Professional Documents

Culture Documents

PCTA79117

PCTA79117

Uploaded by

long chanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCTA79117

PCTA79117

Uploaded by

long chanCopyright:

Available Formats

PCTA79117

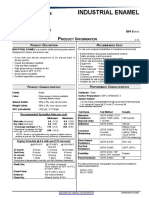

ENVIROCRON® 04 Powder Coat

Highlights Technical Properties

PPG’s Enviracryl™ and Envirocron™ Property Test Method Value

powder coatings are aesthetically pleasing,

produce a durable uniform finish and can Color __________ RAL 7035 Light Grey UD

be custom formulated with finishes from Appearance Smooth

high gloss to low gloss, and in a variety of Gloss ASTM D-523 80 Minimum @ 60°

textures. Adhesion ASTM D-3359 100% (5B Pass)

PPG’s “World Class” Ultradurable

Hardness ASTM D-3363 2H Pencil (Eagle)

Polyester Powder Coatings provide a

combination of good physical and chemical Impact Resistance ASTM D-2794 100 In.-lbs. Direct

resistance properties with excellent Conical Mandrel ASTM D-522 1/8'' Mandrel

resistance to outdoor weathering. This - No Cracking

extensive line of Polyester Powders is Salt Spray ASTM B-117 1000 Hrs. Pass

manufactured to meet the increasing <1/8'' Scribe Creep

requirement demands of the appliance and - No Blisters

industrial markets. These sophisticated

Humidity ASTM D-1735 1000 Hrs. Pass

Polyesters are the solution to your

smoothness, low-bake, durability and <1/16'' Scribe Creep

physical property requirements. An - No Blisters

unsurpassed application development

program enables consistently friendly use Film Properties were determined using 2.5 - 3.5 mils powder film over iron

on a variety of substrates. phosphated, chrome rinse pretreated, 22 gauge, unpolished cold rolled steel test

panels.

Product Features

Available in a wide range of colors and

glosses Application Data

Excellent Exterior durability Application Type: Electrostatic Spray

Good chemical resistance

Recommended Bake: 10 Minutes at 400 °F Metal Temperature

Specifically formulated to meet the

requirements of See Cure Curve PCT-001

AAMA 2604 Specific Gravity: 1.50 ± .05

Theoretical Coverage: 128 Sq. Ft. per pound at 1.0 mil

Shelf Life from Date of 80 °F Maximum - 12 Months

Manufacture (@40-60% RH):

PPG recommends that all material be used in FIFO order (first in - first out).

Materials that exceed the recommended shelf life should be tested prior to use.

* Statements and methods described herein are based upon the best information and practices known to PPG Industries, Inc. (“PPG”). Any statements or methods mentioned herein are general

suggestions only and are not to be construed as representations or warranties as to safety, performance, or results. Since the suitability and performance of the product is highly dependent on the

product user’s processes, operations, and numerous other user-determined conditions, the user is solely responsible for, and assumes all responsibility, risk and liability arising from, the determination

of whether the product is suitable for the user’s purposes, including without limitation substrate, application process, pasteurization and/or processing, and end use. No testing, suggestions or data

offered by PPG to the user shall relieve the user of this responsibility. PPG does not warrant freedom from patent infringement in the use of any formula or process set forth herein. Continuous

improvements in coatings technology may cause future technical data to vary from what is in this bulletin. Contact your PPG representative for the most up to date information.

ENVIROCRON and the PPG logo are registered trademarks of PPG Industries Ohio, Inc.

1 PPG Industries 19699 Progress Drive Strongsville, OH 44149 800-708-9678 www.ppgindustrialcoatings.com powder@ppg.com 1/11/2022

You might also like

- Jota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)Document5 pagesJota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)long chanNo ratings yet

- PCTT60146Document1 pagePCTT60146LIM YE HENGNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsAndras StegerNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- RRS8-00006 Red Superdurable Ral3001Document1 pageRRS8-00006 Red Superdurable Ral3001Jesus Antonio Zuniga MartinezNo ratings yet

- GP Resin - SpecsDocument3 pagesGP Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- En Anderol 5320 Xep 20120328Document1 pageEn Anderol 5320 Xep 20120328Shaara NeyNo ratings yet

- Product Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Document2 pagesProduct Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Ina - EdenGarden UmbrellasNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Interpon 600 Data Sheet PDFDocument1 pageInterpon 600 Data Sheet PDFLingaiyan SurenNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Interpon 600 Data SheetDocument1 pageInterpon 600 Data SheetLingaiyan SurenNo ratings yet

- Interpon 600 Data SheetDocument1 pageInterpon 600 Data SheetLingaiyan SurenNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Zylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Document3 pagesZylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Fernando Garcia HiguitaNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Pak Petrochemical: Diamond Gp-550 PDocument2 pagesPak Petrochemical: Diamond Gp-550 PzulfiqarawanNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Pyroclad X1: Selection & Specification DataDocument6 pagesPyroclad X1: Selection & Specification DataDuongthithuydungNo ratings yet

- Hdpe tds1Document1 pageHdpe tds1mrityunjaysatapatiNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pages3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNo ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiHrvoje RuzicNo ratings yet

- PDS Spheerol AP RangeDocument2 pagesPDS Spheerol AP RangeFathan AdnanNo ratings yet

- Thermo Lag - 3000 SP - PDS FireproofingDocument4 pagesThermo Lag - 3000 SP - PDS FireproofingAdil KhanNo ratings yet

- Datasheet BASF Entertite G SPF PDFDocument2 pagesDatasheet BASF Entertite G SPF PDFKhin Sandi KoNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- Exceed™ XP 8656ML: Performance PolymerDocument2 pagesExceed™ XP 8656ML: Performance PolymerCristian RodriguezNo ratings yet

- PE/P/Q FTX Serie119Document2 pagesPE/P/Q FTX Serie119havalos.durosaNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Aoc Ve F010 PDFDocument4 pagesAoc Ve F010 PDFFrancis BoeyNo ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Marpol - Coatings - Series - Tech - Specs PDFDocument12 pagesMarpol - Coatings - Series - Tech - Specs PDFYashwant RajeshirkeNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- FDS THERMOLAG 3000 P Part B - 04 2016..Document7 pagesFDS THERMOLAG 3000 P Part B - 04 2016..Ayman JadNo ratings yet

- Uws9-0g016 Pds EnglishDocument1 pageUws9-0g016 Pds EnglishTAMAYO ZAPATA WILBERTH FRANCISCONo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- Exceed S 9243MLDocument2 pagesExceed S 9243MLzhen liuNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Technical Data Sheet (ABS) - SmithsDocument1 pageTechnical Data Sheet (ABS) - SmithsKelvin Tai Wei LimNo ratings yet

- Jotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - EnglishDocument5 pagesJotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - Englishlong chanNo ratings yet

- TDS - 7-2502NS - Non-Slip Red FBEDocument1 pageTDS - 7-2502NS - Non-Slip Red FBElong chanNo ratings yet

- Nap-Gard 7-2504 Gold-Dual Powder System: Technical Data SheetDocument3 pagesNap-Gard 7-2504 Gold-Dual Powder System: Technical Data Sheetlong chanNo ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- Alkyl Halides & Aryl Halides: Victor GrignardDocument50 pagesAlkyl Halides & Aryl Halides: Victor GrignardsarahNo ratings yet

- 8.3 Reactions of Metals With OxygenDocument21 pages8.3 Reactions of Metals With Oxygendua ahmadNo ratings yet

- Module 1Document100 pagesModule 1Suhil IrshadNo ratings yet

- Plastics: ClassificationDocument6 pagesPlastics: ClassificationFortiter FysproNo ratings yet

- Kraton Polymers For Modification of Engineering ThermoplasticsDocument21 pagesKraton Polymers For Modification of Engineering ThermoplasticsAlexandra Ubaque Bedoya100% (2)

- Electron Configurations of The Elements (Data Page) - WikipediaDocument25 pagesElectron Configurations of The Elements (Data Page) - WikipediaAlex OmungaNo ratings yet

- QUARTZLOCK Two Component (EWG Series) Epoxy Grout TDS SheetDocument3 pagesQUARTZLOCK Two Component (EWG Series) Epoxy Grout TDS SheetGhulam Kibria KhanNo ratings yet

- 1995 - Davies Et Al. - Structures of Oligosaccharide-Bound Forms of The Endoglucanase V From Humicola Insolens at 1.9 Å ResolutionDocument11 pages1995 - Davies Et Al. - Structures of Oligosaccharide-Bound Forms of The Endoglucanase V From Humicola Insolens at 1.9 Å ResolutionYOTIN JUPRASONGNo ratings yet

- AMINAS2Document36 pagesAMINAS2Tania RodriguezNo ratings yet

- Colligative Properties: Engr. Yvonne Ligaya F. Musico 1Document36 pagesColligative Properties: Engr. Yvonne Ligaya F. Musico 1MoiMoi P.S.No ratings yet

- MCQs & Structure Hydrogen & Dative BondingDocument5 pagesMCQs & Structure Hydrogen & Dative BondingChristina T Z-chYnNo ratings yet

- Dictionary Org Chem PDFDocument872 pagesDictionary Org Chem PDFNutan PavitrakarNo ratings yet

- Taller de EmasasDocument18 pagesTaller de EmasasFrancisco Alejandro Rosero SeguraNo ratings yet

- Technical Data of Powder CoatingDocument1 pageTechnical Data of Powder CoatingLahore 4C2No ratings yet

- Ferrochromium: Standard Specification ForDocument3 pagesFerrochromium: Standard Specification ForleonciomavarezNo ratings yet

- Mindmap DnaDocument7 pagesMindmap Dnafresh wooNo ratings yet

- JS 1792-2008 التعداد والكشف عن البكتيريا الهوائية PDFDocument26 pagesJS 1792-2008 التعداد والكشف عن البكتيريا الهوائية PDFhiba JamalNo ratings yet

- Aiims BiochemDocument39 pagesAiims Biochemshalialoo22No ratings yet

- Expt. 8 Salivary DigestionDocument25 pagesExpt. 8 Salivary DigestionLESLIE JANE BALUYOS JALANo ratings yet

- 5.3 Stiochiometry QP - Igcse Cie Chemistry - Extended Theory PaperDocument3 pages5.3 Stiochiometry QP - Igcse Cie Chemistry - Extended Theory PaperWaseem AhmedNo ratings yet

- TYPES 2N1671, 2N1671A, 2N1671B, 2N2160 P-N Grown Silicon Unijunction TransistorDocument1 pageTYPES 2N1671, 2N1671A, 2N1671B, 2N2160 P-N Grown Silicon Unijunction Transistorluis.sinatoNo ratings yet

- CHEM201 FinalExam AnswersDocument16 pagesCHEM201 FinalExam AnswersGlenn Farah Faye RausaNo ratings yet

- Molecular Shape and Molecular PolarityDocument15 pagesMolecular Shape and Molecular PolaritySonny Boy SajoniaNo ratings yet

- Final Thesis by Fawad AhmadDocument74 pagesFinal Thesis by Fawad AhmadShahab ShafiNo ratings yet

- CBSE-Cls6-Separation of Substances NotesDocument12 pagesCBSE-Cls6-Separation of Substances NotesPankaj KumarNo ratings yet

- 10 Science Hindi SM 2024Document256 pages10 Science Hindi SM 2024akarshkumar579No ratings yet

- High-Surface-Area Porous Carbons Produced by The MildDocument10 pagesHigh-Surface-Area Porous Carbons Produced by The MildRishyavandhan VNo ratings yet

- Fuel Engineering ManualDocument42 pagesFuel Engineering Manualmaz zlsNo ratings yet

- Genral Science Notes For Grade SeventhDocument52 pagesGenral Science Notes For Grade SeventhZohaib AhmadNo ratings yet

- Synthesis of Vitamin D (Calciferol) - Application of Pericyclic ReactionDocument4 pagesSynthesis of Vitamin D (Calciferol) - Application of Pericyclic ReactionSubhro ChatterjeeNo ratings yet