Professional Documents

Culture Documents

Machine PM Check Sheet

Machine PM Check Sheet

Uploaded by

charul2298Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine PM Check Sheet

Machine PM Check Sheet

Uploaded by

charul2298Copyright:

Available Formats

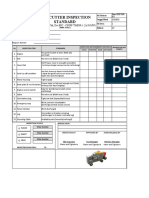

Doc.No.

- MHA/MM/PM - 01

PREVENTIVE MAINTENANCE CHECKSHEET Issue . Date :- 22.03.2024

REV.No.

Rev. date:-

Date:- Month:- Time:- Machine Name::- INJECTION MOULDING Machine No : IMM-

Observation

Checking Target & Change Spare

Sr.No. CHECK POINT :- STANDARD:- Details of Abnormality Remarks

Method OK NOT OK responsibility for Part

(If Not OK) correction

INJECTION UNIT:-

No leakage on barrel head & nozzel

1 Barrel head Nozzel Visual

threads.

Injection nozzel safey Injection guard movement is good and Visual/

2

guard reliable. Manually

check if nozzel &

No wave & jerk sound should be

3 barrel have Abnormal

observed

sound

Check the barrel & check tieghting screw for screw coupling Visual/

4

srew connection barrel nut. Manually

check the linearty of back pressure &

Linear inspction of visual in

5 adjust under the condition of holding the

charge back pressure pressure gauge

mold.

Nozzel centering

check if the nozzel molding matches with Visual/

6 (during mold

mold angle. Manually

changing )

Check if the thermocouple working or

7 Thermocouple PLC (Visual)

not.

Screw Tip, check ring

8 No visible wear on the surface . Visual

& sealing ring wear

Barrel inner -diameter Visual/

9 Fitment should be ok

wear Manually

Clamping Unit

Safety door (Operating

Not broken, Open/Closed states without Visual/

10 side, Non- operational

exceptions. Manually

side)

Anti- Vibration pad for

11 Should be proper and available Visual

Safety door

Front & rear door limit

12 Should be working in good condition Visual

switch inspection

Press the front & rear emergency stop

13 Emergency Stop button button to confirm that the motor is Visual

stopped while the motor running.

Toggle connection bolts Visual/

14 Bolts should be tight

positioning stop Manually

15 Toggle Guide rod Move Freely, lubrication is normal Visual

Electrical Parts

Visual/

16 Supply Voltage should be Normal Voltage(440voltage)

multimeter

Visual/

17 Earthing voltage Normal Voltage(1-1.5 voltage)

multimeter

18 Panel cleaning Should be neat 7 clean Visual

Electrical Cabinet

19 Cooling fan should be work properly Vsual

Exhaust Fan

Check for loose connection

Inside the Electrical Dust accumulation & resin powder in

20 Visual

cabinet the cleaning.

Insulation of the main power cercuit

Inspection &

Should be in proper

21 correction of Visual

condition and working

transducer

Servo Control

dust cleaning, tietening screw of

varrious components, cleaning messy

22 Servo control cabinet wires, temprature measurment & Visual

cooling inspection of the controller

surface,air check fan.

dust cleaning, tietening screw of

varrious components, cleaning messy

23 Servo Motor wires, temprature measurment & Visual

cooling inspection of the controller

surface,air check fan.

Reactor, filter, Normal & reliable operation ,no aging Visual/

24

resistance deformation. Manually

cooling water Should be in proper

25 Visual

Inspection condition

Hydrolic System

Is the hydrolic oil level within

26 Oil Level check visual

permissible range

Check Hydraulic oil Visual/Oil

27 Should be contamination free

condition Checking kit

Change or clean hyd.

Visual/Oil

28 Oil and oil suction Should be clean

Checking kit

filter

Check condition of There should be no leakage and hose

29 hydraulic and water pipes should not be damage / prone to Visual

hoses leakage.

Visual/

30 Oil temprature Miantenance of heat exchanger

Manually

Lubricating

Lubrication pump Whether the oil descharge the pressure Visual/

31

working state is normal. Manually

Lubrication prassure Visual/

32 Relay should be in effective condition

relay Manually

Lubrication pipe line & lubrication

Lubrication pipe line & Visual/

33 points should not be damage, broken &

lubrication points Manually

leakage .

Mold adjustment and Visual/

34 Fill with grease and go the whole trip.

maintenance Manually

Add luricating oil where need to refule Visual/

35 Fill oil manually

manually. Manually

Over all machine Machine should be proper clean after Visual/

36

cleaning maintenance. Manually

Rev. No.- Rev. Date:- Rev. History

PM Done by- Verified By-

You might also like

- Vacuum Casting ProcessDocument19 pagesVacuum Casting ProcessCristiNo ratings yet

- Designing For Injection MoldingDocument28 pagesDesigning For Injection Moldingnado100% (2)

- John Deere 3800 Telescopic Handler ManualDocument196 pagesJohn Deere 3800 Telescopic Handler Manuallorant0511No ratings yet

- Telehandler ChecklistDocument1 pageTelehandler Checklistjapv_pasNo ratings yet

- Drilling Machine Inspection ChecklistDocument1 pageDrilling Machine Inspection ChecklistKevin MichaelNo ratings yet

- Injection Moulding MachineDocument35 pagesInjection Moulding MachineRajesh Kumar88% (8)

- JAPL-F-TE-004-Bending Machine ChecklistsDocument1 pageJAPL-F-TE-004-Bending Machine ChecklistsAli Hassan83% (6)

- PolymersDocument83 pagesPolymersDaily Learners KalraNo ratings yet

- F Mint 08 Preventive, Maintenance Check SheetDocument10 pagesF Mint 08 Preventive, Maintenance Check SheetBangali SinghNo ratings yet

- Daily Check Sheet 2017Document1 pageDaily Check Sheet 2017Kumaravel100% (2)

- Injection MouldinDocument32 pagesInjection MouldinKarthick KarthickNo ratings yet

- Plastics ExtrusionDocument37 pagesPlastics Extrusionshashanksir80% (5)

- DJF5053-Jigs & Fixtures and Tooling DesignDocument21 pagesDJF5053-Jigs & Fixtures and Tooling DesignMd Aziq Md RaziNo ratings yet

- Form-HSE-TMR-005 Welding InspectionDocument1 pageForm-HSE-TMR-005 Welding Inspectionkenia info100% (1)

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- A13 - Daily Weighing Scale Checklist-NemDocument1 pageA13 - Daily Weighing Scale Checklist-NemSuresh Selvaraju100% (3)

- Injection Moulding 2023 Final Year ProjectDocument22 pagesInjection Moulding 2023 Final Year ProjectVenukanth S-2019No ratings yet

- Arburg Thermoset 522948 en Gb-1Document12 pagesArburg Thermoset 522948 en Gb-1retnadiah354No ratings yet

- Ahmedabad and Gujarat Sample DataDocument20 pagesAhmedabad and Gujarat Sample DataPriya Shinde100% (1)

- Preventive Maintenance Check SheetDocument4 pagesPreventive Maintenance Check Sheetrahul_2005No ratings yet

- Molded Parts DefectsDocument9 pagesMolded Parts DefectsPadmanava DasguptaNo ratings yet

- Handbook of Metal Injection MoldingDocument3 pagesHandbook of Metal Injection MoldingPk Jha0% (2)

- Formulas y Calculos de PerforacionDocument22 pagesFormulas y Calculos de Perforacionjairaso2950No ratings yet

- Preventive Maintenance Check Sheet: Doc - No.:6660-004-C0241-F02 Effective Date:01-07-2020 Rev - No./Date.: 00Document1 pagePreventive Maintenance Check Sheet: Doc - No.:6660-004-C0241-F02 Effective Date:01-07-2020 Rev - No./Date.: 00sandeep thapliyalNo ratings yet

- Daily Maintenance Check SheetDocument5 pagesDaily Maintenance Check SheetPearlsgodNo ratings yet

- Roller ChecklistDocument1 pageRoller ChecklistArsalan AhmadNo ratings yet

- Weibang Lawnmower ManualDocument11 pagesWeibang Lawnmower ManualJames LoewenNo ratings yet

- Ink Jet PrinterDocument1 pageInk Jet Printerkashifurrahaman8No ratings yet

- Petrol Chainsaws: Owner's ManualDocument4 pagesPetrol Chainsaws: Owner's Manualkatta ngaNo ratings yet

- Form-I-005 Compressor, Gen-Set, Water Jet FormDocument1 pageForm-I-005 Compressor, Gen-Set, Water Jet FormHSSE PTCADNo ratings yet

- F 2 PDFDocument9 pagesF 2 PDFkatta ngaNo ratings yet

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukDocument4 pagesLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanNo ratings yet

- Induction Sealing MachineDocument2 pagesInduction Sealing Machinekashifurrahaman8No ratings yet

- Bench DrillingDocument1 pageBench DrillingPiyush VyasNo ratings yet

- RENASYS GO Service Manual PI03899 Final 1374229048Document24 pagesRENASYS GO Service Manual PI03899 Final 1374229048Huy Trần ThiệnNo ratings yet

- Strapping M C - 1Document1 pageStrapping M C - 1sandeep thapliyalNo ratings yet

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Document1 pageStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- Telehandler ChecklistDocument1 pageTelehandler ChecklistSteinol SolutionsNo ratings yet

- Band Saw2Document2 pagesBand Saw2Piyush VyasNo ratings yet

- LEC - HSE-Welding Appliance Inspection StandardDocument1 pageLEC - HSE-Welding Appliance Inspection StandardSyafriansyahNo ratings yet

- Coating PanDocument2 pagesCoating Pankashifurrahaman8No ratings yet

- Digital Ratchet: Instruction ManualDocument28 pagesDigital Ratchet: Instruction ManualMakassar TeknikNo ratings yet

- Form-HSE-TMR-012 Bar Bender InspectionDocument1 pageForm-HSE-TMR-012 Bar Bender Inspectionkenia infoNo ratings yet

- Torque Multipliers: User's ManualDocument16 pagesTorque Multipliers: User's ManualJuan Manuel MedagliaNo ratings yet

- Form I 002 Grinding FormDocument1 pageForm I 002 Grinding FormHSSE PTCADNo ratings yet

- Brass Plating Line - PencDocument2 pagesBrass Plating Line - PencPiyush VyasNo ratings yet

- CI 42 040 NL enDocument4 pagesCI 42 040 NL enHafsa BoudguigNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Material Pass BoxDocument1 pageMaterial Pass Boxkashifurrahaman8No ratings yet

- Installation and Operation Instruction: Flowcon SM 2"-10", 50-250MmDocument8 pagesInstallation and Operation Instruction: Flowcon SM 2"-10", 50-250MmBlack SmithNo ratings yet

- Wheel Alignment and Balancing 2Document57 pagesWheel Alignment and Balancing 2Alan PeterNo ratings yet

- Hi VacDocument4 pagesHi VacIfex SalemNo ratings yet

- Final Inspection Report Buritica 金矿项目最终验收报告: Of Buritica Gold ProjectDocument5 pagesFinal Inspection Report Buritica 金矿项目最终验收报告: Of Buritica Gold ProjectJUAN CARLOS SUAREZNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- Zeagle Flathead Owners +manualDocument10 pagesZeagle Flathead Owners +manualFrancisco Manuel Izquierdo NavarroNo ratings yet

- Preventive Maintenance Check Sheet: Doc - No.:6660-004-C0241-F02 Effective Date:01-07-2020 Rev - No./Date.: 00Document1 pagePreventive Maintenance Check Sheet: Doc - No.:6660-004-C0241-F02 Effective Date:01-07-2020 Rev - No./Date.: 00sandeep thapliyalNo ratings yet

- Dozer Checklist: Y N Y NDocument1 pageDozer Checklist: Y N Y NEkaWulandariNo ratings yet

- 10 Iris1Document3 pages10 Iris1AndiosoNo ratings yet

- Hayward Gordon ULC: Start-Up Checklist Page 1 of 2Document2 pagesHayward Gordon ULC: Start-Up Checklist Page 1 of 2blackhand20xxNo ratings yet

- Multi Mill SOPDocument14 pagesMulti Mill SOPDilraj KohliNo ratings yet

- Audi q5 Installation ProcedureDocument8 pagesAudi q5 Installation ProcedureLap TranNo ratings yet

- Check Sheet: Inspected by Checked by Aknowledged by Skill Worker HPSI Supervisor HasindDocument1 pageCheck Sheet: Inspected by Checked by Aknowledged by Skill Worker HPSI Supervisor HasindMuhammadRizaldiAfriliansyahNo ratings yet

- Daily Maintainance Checklist For Bending MachineDocument1 pageDaily Maintainance Checklist For Bending Machinesri Venkateshwara gear wheelsNo ratings yet

- Micro-Line Straight Handpiece-Angled Handpiece (TA-Nr. 012581) (03-13)Document6 pagesMicro-Line Straight Handpiece-Angled Handpiece (TA-Nr. 012581) (03-13)Renata NataNo ratings yet

- Warning!: Rough Shifts, Flares During Up Shifts & Kick Down. Rough Coast Downshifts No Pressure Rise, TCC Slip/shudderDocument7 pagesWarning!: Rough Shifts, Flares During Up Shifts & Kick Down. Rough Coast Downshifts No Pressure Rise, TCC Slip/shudderautomaticosbrasilNo ratings yet

- Pick and Carry Crane (F15) ChecklistDocument1 pagePick and Carry Crane (F15) ChecklistehsNo ratings yet

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Form-HSE-TMR-011 Bar Cutter InspectionDocument1 pageForm-HSE-TMR-011 Bar Cutter Inspectionkenia infoNo ratings yet

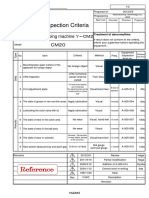

- A005e - CM20Document17 pagesA005e - CM20san nguyễn vănNo ratings yet

- PM Check SheetDocument7 pagesPM Check Sheetcharul2298No ratings yet

- Process Audit Check SheetDocument2 pagesProcess Audit Check SheetAstronNo ratings yet

- ManufacturingTechnology I GKVDocument20 pagesManufacturingTechnology I GKVaswin jithuNo ratings yet

- Plastics SolutionsDocument20 pagesPlastics SolutionsGavazzi JuarezNo ratings yet

- Siddesh Final NTTFDocument19 pagesSiddesh Final NTTFSiddeshNo ratings yet

- Integrated Systems SIPA SystemDocument6 pagesIntegrated Systems SIPA Systemhieuvu0326No ratings yet

- Proteze MobileDocument12 pagesProteze MobileAndreea IoanaNo ratings yet

- Proto Labs Whitepaper PDFDocument15 pagesProto Labs Whitepaper PDFSugarboy3 SurNo ratings yet

- Map Project MbaDocument58 pagesMap Project Mbaankit PadhyaNo ratings yet

- Advance Injection Mould DesignDocument175 pagesAdvance Injection Mould DesignMuhammed K MNo ratings yet

- Technyl Nylon A 218 V30 (Natural)Document6 pagesTechnyl Nylon A 218 V30 (Natural)Phuoc Thinh TruongNo ratings yet

- Process Variables & Trouble ShootingDocument20 pagesProcess Variables & Trouble ShootingrkneyveliNo ratings yet

- Operation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C SequenceDocument165 pagesOperation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C SequenceJam AnjumNo ratings yet

- An Organizational Study Report On: Makar Electronics Pvt. LTDDocument13 pagesAn Organizational Study Report On: Makar Electronics Pvt. LTDSantosh Deepak.DasariNo ratings yet

- Ed - 5B.Result Interpretation - PackingDocument16 pagesEd - 5B.Result Interpretation - PackingrobNo ratings yet

- 02 Sakai PDFDocument11 pages02 Sakai PDFNitin PatilNo ratings yet

- CES EduPack 2019 Quick Start ExercisesDocument34 pagesCES EduPack 2019 Quick Start ExercisespauloibarraNo ratings yet

- Narendar Singh-Resume-Mold Designer-3.5 Years ExperienceDocument3 pagesNarendar Singh-Resume-Mold Designer-3.5 Years ExperienceNarendar SinghNo ratings yet

- TURN HTY Injection Molding Machine Quotation11-1-2022 PDFDocument7 pagesTURN HTY Injection Molding Machine Quotation11-1-2022 PDFGraham JakeNo ratings yet

- NX Mold DesignDocument3 pagesNX Mold DesignNguyễn Thế Quang DũngNo ratings yet