Professional Documents

Culture Documents

DNFT Installation

Uploaded by

Saleh Alomari0 ratings0% found this document useful (0 votes)

3 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesDNFT Installation

Uploaded by

Saleh AlomariCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

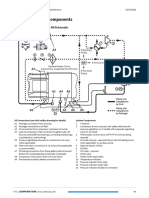

JG-JGA Maintenance & Repair Manual – Instrumentation 01/27/2023

DNFT Installation remove magnet housing. Do not remove

magnet, spring, or spacer from magnet

Figure: Typical DNFT Magnet Assemblies housing.

2. Remove piston enclosure plug from the end

of desired divider valve. The DNFT installs on

any of the divider valves of the divider block.

The DNFT requires the correct magnet

assembly to match the divider valve

manufacturer.

NOTE: Do not install a DNFT on Lincoln divider valves

with cycle indicator pins.

3. If applicable, verify O-ring or metal gasket is

in place on magnet housing. Thread magnet

housing into the end of the divider valve.

Torque to 15 lbs x ft (20 N•m) maximum.

4. Slide DNFT all the way onto hex of magnet

housing. Torque Allen set screws on the hex

1 Trabon Style O-ring Seal 7/16-20 of magnet housing to 25 lbs x inch, (2.8 N•m)

2 Trabon Metal Gasket Seal 7/16-20 (1994 or earlier) maximum.

3 Lincoln O-Ring Seal 7/16-20 Extended Nose 5. The LED on the DNFT indicates each divider

valve cycle to allow lubricator pump

Figure: Typical DNFT Installation adjustment for Ariel recommended cycle

time and oil consumption. If the LED fails to

blink during compressor operation or by

manually pumping oil into the divider valve,

then the DNFT requires adjustment.

6. The divider valve must cycle during DNFT

adjustment. To cycle, either run the

compressor or manually pump oil through

the distribution block with a purge pump.

7. To adjust, slide DNFT all the way onto hex of

magnet housing. Tighten Allen set screws to

1 Divider Valve Piston 25 lbs x inch (2.8 N•m) maximum. A blinking

2 Magnet

LED indicates correct adjustment. If the LED

fails to blink with divider valve cycling, slide

3 Magnet Housing

DNFT back on the hex of the magnet housing

4 Set Screws (2)

in 1/16" increments until it does.

5 LED

6 Control Housing 8. Make all conduits and connections

7 Wire Leads appropriate for area classification. Insulate

8 O-Ring

unused wires from the ground, other wires,

and the case. Support conduit and fittings to

9 Divider Valve

avoid bending the magnet housing.

10 Piston Enclosure Plug

1. Loosen the Allen set screws on the DNFT and

ARIEL CORPORATION | www.arielcorp.com 17

JG-JGA Maintenance & Repair Manual – Instrumentation 01/27/2023

9. After DNFT installation and before

compressor start-up, purge all air from the

divider block lubrication system with a purge

pump.

NOTE: When installing multiple DNFTs, wire each to a

separate alarm circuit of the control panel, annunci-

ator, or PLC to simplify lubrication system and DNFT

troubleshooting. Always secure the green ground

wire to "earth ground" in the control panel. Do not

ground to electrical conduit or skid. Improper

grounding can result in unreliable monitor operation.

Figure: A-10754 Programmable DNFT Wiring Connections for Unit in Operation

Figure: A-10753 and A-10772 DNFT Wiring Connections for Unit in Operation

Figure: A-20513 24 VDC Programmable DNFT Wiring Connections for Unit in Operation

ARIEL CORPORATION | www.arielcorp.com 18

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Digital No Flow Timer (DNFT)Document6 pagesDigital No Flow Timer (DNFT)Oscar MonteroNo ratings yet

- Transistor Switching and Sequential CircuitsFrom EverandTransistor Switching and Sequential CircuitsRating: 5 out of 5 stars5/5 (1)

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- ER-105-3 Digital No-Flow Timer (DNFT)Document8 pagesER-105-3 Digital No-Flow Timer (DNFT)EzequielNo ratings yet

- Nicor LED VT2 LED VAPORTITE Installation InstructionsDocument4 pagesNicor LED VT2 LED VAPORTITE Installation Instructionsfemowox506No ratings yet

- Typical Install: InstructionsDocument9 pagesTypical Install: InstructionsPrzemysław OstałowskiNo ratings yet

- 13 51 017 Removing and Installing - Replacing High Pressure Pump (N57 D30 O - T 1)Document1 page13 51 017 Removing and Installing - Replacing High Pressure Pump (N57 D30 O - T 1)Tapciuc ciuc Florin VirgilNo ratings yet

- Centrigard Centrifuga CHDocument6 pagesCentrigard Centrifuga CHDenis HernandezNo ratings yet

- Match-It Fan&coil Manual de Instalación y OperaciónDocument40 pagesMatch-It Fan&coil Manual de Instalación y OperaciónGustavo AngelesNo ratings yet

- Ma 1500000 WMDocument7 pagesMa 1500000 WMCarlos ReyesNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- Instructions For Assembly, Operation and Maintenance of Indoor Disconnectors and Earthing SwitchesDocument4 pagesInstructions For Assembly, Operation and Maintenance of Indoor Disconnectors and Earthing SwitchesKevin MweneSafariNo ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- Section 11 Engine Fuel SystemDocument3 pagesSection 11 Engine Fuel SystemtechnicmerpatipilotschoolNo ratings yet

- Warning: No Smoking! No Open Flame! While Installing Your Dynojet KitDocument2 pagesWarning: No Smoking! No Open Flame! While Installing Your Dynojet KitBob McRawNo ratings yet

- Mallory Installation InstructionsDocument4 pagesMallory Installation Instructionssantacruz08aNo ratings yet

- In-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101Document18 pagesIn-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101creative BrandwiseNo ratings yet

- Atvus PRVDocument6 pagesAtvus PRVvipulpanchotiyaNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dtDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dtMynor Witt100% (5)

- Sincronizacion de Motores Ssangyong d20dt d27dt PDFDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dt PDFMynor WittNo ratings yet

- Master Solenoid Kit: MS KM-175 93Document1 pageMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliNo ratings yet

- HDLS Series Switches: Installation Instructions For TheDocument4 pagesHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaNo ratings yet

- K550 K550-38 New LabelDocument14 pagesK550 K550-38 New LabelJannie CoetzeeNo ratings yet

- 47 XinstDocument2 pages47 XinstA330TurbinexNo ratings yet

- Dynojet InstructionsDocument2 pagesDynojet Instructionschris neelyNo ratings yet

- Av NG R 2 4L Cal Ber 1.8L Caliber 2 0L Caliber 2 4L ED3 2008 2007-08 2007-08 2007 08Document37 pagesAv NG R 2 4L Cal Ber 1.8L Caliber 2 0L Caliber 2 4L ED3 2008 2007-08 2007-08 2007 08miguel cruzNo ratings yet

- Cadenas DodgeDocument37 pagesCadenas DodgeAlfredo SalasNo ratings yet

- GN128 Explosion Proof Piston - 0Document2 pagesGN128 Explosion Proof Piston - 0Luz Stella Calixto GomezNo ratings yet

- Gti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Promyvka I Konservatsiya MotoraDocument22 pagesGti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Promyvka I Konservatsiya Motoraporter1980No ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- LVDT Oscillator Demodulator G123-817-006: Application NotesDocument4 pagesLVDT Oscillator Demodulator G123-817-006: Application NotesAziz TaziNo ratings yet

- SKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enDocument9 pagesSKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enErne Lange OlsenNo ratings yet

- Solenoid Valves: Fitters NotesDocument12 pagesSolenoid Valves: Fitters Notes2nd engineerNo ratings yet

- Ngi 1000 IOM - 9 17Document22 pagesNgi 1000 IOM - 9 17A2 BhaskarNo ratings yet

- Hydraulic Recovery Winch: ModelDocument2 pagesHydraulic Recovery Winch: ModelNoman MubarakNo ratings yet

- Taro 2l Engine ManualDocument158 pagesTaro 2l Engine ManualAlexandru CraiovanNo ratings yet

- Petronix d175510 - Rover v8Document2 pagesPetronix d175510 - Rover v8Tony CapuanoNo ratings yet

- Operation and Maintenance Manual For Step AttenuatorsDocument4 pagesOperation and Maintenance Manual For Step AttenuatorsDakwah DandiNo ratings yet

- In-Vehicle Repair: Output Shaft Speed (OSS) SensorDocument11 pagesIn-Vehicle Repair: Output Shaft Speed (OSS) SensorAlex Maceira GraterolNo ratings yet

- Sonnax 09ADocument2 pagesSonnax 09Aossoski100% (3)

- Mallory Instructions Unilite Distributor 37 38 45 47Document12 pagesMallory Instructions Unilite Distributor 37 38 45 47teoma34No ratings yet

- Dss 1 SwiftshiftinstructionsDocument2 pagesDss 1 SwiftshiftinstructionsJorge BaptistaNo ratings yet

- Warning: No Smoking! No Open Flame! While Installing Your Dynojet KitDocument2 pagesWarning: No Smoking! No Open Flame! While Installing Your Dynojet KitEmiliano Arocha CorsoNo ratings yet

- KS-AX4504 KS-AX4302: Power Amplifier: Instructions Amplificateur de Puissance: Manuel D'InstructionsDocument3 pagesKS-AX4504 KS-AX4302: Power Amplifier: Instructions Amplificateur de Puissance: Manuel D'InstructionsDiego De La VegaNo ratings yet

- NKF-770 TD Exchange Procedure (JLN-550Ver1 0)Document11 pagesNKF-770 TD Exchange Procedure (JLN-550Ver1 0)Abel Francisco Villadiego CaballeroNo ratings yet

- MN 03007Document16 pagesMN 03007hyarub9No ratings yet

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechNo ratings yet

- Valvula DireccionDocument8 pagesValvula DireccionVictor Manuel Lozada ObessoNo ratings yet

- dp45 Low Pressure Variable Reluctance SensorDocument4 pagesdp45 Low Pressure Variable Reluctance SensorLuis OrtizNo ratings yet

- Repair Instruction Repair Instruction Repair Instruction Repair InstructionDocument6 pagesRepair Instruction Repair Instruction Repair Instruction Repair Instructiontsanjuna6623No ratings yet

- 1977 Jeep-1977 TSBDocument126 pages1977 Jeep-1977 TSBperzaklieNo ratings yet

- E32 Autobox DismantlingDocument23 pagesE32 Autobox DismantlingSteven J Baynes100% (1)

- 1955 Seagrave Model 530-BH ManualsDocument129 pages1955 Seagrave Model 530-BH Manualsbones333100% (3)

- Imo 004enDocument4 pagesImo 004enHASBUL AZIZI BIN MAHMUNNo ratings yet

- PACCAR Alternator InstructionsDocument7 pagesPACCAR Alternator Instructionsquepex76No ratings yet

- VSRSG Ptter Flow SwitchDocument4 pagesVSRSG Ptter Flow SwitchChristine May CagaraNo ratings yet

- B-Max, 1.6l TimingDocument25 pagesB-Max, 1.6l TimingJhoan Smith Posso SantiagoNo ratings yet

- Service Bulletin: General 161 Supplement 1 To Fit The Perkins LC Governor February 2002Document4 pagesService Bulletin: General 161 Supplement 1 To Fit The Perkins LC Governor February 2002Brad100% (1)

- Engine SystemsDocument197 pagesEngine Systems0128 Nguyễn Thanh BìnhNo ratings yet

- Oil StrainerDocument1 pageOil StrainerSaleh AlomariNo ratings yet

- Frame Oil System ComponentsDocument1 pageFrame Oil System ComponentsSaleh AlomariNo ratings yet

- Thermal GrowthDocument1 pageThermal GrowthSaleh AlomariNo ratings yet

- JA-JGA Repair ToolsDocument2 pagesJA-JGA Repair ToolsSaleh AlomariNo ratings yet

- S2VNA Operating ManualDocument271 pagesS2VNA Operating ManualHever RodriguezNo ratings yet

- Cestodes - Summary TableDocument2 pagesCestodes - Summary TableLace Azores100% (4)

- FPJ Indore Edition 15 January 2023Document22 pagesFPJ Indore Edition 15 January 2023Abhishekh GuptaNo ratings yet

- Restricted Substances List: Apparel and Footwear International RSL Management GroupDocument38 pagesRestricted Substances List: Apparel and Footwear International RSL Management GroupantoniaNo ratings yet

- Evaporation Loss During Sprinkler IrrigationDocument10 pagesEvaporation Loss During Sprinkler IrrigationAymen Al Al-BaajNo ratings yet

- 1314lab - Stoichiometry and Measurements LabDocument4 pages1314lab - Stoichiometry and Measurements Labapi-239310645No ratings yet

- Frame 8124B Winding 6S: Arep/PmgDocument3 pagesFrame 8124B Winding 6S: Arep/PmgscribdledeeNo ratings yet

- Economic Analysis (Summary) A. Recent Economic Developments Gross Domestic Product Dynamics. Armenia Experienced Remarkable Economic GrowthDocument7 pagesEconomic Analysis (Summary) A. Recent Economic Developments Gross Domestic Product Dynamics. Armenia Experienced Remarkable Economic GrowthcarlotilloNo ratings yet

- Neets Project V GuardDocument81 pagesNeets Project V GuardNeetha Kanjakulath K67% (6)

- Sps. Ermino v. Golden VillageDocument2 pagesSps. Ermino v. Golden Villagejanine nenaria50% (2)

- Distributed Information Systems: Lecture9 - Networkingbasics: Osi Model Basedon Agrawalandsharma, ProspectpressDocument172 pagesDistributed Information Systems: Lecture9 - Networkingbasics: Osi Model Basedon Agrawalandsharma, ProspectpressSaitejNo ratings yet

- Blg20m12v Bda Cust EngDocument7 pagesBlg20m12v Bda Cust EngMihaiCiorbaruNo ratings yet

- Using The Varian AA240 Atomic Absorption SpectrometerDocument13 pagesUsing The Varian AA240 Atomic Absorption SpectrometerBerenice LoredoNo ratings yet

- Wind ASCE 7-10 Vs 7-05Document3 pagesWind ASCE 7-10 Vs 7-05Homer SilvaNo ratings yet

- Weekly Training Schedule - Samples: Warmup SMR (Foam Roll, LAX Ball,) 5-10 Rolls or 30sec EachDocument6 pagesWeekly Training Schedule - Samples: Warmup SMR (Foam Roll, LAX Ball,) 5-10 Rolls or 30sec Eachogalloza100% (2)

- User's Guide: Modeling Guitar ProcessorDocument28 pagesUser's Guide: Modeling Guitar ProcessorGabriel AlencarNo ratings yet

- STUDIOBRICKS QUOTE ONE ONE PLUS Automized Quote10Document38 pagesSTUDIOBRICKS QUOTE ONE ONE PLUS Automized Quote10Brady WilliamsNo ratings yet

- DigSilent Training Program - RwandaDocument5 pagesDigSilent Training Program - RwandaBUNANI CallixteNo ratings yet

- Filipino Scientist and Their InventionDocument5 pagesFilipino Scientist and Their InventionRica DumalaogNo ratings yet

- Nurse Role in Intravenous TherapyDocument53 pagesNurse Role in Intravenous Therapyapi-300218860100% (2)

- CE-411 Structural Analysis and Design II (2010-2016) PDFDocument28 pagesCE-411 Structural Analysis and Design II (2010-2016) PDFAhmed RolinNo ratings yet

- TsofDocument2 pagesTsofPratik RatwaniNo ratings yet

- Female Sex HormonesDocument30 pagesFemale Sex HormonesMagdy El-GammalNo ratings yet

- DNA and Proteins Doodle Notes 2Document10 pagesDNA and Proteins Doodle Notes 2Leila BeyyoudhNo ratings yet

- Construction Management: Divya Negi Faculty, B.Voc., ABITDocument11 pagesConstruction Management: Divya Negi Faculty, B.Voc., ABITDIVYA NEGINo ratings yet

- Camouflage Yourself and Individual EquipmentDocument16 pagesCamouflage Yourself and Individual EquipmentInficeman100% (1)

- Hoa AnswerDocument8 pagesHoa AnswerMariaDaroingNo ratings yet

- 2078.01.25 Final Draft of CementDocument57 pages2078.01.25 Final Draft of CementAviation NepalNo ratings yet

- Biomolecules - FIDPDocument1 pageBiomolecules - FIDPAustin Capal Dela Cruz0% (1)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Offshore Projects and Engineering ManagementFrom EverandOffshore Projects and Engineering ManagementRating: 5 out of 5 stars5/5 (2)

- The Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesFrom EverandThe Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesRating: 4 out of 5 stars4/5 (16)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Decommissioning Forecasting and Operating Cost Estimation: Gulf of Mexico Well Trends, Structure Inventory and Forecast ModelsFrom EverandDecommissioning Forecasting and Operating Cost Estimation: Gulf of Mexico Well Trends, Structure Inventory and Forecast ModelsNo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeFrom EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNo ratings yet

- Ship and Mobile Offshore Unit Automation: A Practical GuideFrom EverandShip and Mobile Offshore Unit Automation: A Practical GuideNo ratings yet

- Practical Engineering Management of Offshore Oil and Gas PlatformsFrom EverandPractical Engineering Management of Offshore Oil and Gas PlatformsRating: 4 out of 5 stars4/5 (7)

- The Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoFrom EverandThe Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoNo ratings yet