Professional Documents

Culture Documents

LIS Dharampur Bairi

LIS Dharampur Bairi

Uploaded by

Rishav Chaudhary0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageLIS Dharampur Bairi

LIS Dharampur Bairi

Uploaded by

Rishav ChaudharyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

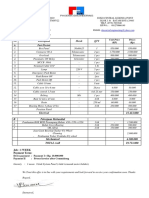

ECONOMIC DIA STATEMENT OF RISING-MAIN

NAME OF WORK:- PROVIDING IRRIGATION FACILITY UNDER HP SHIVA PROJECT FOR CHAUNTRA,GOPALPUR AND DHARAMPUR BLOCKS, DISTRICT MANDI(HIMACHAL PRADESH)- PACKAGE-07

Name of Scheme:- LIS Bairi, Block Dharampur

Rising Main:- Existing Pump House to Existing Tank (Only Pumping Machinery is to be provided)

Jan. Feb. Mar. Apr. May. Jun. Jul. Aug. Sep. Oct. Nov. Dec.

MSERW PIPE (IS/ISO:3183-2007) GMS TUBE (IS:1239-1990/2004 -Part

Daily Water Requirement of 10.44 Hect. (lps) 8.07 8.07 8.07 8.07 8.07 8.07 8.07 8.07 8.07 8.07 8.07 8.07 PIPE RATE

Pumping Hour per day 16.00 16.00 16.00 16.00 16.00 16.00 16.00 16.00 16.00 16.00 16.00 16.00 Dia.of Pipe Rate

Pumping Hour per Month 496.00 448.00 496.00 480.00 496.00 480.00 496.00 496.00 480.00 496.00 480.00 496.00 25 mm 177.70

32 mm 237.00

40 mm 271.30

50 mm 430.50

DATA CALCULATION :- 65 mm 630.00

1 Peak average Daily water requirement = 8.07 lps 1 Water requirement (mld) = 0.697 mld 80 mm 716.00

2 Pumping hour = 16.00 Hrs 2 Annual Pumping Hours = 5840.000 hours 100 mm 930.50

3 Design Discharge = 12.10 lps 3 Average Pumping Hours = 16.000 hours 125 mm 1250.00

4 Length of Rising Main = 200.00 Rmt 4 Static Suction Lift = -0.600 m 150 mm 1955.70

5 R.L. of Highest Discharge Point = 699.36 m 5 Static Delivery head = 204.509 m 200 mm 2778.02

6 Pump Shaft Level = 494.85 m 6 Design Discharge (klpd) = 1045.440 klpd 250 mm 3477.72

7 LWL in the Well/source = 495.45 m 300 mm 4071.21

8 Cost of Pumping Unit /K.W. = 8713.00 /- 350 mm 4546.44

9 Class of Pipe = GI PIPE 400 mm 5205.63

10 Value of 'C' = 100.00 450 mm 5861.54

11 %age of stand bye pumping set = 100.00 % 500 mm 7597.11

12 Design Period of Pumping Machinery = 15.00 Yrs. 600 mm 7839.11

13 Energy Charges per KWH = 3.50 /- 650 mm 9014.97

14 Combined Efficiency of P/Machinery = 0.60 700 mm 10367.22

15 Capital intrest rate = 8.50 % 750 mm 11922.30

16 Residual head = 3.00 m

S. Dia Frictional Velocity Total Losses Total KW Reqd. Cost of Cost of Total cost Annual Capitalised Total captl. Cost Capl. Cost of Total Cap. Most

No. of Losses/ Losses For Bends Head Including pump pipe per of pipe energy energy cost of pump & engy. pump & engy. cost for economical

Pipe 1000 m @ 10% stand-bye metre cost Ist 15 years for Ist 15 Yrs. for next 15 Yrs. 30 years dia

(mm) (m) (m/sec.) (m) (m) (m) (KW) (1000 Rs.) (Rs.) (1000 Rs.) (1000 Rs.) (1000 Rs.) (1000 Rs.) (1000 Rs.) (1000 Rs.) (mm)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

1 100 44.09 1.54 8.82 0.88 216.61 85.76 747.23 930.50 186.10 1752.93 14556.78 15304.01 4501.52 19991.63 0

2 125 14.87 0.99 2.97 0.30 210.18 83.21 725.01 1250.00 250.00 1700.81 14123.95 14848.96 4367.67 19466.63 0

3 150 6.12 0.69 1.22 0.12 208.26 82.45 718.39 1955.70 391.14 1685.28 13994.95 14713.34 4327.78 19432.26 150

4 200 1.51 0.39 0.30 0.03 207.24 82.05 714.90 2778.02 555.60 1677.10 13927.05 14641.95 4306.78 19504.34 0

5 250 0.51 0.25 0.10 0.01 207.02 81.96 714.12 3477.72 695.54 1675.26 13911.78 14625.90 4302.06 19623.50 0

The economical diameter of Rising Main is = 150 mm

DATA :- DESIGN OF PUMPING MACHINERY

1 Peak Design pumping rate = 12.10 lps Suction : Rising Main:

2 Pumping hours = 16.00 hrs 1 Friction Losses in sucn.pipe = 0.0612 m 1 Velocity in R.Main = 0.69 m/s

3 Length of rising main = 200.00 m 2 Velocity in Suction pipe = 0.6847 m/s 2 Friction losses in R.Main = 1.22 m

4 No. of pumping sets required = 1.00 sets 3 Velocity Head V^2/2g = 0.0239 m 3 Losses due to bends @ 5% = 0.06 m

5 Dia of rising main = 150.00 mm 4 Entrance Losses = 0.0112 m 4 Exit losses = 0.32 m

6 Static delevery lift (PSL-Delevery Pt.) = 204.51 m 5 Losses due to sluice Valve = 0.0119 m 5 Rasidual head = 3.00 m

7 Static sucn. Lift (PSL-LWL) = -0.60 m 6 Losses due to foot valve = 0.0000 m 6 Static head = 204.51 m

8 Detail of system :- Suction Delivery 7 Losses due to Bend = 0.0050 m 7 Velocity head(V^2/2g) = 0.02 m

a) Dia of pipe = 150 mm 125 mm 8 Losses due to expender = 0.0000 m Total losses = 209.14 m

b) Length of pipe = 10.00 m 5.00 m 9 Static Suction lift = -0.6000 m Total head = 207.89 m

c) No. of L.R. bends = 1.00 Nos. 1.00 Nos. Total losses = -0.4867 m Total BHP @ 60% efficiency = 61.49 HP

d) Foot valve = 0.00 Nos. 0.00 Nos. = 61.488 HP x 1

As per Ch. Curve

e) Sluce valve = 1.00 Nos. 1.00 Nos. Say = HP x 1

f) Reflux valve = 0.00 Nos. 1.00 Nos. Delivery: NPSHA

g)Unequal T = 0.00 Nos. 1.00 Nos. 1 Velocity in delevery pipe = 0.9860 m/s Losses in NPSH due to V. Pressure = 0.2373 m

h) Expender(increaser) = 0.00 Nos. 1.00 Nos. 2 Friction losses in delry. pipe = 0.0744 m Losses in NPSH due to Atm. Press. = 1.06 m

10 Altitude of Pump house = 880.00 m above MSL 3 Velocity Head V2/2g = 0.0496 m Suction Head for NPSH = 0.00 m

11 Normal water temprature = 20.00 degree C 4 Losses due to sluice Valve = 0.0248 m NPSH available = 9.0367 m

As per Ch. Curve

5 Losses due to reflux valve = 0.0248 m Use 1 sets of HP each

6 Losses due to Bend = 0.0104 m with 1 set as stand-by 1 W + 1 SB

7 Losses due to expander = 0.0496 m Capacity = 12.10 lps each and

Total losses = 0.2334 m Total head = 208.00 meters

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- CAT 6060 - Service TrainingDocument490 pagesCAT 6060 - Service Traininghector100% (3)

- Canrig 6027 E PDFDocument7 pagesCanrig 6027 E PDFAnonymous 1AAjd0100% (1)

- Engineering Standards: Name Engineering Standard NumberDocument10 pagesEngineering Standards: Name Engineering Standard NumberpathinathanNo ratings yet

- Yale-Manual de PartesDocument150 pagesYale-Manual de PartesAlejandro Ojeda100% (8)

- LIS Gopalpur Raserh SubmersibleDocument2 pagesLIS Gopalpur Raserh SubmersibleRishav ChaudharyNo ratings yet

- LIS Gopalpur Seer Khad Mataur TandaDocument2 pagesLIS Gopalpur Seer Khad Mataur TandaRishav ChaudharyNo ratings yet

- LIS Gopalpur RaserhDocument2 pagesLIS Gopalpur RaserhRishav ChaudharyNo ratings yet

- LIS Dharampur Sandhole 1Document2 pagesLIS Dharampur Sandhole 1Rishav ChaudharyNo ratings yet

- LIS Dharampur Churu Tubewell Submersible2Document2 pagesLIS Dharampur Churu Tubewell Submersible2Rishav ChaudharyNo ratings yet

- LIS Dharampur Baroti 2Document2 pagesLIS Dharampur Baroti 2Rishav ChaudharyNo ratings yet

- LIS Dharampur SeohDocument2 pagesLIS Dharampur SeohRishav ChaudharyNo ratings yet

- LIS Dharampur Baroti 3Document2 pagesLIS Dharampur Baroti 3Rishav ChaudharyNo ratings yet

- LIS Chauntra Kothi 2Document2 pagesLIS Chauntra Kothi 2Rishav ChaudharyNo ratings yet

- LIS Gopalpur Bag Chukku SubmersibleDocument2 pagesLIS Gopalpur Bag Chukku SubmersibleRishav ChaudharyNo ratings yet

- LIS Gopalpur Seer Khad Bhambla SubmersibleDocument2 pagesLIS Gopalpur Seer Khad Bhambla SubmersibleRishav ChaudharyNo ratings yet

- LIS Gopalpur Seer Khad BahiDocument2 pagesLIS Gopalpur Seer Khad BahiRishav ChaudharyNo ratings yet

- LIS Gopalpur Sulpur BahiDocument2 pagesLIS Gopalpur Sulpur BahiRishav ChaudharyNo ratings yet

- LIS Gopalpur BhadarwarDocument2 pagesLIS Gopalpur BhadarwarRishav ChaudharyNo ratings yet

- LIS Dharampur Baroti1Document2 pagesLIS Dharampur Baroti1Rishav ChaudharyNo ratings yet

- LIS Gopalpur Seer Khad Mataur Tanda SubmersibleDocument2 pagesLIS Gopalpur Seer Khad Mataur Tanda SubmersibleRishav ChaudharyNo ratings yet

- LIS Dharampur Brang 2Document2 pagesLIS Dharampur Brang 2Rishav ChaudharyNo ratings yet

- LIS Gopalpur RaserhDocument2 pagesLIS Gopalpur RaserhRishav ChaudharyNo ratings yet

- LIS Gopalpur Thouna SubmersibleDocument2 pagesLIS Gopalpur Thouna SubmersibleRishav ChaudharyNo ratings yet

- LIS Chauntra Khadiyar and DolDocument2 pagesLIS Chauntra Khadiyar and DolRishav ChaudharyNo ratings yet

- LIS Chapla Dam Nalwari#Document2 pagesLIS Chapla Dam Nalwari#Rishav ChaudharyNo ratings yet

- LIS Dharampur Kothuwan DhallaraDocument2 pagesLIS Dharampur Kothuwan DhallaraRishav ChaudharyNo ratings yet

- LIS Chauntra Dhelu TubewellDocument2 pagesLIS Chauntra Dhelu TubewellRishav ChaudharyNo ratings yet

- DS 6822MXDocument2 pagesDS 6822MXThero T KemeloNo ratings yet

- Annexure 12 - Tool For Economic Size of Pumping MainDocument6 pagesAnnexure 12 - Tool For Economic Size of Pumping MainnarendraNo ratings yet

- Eco Dia (North)Document1 pageEco Dia (North)rajinder_hpiphNo ratings yet

- Pipe Culvert - MTODocument34 pagesPipe Culvert - MTOEmmanuel De Lara Sto TomasNo ratings yet

- C3 PDFDocument1 pageC3 PDFJoannaNo ratings yet

- Sps and Wetwell NTL 2Document2 pagesSps and Wetwell NTL 2Project ManagerStructuresNo ratings yet

- JalminnarDocument2 pagesJalminnarYash RajNo ratings yet

- Scope of Work: CLASHEER II No Description Merek QTY Unit Price (RP) Prices (RP) A. Part ElectricDocument1 pageScope of Work: CLASHEER II No Description Merek QTY Unit Price (RP) Prices (RP) A. Part ElectricMaroned BinslanNo ratings yet

- Bill of Materials CompleteDocument3 pagesBill of Materials CompletereynoldNo ratings yet

- Kurseong Collector Well To Lake With Proposed RWRDocument154 pagesKurseong Collector Well To Lake With Proposed RWRprabhjot26No ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- PS1909 SpfeDocument2 pagesPS1909 SpfeCelular Oil Control 05No ratings yet

- Permintaan Sparepart Wko-036Document3 pagesPermintaan Sparepart Wko-036ary fauzi rahmanNo ratings yet

- QuotationDocument9 pagesQuotationapi-3841821No ratings yet

- Electro Mechanical Group 6 CommentsDocument3 pagesElectro Mechanical Group 6 CommentssultanNo ratings yet

- VT IPH 21 BDI 90115 enDocument16 pagesVT IPH 21 BDI 90115 enwag008No ratings yet

- Repari Manuaall PDFDocument216 pagesRepari Manuaall PDFaldy yasiNo ratings yet

- Eco-Dia (North) Twell at Hagwal 1Document1 pageEco-Dia (North) Twell at Hagwal 1rajinder_hpiphNo ratings yet

- Ficha Técnica Tornos Convencionales CDS CW - Compressed1 PDFDocument1 pageFicha Técnica Tornos Convencionales CDS CW - Compressed1 PDFedisonNo ratings yet

- TaperedRollerBearings TS (TaperedSingle) ImperialDocument5 pagesTaperedRollerBearings TS (TaperedSingle) ImperialRonald esquivelNo ratings yet

- By Pass Valve BifurcationDocument5 pagesBy Pass Valve BifurcationSarthak EnterprisesNo ratings yet

- Piling - BurDocument75 pagesPiling - BurzulfaisalNo ratings yet

- Additional Work Erection Runway Up To 31 October 2023Document2 pagesAdditional Work Erection Runway Up To 31 October 2023BudiNo ratings yet

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaNo ratings yet

- BQ Kolaka 2023 EmailDocument3 pagesBQ Kolaka 2023 EmailBelly KrisnadiNo ratings yet

- Delivery Note-Number Painting KafdDocument5 pagesDelivery Note-Number Painting KafdAbdul samee MianNo ratings yet

- 8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsDocument12 pages8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsSandro ChiliquingaNo ratings yet

- Agua PotableDocument1 pageAgua Potablemirelly yazminNo ratings yet

- CM Construction and Features: One Moving ComponentDocument4 pagesCM Construction and Features: One Moving ComponentJohn Jairo SimancaNo ratings yet

- Screenshot 2024-05-07 at 10.39.38 AMDocument1 pageScreenshot 2024-05-07 at 10.39.38 AMPreetham MudyaNo ratings yet

- Rural Water Supply: Rajahmundry DivisionDocument4 pagesRural Water Supply: Rajahmundry DivisionSheshadri PanduriNo ratings yet

- HH221434 HH221410 B TaperedRollerBearings TSF (TaperedSinglewithFlange) Imperial PDFDocument5 pagesHH221434 HH221410 B TaperedRollerBearings TSF (TaperedSinglewithFlange) Imperial PDFjcojedar2009No ratings yet

- Ndma-Sirata Logologo ProjectDocument6 pagesNdma-Sirata Logologo ProjectpartoneinvestmentNo ratings yet

- Hein Krimpenfort - TECNIFLOW Feluwa-RELAVES PERU 20 DEEVDocument40 pagesHein Krimpenfort - TECNIFLOW Feluwa-RELAVES PERU 20 DEEVrolandoh1No ratings yet

- Distribution ADBDocument1 pageDistribution ADBRishav ChaudharyNo ratings yet

- Anubhav SharmaDocument17 pagesAnubhav SharmaRishav ChaudharyNo ratings yet

- Distribution NEW ADBDocument1 pageDistribution NEW ADBRishav ChaudharyNo ratings yet

- LIS Dharampur Baroti 2Document2 pagesLIS Dharampur Baroti 2Rishav ChaudharyNo ratings yet

- LIS Dharampur Baroti1Document2 pagesLIS Dharampur Baroti1Rishav ChaudharyNo ratings yet

- LIS Dharampur Baroti 3Document2 pagesLIS Dharampur Baroti 3Rishav ChaudharyNo ratings yet

- LIS Dharampur SeohDocument2 pagesLIS Dharampur SeohRishav ChaudharyNo ratings yet

- LIS Dharampur Kothuwan DhallaraDocument2 pagesLIS Dharampur Kothuwan DhallaraRishav ChaudharyNo ratings yet

- LIS Chauntra Dhelu TubewellDocument2 pagesLIS Chauntra Dhelu TubewellRishav ChaudharyNo ratings yet

- Hypothesis Testing 1,2 PPT 1Document30 pagesHypothesis Testing 1,2 PPT 1Said VarshikNo ratings yet

- 1 Design of Machine Tool DrivesDocument23 pages1 Design of Machine Tool DrivesFurkan AhmadNo ratings yet

- CEA - ARCO - CONVEX - ENG (Ver.2018)Document4 pagesCEA - ARCO - CONVEX - ENG (Ver.2018)Renan Marcelo de LaraNo ratings yet

- Dynamic Analysis of Towers: Dr. K. Muthumani & Dr. N.GopalakrishnanDocument154 pagesDynamic Analysis of Towers: Dr. K. Muthumani & Dr. N.GopalakrishnanSube OhNo ratings yet

- Epm240mini Voting PDFDocument28 pagesEpm240mini Voting PDFZakwan WanNo ratings yet

- Detecting Alzheimers Disease Using Artificial Neural NetworksDocument56 pagesDetecting Alzheimers Disease Using Artificial Neural NetworkshodNo ratings yet

- Structure Union: 1) What Is The Difference Between Structure and Union? AnsDocument4 pagesStructure Union: 1) What Is The Difference Between Structure and Union? AnsSWABHIMAN SINGH PARIDANo ratings yet

- Artikel Fisika Bahasa Inggris Tentang Optik-5Document4 pagesArtikel Fisika Bahasa Inggris Tentang Optik-5Xerxes Xanthe XyzaNo ratings yet

- DLL 29Document15 pagesDLL 29CLARISSA TAGUBANo ratings yet

- MPS 020 - 032Document32 pagesMPS 020 - 032khoi nguyenvanNo ratings yet

- ArcGIS Data ViewerDocument42 pagesArcGIS Data ViewerDeepak DhakalNo ratings yet

- Section Iv Scope of WorkDocument8 pagesSection Iv Scope of WorkYass AhmedNo ratings yet

- Setting Over Current Relays On ETAPDocument18 pagesSetting Over Current Relays On ETAPSarmad KhanNo ratings yet

- UntitledDocument16 pagesUntitledsteveNo ratings yet

- Cycle Time Reduction PrinciplesDocument3 pagesCycle Time Reduction PrinciplesDhatrpriya Rao NallacheruvuNo ratings yet

- Keithley Model 2000 Multimeter Repair ManualDocument109 pagesKeithley Model 2000 Multimeter Repair Manualwolfovic3932No ratings yet

- Canal StructuresDocument5 pagesCanal StructuresNikhil KumbharNo ratings yet

- Car Rental Website DesignDocument58 pagesCar Rental Website DesignInstan PerfectNo ratings yet

- Proffesional Training of PCB Design at Navi MumbaiDocument33 pagesProffesional Training of PCB Design at Navi MumbaiVibrantGroup MumbaiNo ratings yet

- Telecommunication Networks 15B11EC611: Dr. Bhagirath Sahu Assistant Professor, JIIT, NoidaDocument21 pagesTelecommunication Networks 15B11EC611: Dr. Bhagirath Sahu Assistant Professor, JIIT, NoidaMOHAMMED FAYEZ KHANNo ratings yet

- Lecture - 6 DES - Cipher Modes - Padding TechniquesDocument37 pagesLecture - 6 DES - Cipher Modes - Padding Techniquesumair hanifNo ratings yet

- Ethernet EvolutionDocument363 pagesEthernet EvolutionTuppiNo ratings yet

- Vortex Shedding Induced Vibrations of A Light MastDocument15 pagesVortex Shedding Induced Vibrations of A Light MastDM2No ratings yet

- Computer Questions O LevelDocument9 pagesComputer Questions O Levellapsa22No ratings yet

- Terminal Weaning or Immediate Extubation For Withdrawing Mechanical Ventilation in Critically Ill PatientsDocument15 pagesTerminal Weaning or Immediate Extubation For Withdrawing Mechanical Ventilation in Critically Ill Patientshardluckmate100% (1)

- Speed Control of DC Motor by Using PWM TechniqueDocument14 pagesSpeed Control of DC Motor by Using PWM TechniquePrincy Merin JoseNo ratings yet

- CC1 Laboratory ExaminationDocument5 pagesCC1 Laboratory ExaminationGreg Amor OmapasNo ratings yet

- Integrated Math 2 Syllabus CompressedDocument2 pagesIntegrated Math 2 Syllabus Compressedapi-333467509No ratings yet