Professional Documents

Culture Documents

IG Maint

Uploaded by

ssabih750 ratings0% found this document useful (0 votes)

8 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageIG Maint

Uploaded by

ssabih75Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

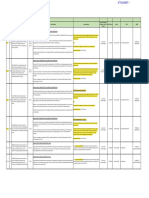

Suggested maintenance programme Component Preventive maintenance

Component Preventative Maintenance Maintenance Interval

Operate the valve Before start up and one week

Flue Gas

Cleaning with Compressed air or steam Before operating the valve

Isolating Valves

Dismantling for inspection and cleaning Boiler shutdown

Water flush After use

Cleaning of demister Three months

Flue Gas

Scrubber Dismantling of level regulators and

Six months

temperature probes for inspection.

Opening for full internal inspection Dry-Docking

Flushing with scrubber water pump for

After use

Overboard pipes and about one hour

valve Dismantling of the valve for overhaul,

from flue gas scrubber. inspection of the pipeline and overboard Dry-docking/repair period

end.

Vibration check While running

Flushing After use

Blowers Internal inspection through hatches After flushing and six months

Dismantling for full overhaul of bearings,

Two years or more frequently if

shaft tightenings and other necessary

required/dry docking

work.

Dismantling of level regulators/float

Six months

valves for inspection

Deck water seal

Opening for total internal inspection One year

Overhaul of auto-valves One year

Moving and lubricating the valve as

Deck mechanical One week and before start

necessary

non-return valve

Opening for internal inspection One year/18 months

Pressure/ Vacuum Operating and lubricating the valves Six months

valves Opening for full overhaul and inspection One year

Deck Isolating Valve Opening for overhaul One year

Removal of condensation in instrument,

Before start

Gas Pressure regulating air supply

system Opening of gas pressure regulating valves

As appropriate

for overhaul

Liquid-filled pressure/ Check liquid level when system is at When opportunity permits and

vacuum breaker atmospheric pressure every six months

You might also like

- Autoclave Maintenance ScheduleDocument3 pagesAutoclave Maintenance ScheduleWaseem TariqNo ratings yet

- NFPA 25 Maintenance and Service KitsDocument1 pageNFPA 25 Maintenance and Service KitsNaing Win TunNo ratings yet

- Maintenance R1Document45 pagesMaintenance R1Juan LaitonNo ratings yet

- Safety Relief Valves - Installation and MaintenanceDocument3 pagesSafety Relief Valves - Installation and MaintenanceBramJanssen76No ratings yet

- Proceso de MuestreoDocument7 pagesProceso de MuestreoAnonymous F2Q7hAtscNo ratings yet

- Baghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesDocument2 pagesBaghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesALI TAVAKOLINIANo ratings yet

- Inspection Testing Maint Fire Protection Equipment Frequency MatrixDocument1 pageInspection Testing Maint Fire Protection Equipment Frequency Matrixمحمد ارشاد شاہNo ratings yet

- Maintenance Autoclave ScheduleDocument2 pagesMaintenance Autoclave Scheduleamanuel waleluNo ratings yet

- Lathe Maintenance ScheduleDocument4 pagesLathe Maintenance ScheduleMohamed ShaabanNo ratings yet

- N-Series High Speed Gear Long-Term Maintenance PlanDocument8 pagesN-Series High Speed Gear Long-Term Maintenance PlanErnani MesquitaNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- Mirrlees Diesels BlackstoneDocument12 pagesMirrlees Diesels Blackstoneophar100% (1)

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Pulse Jet Cleaning Collectors Preventative MaintenanceDocument2 pagesPulse Jet Cleaning Collectors Preventative Maintenanceehsan.aziziNo ratings yet

- Controles de Materia ParticuladaDocument1 pageControles de Materia ParticuladaItalo VaccaroNo ratings yet

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- Manual Mantenimiento Compresor QR25 Modelo 325Document13 pagesManual Mantenimiento Compresor QR25 Modelo 325Rafa D'voxNo ratings yet

- Fuel Oil PurifierDocument21 pagesFuel Oil PurifierJakee PB50% (2)

- Tips For InspectionDocument31 pagesTips For Inspectionali morisyNo ratings yet

- The Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarDocument5 pagesThe Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarMohamed IbrahimNo ratings yet

- Maintaining Valves The Right Way: by Nwaoha Chikezie of CASEIDocument2 pagesMaintaining Valves The Right Way: by Nwaoha Chikezie of CASEIRajibNo ratings yet

- 5i Lub Conversion ProceduresDocument2 pages5i Lub Conversion Proceduresfmk342112No ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- Service Manual: 311D LRR ExcavatorDocument46 pagesService Manual: 311D LRR ExcavatorBuku Digital50% (2)

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USDocument9 pagesPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardeNo ratings yet

- Wartsila - 18V34SG Maintenance ScheduleDocument8 pagesWartsila - 18V34SG Maintenance ScheduleironiteNo ratings yet

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Tolias EgwNo ratings yet

- Assignment 1: College of Engineering and TechnologyDocument5 pagesAssignment 1: College of Engineering and TechnologyTshepho Ketshepha KeisangNo ratings yet

- Valve InspectionDocument5 pagesValve InspectionLipika Gayen100% (1)

- Maintenance Schedule QDT425+Document2 pagesMaintenance Schedule QDT425+Naveedullah AwanNo ratings yet

- 24.2 Oxygen System Pipework, Valves and Relevant Fittings: When NewDocument1 page24.2 Oxygen System Pipework, Valves and Relevant Fittings: When NewAnthony KotianNo ratings yet

- Sampling Intervals and Locations by Equipment TypeDocument2 pagesSampling Intervals and Locations by Equipment Typejuanmanuel_4615958No ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- En Purge Systems DatasheetDocument2 pagesEn Purge Systems DatasheetFitri MuliaNo ratings yet

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDocument51 pagesSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102No ratings yet

- Maintenance of Absorption Column and Stripping ColumnsDocument2 pagesMaintenance of Absorption Column and Stripping ColumnsJoseph OrjiNo ratings yet

- Overhaul of PurifierDocument37 pagesOverhaul of PurifierSayem kaif100% (1)

- Check List For Water Mist Water Spray and Sprinkler SystemDocument1 pageCheck List For Water Mist Water Spray and Sprinkler Systemefendi kaptanNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- Sludge Pump - SVIB - 4 - 1058906028 - 1818114 - 02 - v1Document16 pagesSludge Pump - SVIB - 4 - 1058906028 - 1818114 - 02 - v1wilson chaconNo ratings yet

- PS 3 Generac O&M WW-Sección 4 MantenimientoDocument15 pagesPS 3 Generac O&M WW-Sección 4 MantenimientoRobertNo ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance ScheduleHải TạNo ratings yet

- DPC 2802 Startup ProcedureDocument6 pagesDPC 2802 Startup ProcedureMuhammad Asad100% (1)

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-22Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-22Tolias EgwNo ratings yet

- Gravel Bed Filters: Learner GuideDocument31 pagesGravel Bed Filters: Learner GuideRobson DE Freitas WerlingNo ratings yet

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceDocument1 pagePreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- G3606 Scope of WorkDocument1 pageG3606 Scope of Workfleetservicevzla.avazquezNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Chapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsDocument16 pagesChapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsГоран ГорановNo ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance Scheduleadel allamNo ratings yet

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNo ratings yet

- PM Schedule For Bag FilterDocument2 pagesPM Schedule For Bag FilterNad DaniNo ratings yet

- Manual For Jackup Refrigeration SystemDocument134 pagesManual For Jackup Refrigeration Systemcastropedro2002No ratings yet

- Vakve Pressure TestingDocument11 pagesVakve Pressure TestingShubhajit ChakrabortyNo ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- 094135-VP-N2-GE-SPC-001-001 - DryerDocument13 pages094135-VP-N2-GE-SPC-001-001 - Dryerphuoc leNo ratings yet

- Maintenance Préventive Du SULLAIR 260Document17 pagesMaintenance Préventive Du SULLAIR 260MMF PLUSNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Anti Poll Locker Inv ClistDocument1 pageAnti Poll Locker Inv Clistssabih75No ratings yet

- Authorisation For Operation of Lifting Appliances and MoorinDocument1 pageAuthorisation For Operation of Lifting Appliances and Moorinssabih75No ratings yet

- Anti Pollution Locker InventoryDocument2 pagesAnti Pollution Locker Inventoryssabih75No ratings yet

- Apr09 StabDocument3 pagesApr09 Stabssabih75No ratings yet

- MMD KarachiDocument3 pagesMMD Karachissabih75No ratings yet

- Ballast Line Testing ProcedureDocument1 pageBallast Line Testing Proceduressabih75No ratings yet

- Masters OralsDocument74 pagesMasters Oralsssabih75No ratings yet

- Prod Carriers and IGDocument1 pageProd Carriers and IGssabih75No ratings yet

- Danger Message Solas ch.5 Reg 31 and 32Document2 pagesDanger Message Solas ch.5 Reg 31 and 32PL BALASUBRAMANIANNo ratings yet

- Topic 7 Ship Ship InteractionDocument13 pagesTopic 7 Ship Ship Interactionssabih75No ratings yet

- Topic 5 Effect of UKC On Ship ManoeuvringDocument22 pagesTopic 5 Effect of UKC On Ship Manoeuvringssabih75No ratings yet

- Topic 4 Prediction Techniques and Comparison With MeasurementsDocument34 pagesTopic 4 Prediction Techniques and Comparison With Measurementsssabih75No ratings yet

- Topic 3 Initial Trim, Propulsion, Variable DepthDocument19 pagesTopic 3 Initial Trim, Propulsion, Variable Depthssabih75No ratings yet

- Topic 8 Tug Ship InteractionDocument8 pagesTopic 8 Tug Ship Interactionssabih75No ratings yet

- Topic 1 IntroductionDocument23 pagesTopic 1 Introductionssabih75No ratings yet

- Safe Carriage of Iron OreDocument4 pagesSafe Carriage of Iron Oressabih75No ratings yet

- Inert Gas Systems 1990Document93 pagesInert Gas Systems 1990Polaris BridgemanNo ratings yet

- STCWDocument2 pagesSTCWssabih75No ratings yet

- Slops RecordDocument1 pageSlops Recordssabih75No ratings yet

- Safe BerthDocument1 pageSafe Berthssabih75No ratings yet

- H05e.2 Accepting Salvage Assistance: E-Mail or Other Form of Communication by Sending A Message As FollowsDocument2 pagesH05e.2 Accepting Salvage Assistance: E-Mail or Other Form of Communication by Sending A Message As Followsssabih75No ratings yet

- NPSHDocument1 pageNPSHssabih75No ratings yet

- Safe PortDocument2 pagesSafe Portssabih75No ratings yet

- GA ActsDocument1 pageGA Actsssabih75No ratings yet

- Anchor TerminologyDocument3 pagesAnchor Terminologyssabih75No ratings yet

- RegistrstionDocument3 pagesRegistrstionssabih75No ratings yet

- P&I ClubDocument2 pagesP&I Clubssabih75No ratings yet

- Oil DischargeDocument1 pageOil Dischargessabih75No ratings yet

- F07b.1 Outline of Bill of Lading Functions: Procedures Used in Tramp and Liner Shipping Operations, As Outlined BelowDocument1 pageF07b.1 Outline of Bill of Lading Functions: Procedures Used in Tramp and Liner Shipping Operations, As Outlined Belowssabih75No ratings yet

- Portfolio Vacuum ProcedureDocument2 pagesPortfolio Vacuum ProcedureAli SalmanNo ratings yet

- KS-SE3 SEL 80 (950rpm, 320mm) Data Sheet-Treated EffluentDocument1 pageKS-SE3 SEL 80 (950rpm, 320mm) Data Sheet-Treated EffluentJaeni GilangNo ratings yet

- Major Losses: Due To Friction, Significant Head Loss Is Associated With The StraightDocument2 pagesMajor Losses: Due To Friction, Significant Head Loss Is Associated With The StraightVarun ShastryNo ratings yet

- File 000004Document291 pagesFile 000004Tripoli ManoNo ratings yet

- BlowerDocument45 pagesBlowerVeky PamintuNo ratings yet

- Hydrodesulfurization Unit For Natural Gas Condensate: Simulation Based On Aspen Plus SoftwareDocument8 pagesHydrodesulfurization Unit For Natural Gas Condensate: Simulation Based On Aspen Plus Softwaremohsen ranjbarNo ratings yet

- THE MACHMETER Chapter 6Document3 pagesTHE MACHMETER Chapter 6RaghavendraSingh100% (1)

- Comments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplyDocument2 pagesComments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplybecpavanNo ratings yet

- Matsunaga Thesis PDFDocument50 pagesMatsunaga Thesis PDFdedi sanatraNo ratings yet

- Pamphlet 60 - Edition 7 - Aug 2013 PDFDocument28 pagesPamphlet 60 - Edition 7 - Aug 2013 PDFmonitorsamsungNo ratings yet

- Camarines Norte State College: College of Engineering SummDocument1 pageCamarines Norte State College: College of Engineering Summshuckss taloNo ratings yet

- Major Ammonia Leak From HP Ammonia Feed Pump1Document2 pagesMajor Ammonia Leak From HP Ammonia Feed Pump1Rana ImtiazNo ratings yet

- Christmas TreeDocument5 pagesChristmas TreeBalanNo ratings yet

- Flow Measurement Lecture 1Document37 pagesFlow Measurement Lecture 1Rahul KalraNo ratings yet

- Ws 2016 13-Pdf-EnDocument2 pagesWs 2016 13-Pdf-EnMuhammadUsmanSaeedNo ratings yet

- Engineers India Limited Allowable Nozzle Loads Specification REV 6588-7-12-0038 0Document5 pagesEngineers India Limited Allowable Nozzle Loads Specification REV 6588-7-12-0038 0darshanNo ratings yet

- ThermoDocument2 pagesThermoDamdam Sacil0% (2)

- LNG BC D 3.2 Gas QualityDocument48 pagesLNG BC D 3.2 Gas QualityAmin RoisNo ratings yet

- 13 10 21Document18 pages13 10 21અનુરુપ સોનીNo ratings yet

- Ped Guidelines PDFDocument261 pagesPed Guidelines PDFariffabusemanNo ratings yet

- Assessment of Valve FailuresDocument57 pagesAssessment of Valve FailuresSergioUlises100% (1)

- Course Task 8 PresentationDocument9 pagesCourse Task 8 PresentationJON EDWARD ABAYANo ratings yet

- Soal UAS ATK 1 2022 - 2023 D3 TKDocument2 pagesSoal UAS ATK 1 2022 - 2023 D3 TKKhalimatus SadiyahNo ratings yet

- Blank Sticker Tabs TemplateDocument3 pagesBlank Sticker Tabs TemplateHina OdaNo ratings yet

- Interface HAZOP List From EPC HAZOP Action (Unit 323)Document1 pageInterface HAZOP List From EPC HAZOP Action (Unit 323)MAHMUDNo ratings yet

- Exacoc DatasheetDocument1 pageExacoc DatasheetThein TunNo ratings yet

- Bab 1 SolutionsDocument37 pagesBab 1 SolutionsNgọc HuyềnNo ratings yet

- Questions Only. Questions (1) and (3) Are Mandatory. QuestionDocument3 pagesQuestions Only. Questions (1) and (3) Are Mandatory. QuestionElzubair EljaaliNo ratings yet

- Price List Senso OilDocument1 pagePrice List Senso Oilsangga kusumanagara jati saputraNo ratings yet