Professional Documents

Culture Documents

BF03397742

BF03397742

Uploaded by

Hoang AnhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BF03397742

BF03397742

Uploaded by

Hoang AnhCopyright:

Available Formats

Effed: of Applied Stress on t:he Mart:ensit:ic Transformation

by S. A. Kulin, Morris Cohen, and B. L. Averböch

The martensitic transformation can be initiated by elastic stresses

at temperatures above M. in a steel containing 20 pet Ni and 0.5 pet

C. Shear strains and normal tensile strains acting on a potential habit

plane promote the transformation but compressive strains oppose it.

T HEformation

strain sensitivity of the martensitic trans-

has long been recognized. is now It

and by the martensi tic re action has been depicted

by Scheil.' Basically, Scheil postulated that: I-at

well known that martensite formation can be in- temperatures hot too far above M. (where austenite

duced by plastic deformation at temperatures be- is less stable than martensite), a critical resolved

low, and not too far above, the M. point.' However, shear stress (within the elastic range) is required

the exact role of elastic vs. plastic strains and of the to promote the transformation to martensite; 2-at

concomitant stresses has proved to be a very elusive and below M" the austenite lattice becomes me-

matter. chanically, as well as thermodynamically, unstable

Many investigators'-O of the steel hardening re- and shears over spontaneously into martensite with-

action have made use of the stresses resulting from out the application of external stress; and 3-at

volume changes to account for such observations as temperatures sufficiently far above M" the critical

the existence of retained austenite and its variation resolved shear stress for martensite formation in-

across the section of a bar, the change in the amount creases to a level above that required for slip, and

of retained austenite with quenching rate, and the plastic flow then supersedes the transformation

self-stopping nature of the transformation when the when external stress is applied.

cooling is stopped. The effect of applied strain as an Scheil's concepts were tested by McReynolds· who

independent variable has been studied in 70 pct Fe- found no change in the elastic moduli (measured

30 pct Ni alloys by Scheir and McReynolds. 8 Some both statically and dynamically) of 71 pct Fe-29 pct

data are also available for lithium and Li-Mg al- Ni alloys in the vicinity of the M, temperature.

loys," Cu-Zn,'o Cu-Sn and Cu-Al alloys," and aus- Since the moduli did not approach zero or become

tenitic stainless steels. 12-'5 negative on cooling to M., it was concluded that the

It has been found that martensite formation can austenite lattice does not become mechanically un-

be induced isothermally, even at temperatures above stable at M" as postulated by Sc heil. McReynolds

M., by mechanical deformation of the parent phase. also reported that M, is not raised by elastic stresses.

The competitive nature of plastic yielding by slip Accordingly, plastic deformation was considered to

stimulate the transformation by generating mar-

S. A. KULlN, Student Associate AlME, is ossociated with West- tensite nuclei in the distorted regions of the parent

inghouse Atomic Power Div., Bettis Field, Pittsburgh; and phase.

M. COHEN, Member AlME, and B. L. AVERBACH, Juniar Member The above issues with regard to the role of ap-

AlME, are ossocioted with the Dept. of Metallurgy, Massachusetts

Institute of Technology, Cambridge, Mass.

plied stress require clarification, if a basic under-

Discussion on this paper, TP 3274E, may be sent, 2 copies, to standing of the martensitic transformation is to be

AlME by Dec. 1, 1952. Manuscript, Feb. 13, 1952. Philadelphia obtained. For example, in the reaction-path the-

Meeting,October 1952. ory,16,17 it is postulated that strain embryos exist

This paper is based on a thesis by S. A. Kulin submitted in in the austenite that provide part of the activation

partial fulfillment of the requirements for the degree of Doctor of energy for the nucleation process. These embryos

Science in Metallurgy at the Mossachusetts Institute of Technology, are visualized to be regions of localized strain in

June 1951. The investigation was sponsored by the Office of Naval which the atoms in the austenite lattice are dis-

Research under Contract N5-ori-07814, Task No. XIV, Designa-

placed part way along the path to their ultimate

tion No. NR-031- 142.

positions in the martensite. Consequently, it would

TRANSACTIONS AlME JUNE 1952, JOURNAL OF METALS-661

room temperature. The structures were eompletely

austenitie after the foregoing eycle, the M, tempera-

ture being about -37°C. * The stress-relieving

• In this aJloy the transformation starts with a burst," an~ hence

M. = Mb. Ho~ever, there are certain conditions (to be dlscussed

later) under which M. > Mb.

'"0: '6,ooo'j:-_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _~-..s?O~'_"__(_I

treatment was introdueed to avoid the superimposi-

tion of quenehing stresses on the applied stresses

'"

w

rr

I-- 12000 .

during subsequent eooling. This faetor will be dis-

'" ' eussed later.

6,000

Prior to microexamination, the speeimens were

usually tempered at 315°C for 10 sec in order to

4,000 "darken" any martensite that might exist.

Tensile stresses were applied to austenitized and

°0 JOD. 200 300 400 500 600 700 800 900 1000

stress-relieved specimens having a gage length of

PlASTIC STRAlf'l x 10 6 2.5 in. and a gage diameter of 0.250 in. The loads

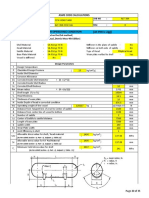

Fig. l-Stress VS. plastie strain at temperatures abave M,. were inereased in small inerements, with intermedi-

Horizontal diseontinuities indieate stress-indueed martensitie ate unloading. The permanent set, if any, was de-

transformation. 20 pet Ni-O.5 pet C steel. termined with two eleetrieal resistanee strain gag es,

mounted longitudinally on eaeh speeimen. For

be predicted that applied stress, even within the simultaneous transformation measurements, the

elastie range, might eontribute to the displacement ehanges in eleetrical resistanee of the specimens

in the embryos and thus enable them to aehieve the were observed by means of a Kelvin double bridge,

eritieal strain for nucleation at temperatures above using potential leads spotwelded near the fillets.

M Furthermore, beeause of the unique nature of

S'

The loading was carried out at various temperature

the atomie displacements that eonvert the austenite levels, maintained constant to ± 0.5°C. The sub-

lattiee into martensite,18 it ean be expeeted that the atmospheric temperatures were aehieved by adding

direetion, as weH as the magnitude, of the applied powdered CO, to the oil bath in whieh the speeimens

stress should be an impor.tant variable in the nu- were immersed during the testing. Other types of

cleation proeess. This paper deseribes a number of stress experiments will be described later in the

eritieal experiments that were designed to resolve paper.

these questions. Martensitic Transformation Under Applied Tensile

Experimental Details Stress

An alloy steel eontaining 20 pet Ni and 0.5 pet C The foregoing "load-unload" procedure was ap-

was chosen for this investigation beeause its normal plied to austenitized and stress-relieved speeimens

martensitie transformation oeeurs in a eonvenient of the 20 pet Ni-O.5 pet C steel at temperatures be-

subzero temperature range, and the extent of iso- tween 20° and -25°C. In eaeh instanee, stress vs.

thermal martensite formation","'·2l is negligibly plastic strain (permanent set) was plotted as shown

small, thereby minimizing any possible complieation in Figs. 1 and 2. The method was eapable of de-

from the time variable during the stress studies. teeting plastic strains down to ±2x10·'. Plastic

The eomplete analysis was 19.99 pet Ni, 0.52 pct C, strains up to 0.012 were studied here.

0.37 pet Mn, 0.47 pet Si, 0.010 pet P, 0.015 pet S, The sudden yielding denoted by the horizontal

0.04 pet Cr, balance Fe. lines in Figs. 1 and 2 eorresponds to martensite for-

The speeimens were austenitized at 1095°C for mation. This was established both by the aecom-

30 min in a purified nitrogen atmosphere, and panying decrease in eleetrieal resistanee and by

quenehed in oil at 20° to 22°C. They were then subsequent microexamination. At temperatures in

sealed in evaeuated Vyeor tubes and stress relieved the vicinity of -15° to -25°C, sharp clicks eould be

at 480°C for 30 min, followed by furnace eooling to heard as rather large amounts of martensite formed

in bursts, even though these temperatures were

definitely above the martensite range for the un-

40,000 stressed material.

·20'(

No transformation was detected in the specimens

36,000 ,--~ strained at 20°C and there was only a slight trace

20'(

at O°C; in these eases, the eleetrical resistanee in-

0'( creased progressively with the plastie deformation.

However, at -15°C and below, appreciable quan-

tities of martensite were produeed during the tests,

"

r and (for a given permanent set) inereased with de-

ereasing temperature. This trend is illustrated by

~ 20,000

w

er:

l

r the data in Table I.

0-

If)

16,000 -20'( ! Even more significant is the fact that the ineeption

of the transformation was indueed at temperatures

12'000l above M, or Mb by tensile stresses weH within the

8,000 elastic range. For example, at 20°C the elastie limit

(corresponding to a permanent set of 2x10·') was

4,000 about 17,000 psi and it would be expeeted to be at

- 2 5'(

least as high at -25°C. However, at the latter tem-

°OC=c:==::'::::j3==4=~::::..~6--:--:'8--:9'---1--::-0--:II-~,2 perature, the transformation was triggered by a

STRAIN x 10 3 tensile stress of only 1000 psi. It may be concluded

Fig. 2-Stress vs. plastic strain at temperatures above M,. 20 pet that the M, (and Mb) temperature ean be raised by

Ni-O.5 pet esteei. Compare with Fig. 1. elastic tensile stresses.

662-JOURNAL OF METALS, JUNE 1952 TRANSACTIONS AlME

From the results of these experiments the yield-

ing by martensite formation and plastic flow by slip .,

may be regarded as two competitive deformation

mechanisms. While it is likely that either may affect

the other, neither one is necessary for the other and

the martensitic transformation sets in befor~ the

slip process if the tensile stress is applied at tem-

peratures not too far above M,. The onset of the

transformation due to tensile stresses within the

elastic range results in a "premature" yielding, and

therefore the material may have an abnormaHy low

yield strength. However, it is evident from Fig. 2

that the formation of martensite under stress pro-

duces more effective "strain hardening" (cf. curves

for -15° and -20°C) than does the ordinary slip

mechanism (cf. curves for 20° to O°C), and hence

relatively high tensile strengths may be encountered

despite the low yield strengths.

It was observed that the austenite twin bound- Fig. 3-Mortensitic chevrons Iying along twin boundaries of 20 pct

aries are sometimes preferred regions for the nu- Ni-O.5 pct C steel ofter plastically straining ot O·C. Tempered at

cleation of martensite under the application of 315· C for 10 sec. Etched with 4 pct nital and 1 pct zephiran

stress. As shown in Fig. 3, the initial martensitic chloride. XSOO.

plat~s were nucleated in pairs, like chevrons, ex-

tendmg more or less symmetrically into both the was austenitized and stress relieved in the usual

twin and the mother crystal. This phenomenon is way. It was then loaded in uniform bending at 20°C

readily explained in terms of the transformation to a maximum fiber stress of 14,000 psi, this being

strain analysis of Machlin.18 The cooperative atomic below the elastic limit of the material at room tem-

dis placements involved in the formation of a mar- perature. While loaded in this way, thespeciinen was

tensite plate require considerable movement in the slowly cooled until a burst of transformation oc-

surrounding austenite, and the associated strain en- curred. The temperature at that instant was

er~y contributes materially to the energy of nucle-

-21.9°C, whieh was weH above the M, = Mb for the

~tlOn. However, since the twin boundary is a mirror

unstressed material. The specimen was immediately

lmag.e of the lattice on either side, the formation of heated to room temperature, unloaded, and tem-

a paIr of plates reduces the strain energy require-

pered to "darken" the martensite.

ments because both plates tend to move the inter- Metallographie examination revealed (Fig. 4)

vening austenite in ab out the same direction. Under that the transformation had taken plaee in the part

these conditions, the twin boundaries should be of the speeimen subjected to tensile stress, whereas

favored sites for nucleation, provided that the plates no transformation was observed in the part under

form cooperatively in pairs. In the specimen repre- compressive stress. Also, the neutral axis of the

sented by Fig. 3, only aminute amount of trans- bent bar had shifted toward the compressive side,

formati0l! occur~ed at O°C on plastically straining presumably beeause of the yielding on the tensile

to 0.012 In. per In., but most of it took place along

side due to the transformation there.

twin planes in the form of double plates. At the

lower straining temperatures where substantial

quantities of martensite appeared, the plates had a

more conventional distribution.

Martensitic Transformation Under Bending Stress

Because of the shear-like nature of the marten-

sitic reactions along the habit plane, it might be

assumed that the stimulating effect of elastic tensile

stress is caused solely by the resolved shear com-

ponent of the applied stress. If this were the case

uniaxial compressive stress should produee simila;

results. A simple bending experiment will suffiee

to prove that such a shear eriterion for the activa-

ti on of the transformation by stress is invalid.

A %x%x4 in. bar of the 20 pet Ni-O.5 pet C steel

Table I. Extent of Transformotion as a Function of Tensile-Test

Temperoture

Pet Martenslte

Temperature of Formed (For PlasUc

:renslle Strain of

Test, oe Approxlmately 0.012)

Fig. 4-longitudinal (vertical) section through bar of 20 pct Ni-O.5

20 o pet C steel cooled to Mb temperature while subjected to elastic

o Trace

-15 0.5 bending. Top is compression side, bottom is tension side. Tempered

-20 12.3 at 315°C for 10 sec. Etched with 4 pct nital and 1 pct zephiron

-25 26.0

chloride. X8.

TRANSACTIONS AlME JUNE 1952, JOURNAL OF METAL5--663

the case of the bending experiments, the trans~or

o AS QuENCHtO mation takes place "prematurely" in the regl<;IllS

o STR ESS RELI(V(D

'0 20'\ No, O.'5-"C STEEL

sustaining tensile stresses, but not in those sus~aIn

ing compressive stresses. The higher the resIdual

'0 - tensile stress in the core of the specimen, the sooner

does the burst occur on cooling and the more re-

'0 stricted it becomes. With little or no residual stress

present, the M. temperature is lower and the bur~t

10 takes place more uniformly throughout the specl-

men.

On the basis of this reasoning, it may be pre-

~~O---~'6~~-4~'--~-'~'--~-'~4--~-'~O~-~'6'-~-'~'--~-'I'

(Mb 1 BuRST TEMPERATuRE ·C dicted that the completely austenitic rim remaining

after the burst in a nonstress-relieved specimen,

Fig. 5-Percent martensite formed during the burst

ys. M. temperature. such as that of Fig. 6, should und ergo transforma-

tion on cooling below the M. temperature, since ~he

martensite formed in the core causes an expanSIOn

These findings demonstrate not only that elastic there which reduces the tensile stresses in the core

tensile stresses promote the transformation, but as weIl as the compressive stresses in the rim. This

also that elastic compressive stresses do not act in was confirmed: on cooling some 10° to 15 °e below

a corresponding manner. Inasmuch as the shear M., the transformation became fairly uniform across

stress on geometrically similar planes is the same in the transverse section of the specimen.

both the tensile and compressive regions of the bent To show the effect of the superimposition of re-

specimen, then it must be the sign of the normal sidual and applied stresses, a 1f4 in. diam x 2ljz in.

stress that is responsible for the striking difference rod was water quenched from the austenitizing tem-

in transformation behavior. Thus, it is now clear perature, placed in elastic bending along the central

that, although the component of shear stress along portion, and then cooled until a burst of transforma-

a habit plane undoubtedly plays an important part tion was noted by electrical resistance measure-

in the activation process, the component of stress ments. After tempering the specimen to "darken"

normal to this plane is likewise important. By the the martensite cross-sections were examined metal-

same token, a critical resolved shear stress or shear lographically in regions subjected to the bending

strain or shear-strain energy cannot provide a suit- and in regions extern al to the bending clamp. Fig.

able criterion for the initiation of the transformation, 7b illustrates the latter situation, with a symmetri-

because the contributions of the magnitude and di- cal core of transformation corresponding to the state

rection of the normal stresses are thereby neglected. of high tension in the interior produced by the water

Effect of Residual Stresses on Transformation

It is evident from the results presented thus far

that residual stresses may influence the transforma-

tion and, in fact, this was the reason for stress re-

lieving the austenitic specimens prior to the applied

stress studies. The role of residual stresses may be

illustrated in the following way: Two series of lJ4

in. diam x 1fz in. long specimens were austenitized,

one series was then stress relieved at 480°C for 30

min and the other was not. On subsequent cooling,

the stress-relieved specimens were found to have

M. temperatures between -34° and -40°C (av-

erage -37°C), while the specimens without stress

relief had M. temperatures between -20° and

-30 0 e (average -26°C). Furthermore, the amount

of transformation occurring during the burst de-

creased with increasing M. temperature. This cor-

relation was the same for both series of specimens

as shown in Fig. 5.

In the nonstress-relieved series, it was found that

the quantity of martensite formed during the burst

varied markedly across the seetion. The specimen

-

with the highest M. at -20 °C was entirely austenitic

,

around the rim, the transformation being confined

to the central portion. Fig. 6 shows the austenitic

rim on a transverse section, with some of the mar-

tensite formed toward the interior of the specimen.

l4

t ~

1*-

/ '

The other sampIes in this series with lower M. tem- I

peratures had progressively less of this rim effect, ~

and the stress-relieved specimens contained a rela-

tively uniform amount of transformation across the

''1' '

section, as in Fig. 7a.

Fig. 6-Martensite formation in 20 pet Ni-O.5 pet C steel austeni-

These results are attributable directly to the tized at 1095°C, quenched to room temperature, and subcooled to

residual stresses in the austenitized steeI. The M. (-20.1 °C). Tempered ot 315°C for 10 sec. Etched with 4 pet

quenching from the austenitizing temperature puts nital ond 1 pet zephiran chloride. Note eompletely austenitic rim.

the specimens into astate of tension in the interior Bottom of picture shows martensitic plates formed toword the in-

and astate of compression near the surface. As in terior of the specimen. X100.

664-JOURNAL OF METALS, JUNE 1952 TRANSACTIONS AlME

quenching. Fig. 7c shows how the core of trans-

formation was changed in shape and shifted to the

side of the specimen where the bending moment had

added tensile components to counterbalance the re-

sidual compressive stresses in the rim.

Criterion for Effectiveness of Applied Elostic Stress

It has been demonstrated that a proper criterion

for the initiation of the transformation by applied

elastic stress must take into ac count the normal, as

weIl as the shear, components. A feasible approach

to the problem is derived from the nature of the

transformation strains. The generation of a mar-

tensitic plate involves two displacements,18 the first

being a homogeneous strain that can be described

as the motion of planes of no rotation and no dis-

tortion lying parallel to the habit plane. The direc-

tion of atom motion does not lie in this plane; hence

the displacement is not one of simple shear. It may

be assumed that this first strain is the primary dis-

placement that occurs during the nucleation process.

The second strain, which finally yields the marten-

sitic structure, is homogeneous only over small re-

gions compared to the volume of the plate, and will

be regarded as playing no significant role in the

activation phenomenon. The planes of no rotation

and no distortion during the first strain slide past

one another, corresponding to a shear strain of about

0.2; but they also move apart, corresponding to a

normal (dilatation) strain of about 0.05.* . Thus, the

• These measurements were made on a 70 pet Fe-30 pet Ni alloy,

having a {259) habit," and are assumed to apply to the alloy under

study here. Both alloys transform in approximately the same range

of subzero temperatures and both exhibit burst phenomena.

effectiveness of an applied stress should depend

upon its ability to produce both shear and normal

strains of the correct magnitude with respect to a

potential habit orientation. Moreover, anormal com-

pressive component will oppose the dilatation strain

of the transformation, whereas anormal tensile

component will aid it.t According to this concept

t The sign of the shear eomponent is of little eonsequenee, sinee

the many habit orientations virtually permit shearing in either

direction.

the results of uniaxial tension and of uniaxial com-

pression are expected to be quite different.

The foregoing combined strain criterion can be

treated quantitatively through the use of a Mohr

two-dimensional strain circle. 23 Because of the sym-

metry involved only plane strains need be con-

sidered and the strain circles are representative of

any longitudinal plane passing through the tension

or compression axis.:j: In this method of depicting

:I: The plane strains are visualized to aet on a potential habit plane

whose normal lies in the plane of the strain elrele. Thus the latter

plane is perpendieular to the potential habit plane, and also eon-

tains the direetion of atom motion during the first transformation

strain.

Fig. 7-Martensite formation in 20 pet Ni-O.5 pet C steel austeni-

plane strains, the principal strains (E, and E2) are tized at 1095·C then treated as indieated. Finally tempered at

plotted along the x-axis from a common origin (Fig. 315·C for 10 sec and etched with 4 pet nital and 1 pet zephiran

chloride. XIO.

8) and a circle is constructed of radius

2 a-(top)-Oil quenched from austeniti:z:ing temperature, stress

relieved at 480·C, and subeooled to Mb (-37·C). Note relatively

with E, taken as the larger strain in the positive uniform distribution of martensite across the transverse seetion.

direction. The circle passes through E, and E2 and has

b-{centerl-Water quenched from austenitizing temperature and

E, + E2

=

subcooled to Mb (-20·C). Note completely austenitic rim with

its center at - - - - Letting v Poisson's ratio, transformation confined to the central portion of the section.

2

c-(bottom)-As in b, but with elastic bending moment superim-

then E2 = - VE, where E, is the principal (positive) posed on quenching stresses during the subeoaling to Mb (-20·Cl.

strain parallel to the tension axis and E2 is the princi- Note the shift of the transformed region toward the tension side

pal (negative) strain perpendicular to the tension (bottom of pieture) of the applied bending moment.

TRANSACTIONS AlME JUNE 1952, JOURNAL OF METAL5-665

of opposite sign in the lateral direction due to

Poisson's ratio.) However, since most of the orien-

tations in this instance sustain normal compressive

strains, a chain of reaction would tend to be in-

hibited, and Mb should be lowered even though M,

11 apeclmen may be raised by the applied compressive stress.

c

Thus, while M, = - 37°C = Mb for the unstressed

A axis

f:-lIf--

, I 'Ilcpplied alloy, it is predicted that M, > - 37°e > Mb for the

tensile

strain uniaxially compressed alloy. Of course, under uni-

axial tension both M, and Mb should be raised ac-

cording to the proposed criterion and this has been

demonstrated already (Figs. 1 and 2).

(al Correspondlng to 0 unloxiol tenstle stress

I To test the above prediction, austenitized and

stress-relieved specimens were elastically loaded at

room temperature, and electrical resistance changes

were measured during subcooling with the speci-

mens und er constant stress. Uniaxial compression of

15,000 psi was applied in one run, and uniaxial ten-

sion of the same magnitude was applied in another.

Unloaded specimens were also checked for compara-

tive purposes. The resulting curves in Fig. 9 show

opplled that M, and Mb were raised by 17°e in the tension

compreSSive straln experiment, while in the compression run, M, was

(bl CorrespondlnQ to 0 unloxtol compress1ve stress raised by 10 0 e and Mb was lowered by Boe.

Fig. 8-Two dimensional Mohr strain circle depicting The relative effectiveness of uni axial tension and

narmal and shear strains as 0 function of orientation. compression in inducing the transformation can be

calculated. Granting that the critical combined

strain can be defined by a shear component '}'. and a

axis. Similarly for uniaxial compression, E, = - 1'E" normal component E., eq 1 yields for uniaxial ten-

where E2 is the principal (negative) strain parallel sion:

to the compression axis, and E, is the principal (posi-

tive) strain perpendicular to the compression axis. -E.(1-1') +YE: (1 +1'),+1',),:

E, (positive) = [2]

These two cases are illustrated in Fig. Ba and b. 21'

A point on the strain circle lying at a radial angle and for uni axial compression:

2a from the x-axis corresponds to a plane whose

normal makes an angle IX with the E, direction. It can -E. (1-,,) -YE: (1 + ,,)2+1',},'-

be shown that abscissa of such a point denotes the E2 (negative) = --~--=-----.:._~-~-~ [3]

21'

normal strain (E) sustained by the plane in question

and the ordinate of the point denotes one-half the It is then assumed that the critical components ')'.

and E. stand in ab out the same ratio as the observed

shear strain ( ; ) sustained by this plane. The shear and normal components (0.2 and 0.05) of the

r

mathematical relationship is:

~

(_El_~_E2_ E, ~ E2 [1] 2 0

>-

....

:>

which is the equation of the strain circle. Because .... 20

(f)

of the random orientation of the potential habit (j)

W

planes and the symmetry of the applied strain Ir

40

system about the specimen axis,§ it is only necessary -'

<!

'::'

§ Also see the second (t) note on p. 665. Ir

....

0

w 60

to consider orientations of IX between 0 and 90°; this -'

w

corresponds to points lying along the semicirc1e ~

ABC in Fig. 8. Between A and B, E and '}' are positive w

80

and the orientations are such that transformation is (f)

<!

aided by the acting strains. On the other hand, be- W

tween Band C, € is negative and these particular ~

w

100

0

orientations sustain normal compressive strains that

oppose the dilatation component of the transforma- -'

~ 120

tion strain. 0

i=

From a comparison of Fig. Ba and b, it is evident 0

<!

that arc AB (tension case) is greater than arc AB Ir

CL

140 (b) (0) (c)

(compressive case), and hence there should be many 20 10 -40 - 50

more favorable orientations for transformation

under uni axial tension than und er uni axial com- Fig. 9-Fractional decrease in electrical resistivity vs. tem-

pression. Yet even in the latter case, the surprising perature far specimen of 20 pct Ni-O.5 pet C steel cooled

conclusion is reached that there should be some (al without applied stress, (bl with uniaxial tensile stress

orientations that are aided by the uniaxial compres- of 15,000 psi, and (cl with uniaxial' compressive stress of

sion. (Actually, this results from the normal strains 15,000 psi.

666-JOURNAL OF METALS, JUNE 1952 TRANSACTIONS AlME

a-Subcooled to -45 ° C with outer rim under triaxial eompressive b-Reeaoled to -45°C without applied stress. Note relative uni-

stress. Note lack of transformation there. formity of the transformation oe ross the section.

Fig. 10-Martensite formation in 20 pet Ni-OS pct C steel austenitixed at 1095°C, water quenched to room temperature, and subcooled

os indicated. Finally tempered at 315°C for 10 sec and etched in 4 pct nital and 1 pet xephiran chloride. Xl0.

first transformation strain.'8 Substituting in eqs 2 the specimen due to the tensile stress there. This

and 3 and letting v = 0.3, it follows that: was found to occur as a burst at -31°C. (It is evi-

E2 (compression) = -1.8 El (tension) [4] dent that the applied compressive stress partly

This indicates that the uniaxial stress in compression cancelled the residual tension in the core and there-

fore the transformation set in at a lower temperature

required to initiate the transformation under a given

than if the compressive load had not been applied.

set of conditions is 1.8 times the uni axial stress in

Without such loading, the water-quenched specimen

tension required to initiate the transformation under

would start to transform in the core at about

the same conditions.

- 26°C.) The aluminum has about the same thermal

A direct experiment to test this calculation has not

coefficient of contraction as the austenitic alloy, and

yet been made, but the fact that the raising of M. by

hence it resisted the expansion due to the trans-

15,000 psi tension is 1.7 times the raising achieved

formation in the core at -31°C. This generated com-

by 15,000 psi compression suggests that the theory

pressive stresses transverse to the specimen axis

stands a good chance of being quantitatively correct.

It would also give strong support to the re action- (estimated to be comparable to the elastic limit) and

path concept which provides the basis for the the applied axial compression completed the state of

triaxial compression. The lateral constraint pro-

'Yo 4 vided by the aluminum block was definitely opera-

assumption that - - ~ - . tive, as indicated by the fact that the applied axial

Eo 1

stress jumped from 15,000 to 16,000 psi simul-

Experiments with Triaxial and Hydrostatic Compressive taneously with the burst. However, the applied load

Stresses was quickly reduced to the original value in the

The positive normal strains that exist in a uni- testing machine before further cooling.

axially compressed specimen because of Poisson's The specimen, triaxially compressed as described,

ratio are eliminated in case of triaxial and hydro- was cooled to - 45°C, held there for 5 min, returned

static compression. Furthermore, in the latter case, to room temperature, and unloaded. The aluminum

the shear components are also avoided. Therefore, block was removed, and a portion of the specimen

the combined strain criterion indicates that both M. that had been surrounded by the block was tempered

and Mb should be lowered by tri axial and hydro- at 315°C to "darken" the martensite. From Fig. 10a,

static compression. it can be seen that the core of the rod had undergone

A 0.34 in. diam x 3 in. long specimen was austeni- transformation, corresponding to the burst at

tized and water quenched. Without being stress re- - 31°C, but the rim was austenitic even after the

lieved, the specimen was copper plated and pressed cooling to - 45°C. The small amount of transforma-

into a central hole in an aluminum block, 2 in. OD tion visible near the edge of the specimen was un-

x 1 in. long. The specimen was then loaded in uni- doubtedly an extraneous effect of the superficial dis-

axial compression to an elastic stress of 15,000 psi tortion that occurred when the rod was forced into

and cooled slowly below room temperature. It was the aluminum block. When the same specimen was

known from the experiments on residual stresses recooled to - 45°C, und er no external stress the

that the transformation would start in the core of martensitic transformation took place in the' pre-

TRANSACTIONS AlME JUNE 1952, JOURNAL OF METALS-667

viously untransformed rim, as shown in Fig. lOb. Martensite Reaction. Cold Working 01 Metals. A.S.M.

This experiment demonstrates that M. and M. ean (1949).

2 H. Scott: Dimensional Changes Accompanying the

be depressed by triaxial compressive stresses.

Through the eourtesy of Professor P. Bridgman Phenomena of Tempering and Aging Tool Steels. Trans.

at Harvard University, a few runs were carried out A.S.S.T. (1926) 9, p. 277.

under hydrostatie pressure. With austenitized and • H. Hanemann and A. Schrader: On Martensite.

stress-relieved speeimens, the burst temperature was Trans. A.S.S.T. (1926) 9, pp. 169-233, 364.

lowered from the customary -37°C to about -78°C • S. L. Hoyt: Stresses in Quenched and Tempered

Steel. Trans. A.S.S.T. (1927) 11, pp. 509-530, 658.

by apressure between 2000 and 4000 atm. The M. 5 K. Tamaru and S. Sekito: On the Quantitative De-

temperature was also lowered by the hydrostatic termination of Retained Austenite in Quenched Steels.

pressure, but the extent was not determined with Sci. Rep., Sendai, Series 1 (1930) 20, p. 377.

eertainty. Further experiments along these lines are 6 F. Lazlo: Tessellated Stresses, Part H. Journal Iron

underway. and Steel lnst. (1943) 148, p. 137.

7 E. Scheil: Uber die Umwandlung des Austenits in

Summary

Martensite in Eisen-Nickel-legierungen unter Belas-

The formation of martensite in a 20 pet Ni-0.5 pct tung. Ztsch. anorg. al/gem. Chemie (1932) 207, p. 21.

C steel und er the application of stress has been 8 A, W. McReynolds: Effects of Stress and Deforma-

studied as a function of the temperature of loading tion on the Martensite Transformation." Journal of

and the state of stress. The principal results may be Applied Physics (1949) 20, p. 896.

summarized as follows: 9 C. S. Barrett and O. R. Trautz: Low Temperature

1-The martensitic transformation ean be initiated Transformation in Lithium and Lithium-Magnesium

by elastic stresses at temperatures above M •. Hence Alloys. Trans. AlME (1948) 175, p. 579; METALS TECH-

the role of applied stress is not merely one of pro- NOLOGY (April 1948).

10 A. B. Greninger and V. G. Mooradian: Strain

ducing nuclei by plastic deformation.

2-It is suggested that the role"qf applied stress at Transformation in Metastable Beta Copper-Zinc and

temperatures just above M, is to supply critical Beta Copper-Tin Alloys. Trans. AlME (1938) 128, p.

strains to existing embryos. This makes it unneces- 337; discussion, p. 355.

11 A. B. Greninger: The Martensite Transformation in

sary to adopt the assumption that the austenite

lattice becomes meehanically unstable at MB' Beta Copper-Aluminum Alloys. Trans. AlME (1939)

3-The normal strain aeting on a potential habit 133, p. 204; discussion, p. 222.

12 K. Mathieu: Effect of Alloy-element Content and

plane has an important effect on the nucleation

process, and therefore a critical resolved shear stress Testing Conditions on Gamma to Alpha Transformation

or strain cannot be regarded as a valid criterion for in Cold-Deformation of Austenitic Steels. Archiv

Eisenhuttenwesen (December 1942) 16, p. 215.

inducing the transformation.

" C. B. Post and W. S. Eberly: Stability of Austenite

4-Shear strains and positive (tensile) normal in Stainless Steels. Trans. A.S.M. (1947) 39, p. 868;

strains acting on a potential habit plane promote discussion, p. 888.

the transformation, but negative (compressive),nor- 14 D. J. McAdam, Jr., W. Geil, and F. J. Cromwell:

mal strains oppose it. Hence, strain energy, being lnfluence of Low Temperatures on the Mechanical

independent of the sign of the normal strain, cannot Properties of 18: 8 Chromium-Nickel Steel. Journal of

provide a suitable criterion for the transformation. Research, Nat. Bur. Standards, Research Paper 1882

5-Based on the reaction-path theory, a combined (1948) 40, p. 375.

15 N. A. Ziegler and P. H. Brace: Hardening of Auste-

strain criterion is presented, which takes into ac-

count the shear and dilatation components of the nitic Stainless Steels by Mechanical Working at Sub-

Zero Temperatures. Proc. A.S.T.M. (1950) 50, p. 861.

atomic displaeements during the transformation, and 16 M. Cohen, E. S. Machlin, and V. G. Paranjpe:

which is consistent with the following observations: Thermodynamics of the Martensitic Transformation.

a-M, and M. are raised by uni axial tension. Thermodynamics in Physical Metallurgy. Trans. A.S.M.

b-M, is raised, but Mb is lowered, by uniaxial (1950) 42A, p. 242.

17 E. S. Machlin and M.. Cohen: The lsothermal Mode

compression.

of the Martensitic Transformation. JOURNAL OF METALS

c-M. and Mb are lowered by tri axial and (May 1952), Trans. AlME, p. 489.

hydrostatic compression. 18 E. S. Machlin and M. Cohen: Habit Phenomenon in

6-Applied and residual stresses appear to be the Martensitic Transformation. Trans. AlME (1951)

additive in their effect on the transformation. 191, p. 1019; JOURNAL OF METALS (November 1951).

19 G. V. Kurdjumow and O. P. Maksimova: Kinetics

7-Yielding by slip or by the stress-induced trans- of Austenite to Martensite Transformation at Low Tem-

formation may be considered as competitive de- peratures. Doklady Akademii Nauk SSSR (1948) 61,

forma.tion processes. Either may precede the other, No. 1, p. 83.

and eIther may influence the other. G. V. Kurdjumow and O. P. Maksimova: On the

Energy of Formation of Martensite NucleL Doklady

Acknowledgments Akademii Nauk SSSR (1950) 73, p. 95.

20 B. S. Lement and S. C. Das Gupta: lsothermal

The authors wish to express their appreciation to

Miriam E. Yoffa and to George Black of the Dept. Formation of Martensite at Sub-Zero Temperatures in

a High Chromium Steel. Trans. AlME (1951) 191, p.

of Metallurgy at the Massachusetts Institute of 727; JOURNAL OF METALS (September 1951).

Technology for assistance in various phases of this 21 S. A. Kulin and G. R. Speich: lsothermal Marten-

investigation. The authors are also indebted to the site Formation in an lron-Chromium-Nickel Alloy.

Office of Naval Research for sponsorship of a re- JOURNAL OF METALS (March 1952), Trans. AlME, p. 258.

search program of which this work was apart. 22 E. S. Machlin and Morris Cohen: The Burst Phe-

nomenon in the Martensitic Transformation. Trans.

References AlME (1951) 191, p. 746; JOURNAL OF METALS (Septem-

1 B. L. Averbach, S. A. Kulin, and M. Cohen: The

ber 1951).

Effect of Plastic Deformation on Solid Reactions: Part 2S R. Heindlhofer: Evaluation of Residual Stress.

II-The Effect of Applied Stress and Strain on the (1948) New York. McGraw-Hill Book Co.

668-JOURNAL OF METALS, JUNE 1952 TRANSACTIONS AlME

You might also like

- Pipe Supports DesignDocument29 pagesPipe Supports Designpbao_12No ratings yet

- Magnetic Fields, Special Relativity and Potential Theory: Elementary Electromagnetic TheoryFrom EverandMagnetic Fields, Special Relativity and Potential Theory: Elementary Electromagnetic TheoryRating: 5 out of 5 stars5/5 (1)

- Shape Memory AlloysDocument44 pagesShape Memory Alloysvarunvaa75% (4)

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- Circulating Load RatioDocument2 pagesCirculating Load RatioNatashaEgieara100% (1)

- 1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueDocument5 pages1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueSRIKANTH K 15PHD1093No ratings yet

- IAS Physics Student Book 1 (2018) AnswersDocument32 pagesIAS Physics Student Book 1 (2018) AnswersGazar77% (56)

- Plastic Deformation of The Intermetallic: Compound MGZNDocument11 pagesPlastic Deformation of The Intermetallic: Compound MGZNFaris FadliNo ratings yet

- JMPS 2004 Zhang DunnDocument26 pagesJMPS 2004 Zhang Dunnp1muellerNo ratings yet

- Stabilisation MST 2007-1Document3 pagesStabilisation MST 2007-1Karan AggarwalNo ratings yet

- High-Purity Silver Deformed To Large StrainsDocument10 pagesHigh-Purity Silver Deformed To Large Strainsomar78210No ratings yet

- Niti Pseudoelasticity and Thermoelasticity..Document7 pagesNiti Pseudoelasticity and Thermoelasticity..Nizam MuhamadNo ratings yet

- Study Microstruture FSWDocument4 pagesStudy Microstruture FSWDaniel MarquesNo ratings yet

- 1 - Ion ActaMet 1982Document11 pages1 - Ion ActaMet 1982Chandra ClarkNo ratings yet

- Theory of Ferromagnetic Hysteresis 15Document13 pagesTheory of Ferromagnetic Hysteresis 15soumyabrataNo ratings yet

- Elastic Constants of BCC Austenite and 2H Orthorhombic MartensiteDocument19 pagesElastic Constants of BCC Austenite and 2H Orthorhombic MartensiteThe live streamerNo ratings yet

- Herzer Soft Magnets1Document6 pagesHerzer Soft Magnets1Abdelkader BENABOUNo ratings yet

- The Microstructure of Metastable Austenite in X5crni18-10Document7 pagesThe Microstructure of Metastable Austenite in X5crni18-10Agnieszka Kurc-LisieckaNo ratings yet

- TABANLI Mean Stress Effects On Fatigue of NiTiDocument5 pagesTABANLI Mean Stress Effects On Fatigue of NiTiR. Murat TabanlıNo ratings yet

- SGSGSDDocument16 pagesSGSGSD1thirdNo ratings yet

- Welding Research: The Effect of Heat Treatment On Type 316 Stainless Steel Weld MetalDocument6 pagesWelding Research: The Effect of Heat Treatment On Type 316 Stainless Steel Weld MetalTasmanijskaNemaNo ratings yet

- Crack Formation PaperDocument17 pagesCrack Formation PaperStutee NandaNo ratings yet

- Microstructural Changes in HSLA-100 Steel Thermally To Simulate The Heat-Affected Zone During Welding CycledDocument17 pagesMicrostructural Changes in HSLA-100 Steel Thermally To Simulate The Heat-Affected Zone During Welding CycledKay WhiteNo ratings yet

- Journal of Magnetism and Magnetic Materials: Seiki Takahashi, Satoru Kobayashi, Toetsu ShishidoDocument6 pagesJournal of Magnetism and Magnetic Materials: Seiki Takahashi, Satoru Kobayashi, Toetsu ShishidoBhabani Sankar SwainNo ratings yet

- Roy BangaloreDocument7 pagesRoy Bangalorew3mengNo ratings yet

- Calculation of Internal Stress of Steel Induced During QuenchingDocument10 pagesCalculation of Internal Stress of Steel Induced During Quenchingkim983124No ratings yet

- CW602N Constitutive AnaylsisDocument9 pagesCW602N Constitutive AnaylsisCaner KirazNo ratings yet

- Ding 2006Document10 pagesDing 2006Prakash Kumar M.Tech., Materials Science & Tech, IIT(BHU)No ratings yet

- Shape Memory AlloysDocument16 pagesShape Memory AlloysIvan HernandezNo ratings yet

- $pin Sesquioxide Vz03 E. BDocument8 pages$pin Sesquioxide Vz03 E. Br.menonNo ratings yet

- The Creep of Cellular SolidsDocument11 pagesThe Creep of Cellular Solidsnq_qthiNo ratings yet

- Dynamic: Wire Drawing RodsDocument9 pagesDynamic: Wire Drawing RodsTugay doğanNo ratings yet

- Crack Propagation of Ti Alloy Via Adiabatic Shear BandsDocument5 pagesCrack Propagation of Ti Alloy Via Adiabatic Shear BandsNormix FlowersNo ratings yet

- 1 2960551 PDFDocument4 pages1 2960551 PDFRicardo AlvesNo ratings yet

- Hippsley, 1981Document12 pagesHippsley, 1981Luan CaetanoNo ratings yet

- Tabanli2001 Article MeanStrainEffectsOnTheFatiguePDocument4 pagesTabanli2001 Article MeanStrainEffectsOnTheFatiguePR. Murat TabanlıNo ratings yet

- The Effect of Microstructural Banding On Failure Initiation of HY-100 Steel - Chae2000Document11 pagesThe Effect of Microstructural Banding On Failure Initiation of HY-100 Steel - Chae2000Angélica NogueiraNo ratings yet

- Strain and FractureDocument6 pagesStrain and FractureSinhro018No ratings yet

- Memory Effects in An Interacting Magnetic Nanoparticle System-PhysRevLett.91.167206Document4 pagesMemory Effects in An Interacting Magnetic Nanoparticle System-PhysRevLett.91.167206Nyiam HlubNo ratings yet

- Deformation and Martensitic TransformationDocument14 pagesDeformation and Martensitic TransformationAmit Ranjan KumarNo ratings yet

- Romero1989 Plastic DeformationDocument11 pagesRomero1989 Plastic DeformationMuhammad Falqi YusufNo ratings yet

- Tempering MartensiteDocument21 pagesTempering Martensitejardel de matosNo ratings yet

- Elastic-Plastic Work-Hardening Deformation2010Document5 pagesElastic-Plastic Work-Hardening Deformation2010аримотома аримотомаNo ratings yet

- SS304 Hardening BehaviourDocument4 pagesSS304 Hardening BehaviourrbagriNo ratings yet

- P. Perzyna, The Thermodynamical Theory of Elasto-Viscoplasticity For Description of Nanocrystalline MetalsDocument60 pagesP. Perzyna, The Thermodynamical Theory of Elasto-Viscoplasticity For Description of Nanocrystalline MetalsRyszard B. PecherskiNo ratings yet

- Nitinol - Its Use in Vascular Surgery and Other ApplicationsDocument6 pagesNitinol - Its Use in Vascular Surgery and Other ApplicationsLucas RobertoNo ratings yet

- 1964 - Nagata1964Document10 pages1964 - Nagata1964Luis VelderrainNo ratings yet

- The Precipitation of A1N and NBC and The Hot Ductility of Low Carbon SteelsDocument11 pagesThe Precipitation of A1N and NBC and The Hot Ductility of Low Carbon SteelsChanthar SoeNo ratings yet

- Kinetics of Martensite Formation in Plain Carbon Steels: Critical Assessment of Possible Influence of Austenite Grain Boundaries and AutocatalysisDocument11 pagesKinetics of Martensite Formation in Plain Carbon Steels: Critical Assessment of Possible Influence of Austenite Grain Boundaries and AutocatalysisjhonNo ratings yet

- Lindigkeit 1981Document7 pagesLindigkeit 1981uristerinNo ratings yet

- High-Temperature Creep On KBR Single CrystalsDocument6 pagesHigh-Temperature Creep On KBR Single CrystalsBorisNo ratings yet

- Stress-Phase-Transformation Interactions - Basic PDocument11 pagesStress-Phase-Transformation Interactions - Basic PRoberto AbreuNo ratings yet

- AN EXTENDED 316L STAINLESS STEEL MODEL SUITABLE FOR I - 2007 - IFAC ProceedingsDocument6 pagesAN EXTENDED 316L STAINLESS STEEL MODEL SUITABLE FOR I - 2007 - IFAC ProceedingssmeykelNo ratings yet

- Shape Memory Alloys (Smas) Are Family of Smart Materials. They HaveDocument21 pagesShape Memory Alloys (Smas) Are Family of Smart Materials. They HaveSubir DebNo ratings yet

- Shape Memory Alloys (Smas) Are Family of Smart Materials. They HaveDocument21 pagesShape Memory Alloys (Smas) Are Family of Smart Materials. They HaveSubir DebNo ratings yet

- Introduction To Shape Memory Alloys: Exp No: L4/S2/MT427/01Document7 pagesIntroduction To Shape Memory Alloys: Exp No: L4/S2/MT427/01Sachith Praminda RupasingheNo ratings yet

- Shape Memory Alloy & It'S ApplicationDocument21 pagesShape Memory Alloy & It'S ApplicationSubir DebNo ratings yet

- Shape Memory AlloysDocument20 pagesShape Memory Alloysarts_hartNo ratings yet

- A Secondar Cooling Pattern For Preventing Surface Cracks of Continuous Casting SlabDocument9 pagesA Secondar Cooling Pattern For Preventing Surface Cracks of Continuous Casting SlabDarkprogNo ratings yet

- Iron Core Asteroid Formation Et AlDocument4 pagesIron Core Asteroid Formation Et AlCraig MawsonNo ratings yet

- Shape Memory Alloys: Department of Applied PhysicsDocument31 pagesShape Memory Alloys: Department of Applied PhysicsNivashini VindhyaNo ratings yet

- 1978 Heikens Propiedades MNSDocument8 pages1978 Heikens Propiedades MNSBrandon MartinezNo ratings yet

- Leica NA700 LevelDocument10 pagesLeica NA700 Levelbbutros_317684077No ratings yet

- Preboard 1 EsasDocument10 pagesPreboard 1 EsasRON MARK EDWARD ANDALUZNo ratings yet

- T 202 ACETONE COLUMN DESIGN - v2Document7 pagesT 202 ACETONE COLUMN DESIGN - v2Jewls HatudNo ratings yet

- CarringtonDocument29 pagesCarringtonTaryn Lee AverittNo ratings yet

- Beck 1987Document17 pagesBeck 1987Gabriel Serra ManhaesNo ratings yet

- Chapter 2 Forces & EquilibriumDocument54 pagesChapter 2 Forces & EquilibriumIsabelNo ratings yet

- Solutions, and The Optional Wickert Textbook Only. No Electronic Devices Other Than Calculators Will BeDocument4 pagesSolutions, and The Optional Wickert Textbook Only. No Electronic Devices Other Than Calculators Will BenuncafalhaNo ratings yet

- Chapter 1-Phy220Document57 pagesChapter 1-Phy220Jordan TuckerNo ratings yet

- Hu 2023 J. Phys. Conf. Ser. 2503 012101Document11 pagesHu 2023 J. Phys. Conf. Ser. 2503 012101Amri MoussaNo ratings yet

- 1.8 Higher Order DerivativesDocument2 pages1.8 Higher Order DerivativesVhigherlearningNo ratings yet

- GeoConvention 2013 - True Residual Oil SaturationDocument22 pagesGeoConvention 2013 - True Residual Oil SaturationPaul ReedNo ratings yet

- The Nastran Demonstration Problem Manual Nastran Demonstration Problem Manual PDFDocument259 pagesThe Nastran Demonstration Problem Manual Nastran Demonstration Problem Manual PDFJitendra ItankarNo ratings yet

- Christensen 1994Document16 pagesChristensen 1994Fernando Andrés Ortega JiménezNo ratings yet

- Study of Ball Valve CharacteristicsDocument6 pagesStudy of Ball Valve CharacteristicsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Arif Sir Question - ch1Document22 pagesArif Sir Question - ch1MEHEDI HASANNo ratings yet

- 4027q1 Specimen PaperDocument16 pages4027q1 Specimen PaperBrãñdøn DzîñgáíNo ratings yet

- Egg Egg: Breaks Does Not BreakDocument3 pagesEgg Egg: Breaks Does Not BreakLily Suhany MahmoodNo ratings yet

- Predicted Paper 1aDocument17 pagesPredicted Paper 1aGbenga AjibikeNo ratings yet

- Grade 8 Science q1w1 - Force Final RevisedDocument7 pagesGrade 8 Science q1w1 - Force Final RevisedJENEBEL DAGOHOYNo ratings yet

- Pta-18 - Key - SolDocument9 pagesPta-18 - Key - SolDeepMath2006No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTNo ratings yet

- How To Determine An Unknown Chloride Titration: Video of The DayDocument2 pagesHow To Determine An Unknown Chloride Titration: Video of The DaynadunNo ratings yet

- Global Sum Dist Eujc 3.8.23 FinalDocument21 pagesGlobal Sum Dist Eujc 3.8.23 FinalUniversität BielefeldNo ratings yet

- Mass Angle of Repose of Open-Graded Rock Riprap: Technical NoteDocument8 pagesMass Angle of Repose of Open-Graded Rock Riprap: Technical NoteCarlos Ediver Arias RestrepoNo ratings yet

- Manufacturing Engineering Forming: Chapter 3: MetalDocument98 pagesManufacturing Engineering Forming: Chapter 3: MetalnunuNo ratings yet