Professional Documents

Culture Documents

MPI - Proc-Spec 2022

MPI - Proc-Spec 2022

Uploaded by

Amit Hasan0 ratings0% found this document useful (0 votes)

27 views11 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views11 pagesMPI - Proc-Spec 2022

MPI - Proc-Spec 2022

Uploaded by

Amit HasanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

WELDING & NDT SERVICES, SURAT

AS) T LEVEL Il

MAGNETIC PARTICLE TI ING

SPECIFICATION

1, SCOPE

This procedure describes the methods and requirements for the detection of surface or near surface

discontinuities, in ferromagnetic materials, when shapes and sizes are suitable for magnetic particle

examination, using the continuous wet Magnetic Particle Inspection method for nuclear systems

components and commercial components. The sensitivity is greatest for surface discontinuities and

diminishes rapidly with increasing depth of subsurface discontinuities below the surface. Typical

types of discontinuities that can be detected by this method are cracks, laps, seams, cold shuts, and

laminations.

2, REFERENCE DOCUMENTS,

ASME Code Section III

ASME Code Section V

ASME Code Section VIII

ASME B31.1

ASME B31.3

ASME B16.34

3, PERSONNEL QUALIFICATION

All personnel working to this procedure shall be qualified in accordance with ASME Code, Section

Ill, Paragraph NB-5500, and SNT-TC-1A. Records of all personnel qualification shall be

maintained by Quality Assurance Department.

4 COMPONENTS FOR INSPECTION

When practical, all suitable shapes and sizes of ferromagnetic materials may be inspected by

magnetic particle testing method, Acceptance examination shall be performed after final post weld

heat treatment, unless otherwise specified by Code or customer requirements.

5 SAFETY REQUIREMENTS

All inspectors performing magnetic particle inspection in accordance with this procedure shall

assure themselves that contacts have been placed firmly on the surface to be inspected prior to

turning on the current and turning off the current before contact removal to prevent arc flashes.

6 EQUIPMENT/ QUALITY ASSURANCE,

6.1 Magnetizing Equipment: The magnetizing equipment apparatus shall be capable of inducing, in

the item under examination, a magnetic field of suitable intensity in the desired direction by either

the circular or the longitudinal method. Direct current, three phase full-wave, single phase half-

wave rectified current or alternating current shall be used to induce the magnetic field, the

effectiveness of the equipment shall be checked prior to each days use by complete Magnetic

Particle Inspection of a test piece containing known defects or equivalent performance and

sensitivity indicators (i.e. Ketos Test Ring, Magnetic Field Indicator (Pie-Gauge), Quantitative

Quality Indicators (QQI's), or Magnetic Field Strength Meter (Hall Effect Gauss Meter), etc.)

Each piece of magnetizing equipment shall be calibrated at a minimum of 6 months, and whenever

the equipment has been subjected to major electric repair, periodic overhaul, or damage.

The accuracy of the unit's ammeter shall be verified at a minimum of 6 months by equipment

traceable to a national standard. Comparative readings shall be taken at least three different current

output levels encompassing the usable range. The unit's meter reading shall not deviate by more

than + 10% of full scale, relative to the actual current value as shown by the test meter.

6.1.3 Electromagnetic Yoke

6.1.3.1 ASME Section V, Article 7

A. The magnetizing force of yokes shall be checked at least once every six months or whenever a

yoke has been subject to major electric repair, periodic overhaul, or damaged. If a yoke has not

een in use for six months or more, a check shall be performed prior to first use.

B, Alternating current electromagnetic yokes shall be checked by lifting a 4.5 kg (10 Ib) weight at

the maximum pole spacing at which it will be used.

C. Direct current electromagnetic yokes shall be checked by lifting a 18 kg (40 Ib) weight at the

maximum pole spacing at which it will be used.

D. Each weight shall be weighed with a scale from a reputable manufacturer and stenciled with the

applicable nominal weight prior to first use. A weight need only be verified again if damaged in a

manner that could have caused potential loss of material.

6.1.3.2 ASTM E709 - Pole Spacing

AC - 4.5 kg (10 Ib). 2 to 6 inch

DC - 18 kg (40 Ib). 2 to 6 inch

6.1.4 Materials

A. Magnetic Particles

1. A Magnaglo Powder (MagnaFlux) Fluorescent or equivalent.

2. Glonetic (C925) Fluorescent Particles Oil Dispersion Premix or 14 or equivalent.

B, Suspension Vehicles

1, Magnaglo Carrier I, oil based (MagnaFlux) or equivalent.

6.1.5 Equipment

Magnaflux Wet Horizontal

Parker Mini Contour Probe

Parker Contour Probe

Magnaflux Black Light

Cables, contact clamps, split coils, contact block or equivalent operating accessories.

6.1.6 Meters and Testing Equipment

Magnetic Field Indicator (pie gauge)

Digital Light Meter

Digital Magnetic Field Strength Meter (Gauss Meter - Gould - Bass)

Ketos Test Ring

Quantitative Quality Indicators (QQI Shims)

Magnetic Field Indicator (10 Gauss Calibrated Indicator)

6.2, Particles: The fluorescent particles shall be suspended in a suitable liquid vehicle. The

particles shall have a high permeability and low retentivity. Particles shall be compatible with the

particular vehicle to be used. Particles shall be in accordance with SE-709.

6.3 The oil shall be a light, well refined petroleum distillate having a minimal natural fluorescence

and having approximately the following characteristics:

A. Viscosity should not exceed 3 centistokes at 100 °F and not more than 5 centistokes at the

lowest temperature at which the vehicle will be used.

B. Minimum flash point should be 200°F.

6.4 Particle Concentration - The concentration of magnetic particles in the liquid vehicle shall be

as follows unless otherwise specified by the particle manufacturer:

Fluorescent Particles 0.1 to 0.4 ml per 100 ml sample

6.5 Suspension Test. The suspension tests of concentration, contamination and brilliance shall be

determined upon start up, every 8 hours or shift change, and whenever the bath is replaced or

adjusted as per the following:

6.6 Black Lights: Filtered ultraviolet radiation shall be used in a darkened area when performing

examinations using fluorescent particles.

Black lights shall be allowed to warm up for at least five minutes prior to use or measurement of

the intensity of the ultraviolet light emitted. Reflectors and filters should be checked and cleaned

daily when in use. Cracked or broken filters shall be replaced immediately.

Black light intensity at the surface under examination shall be checked at least once every eight

hours, and whenever the work location is changed, or whenever the bulb is changed. A minimum of

1000 microwatts per square centimeter (1000 1 W/em?) shall be required.

6.6.3. Ambient white light intensities. The ambient white light intensity shall be determined upon

start up each week and whenever any change is suspected. The intensity of the ambient white light

shall be measured at the inspection surface. The intensity shall be a maximum of 20 Ix (2 foot-

candles). If the intensity is more than specified, check for light leaks in curtains, etc.

6.7 Strength of magnetic field: The applied magnetic field shall have sufficient strength to produce

satisfactory indications, but must not be strong enough to cause masking of relevant indications by

non-relevant accumulations of magnetic particles.

6.7.1 Known or artificial defects: Adequate magnetic field strength may be determined by testing

parts having known or artificial defects of the type, size, and location specified in the acceptance

requirements. Artificial flaws may be used to establish magnetic field strength, examples of these

are, Magnetic Field Indicator (Pie gauge), Quantitative Quality Indicators (QQI shims) or

equivalent.

Magnetic Field Indicator (Pie Gauge): When using this indicator, a suitable field strength is

indicated when a clearly defined line (or lines) of magnetic particles form(s) across the copper face

of the indicator (the slots are against the piece) when the magnetic particles are applied

simultaneously with the magnetizing force. When a clearly defined line of particles is not formed,

or is not formed in the desired direction, the magnetizing technique shall be changed or adjusted.

Quantitative Quality Indicators (QQI Shims): To be effective, the shim must be in intimate contact

with the part surface and placed flaw-side-down. Be sure, that the surface opposite the Flaw is not

covered and that no air gap exists between the shim and the part. A suitable field strength is

indicated when a clearly defined line (or lines) of magnetic particles, representing the 30% depth

flaw, appear(s) on the shim face when magnetic particles are applied simultaneously with the

magnetizing force

Hall-effect probe gaussmeter: Adequate magnetic field strength may be determined by using a hall-

effect probe gaussmeter capable of measuring the peak values of the tangential field. Tangential

applied field strengths in the range of 30 to 60 gauss are adequate field strengths for magnetic

particle inspection.

Formulas: Adequate magnetic field strength may be determined by use of the formulas given in the

following paragraphs 6.7.4 through 6.7.6.4. If the formulas are utilized, they shall be verified

through the use of known or artificial defects as specified in paragraph 6.7.1 or through the use of

the hall-effect probe gaussmeter as specified in paragraph 6.7.2.

Direct circular magnetization: When magnetizing by passing current directly through the part (ie.

using "head shots"), the current shall be from 800 A per inch of part diameter to 1000 A per inch of

part diameter. The diameter of the part shalll be taken as the largest distance between any two

points, 180 degrees apart on the outside circumference of the part.

6.7.4.1 Parts with geometric shapes other than round the greatest cross-sectional diagonal ina

plane at right angles to the current flow shall determine the inches to be used in 6.7.4 above.

6.7.4.2 If the current levels required for 6.7.4 cannot be obtained, the maximum current obtainable

shall be used and the field adequacy shall be demonstrated in accordance with one more of the

following reference 6.7, 6.7.1 and 6.7.2.

6.7.5 Central conductor circular magnetization: Circular magnetization may be provided by

passing current through a conductor which passes through the inside of the part. If only the inside

of the part is to be inspected, the diameter shall be the largest distance between two points, 180

degrees apart on the inside circumference of the part. Otherwise, the diameter is determined as in

paragraph 6.7.4.

Centrally located conductor: When the axis of the central conductor is located near the central axis

of the part, the same current levels as given in paragraph 6.7.4 ("Direct circular magnetization")

shall apply.

Offset central conductor: When the conductor passing through the inside of the part is placed

against an inside wall of the part, the current levels as given in paragraph 6.7.4 ("Direct circular

magnetization") shall apply except that the diameter shall be considered the sum of the diameter of

the central conductor and twice the wall thickness of the part. The distance along the part

circumference (interior or exterior) which is effectively magnetized shall be taken as four times the

diameter of the central conductor. The entire circumference shall be inspected by rotating the part

on the conductor, allowing for approximately a 10 percent magnetic field overlap.

6.7.6 Longitudinal magnetization coils (ASTM E709): Longitudinal magnetization is often

accomplished by passing current through a coil encircling the part, or section of the part, to be

tested (i.e. by using a "coil shot"). For low or intermediate fill factor coils, the effective field

extends a distance on either side of the coil center approximately equal to the radius of the coil

For cable wrap or high fill factor coils, the effective distance of magnetization is 9 inches on either

side of the coil center. For parts longer than these effective distances, the entire length shall be

inspected by repositioning the part within the coil, allowing for approximately 10 percent effective

magnetic field overlap. The formulas are included for historical continuity only. If used, its use

should be limited to simple shaped parts

6.7.6.1 Longitudinal magnetization with low fill factor coils

When the cross sectional area of the coil is 10 or more times the cross sectional area (including

hollow portions) of the part being inspected, then the product of the number of coil turns, N, and

the current in amperes through the coil, I, shall be:

a) For parts positioned in the center of the coil:

NI= 43000 R / [(6L/ D) — 5] ( 10%)

Where: R = radius of the coil in inches L = length of the part in inches D = diameter of the part in

inches

b) For parts positioned to the side of the coi

NI= 45000 / (L/D) (+ 10%)

where:

L = length of the part in inches

D = diameter of the part in inches

6.8 System Performance of Horizontal Units. The Ketos (Betz) ring shall be used to evaluate and

compare the overall performance and sensitivity of the wet Fluorescent magnetic particle technique

using a central conductor magnetization technique. This test shall be run at least once per week (or

prior to use) if not run the week before. ,

The test ring is circularly magnetized with full-wave rectified Ac passing through a central

conductor with a I to 1.25 in. diameter hole located in the ring center. The conductor should have a

length greater than 16 in. The currents used shall be 1400, 2500 and 3400 amps. The minimum

number of holes shown shall be three, five and six, respectively. The ring edge should be examined

with the black light. This test shall be run at the three amperages if the unit will be used at these or

higher amperages. The amperage values stated shall not be exceeded in the test. If the test does not

reveal the required number of holes, the equipment shall be taken out of service and the cause of

loss of sensitivity determined and corrected.

7.0 PROCESS:

7.1 Temperature During Test: Wet magnetic particle examinations shall not be performed when

the temperature of the wet particle suspension and/or the surface of the part exceeds 57 °C (135 °F).

7.2 Surface Preparation

Surfaces may be in the as-welded, as-rolled, as-cast, or as-forged condition. However, surface

preparation by grinding or machining may be necessary in some cases where surface irregularities

would otherwise mask the indication of discontinuities.

Prior to magnetic particle examination, the surface to be examined and any adjacent area within at

least 1 inch of the area to be examined shall be dry and free of any dirt, grease, lint, scale, welding

flux, spatter, oil, or other extraneous matter that would interfere with the examination.

Cleaning may be accomplished using detergents, organic solvents, descaling solutions, paint

removers, vapor degreasing, sand or grit blasting, or ultrasonic cleaning, customer approval of the

cleaning method may be required.

If non-magnetic coatings are left on the part in the area being examined, it must be demonstrated

that indications can be detected through the maximum coating thickness applied, but they must be

removed at all points where electrical contact is to be made for direct magnetization. When Ac

yoke technique is used, the demonstration must be in accordance with Mandatory Appendix "I", of

Article 7 in Section V.

When nonmagnetic coatings are applied temporarily to uncoated surfaces only in amounts

sufficient to enhance particle contrast, it must be demonstrated that indications can be detected

through the enhancement coating.

7.3 Preliminary Examination

Before the magnetic particle examination is conducted, a check of the examination surface shall be

conducted to locate any discontinuity surface openings which may not attract and hold magnetic

particles because of their width.

The Continuous Method: The magnetizing current shall be turned on after the particles have been

applied. Flow of the particles shall stop with the application of current. Wet particles applied from

aerosol spray cans may be applied before and/or after magnetizing current is applied. Wet particles

may be applied during the application of magnetizing current if they are not applied directly to the

examination area and are allowed to flow over the examination area or are applied directly to the

examination area with low velocities insufficient to remove accumulated particles.

Direction of Magnetization: At least two separate examinations shall be carried out on each area.

The second examination shall be with the lines of magnetic flux approximately perpendicular to

those used for the first examination in that area. A different means of magnetizing may be used for

the second examination. The direction of magnetization shall be determined by particle indications

obtained using an indicator or shim reference 6.7.1.

Examination Coverage: Examinations shall be conducted with sul ent overlap to assure 100%

Coverage at the required sensitivity. Surfaces not *readily accessible by MT shall be examined by

liquid penetrant using CCI NDE-102.*Definition of "readily accessible"; Any inside or external

surface that can be magnetic particle examined by hand, that is, without the use of special

equipment not listed in this procedure

7.7 Magnetizing Current/Magnetic Field Indicators (ASME Section V, Article 7)

7.7.1 The field adequacy shall be demonstrated using one of the magnetic field indicators per 6.7.1

for the following conditions.

A. If the current levels required for 6.7.4 cannot be obtained, the maximum current obtainable shall

be used and the field adequacy shall be demonstrated in accordance with, 6.7.1.1, and/or 6.7.1.2.

B. When the central conductor technique is used.

C. If the area to be magnetized in accordance with 7.7.3 extends beyond 9 inches on either side of the coil.

D, For large parts magnetized in accordance with 7.7.3.

7.7.2. Circular Magnetization produced by direct contact or by a central conductor placed through

The test piece shall be determined by requirements in paragraphs 6.7.4, 6.7.4.1, 6.7.4.2, 6.7.5,

6.7.5.1, 6.7.5.2 and 7.7.1 (A).

8.0 EXAMINATION SEQUENCE,

Examination shall be accomplished under proper lighting conditions for the type of particles used.

When fluorescent particles are used, the examination shall be accomplished in a darkened area. The

examiner shall be in the darkened area for at least 5 minutes prior to performing an examination

using fluorescent particles to enable his eyes to adapt to dark viewing. If the examiner wears

glasses or lenses, they shall not be photo sensitive.

8.1 Direct Contact Method (Circular Field)

A. Firm electrical contact shall be made to the test piece, for example; either contact heads, clamps

or magnetic leeches may be used.

B, The correct magnetizing current shall be determined.

C. The liquid vehicle containing the particles. (suspension) shall be applied to the entire area under

examination, by spraying or flowing.

D. While the suspension is still running on the test piece, the magnetizing current shall be switched

on for a minimum of 0.5 second with two or more shots given to the part.

E. The test piece shall then be examined for indications.

8.2 Central Conductor Method (Circular Field)

A. Where large diameter cylinders are to be examined, the conductor shall be positioned close to

the internal surface of the cylinder. When the conductor is not centered, the circumference of the

cylinder shall be examined in increments and a magnetic particle field strength indicator shall be

used to determine the extent of the are that may be examined for each conductor position. Bars, or

cables passed through the bore of a cylinder, may be used to induce circular magnetization.

B. The field of strength required shall be equal to that determined for a single turn central

conductor. The magnetic field will increase in proportion to the number of times the central

conductor cable passes through the hollow part. For example, if 6000 amperes are required to

examine a part using a single central conductor, 3000 amps are required when 2 turns of the

through cable are used, and 1200 amps are required if 5 turns are used.

C. Firm electrical contact shall be made to the central conductor.

D. The suspension shall be applied to the entire area under examination, by spraying or flowing,

E, While the suspension is still running on the test piece, the magnetizing current shall be switched

on for a minimum of 0.5 second with two or more shots given to the part.

F, The test piece shall then be examined for indications.

8.3 Multi-turn Fixed Coil/Cables (Longitudinal Field)

A. Small parts shall be placed inside the coil close to one side. Large parts shall be centered in the

coil, cable wrap when used should be 3 to 5 turns.

B, The correct magnetizing current shall be determined.

C. The suspension shall be applied to the entire area under examination.

D. While the suspension is still running on the test piece, the magnetizing current shall be passed

Through the coil for a minimum of 0.5 second, with two or more shots given to the part.

E. The test piece shall then be examined for indications.

F, For test pieces over 18 inches in length, repeat steps (A) through (E) with coil successively

Placed at intervals not to exceed 18 inches until the entire length of the test piece has been

Covered.

8.4 Yoke Method (Longitudinal Field)

Each separate application of the examination shall overlap a preceding application until the extent

Of the area under examination has been completely covered.

9.0 INTERPRETATION OF RESULTS

All indications revealed by magnetic particle inspection are not necessarily defective since non-

relevant indications are sometimes encountered, Non-relevant or false indications are quite

common but may be easily identified. Examples of such indications are as follows:

9.1 Magnetic Writing

The indication is fuzzy and will be destroyed by demagnetization. These indications are caused by

contact with other steel or magnets while magnetized:

9.2 Change in Section

The distribution of magnetic field in an area of change in section of the piece being tested is such

that the test pattern is broad and fuzzy.

9.3. Flow Lines

These are large groups of parallel indications that occur in some forgings when magnetized with

High currents.

10.0 EVALUATION OF INDICATIONS

All indications believed to be non-relevant shalll be evaluated by removing the surface roughness or

shall be re-inspected by other nondestructive test methods. If re-inspection reveals any indications,

these indications shall be considered as relevant and shall be treated as defects and removed.

Linear indications are indications in which the length is greater than three times the width.

Rounded indications are indications which are circular or elliptical with the length less than three

times the width.

11.0 ACCEPTANCE CRITERIA

11.1 All indications shall be evaluated with the applicable acceptance standards.

11.2 All repairs shall be re-inspected in accordance with this procedure.

12.0 POST INSPECTION OPERATIONS.

Demagnetization following examination is required where residual magnetism can interfere with

subsequent processes or usage. Parts shall be demagnetized following the inspection. Following

demagnetization, the residual magnetic field shall be checked using a residual magnetic field

indicator. All parts shall be considered to be suitably demagnetized when after demagnetization

residual fields do not exceed 3G (gauss) anywhere in the piece, unless otherwise agreed upon or as

specified on the engineering drawing or in the contract, purchase order, or specification.

When post cleaning is required, it should be conducted as soon as practical using a process that

does not adversely affect the part.

13, REPORT REQUIREMENTS

13.1 All nondestructive inspection made to this procedure process specification shalll be recorded

on the shop Traveler prior to the commencement of the next consecutive operation, signed and

dated by the NDE Inspector as required.

13.2 For each examination, the following information shall be recorded:

a. date and time examinations were performed

b. magnetic particle equipment and type of current

c. magnetic particles type used (fluorescent, wet)

d. map or record of indication per 13.4 or 14.0 as applicable

e, material and thickness

13.3 Records of reports shall be maintained in accordance with QAM-100/QAM-101

Non-rejectable indications shall be recorded as specified by the referring Code Section.

14.0 REJECTS

14.1 All parts that do not meet the applicable acceptance standards shall be rejected and reported

on an NCMR or DR and processed in accordance with QAM-100/QAM-101.

Rejectable indications shall be recorded per paragraph 14.1. As a minimum, the type of indication

(Linear or rounded), location and extent (length or diameter or aligned) shall be recorded.

15.0 PERFORMANCE DEMONSTRATION

15.1 Performance demonstration, when required by the referencing Code Section, shall be

Documented.

of ultraviolet light at the surface under examination shall be checked

A. at least once every eight hours

B, whenever the bulb is changed

C. whenever the work location is changed

D. whenever the filter is changed

E. any of the above

2. Adequate magnetic field strength may be determined by using:

A.apie gauge

B, shims

C. Ketos test ring

D. any of the above

3. When wet magnetic particle examination is performed, temperature of the wet particle

Suspension or temperature of the surface shall not exceed:

A.100 °F

B.120 °F

C.135 °F

D.200 °F

4. the concentration of fluorescent particles in the liquid vehicle shall be between:

A. 0.1 mL and 0.4 mL per 10 mL.

B. 0.1 mL and 0.4 mL per 100 mL,

C. 0.1 mL and 0.4 mL per 1000 mL.

D. none of the above

a bar 38 cm (15 in.) long and 7.6 cm (3 in.) in diameter using a 3-turn coil. If the part

the center of the low fill factor coil, what amperage will be used for longitudinal

Magnetization?

A. 3000

B. 2400

C.574

D. 1720

6. Magnetizing equipment shall be calibrated

A. at a minimum of 6 months

B. whenever the equipment has been subjected to major electric repair, periodic overhaul, or damage

C. at a minimum of 12 months

D. both A and B

7. To test a bar 30.5 em (12 in.) long and 5.1 em (

part Positioned to side of the low fill factor coil, what amperage will be used for longitudinal

Magnetization?

A. 7500 A

B. 875A

C. 2000 A

D. 1875.4

8. According to the specification, if surfaces not readily accessible by MT shall be examined by:

A.RT

B.UT

C.PT

D.ET

9. The kinematic viscosity of carrier oil should:

A. not exceed 3 mm/s? (3 centistokes) at 100 °F

B. not exceed 5 mm/s? (5 centistokes) at the lowest temperature at which the vehicle will be used

C. be greater than 5 mm/s? (5 centistokes) at room temperature

D. both A and B

10. According to the specification, the intensity of ambient light shall be less than __Ix.

D. 200

11. According to the specification, which of the following reference documents is used for

Qualification of testing personnel?

A. ASME Code, Section III, Paragraph NB-5500 B, ASNT SNT-TC-1A

C. MIL-STD-410E D. ISO 9000

E. Both A and B

12. All parts shall be considered to be suitably demagnetized when:

A. its residual magnetic field measures less than 10 gauss

B.it no longer produces an indication

C. it's no longer attracted to a magnet

D. its residual magnetic field measures less than 3 gauss

13. According to the specification, the accepted minimum intensity of black at test surface is

wW/ cm?.

A. 500

B. 700

C. 1000

fing power for AC mode shall be:

A. Maximum 4.5 kg for the maximum pole spacing.

B. minimum 4.5 kg for the maximum pole spacing.

C. minimum 4.5 kg for the minimum pole spacing.

D. none of the above.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

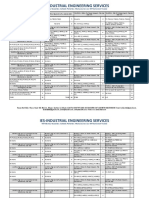

- BOQ For C.P. Work - Quotation - 10-Mar-21Document1 pageBOQ For C.P. Work - Quotation - 10-Mar-21Amit Hasan100% (1)

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportAmit HasanNo ratings yet

- Level Iii Basic QuestionsDocument7 pagesLevel Iii Basic QuestionsAmit HasanNo ratings yet

- List of EquipmentDocument11 pagesList of EquipmentAmit HasanNo ratings yet

- Basic Question BankDocument27 pagesBasic Question BankAmit HasanNo ratings yet

- MPI - Problems - Solutions 2022Document4 pagesMPI - Problems - Solutions 2022Amit HasanNo ratings yet

- Coating Thickness GaugeDocument2 pagesCoating Thickness GaugeAmit HasanNo ratings yet

- Basic ASNT Questions 2022Document6 pagesBasic ASNT Questions 2022Amit HasanNo ratings yet

- Cothodic Protection BOQ - N. Hasnat InfrastructureDocument2 pagesCothodic Protection BOQ - N. Hasnat InfrastructureAmit HasanNo ratings yet

- MPI - Formula - Data 2022Document4 pagesMPI - Formula - Data 2022Amit HasanNo ratings yet

- 33.proven MSDSDocument7 pages33.proven MSDSAmit HasanNo ratings yet

- 2023 Doppler CatalogDocument52 pages2023 Doppler CatalogAmit HasanNo ratings yet

- Introduction To Ultrasonic Testing SD 218: © Amit Hasan Ies Industrial Engineering Services, BangladeshDocument72 pagesIntroduction To Ultrasonic Testing SD 218: © Amit Hasan Ies Industrial Engineering Services, BangladeshAmit HasanNo ratings yet

- IES Profile Book 21 01 2021 Last Ed - CompressedDocument32 pagesIES Profile Book 21 01 2021 Last Ed - CompressedAmit HasanNo ratings yet

- Bashundhara Preheat Job 1Document1 pageBashundhara Preheat Job 1Amit HasanNo ratings yet

- Bashundhara Preheat Job 2Document1 pageBashundhara Preheat Job 2Amit HasanNo ratings yet

- Bsti - Final 21Document324 pagesBsti - Final 21Amit HasanNo ratings yet

- Ies-Industrial Engineering ServicesDocument2 pagesIes-Industrial Engineering ServicesAmit HasanNo ratings yet

- Polimaster Security and Safety-Radiation Equipment-Homeland Security Bangladesh - ROSS PDFDocument30 pagesPolimaster Security and Safety-Radiation Equipment-Homeland Security Bangladesh - ROSS PDFAmit HasanNo ratings yet

- Ies-Industrial Engineering Services: Challan For InstrumentDocument4 pagesIes-Industrial Engineering Services: Challan For InstrumentAmit HasanNo ratings yet

- Ies-Industrial Engineering ServicesDocument6 pagesIes-Industrial Engineering ServicesAmit HasanNo ratings yet

- Temporary Cathodic Protecton Work Description SL. No Description Unit Quantity 1.0Document3 pagesTemporary Cathodic Protecton Work Description SL. No Description Unit Quantity 1.0Amit HasanNo ratings yet

- Orion Power Shonargaon Limited 153-154, Tejgaon Industrial Area Dhaka-1208, BangladeshDocument4 pagesOrion Power Shonargaon Limited 153-154, Tejgaon Industrial Area Dhaka-1208, BangladeshAmit HasanNo ratings yet

- Aboni UTG Report 03Document1 pageAboni UTG Report 03Amit HasanNo ratings yet

- Item - 2 SpecficationDocument1 pageItem - 2 SpecficationAmit HasanNo ratings yet