Professional Documents

Culture Documents

Llilllr, Enonaronrns: FTCTD

Uploaded by

Lupita ReyesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Llilllr, Enonaronrns: FTCTD

Uploaded by

Lupita ReyesCopyright:

Available Formats

r ftctD

ll;\

I VL'

llilllr,enonaronrns I ril I illorr!il!

( r'rri6{$rt llll +l

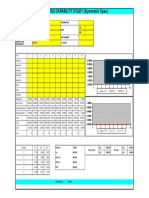

Client: Thousand Oaks Optical Date: 05 November 2015

3997 Airway Ave. Report: T10330-01-l

Kingman, AZ 86401 Issue: 1

USA Page: I of2

Objective:

Contract testing to I SO I 23 I 2-2:201 5(E) "Eye and face protection Sunglasses and related eyewear Part 2:

Filters for direct observation ofthe sun".

- -

Clauses: 4.1 Transmittance-General

4.2 Material and surface qualitY

Samples:

Black Polvmer Film with Reflective Coati

Lot # Description Ouantitv Sample ID

I 0021 5 Plastic Film 8.5" x I l" x 0.002" 0A-l

Date(s) submitted: 30 October 2015

Procedures:

Testing protocols in accord with good laboratory practice were employed for all tests.

All tests were conducted in a standard laboratory atmosphere unless otherwise specified.

Two pieces were cut from sample provided and measured'

Assessment Summary:

Date(s) tested: 03 November 20 l5

ISO 123 12-2:20l5( E) Requirements Comoliant Non-Compliant

4 Reouirements and associated test methods

4.1 Transmittance

4.1 .l General

4.2 Material and surface qualitY

IC$

lltrGft,enoneronrns l.{ I ill1{r{iil\

( r'rlifirr1.: ,l::.111

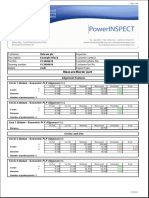

Client: Thousand Oaks Optical Date: 05 November 201 5

3997 Airway Ave. Report: T10330-01-l

Kingman, AZ 86401 Issue: I

USA Page: 2 of2

Results:

4.1.1 Transmittance-General

Sample ID: 0A-1a 0A-lb Reouiremenl

Luminous (rv) (%) 0.00021 0.0002 r 0.000061 to 0.0032

280 to 3l5nm (rsuvs ) (7o) < 0.0001 < 0.000 t :IV

3|5 to 380nm (rsrrr r. ) (%o) < 0.0001 < 0.0001 rTV

780 to 2000nm (tsrn ) (%) 0.01 6 0.01 7 1J

Pass/Fail Pass

0.10

0.09

d4

0.0E s ff

..ss-

0.01

0

? 0.06

--d

-**

0.05

d_

G

L

0.04

0.03

d

0_o?

sfq

0.01

0.00

100 400 600 800 1000 1200 i400 i600 1800 2000

Wavelength {nm)

-0A-1a -0A-1b

Note: Noisc between 800 and 900nm is due to the detector changeover o1'the instrument and not a feature ofthe samplcs

measurcd

4.2.1 Filter material and surface quality; Result: Pass

Requirement: Except in a maiginal-area 5 mm wide, filters shall be free from defects likely to impair vision in use,

such as bubblcs, ,".ot"lr"r, inclusions, dull spots, pitting, scouring, pocking, scaling, and undulations. Metal

coated filter materials shall not exhibit more than one pinhole defect not greater than 200 pm in average

diameter within any 5 mm diameter circular zone.

Estimates of Uncertainties:

ISO I 23 I I :201 3( E) Test Method E,stimated Uncertainty

7.1.1 Measurement of spectral transmittance

0.0032% to 0.000061% 0.987o Relative

t"tit".t"d have been calculate in accordance with the principles of ISO/lEC Guide 98-3:2008.

Uncertainty""c.tt"irtics

ofmeasurement-Part 3: Guide to the expression ofuncertainty in measurement

(GIJM: I 995).

Estimated uncertainties have a 95%o confidence level

A coverage factor (k) of2.0 was used.

You might also like

- Brammer Standard Company, Inc.: Certificate of AnalysisDocument7 pagesBrammer Standard Company, Inc.: Certificate of AnalysisDuong phamNo ratings yet

- Brammer Standard Company, Inc.: Certificate of AnalysisDocument6 pagesBrammer Standard Company, Inc.: Certificate of AnalysisBala guruNo ratings yet

- Schottky Barrier Rectifiers 20 To 40 Volt 1 Ampere: Voltage CurrentDocument4 pagesSchottky Barrier Rectifiers 20 To 40 Volt 1 Ampere: Voltage CurrentalexsanNo ratings yet

- Refractive Index of SF5 - SCHOTTDocument3 pagesRefractive Index of SF5 - SCHOTTJoseph007bstNo ratings yet

- Utl 001 002 PDFDocument2 pagesUtl 001 002 PDFfreeman11072000No ratings yet

- DiferentialDocument3 pagesDiferentialArip SaepudinNo ratings yet

- Fluid Lab 2021 SheetDocument4 pagesFluid Lab 2021 SheetOsmanli soonNo ratings yet

- 1211pd03-Pl-1211-01027a (Filler Rod Electrode)Document3 pages1211pd03-Pl-1211-01027a (Filler Rod Electrode)HanifZawawiNo ratings yet

- Chemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022Document3 pagesChemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022MAHESH BELENo ratings yet

- PB Arang Aktif 11032020 BDocument2 pagesPB Arang Aktif 11032020 BSiti Sarifa YusuffNo ratings yet

- University of Southampton Research Repository Eprints SotonDocument48 pagesUniversity of Southampton Research Repository Eprints SotonreenaNo ratings yet

- NHSB046T: Specifications For Blue LedDocument17 pagesNHSB046T: Specifications For Blue LedbobbbNo ratings yet

- FAULTS A Program For Refinement of StructuresDocument17 pagesFAULTS A Program For Refinement of StructuresKiki Rezki LestariNo ratings yet

- India Test House: SAMPLE: Steels For Piston Pins MEASURAND: Chromium TEST METHOD: IS 228 (Part 6) : 1987 (RA 2018)Document2 pagesIndia Test House: SAMPLE: Steels For Piston Pins MEASURAND: Chromium TEST METHOD: IS 228 (Part 6) : 1987 (RA 2018)Gaurav KumarNo ratings yet

- MTC For E-7018Document2 pagesMTC For E-7018Babar Manzoor Ghauri100% (1)

- Ball Bounce TutorialDocument15 pagesBall Bounce TutorialMangisi Haryanto ParapatNo ratings yet

- Icp N70Document6 pagesIcp N70saul camposNo ratings yet

- LDR Orp12Document2 pagesLDR Orp12Faulhaber AdrianNo ratings yet

- Lab 1Document22 pagesLab 1simran goelNo ratings yet

- Pea GravelDocument1 pagePea GravelATC SurveyNo ratings yet

- Le Cle I Re Foucault Final BDocument6 pagesLe Cle I Re Foucault Final BdanyNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Universal OD Grinding - No PlanDocument1 pageUniversal OD Grinding - No PlanAzhar ImamNo ratings yet

- BQ 01/02/07/06/05/04: Lead Free: BF 01/02/07/06/05/04: Radial LeadsDocument4 pagesBQ 01/02/07/06/05/04: Lead Free: BF 01/02/07/06/05/04: Radial LeadsElectronicos CaldasNo ratings yet

- Beam B9 ResultsDocument3 pagesBeam B9 ResultsVinh DuongNo ratings yet

- Photovoltaic Infrared Sensor: General DescriptionDocument6 pagesPhotovoltaic Infrared Sensor: General DescriptionPreventa FibersideNo ratings yet

- Annual Protection Maintenance On 10MVA Transformer T1 at Chavuma Substation - 2022Document17 pagesAnnual Protection Maintenance On 10MVA Transformer T1 at Chavuma Substation - 2022Friday HaankumbaNo ratings yet

- Project: Hw2 Beam Deflections (Extreme Rows Only)Document3 pagesProject: Hw2 Beam Deflections (Extreme Rows Only)Ali Ib TarshaNo ratings yet

- K1010 Series: CosmoDocument11 pagesK1010 Series: CosmoAsad IqbalNo ratings yet

- (Primero) BallParam DirectDocument52 pages(Primero) BallParam DirectMeyer de la CruzNo ratings yet

- Cataloge of DengFeng Weld PDFDocument143 pagesCataloge of DengFeng Weld PDFLeo SembiringNo ratings yet

- Ballparam DirectDocument47 pagesBallparam DirectalinoriNo ratings yet

- Site Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Document6 pagesSite Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Gajendran SriramNo ratings yet

- General EBridge InglesDocument64 pagesGeneral EBridge InglesCarlos GutiérrezNo ratings yet

- 33kV EF - Ovt:: Test Object - Overcurrent ParametersDocument3 pages33kV EF - Ovt:: Test Object - Overcurrent ParametersSandamali SanchalaNo ratings yet

- Asset Condition Monitoring Techniques Concemino 060712 PDFDocument49 pagesAsset Condition Monitoring Techniques Concemino 060712 PDFAnonymous OFwyjaMy100% (1)

- Job Information: Job No Sheet No RevDocument95 pagesJob Information: Job No Sheet No RevANKESH SHRIVASTAVANo ratings yet

- Pressure Sheet 2010Document29 pagesPressure Sheet 2010Imad AghilaNo ratings yet

- Adobe Scan 12 Sep 2023Document1 pageAdobe Scan 12 Sep 2023salebratoNo ratings yet

- Meas Ure:mas Ter PartDocument6 pagesMeas Ure:mas Ter PartMartin huntNo ratings yet

- Tutorial 2Document5 pagesTutorial 2Trần Trung KiênNo ratings yet

- +K01 FinalDocument94 pages+K01 FinalMERLYNNo ratings yet

- Naca 0012Document10 pagesNaca 0012Ricardo TatamuesNo ratings yet

- Spectrum Peak Pick Report: Data Set: File - 190123 - Ukom Ida - RawdataDocument6 pagesSpectrum Peak Pick Report: Data Set: File - 190123 - Ukom Ida - RawdataRezky Putra PratamaNo ratings yet

- Nitrit Hasil BackupDocument1 pageNitrit Hasil Backupsalahuddin ayyubiNo ratings yet

- Slides Doping ProfileDocument36 pagesSlides Doping Profileombraga1896No ratings yet

- Sebutkan Dan Jelaskan Macam Macam Lambang Alat Ukur Dan Hitung Kelas Alat Ukurnya..Document10 pagesSebutkan Dan Jelaskan Macam Macam Lambang Alat Ukur Dan Hitung Kelas Alat Ukurnya..Bonaventura BerlianNo ratings yet

- Experiment No. - 7 EXPERIMENT NAME: Measurement of Capacitance by de Sauty's Modified Bridge TheoryDocument3 pagesExperiment No. - 7 EXPERIMENT NAME: Measurement of Capacitance by de Sauty's Modified Bridge TheoryDibyajit Sen100% (3)

- 7 Paul Stanton Api Standard 2rdcDocument20 pages7 Paul Stanton Api Standard 2rdcresp-ectNo ratings yet

- Size Effects of Reinforced Concrete Beams in ShearDocument8 pagesSize Effects of Reinforced Concrete Beams in ShearYosNo ratings yet

- WTG-25 L1Document41 pagesWTG-25 L1IvanNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Susgar Csube RselayDocument2 pagesSusgar Csube RselayMarudhasalamMarudhaNo ratings yet

- Scope:: About The Ballparam - Reverse Spreadsheet ..Document55 pagesScope:: About The Ballparam - Reverse Spreadsheet ..Monica Carolina Tobar BastiasNo ratings yet

- Training Course: XL2 800 & XL2 980Document153 pagesTraining Course: XL2 800 & XL2 980Utw InspeçõesNo ratings yet

- Bobinas SMD YOSONIC TECHNOLOGYDocument113 pagesBobinas SMD YOSONIC TECHNOLOGYGerardo MediabillaNo ratings yet

- Sia MoDocument1 pageSia MoDeepak BhatiNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- 1490882846Document28 pages1490882846Tucciy Alentine MaeNo ratings yet

- Verbal and Nonverbal CommunicationL2Document10 pagesVerbal and Nonverbal CommunicationL2margilyn ramosNo ratings yet

- QI-WEEK 4-ADM BasedDocument10 pagesQI-WEEK 4-ADM BasedMarloCris ToqueroNo ratings yet

- Free Span & FatigueDocument53 pagesFree Span & FatigueaddypurnamaNo ratings yet

- Individual Personality and Its Effect On Team ProductivityDocument9 pagesIndividual Personality and Its Effect On Team Productivitystephen olowoNo ratings yet

- Aerodynamic and Flow Characteristics of Tall Buildings With Various Unconventional ConfigurationsDocument16 pagesAerodynamic and Flow Characteristics of Tall Buildings With Various Unconventional ConfigurationsVinay GoyalNo ratings yet

- Fret Position Calculator - Stewmac CavaquinhoDocument1 pageFret Position Calculator - Stewmac CavaquinhoJosé Luiz Magalhães de CarvalhoNo ratings yet

- Science-9 q4 Mod5 Heat and WorkDocument20 pagesScience-9 q4 Mod5 Heat and WorkEden Cabarrubias86% (7)

- LESSON 7 Thesis Statement Topic Sentence and Supporting DetailsDocument23 pagesLESSON 7 Thesis Statement Topic Sentence and Supporting DetailsDennis EmNo ratings yet

- Morph Elegant Powerpoint TemplateDocument6 pagesMorph Elegant Powerpoint TemplateAl FaritsiNo ratings yet

- CM2 CFS100 2002 04Document32 pagesCM2 CFS100 2002 04Akmal ZuhriNo ratings yet

- Theories On Human DevelopmentDocument42 pagesTheories On Human DevelopmentHANS CHRISTIAN DELOS REYESNo ratings yet

- Day 02 ESP Basic Design and Operational FactorsDocument113 pagesDay 02 ESP Basic Design and Operational FactorsMustafa Abdel-WahabNo ratings yet

- NDT Question and AnswerDocument11 pagesNDT Question and AnswerNina Aziz100% (1)

- Electrical Method PDFDocument65 pagesElectrical Method PDFVioleta Reyes OrozcoNo ratings yet

- Papyrus History Lesson by SlidesgoDocument15 pagesPapyrus History Lesson by SlidesgoLIZA LOREJONo ratings yet

- 2.4 Electrical DrawingDocument141 pages2.4 Electrical DrawingFurqoni Bulan RizkiNo ratings yet

- Civil Engineering Laws and Ethics in The PhilippinesDocument16 pagesCivil Engineering Laws and Ethics in The PhilippinesMonde Nuylan90% (48)

- AcknowledgmentsDocument268 pagesAcknowledgmentsleonard andrewNo ratings yet

- Outcomes Advanced TB Review Test 2 PDFDocument3 pagesOutcomes Advanced TB Review Test 2 PDFВиктория ЛысенкоNo ratings yet

- Unesco 5 Pillars For EsdDocument6 pagesUnesco 5 Pillars For EsdMary Lois Dianne TinaNo ratings yet

- Lesson Plan in Mathematics VI AicelDocument3 pagesLesson Plan in Mathematics VI AicelRoderick GatdulaNo ratings yet

- Creating A UML Design From Scratch - Object Model + Class DiagramDocument1 pageCreating A UML Design From Scratch - Object Model + Class DiagramHoang Nhu VinhNo ratings yet

- Lec# 16 Breakdown in LiquidsDocument12 pagesLec# 16 Breakdown in LiquidsVishal MeghwarNo ratings yet

- 7728 ID Optimasi Dosis Pupuk Nitrogen Dan Fosfor Pada Tanaman Kelapa Sawit Elaeis GuineeDocument7 pages7728 ID Optimasi Dosis Pupuk Nitrogen Dan Fosfor Pada Tanaman Kelapa Sawit Elaeis GuineeHdyt FFNo ratings yet

- Lesson 3.2. Chemical Reactors Design PDFDocument28 pagesLesson 3.2. Chemical Reactors Design PDFJulia Vago EncinaNo ratings yet

- Chap02 PDFDocument32 pagesChap02 PDFAzalia Delgado VeraNo ratings yet

- Chapter 15 Air: Class ViDocument24 pagesChapter 15 Air: Class ViAasthaNo ratings yet

- Jacketse: An Offshore Wind Turbine Jacket Sizing Tool: Theory Manual and Sample Usage With Preliminary ValidationDocument67 pagesJacketse: An Offshore Wind Turbine Jacket Sizing Tool: Theory Manual and Sample Usage With Preliminary ValidationAlexandru SimionNo ratings yet

- FIRST QUARTER-3rd Summative TestDocument4 pagesFIRST QUARTER-3rd Summative TestLordy Picar100% (2)