yet

- EasysDocument13 pagesEasysPaschal AbarahNo ratings yet

- Nitestar Distance Measuring Instrument (DMI)Document4 pagesNitestar Distance Measuring Instrument (DMI)Leon VaiciusNo ratings yet

- PayloadDocument4 pagesPayloadXabi AdinNo ratings yet

- Revised Agenda 10 DecDocument96 pagesRevised Agenda 10 DecSachin PardeshiNo ratings yet

- Turnkey Weld Inspection Solutions Using PAUT and TOFDDocument10 pagesTurnkey Weld Inspection Solutions Using PAUT and TOFDPRAKASH PRAMANIKNo ratings yet

- Netra Final Draft Spec - 14.06.19Document89 pagesNetra Final Draft Spec - 14.06.19RCC PGTNo ratings yet

- Specification For Train Protection & Warning System (TPWS) : Government of India Ministry of RailwaysDocument32 pagesSpecification For Train Protection & Warning System (TPWS) : Government of India Ministry of RailwaysKrishna PrasadNo ratings yet

- Tyre Pressure Monitoring System-1Document8 pagesTyre Pressure Monitoring System-1Khamis Khamis Moh'dNo ratings yet

- Medi-Caps University, Indore: SESSION 2021-2022 Software Engineering (CS3CO26) Lab FileDocument20 pagesMedi-Caps University, Indore: SESSION 2021-2022 Software Engineering (CS3CO26) Lab FileHarshajNo ratings yet

- Final Draft Spec SPN TC 63 2006Document18 pagesFinal Draft Spec SPN TC 63 2006Pandey ShaileshNo ratings yet

- Revised Technical Specifications - MarkedDocument42 pagesRevised Technical Specifications - MarkedKaren M.No ratings yet

- En 30206503v020101pDocument40 pagesEn 30206503v020101pDmitry BlokhinNo ratings yet

- 1MA152 3e ITS Using 802 11pDocument26 pages1MA152 3e ITS Using 802 11pArjun HariharanNo ratings yet

- Policy On Laying Ofc Cables in S&T Works 04.10.23Document4 pagesPolicy On Laying Ofc Cables in S&T Works 04.10.23PAVAN KUMAR GUDAVALLETINo ratings yet

- Land Survey by Robot PDFDocument11 pagesLand Survey by Robot PDFiNotorious DanNo ratings yet

- Code of Procedure For USFD of Railway Axles For Large Track Machines PDFDocument78 pagesCode of Procedure For USFD of Railway Axles For Large Track Machines PDFRamakrishnan AmbiSubbiah100% (2)

- Train Protection & Warning System: Indian RailwaysDocument3 pagesTrain Protection & Warning System: Indian RailwaysSahil SharmaNo ratings yet

- Road Condition Monitoring Using On-Board Three-Axis Accelerometer and GPS SensorDocument6 pagesRoad Condition Monitoring Using On-Board Three-Axis Accelerometer and GPS SensorTanimunNo ratings yet

- The Dynatest Model 5051 Mark Iv Portable RSP Test System Specifications GeneralDocument7 pagesThe Dynatest Model 5051 Mark Iv Portable RSP Test System Specifications GeneralMadalina StefanNo ratings yet

- 10 18245-Ijaet 982530-1923815Document10 pages10 18245-Ijaet 982530-1923815Frankenstein ReichNo ratings yet

- Link Budget Analysis Guide: November 21, 2014Document19 pagesLink Budget Analysis Guide: November 21, 2014Анатолий МаловNo ratings yet

- Railway Material Trolley-RDSODocument10 pagesRailway Material Trolley-RDSOAmbuj_Saxena92No ratings yet

- Nakshatra Trials: at Cod, AgraDocument12 pagesNakshatra Trials: at Cod, AgrasaurabhNo ratings yet

- Fo - QR Ehvj JH MX) 'Kqyd VKSJ Yksm Fu A K.K Osq Fy, Vkadm+Ksa DK Fofue LG KSXH Fof'Kf"VDocument23 pagesFo - QR Ehvj JH MX) 'Kqyd VKSJ Yksm Fu A K.K Osq Fy, Vkadm+Ksa DK Fofue LG KSXH Fof'Kf"VNikhil EkvachaneNo ratings yet

- Feature Deployment and Testing GuideDocument21 pagesFeature Deployment and Testing GuidelikameleNo ratings yet

- Specification Kacharapara 200510Document58 pagesSpecification Kacharapara 200510riyyo2424No ratings yet

- Freight LocomotiveDocument68 pagesFreight Locomotivedeepak_gupta_pritiNo ratings yet

- Approved Final Specification Lan ExtenderDocument13 pagesApproved Final Specification Lan ExtenderShubham KumarNo ratings yet

- Linear ScaleDocument19 pagesLinear ScaleHà ChínhNo ratings yet

- ETSI TS 03.47 V 5.0.0 Protocols For Interconnecting SMSC and MSCDocument43 pagesETSI TS 03.47 V 5.0.0 Protocols For Interconnecting SMSC and MSCVladimir TsagovNo ratings yet

- Ijett V4i10p127 PDFDocument6 pagesIjett V4i10p127 PDFAshok Siva Kumar PoojalaNo ratings yet

- Summer Training Report Bel Bharat ElectronicsDocument40 pagesSummer Training Report Bel Bharat ElectronicsHarish Kr SinghNo ratings yet

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesFrom EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesNo ratings yet

- Mobile Network Optimization: A Guide for 2G and 3G Mobile Network OptimizationFrom EverandMobile Network Optimization: A Guide for 2G and 3G Mobile Network OptimizationRating: 3.5 out of 5 stars3.5/5 (3)

- Unit Cost 2023-24 Based On 2022-23 Expenses 20.9.2023Document3 pagesUnit Cost 2023-24 Based On 2022-23 Expenses 20.9.2023Karthikeyan RajamanickamNo ratings yet

- Entrance Examsyllabus 1 PDFDocument6 pagesEntrance Examsyllabus 1 PDFvipul0457No ratings yet

- Unit Cost Comparision Table 2023-24 Vs 2022-23Document1 pageUnit Cost Comparision Table 2023-24 Vs 2022-23Karthikeyan RajamanickamNo ratings yet

- Consignment Receipt Note (CRN) : Signature Not VerifiedDocument1 pageConsignment Receipt Note (CRN) : Signature Not VerifiedKarthikeyan RajamanickamNo ratings yet

- RCD, WadiDocument3 pagesRCD, WadiKarthikeyan RajamanickamNo ratings yet

- BSNL Portal - Value Added Services - Receipt DetailsDocument1 pageBSNL Portal - Value Added Services - Receipt DetailsKarthikeyan RajamanickamNo ratings yet

- Stab HW 22012Document2 pagesStab HW 22012Karthikeyan RajamanickamNo ratings yet

- CE304 StabilityDocument2 pagesCE304 StabilityKarthikeyan RajamanickamNo ratings yet

- IES OBJ Civil Engineering 2002 Paper IIDocument16 pagesIES OBJ Civil Engineering 2002 Paper IIKarthikeyan RajamanickamNo ratings yet

- Cauchy Stress ModelingDocument2 pagesCauchy Stress ModelingKarthikeyan RajamanickamNo ratings yet

- Heave MeasurementDocument1 pageHeave MeasurementKarthikeyan RajamanickamNo ratings yet

- Lime StabilizationDocument9 pagesLime StabilizationKarthikeyan Rajamanickam0% (1)

- Castrol IndiaDocument5 pagesCastrol Indiasindhu palanisamyNo ratings yet

- Aa Sim Study GuideDocument229 pagesAa Sim Study Guidelangkawi100% (1)

- Tvs Iqube BrochureDocument48 pagesTvs Iqube Brochurerameshwar patilNo ratings yet

- Ladders and Rolling TowersDocument88 pagesLadders and Rolling TowersJulián MaldonadoNo ratings yet

- Index Closing PriceDocument322 pagesIndex Closing PricePoorna VinayNo ratings yet

- Gasp 2020 2022 EditionDocument137 pagesGasp 2020 2022 EditionMuhammad RizkyNo ratings yet

- Electro Shear Brake BrochureDocument20 pagesElectro Shear Brake BrochureNatalio GarzonNo ratings yet

- ActivityDocument36 pagesActivityRhytham SoniNo ratings yet

- Vibration Isolation: J. M. Kelly, Earthquake-Resistant Design With Rubber © Springer-Verlag London Limited 1993Document2 pagesVibration Isolation: J. M. Kelly, Earthquake-Resistant Design With Rubber © Springer-Verlag London Limited 1993Boanerges ValdezNo ratings yet

- Reliance General Insurance Company LimitedDocument8 pagesReliance General Insurance Company Limitedaamir khanNo ratings yet

- LEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Document39 pagesLEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Rana Danish100% (1)

- ATR 42 300 Aircraft Handling ManualDocument28 pagesATR 42 300 Aircraft Handling Manualmickhail alvarez100% (1)

- Engine Electrical System: 7. RHD 3.0 L ModelDocument16 pagesEngine Electrical System: 7. RHD 3.0 L ModelСергей ЕсиповNo ratings yet

- Cetak Soal Tugas - Sistem Informasi Pembelajaran (SIP) SMA Kusuma Bangsa Palemba 5Document4 pagesCetak Soal Tugas - Sistem Informasi Pembelajaran (SIP) SMA Kusuma Bangsa Palemba 5Gora Marondos Kayara SaragihNo ratings yet

- Turismo Veloce RC SCS My22 en YBBsnYBDocument1 pageTurismo Veloce RC SCS My22 en YBBsnYBPavelNo ratings yet

- All India Local Cashless Garages List V2Document50 pagesAll India Local Cashless Garages List V2K AnshNo ratings yet

- Ford Motors 20 12 18 PDFDocument77 pagesFord Motors 20 12 18 PDFamira alyNo ratings yet

- Master Guide To BerthingDocument36 pagesMaster Guide To Berthingkillthenois420No ratings yet

- Attendance Roster With Date ColumnDocument399 pagesAttendance Roster With Date ColumnNadeem KhalidNo ratings yet

- Capital Region 2022 School Board ElectionsDocument20 pagesCapital Region 2022 School Board Electionscbs6albanyNo ratings yet

- Informe Isuzu Septiembre 2022Document24 pagesInforme Isuzu Septiembre 2022Compania CuencanaNo ratings yet

- Newton'S Laws of Motion: I. Law of Inertia Ii. F Ma Iii. Action-ReactionDocument33 pagesNewton'S Laws of Motion: I. Law of Inertia Ii. F Ma Iii. Action-ReactionJapheth PasatiempoNo ratings yet

- Bích Neo - Cat-Minh - Asia-Bollard PDFDocument4 pagesBích Neo - Cat-Minh - Asia-Bollard PDFPhúc HuyNo ratings yet

- LEMAG-LS-and-PEAKmag-H066 - 1902-1 - Peak Pressure Gauge For EngineDocument2 pagesLEMAG-LS-and-PEAKmag-H066 - 1902-1 - Peak Pressure Gauge For EngineMUHAMMAD AHMEDNo ratings yet

- 12 - ATPL Questions - Ops ProcDocument149 pages12 - ATPL Questions - Ops ProcRitwik ChowdhuryNo ratings yet

- Main Deck PlanDocument1 pageMain Deck PlanElmer HabloNo ratings yet

- Catalo My Filter GearboxDocument10 pagesCatalo My Filter GearboxYousfi AhmedNo ratings yet

- Powertronic Installation Manual Royal Enfield Himalayan (2017-2020) & 2021 With ChokeDocument29 pagesPowertronic Installation Manual Royal Enfield Himalayan (2017-2020) & 2021 With ChokeGauravNo ratings yet

- Laporan Februari Terbaru Tahun 2021Document538 pagesLaporan Februari Terbaru Tahun 2021Produksi Plant3No ratings yet

- 1500Z TB129 PDFDocument313 pages1500Z TB129 PDFjanosNo ratings yet