Professional Documents

Culture Documents

MPI - Formula - Data 2022

MPI - Formula - Data 2022

Uploaded by

Amit Hasan0 ratings0% found this document useful (0 votes)

20 views4 pagesOriginal Title

MPI - Formula _ Data 2022

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views4 pagesMPI - Formula - Data 2022

MPI - Formula - Data 2022

Uploaded by

Amit HasanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

WELDING & NDT SERVICES, SU

MAGNETIC PARTICLE TESTING

FORMULAE AND DATA

1.Longitudinal magnetization

i) For relatively uniform cross sections

A. For Low fill factor coils

(cross sectional area of the coil is ten or more times the cross sectional area of the test part)

For parts positioned to the side of the coil:

NI= 45000 (L/D)

where N = number of turns in the coil

I=current (A)

D = length-to-diameter ratio of the part to be magnetized

For parts positioned in the centre of the coil:

NI= 43000 R/[(6L/D)—5]

where N = number of turns in the coil

I=current [A]

R= radius of coil [in.]

D = Iength-to-diameter ratio of the part to be magnetized

The above formulae hold only if L/D is greater than 2 and less than 15.

If L/D is less than 2, pole pieces (pieces of ferromagnetic material with the same diameter as the

part being tested) are placed on each end of the part to effectively increase L/D to 2 or greater.

If L/D is greater than 15, the value of 15 shall be substituted for L/D.

B. For High fill factor coils or Coil wrap

[the cross sectional area of the coil is less than twice the cross sectional area of test part (including

hollow portions)]

N I= 35000/ [(L/D) + 2] (10%)

C. For Intermediate fill factor coils

(cross sectional area of the coil is between 2 and 10 times the cross sectional area of test part)

NI= (N Dn [(10-r) / 8] + (N Dh: [(r-2)/ 8)]

where (N I)i = value of NI calculated for low fill factor coils

(N Dp = value of NI calculated for high fill factor coils

r= ratio of the cross sectional area of the coil to the cross sectional area of the part

(ii). For oddly shaped uniform cross sections or

1=(P/3.14) x 1000

where P = perimeter of cross section [in.]

I =current [A]

iii) Calculating the L/D ratio for a hollow or cylindrical part

When calculating the L/D ratio for a hollow or cylindrical part, D shall be replaced with an

effective diameter, Des, calculated using:

A) Hollow Piece

Deir =[(Ar An) / 3.14]!?

where A‘ total cross sectional area of the part [in.”]

Ai= cross sectional area of the hollow portion of the part [in.2]

B) Cylindrical Piece

Dew=[ OD? — ID? ]'2

where OD = outside diameter of the cylinder

ID = inside diameter of the cylinder

2.0=B/H

where jt = magnetic permeability [H/m]

B=magnetic flux density [T]

H= magnetizing force [A/m]

3. Prod [Circular magnetization]

I= 90-110A per inch of prod spacing, if part thickness < 19 mm.

I= 125 A per inch of prod spacing, if part thickness >19 mm.

4, Fill factor (q) in Longitudinal magnetization using coil

1) = Cross sectional area of test part/ Cross sectional area of coil

=n di? / m do?

T-di2/ do?

where di = diameter of testing part

d= diameter of coil

5, Inverse square law of photometry

E=1/@

where I = source illuminance

E = surface illuminance

d = distance between the point and source

Tid)? = Ind2?

where I) = illuminance of light at distance di

Iz = illuminance of light at distance d2

ja do / di?

Wi fai?! do"

D2 = [(lh) dey?

Di =([ (yh) d2?]!2

6. In Longitudinal magnetization to obtain the same strength of magnetization

Nil=Nehb

where Ni = number of turns in the coil at current I,

N2 = number of turns in the coil at current In

h=Ni l/ No

No=Ni l/h

7. pte= Who

where jr = relative permeability

Ho = permeability of space

8B=F/A

where F = magnetic flux [Wb]

B, = magnetic flux density [Wb/ m2]

‘A= area perpendicular to the flux [m2]

9. Circular magnetization

When magnetizing by passing direct current (DC) directly through the part (i.e. head shots):

T= 800 to 1000 A per inch of part diameter or cross section.

For material with higher j: higher current (1000 A) is required.

When magnetizing by passing alternative current (AC) directly through the part:

I= 500 to 600 A per inch of part diameter or cross section.

For material with higher 1 higher current (1000 A) is required.

10. The magnetic flux leakage strength decreases with distance (d) from the defect surface, which

is approximately proportional to 1/d?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BOQ For C.P. Work - Quotation - 10-Mar-21Document1 pageBOQ For C.P. Work - Quotation - 10-Mar-21Amit Hasan100% (1)

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportAmit HasanNo ratings yet

- Level Iii Basic QuestionsDocument7 pagesLevel Iii Basic QuestionsAmit HasanNo ratings yet

- List of EquipmentDocument11 pagesList of EquipmentAmit HasanNo ratings yet

- Basic Question BankDocument27 pagesBasic Question BankAmit HasanNo ratings yet

- MPI - Problems - Solutions 2022Document4 pagesMPI - Problems - Solutions 2022Amit HasanNo ratings yet

- Coating Thickness GaugeDocument2 pagesCoating Thickness GaugeAmit HasanNo ratings yet

- Basic ASNT Questions 2022Document6 pagesBasic ASNT Questions 2022Amit HasanNo ratings yet

- Cothodic Protection BOQ - N. Hasnat InfrastructureDocument2 pagesCothodic Protection BOQ - N. Hasnat InfrastructureAmit HasanNo ratings yet

- MPI - Proc-Spec 2022Document11 pagesMPI - Proc-Spec 2022Amit HasanNo ratings yet

- 33.proven MSDSDocument7 pages33.proven MSDSAmit HasanNo ratings yet

- 2023 Doppler CatalogDocument52 pages2023 Doppler CatalogAmit HasanNo ratings yet

- Introduction To Ultrasonic Testing SD 218: © Amit Hasan Ies Industrial Engineering Services, BangladeshDocument72 pagesIntroduction To Ultrasonic Testing SD 218: © Amit Hasan Ies Industrial Engineering Services, BangladeshAmit HasanNo ratings yet

- IES Profile Book 21 01 2021 Last Ed - CompressedDocument32 pagesIES Profile Book 21 01 2021 Last Ed - CompressedAmit HasanNo ratings yet

- Bashundhara Preheat Job 1Document1 pageBashundhara Preheat Job 1Amit HasanNo ratings yet

- Bashundhara Preheat Job 2Document1 pageBashundhara Preheat Job 2Amit HasanNo ratings yet

- Bsti - Final 21Document324 pagesBsti - Final 21Amit HasanNo ratings yet

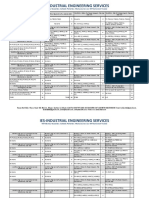

- Ies-Industrial Engineering ServicesDocument2 pagesIes-Industrial Engineering ServicesAmit HasanNo ratings yet

- Polimaster Security and Safety-Radiation Equipment-Homeland Security Bangladesh - ROSS PDFDocument30 pagesPolimaster Security and Safety-Radiation Equipment-Homeland Security Bangladesh - ROSS PDFAmit HasanNo ratings yet

- Ies-Industrial Engineering Services: Challan For InstrumentDocument4 pagesIes-Industrial Engineering Services: Challan For InstrumentAmit HasanNo ratings yet

- Ies-Industrial Engineering ServicesDocument6 pagesIes-Industrial Engineering ServicesAmit HasanNo ratings yet

- Temporary Cathodic Protecton Work Description SL. No Description Unit Quantity 1.0Document3 pagesTemporary Cathodic Protecton Work Description SL. No Description Unit Quantity 1.0Amit HasanNo ratings yet

- Orion Power Shonargaon Limited 153-154, Tejgaon Industrial Area Dhaka-1208, BangladeshDocument4 pagesOrion Power Shonargaon Limited 153-154, Tejgaon Industrial Area Dhaka-1208, BangladeshAmit HasanNo ratings yet

- Aboni UTG Report 03Document1 pageAboni UTG Report 03Amit HasanNo ratings yet

- Item - 2 SpecficationDocument1 pageItem - 2 SpecficationAmit HasanNo ratings yet