Professional Documents

Culture Documents

100820-PENA-0001-09 Client Action Item List 5-18-21

100820-PENA-0001-09 Client Action Item List 5-18-21

Uploaded by

ganeshcivil1984Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

100820-PENA-0001-09 Client Action Item List 5-18-21

100820-PENA-0001-09 Client Action Item List 5-18-21

Uploaded by

ganeshcivil1984Copyright:

Available Formats

A. Ahrabi T. Ake F.

Pyne

Meeting Date:

(BPE) (BPE) (BPE) As of 2/9/21, a reoccurrence TEAM meeting has been set up and invitation sent out.

T.

Srinivas Shailendra

Veerendar Aluvala Balamurugan

May 18, 2021 Arugula Kumar Das

(BHEL) Murali

(BHEL) (BHEL)

(BHEL)

Vijaya Kumar Saravanakum

A Ganesan

Reference Document: Talluri a

(BHEL)

(BHEL) (BHEL)

100820-PENA-0001-09

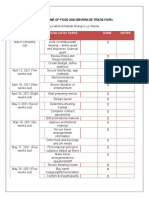

Microsoft TEAM Meeting notes from 5/18/21 at 7:00 AM Items "Closed" are highlighted in Green and will be hidden a week later.

Date Completion

Item Description Due Date Owner Status Comments

initiated Date

3/22/21, Please provide Yadadri comparison for our review.

3/23/21, BHEL provided Yadadri comparison.

3/25/21, BHEL shared list of documents submitted earlier with status as on today for Yadadri project.

Yadadri 800MW flow modeling approach- A comparison of parameters is 3/29/21, BHEL submitted flow model spec along with some documents in this week.

5.0 3/22/21 BHEL Open

also enclosed 4/20/21, BPE will review documents as they are submitted.

5/11/21, BPE has received GAs. BHEL will submit the updated GAs through our FTP site to include the oversized

dampers / blanking plates.

5/18/21, Still with BHEL

3/22/21, Submitted STAAD file and supporting documentation has been queued for review by our Stress Analysis

engineering.

3/29/21, BPE expects to have comments back to BHEL by 4/2/21.

4/20/21, BPE expects to have comments back to BHEL by 4/23/21

4/27/21, Transmittal 100820-DTNG-0037to BHEL.

Comments to the STAAD model as follows:

1. All primary load cases have been reviewed and are ok as is.

Comments on Bhusawal SCR Staad model submitted to M/S BPE in 2. The Code Check for the steel design shows 4 beams which are overstressed. However these are just small sections of

11.0 3/22/21 4/5/21 F. Cordella Open

LOTB-SS001 shall be provided beams and are ok as is.

3. The STAAD program does not do a code check on plate elements. How does BHEL qualify the stress in the plate

elements as acceptable ?

4. Have the deflections been evaluated ?

Overall, the model looks good.

BHEL to advise on item 3 and 4.

5/11/21, Status on item 3 and 4??

5/18/21, A. Ahrabi to reference BHEL transmittal LOTB-SS003. It is with BPE SA for review.

4/12/21, It is not clear what is requested by this feedback. If the request is to tie two compressors to common lines then

BPE recommends the standard arrangement of two complete compressor skids each with trap, 4-way valve, and

As per our customer feedback “Common line is to be provided after

compressor (see 100806-10551-094900015 Ammonia Railcar Unloading System P&ID). In the arrangement, one would

22.0 4/7/21 Ammonia unloading compressor and before 4way valve”. BPE may check 4/13/21 BHEL Open

close two manual valves to isolate one compressor, then open two valves to bring the other compressor in service.

the provision of common line in the compressor skid.

4/20/21, BHEL to provide a P&ID / Sketch to show their suggested layout and question.

5/18/21, Still with BHEL

4/20/21, Per Mr. Veerendar , BHEL has proposed a new arrangement for inlet / outlet duct based on the damper location.

BHEL will be providing BPE with new arrangement drawings for review. See email dated 4/20/21.

31.0 4/20/21 For Yadadri project Change in Damper location 4/27/21 BHEL Open 5/11/21, Based on our meeting between BPE and BHEL on May 7, 2021, We have received email information. on the

arrangements / damper size and locations. BHEL will transmit the same through FTP site.

5/18/21, Still with BHEL. Due by 5/24/21

5/7/21, BHEL received the calculations made (excel file) by BPE through email. BHEL will check the receipt of same through

CODOCx and confirm. 5/14/21 BHEL returned calculation with clarification for BPEI reply. Apart from questions draft loss

41.0 5/7/21 Yadadri, Draft loss calculations at Design Point 5/21/21 BPE Open

sheets are o.k.

5/18/21, Terry Ake has recieved the infomation through an email. Will have this recieved through DCAP.

5/7/21, The economizer bypass inlet should be lower to allow for possible mixing device for the economizer bypass flow (previous

revision showed the bottom of the inlet and control damper at the 4475 elevation). BHEL clarified that the changes were made to

42.0 5/7/21 Yadadri, Location of econ. Bypass duct 5/21/21 BHEL 5/18/21 Closed reduce the resistance in the eco bypass duct. This change was necessary to have required bypass flow through this ducting during

lower loads.

5/18/21, BHEL will be sending revised GAs This item is closed.

5/7/21, Per Dr. Ruscheweyh' comment an additional damper to be added in the bypass duct in order to avoid excessive ash

accumulation. BHEL understand the concern of ash accumulation and will discuss internally. Reply separately with

43.0 5/7/21 Bhusawall, Additional Damper in Bypass duct 5/21/21 BHEL Open alternate solutions.

5/18/21, Still with BHEL. This info from BHEL is need as teh flow modeling is currently on going. Updated info

from BHEL may impact cost and schedule with modeling efforts.

5/7/21, Yadadri flow model PO – BHEL requested BPE to provide a preliminary schedule with start date (as early as possible) with an

expected date of PO from BHEL similar to Bhusawal.

44.0 5/7/21 Yadadri, Flow modeling by Howden. 5/21/21 BPE 5/18/21 Closed

5/17/21, BPE emailed the preliminary schedule to BHEL. Due to Howden's current work load and upcoming holidays, Howden will not

be able to start on flow model efforts for Yadadri until earliest Mid-July.

5/11/21, Can anhydrous ammonia pipe be routed along with demineralized water pipe on a pipe rack.

Is there any safety/performance related concerns are associated with this type of routing as per applicable codes.

45.0 5/11/21 Routing of Anhydrous ammonia pipe 5/21/21 BPE 5/18/21 Closed 5/18/21, similar to action item No. 24, All piping should follow requirements for support, slope, and access. Industry standard is to

have elecrical lines at the upper level, utilities would be next level down and then the process lines at the lowwer level on the pipe

rack. BPE does not have concerns with having the ammonia piping an dthe DM piping on the same rack.

5/11/21, How ammonia slip/unreacted ammonia at reactor outlet will be maintained within the allowable limits (3 ppm of 2.5 ppm).

BPE is requested to suggest techno-economical method (Among the existing methods) to address unreacted ammonia at reactor

outlet.

Also, let us know the practice / recommendation by BPE when there is no specific requirement from customer on ammonia analyzer to

measure Ammonia slip.

46.0 5/11/21 Ammonia slip / Unreacted ammonia at reactor outlet 5/21/21 BPE 5/18/21 Closed

5/11/21, Per BPE, In-line ammonia slip analyzers do not work very well, specially in a high ash environment. Following are few options

that the plant has for measuring the outlet ammonia slip levels

- Perform a wet chemistry analysis.

- Sample fly ash at the outlet of the SCR for ammonia content.

- Monitor pressure drop across the Air heater.

5/18/21, Per an email from Mr. Shailendra Kumar Das on5/17/21

BHEL is planning to release the document for Hydrostatic Relief valve Selection for Bhusawal 660 MW contract. Kindly let

us know what are the parameters are to be provided by Process group for the selection of hydrostatic relief valve. Based on

our understanding the following parameters are mentioned :

a. Relieving Capacity – Relieving capacity of hydrostatic relief valve will be maximum flow in kg/hr in that line.

47.0 5/18/21 Bhusawal, Hydrostatic relief valve data 5/21/21 BPE Open

b. Set Pressure – Set pressure will be equal to the MAWP or Design pressure of the pipe line

c. Allowable Over pressure – This is equals to ratio of Design pressure to operating pressure of that pipe line

d. Relieving flow temperature – Relieving flow temperature will be design temperature of the pipeline

e. Relieving flow pressure – Relieving flow pressure will be design pressure of the pipeline

f. Number of valves to be provided for each pipeline –

5/18/21, BPE engineering will review and advise.

48.0

49.0

50.0

You might also like

- Homebase Air Conditioner 253797 Manual PDFDocument14 pagesHomebase Air Conditioner 253797 Manual PDFGavin ManNo ratings yet

- World Cup Laundry Liquid Detergent - (GanttPRO - Com) - 28 05 2021 06 47AMDocument6 pagesWorld Cup Laundry Liquid Detergent - (GanttPRO - Com) - 28 05 2021 06 47AMArun Kumar PandeyNo ratings yet

- Project Responsibility, Plan and Status: Business Case - BCI20210407040641Document4 pagesProject Responsibility, Plan and Status: Business Case - BCI20210407040641ranj kNo ratings yet

- GM ScheduleDocument9 pagesGM ScheduleShivaNo ratings yet

- Weekly Report: For Construction Drawing (5/24/2021) On-GoingDocument7 pagesWeekly Report: For Construction Drawing (5/24/2021) On-GoingDorothy Jacoba CaniaNo ratings yet

- Project 1Document25 pagesProject 1ankitNo ratings yet

- UntitledDocument2 pagesUntitledBalakrishna G SettyNo ratings yet

- D PharmaDocument11 pagesD PharmaTiger DdtNo ratings yet

- 'Project Metodology Project Approach SummaryDocument10 pages'Project Metodology Project Approach SummaryAldrin AntonioNo ratings yet

- Schedule of Even End Iind Semester On Line Examination August 2021Document25 pagesSchedule of Even End Iind Semester On Line Examination August 2021Aashish KushwahaNo ratings yet

- May 2021 Hyderabad ZoneDocument4 pagesMay 2021 Hyderabad ZoneYakshit JainNo ratings yet

- ET712080243IN SpeedPost Track ConsignmentDocument2 pagesET712080243IN SpeedPost Track ConsignmentvaseenandanNo ratings yet

- AS-AL Timetable Zone 3Document4 pagesAS-AL Timetable Zone 3T.F. EvansNo ratings yet

- Student Performance ReportDocument4 pagesStudent Performance ReportJoel JoelNo ratings yet

- Stockyard Report Management: Stock in HandDocument2 pagesStockyard Report Management: Stock in HandRUPINDER BRARNo ratings yet

- Status Covid Vax 15july2021Document3 pagesStatus Covid Vax 15july2021rakesh kapilNo ratings yet

- Status Covid Vax 15july2021Document3 pagesStatus Covid Vax 15july2021NomanNo ratings yet

- Status Covid Vax 15july2021Document3 pagesStatus Covid Vax 15july2021RohitNo ratings yet

- Status Covid Vax 15july2021Document3 pagesStatus Covid Vax 15july2021Macdiel PardilloNo ratings yet

- Status of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessDocument3 pagesStatus of COVID-19 Vaccines Within WHO EUL/PQ Evaluation Processmasudulamin14No ratings yet

- MH Statment Regarding The Lowered RebarDocument1 pageMH Statment Regarding The Lowered RebarbkgossNo ratings yet

- DownloaderDocument2 pagesDownloaderRizwan FarooqNo ratings yet

- Date Occasion: HolidaysDocument2 pagesDate Occasion: HolidaysSaurabh VermaNo ratings yet

- Annual Home Examinations 2021Document1 pageAnnual Home Examinations 2021Javed KhokharNo ratings yet

- Follow UpDocument10 pagesFollow UpteemertechNo ratings yet

- HydrabadDocument3 pagesHydrabadYakshit JainNo ratings yet

- Project UpdateDocument3 pagesProject UpdateBrent Owen PastorNo ratings yet

- Bks RVNL ArbitrationDocument2 pagesBks RVNL Arbitrationshamim ahmadNo ratings yet

- Date Occasion: HolidaysDocument2 pagesDate Occasion: HolidaysSJNo ratings yet

- Laboratory Assessment Task 1Document2 pagesLaboratory Assessment Task 1Kathlyn TabanNo ratings yet

- Laboratory Assessment Task 1Document2 pagesLaboratory Assessment Task 1Kathlyn TabanNo ratings yet

- E23 Con Bmba 1569Document2 pagesE23 Con Bmba 1569bishalsiwakoti2k21bmba02No ratings yet

- ET712078973IN SpeedPost Track ConsignmentDocument2 pagesET712078973IN SpeedPost Track ConsignmentvaseenandanNo ratings yet

- GLJV-G2000-MGT-PMC-CSV-MOM-0037-A0: #PAGES: 1/4 Place: TIME: 3:00 PM Document Number: Meeting DateDocument5 pagesGLJV-G2000-MGT-PMC-CSV-MOM-0037-A0: #PAGES: 1/4 Place: TIME: 3:00 PM Document Number: Meeting DateMukhtar AhmedNo ratings yet

- MOM Belgaum 12.08.2021Document1 pageMOM Belgaum 12.08.2021Ravi TejaNo ratings yet

- Huddle General Ledger de Abril para DGIDocument107 pagesHuddle General Ledger de Abril para DGIJahgson QuickCounterNo ratings yet

- Project: AV006 - CHH Master Drawing Deliverables: 1 Front End Engineering DesignDocument1 pageProject: AV006 - CHH Master Drawing Deliverables: 1 Front End Engineering DesignAlleo MarquezNo ratings yet

- Paavai College of EngineeringDocument1 pagePaavai College of EngineeringpceautohodNo ratings yet

- Status Covid Vax 02july2021Document3 pagesStatus Covid Vax 02july2021Ravi RanjanNo ratings yet

- MOA Date Amount (In Pesos) Supposed Authority Funding SourceDocument11 pagesMOA Date Amount (In Pesos) Supposed Authority Funding SourceTj CabacunganNo ratings yet

- Summary of All Transactions by DateDocument15 pagesSummary of All Transactions by DateMwesigwa DaniNo ratings yet

- Mat Cscec 05 El LC 0019 00Document2 pagesMat Cscec 05 El LC 0019 00Chris LimNo ratings yet

- Document Record - Account DivisionDocument9 pagesDocument Record - Account DivisionnadyaNo ratings yet

- Closing Schedule TF 28Document1 pageClosing Schedule TF 28rannuNo ratings yet

- Ministry of Housing & Urban Affairs OM No. 10/02/208-ECIV (MC) Dated 07.03.2022Document5 pagesMinistry of Housing & Urban Affairs OM No. 10/02/208-ECIV (MC) Dated 07.03.2022AlokSangwanNo ratings yet

- CETExamSchedule2021 Finall 3Document1 pageCETExamSchedule2021 Finall 3Komal PatilNo ratings yet

- Case 1 - Verceles vs. Commission On AuditDocument10 pagesCase 1 - Verceles vs. Commission On AuditJuliet Ghaile Ann BenicoNo ratings yet

- 1 Lesson Planning ICE 3171923 Odd 2021Document3 pages1 Lesson Planning ICE 3171923 Odd 2021Akhilesh NavikNo ratings yet

- CRS, Barkakana TF 2023-24Document1 pageCRS, Barkakana TF 2023-24Shubham SinghNo ratings yet

- Status of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessDocument4 pagesStatus of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessTestgame GameonlyNo ratings yet

- Đề Thi 21-8-2021 VKTCK Tiếng AnhDocument2 pagesĐề Thi 21-8-2021 VKTCK Tiếng AnhMinh ThànhNo ratings yet

- Hydrabaddec 21Document1 pageHydrabaddec 21Yakshit JainNo ratings yet

- JHKIHIHDocument1 pageJHKIHIHravenNo ratings yet

- PUBLIC NOTICE 09 August 2021 Sub - Re-Opening THDocument1 pagePUBLIC NOTICE 09 August 2021 Sub - Re-Opening THTilak NeemaNo ratings yet

- MACHINE REPAIR LOGDocument34 pagesMACHINE REPAIR LOGwikara godaiNo ratings yet

- Module 3 Audit Report 15092021Document32 pagesModule 3 Audit Report 15092021warkaoakaNo ratings yet

- Quality Control Process Chart: Prototype Pre-Launch ProductionDocument6 pagesQuality Control Process Chart: Prototype Pre-Launch ProductionMaria Katherine Cruz PantojaNo ratings yet

- 1 Methanol Injection PackagesDocument3 pages1 Methanol Injection PackagesDeffous AbdelhadiNo ratings yet

- DownloaderDocument4 pagesDownloaderAnkita ChauhanNo ratings yet

- Seminar 5 2017 6 Per PageDocument12 pagesSeminar 5 2017 6 Per PageStephanie XieNo ratings yet

- FX - 860-GA & BOM DRG No With DescriptionDocument2 pagesFX - 860-GA & BOM DRG No With Descriptionganeshcivil1984No ratings yet

- SafariDocument1 pageSafariganeshcivil1984No ratings yet

- Safari 3Document1 pageSafari 3ganeshcivil1984No ratings yet

- 4-11-2022 Supreme Court Judgement For Pension Scheme - Google SearchDocument1 page4-11-2022 Supreme Court Judgement For Pension Scheme - Google Searchganeshcivil1984No ratings yet

- Iyyappan Inst SupDocument7 pagesIyyappan Inst Supganeshcivil1984No ratings yet

- Ashrae Journal Ducting Cinema PDFDocument16 pagesAshrae Journal Ducting Cinema PDFVelram ShanmugamNo ratings yet

- APPROVED - Module 15 - Mechanical Installation in Buildings - July 09Document109 pagesAPPROVED - Module 15 - Mechanical Installation in Buildings - July 09George100% (1)

- HVAC Duct Shapes Identification and Description of Design ConfigurationDocument19 pagesHVAC Duct Shapes Identification and Description of Design ConfigurationDarwin DarmawanNo ratings yet

- Diffusers Brochure 6582Document12 pagesDiffusers Brochure 6582Michael WangNo ratings yet

- Compliance Statement - FormDocument16 pagesCompliance Statement - Formaqil khanNo ratings yet

- Prefunctional ChecklistsDocument37 pagesPrefunctional Checklistsrenjithv_4100% (1)

- Ventilation ReportDocument13 pagesVentilation ReportSwasti DixitNo ratings yet

- Som 6664411Document50 pagesSom 6664411Bouazza100% (1)

- Fountain TechnologyDocument180 pagesFountain TechnologyMirhad Pjanić100% (1)

- Fire Protection of BuildingsDocument141 pagesFire Protection of BuildingsWashington Anjichi Okang'a100% (3)

- RR-0211 Mold Causes CleanupDocument7 pagesRR-0211 Mold Causes CleanupbamboobuckNo ratings yet

- ICP Commercial - Laundry AC - 2Document31 pagesICP Commercial - Laundry AC - 2Marcos FigueroaNo ratings yet

- Powder CoatingDocument15 pagesPowder Coatinganon_778165449No ratings yet

- EagleBurgmann - Flexgen Expansion Joints - ENDocument5 pagesEagleBurgmann - Flexgen Expansion Joints - ENShirley FarraceNo ratings yet

- Designing With Structural Insulated Panels - AdvancedDocument87 pagesDesigning With Structural Insulated Panels - AdvancedhenryvargaNo ratings yet

- Get Approved HVAC Shop DrawingsDocument4 pagesGet Approved HVAC Shop DrawingsManibalanNo ratings yet

- As Flexible and Logical As You Want It. Make The Most Of: Your TimeDocument52 pagesAs Flexible and Logical As You Want It. Make The Most Of: Your TimeTomasPavlovicNo ratings yet

- Guideline On Air Handling On Food IndustryDocument6 pagesGuideline On Air Handling On Food IndustrysubirmeNo ratings yet

- UI - SC - pdf910 (SOLAS) PDFDocument360 pagesUI - SC - pdf910 (SOLAS) PDFVincent Paul SantosNo ratings yet

- 441 GC & EspDocument6 pages441 GC & EspMKPashaPashaNo ratings yet

- Maintenance Plan - ACUDocument5 pagesMaintenance Plan - ACUTESDA PasMakNo ratings yet

- MIT - Precast Floor System 1962Document159 pagesMIT - Precast Floor System 1962Nelson ChinNo ratings yet

- Damper (DAMPND12INC-B)Document10 pagesDamper (DAMPND12INC-B)Gerardo Zumbado MNo ratings yet

- 3472 Vol 2b-Pac Tech.-Spec.Document123 pages3472 Vol 2b-Pac Tech.-Spec.Satadal LahiriNo ratings yet

- VAQ Station For Climate Control: Application NotesDocument11 pagesVAQ Station For Climate Control: Application NotesAnkit JainNo ratings yet

- Baird Uc TedDocument17 pagesBaird Uc TedJeffFordNo ratings yet

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDocument40 pagesA Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsLidijaSpaseskaNo ratings yet

- Dwyer MSX - I PressureDocument1 pageDwyer MSX - I Pressureminh hoang DoanNo ratings yet

- Rotating Vane Anemometers RVA501-801 AlnorDocument2 pagesRotating Vane Anemometers RVA501-801 AlnorJhon Jaime Cardenas MonsalveNo ratings yet