Professional Documents

Culture Documents

Esgdb23 e P097-101

Esgdb23 e P097-101

Uploaded by

sushantOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esgdb23 e P097-101

Esgdb23 e P097-101

Uploaded by

sushantCopyright:

Available Formats

Nissan Motor Corporation

Contents Corporate direction Environmental Social Governance Data

Social policies Diversity, equity Product safety Supply chain Human resource Employees’ health Community

Human rights Traffic safety Labor practices

and philosophy and inclusion and quality management development and safety engagement

Supply chain management

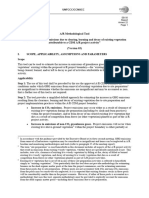

Supply chain strategy We use common, transparent processes and criteria The Alliance Purchasing Organization (APO)

worldwide to select suppliers and are open to doing created by Renault, Nissan, and Mitsubishi Motors

The challenges facing modern societies, such as climate business with new partners, regardless of nationality, size,

change and energy issues, are increasingly global in their or transaction ties in the past. Suppliers are selected after

scope. To meet these challenges, it is essential for Nissan to the relevant Nissan divisions meet to examine submitted

identify relevant issues at each stage along the supply chain

Alliance Purchasing Organization

proposals from a range of perspectives. We explain our

and make ongoing efforts to address them. decisions to every supplier that takes part in the supplier Purchasing domains: All (components, materials, equipment, molds,

service support)

Nissan s business and supply chain expand across the globe. selection process as part of a thoroughly fair, impartial, and

[vehicles/units],

Purchasing functions: All (planning, procurement, projects

We share Nissan s vision and policies with business partners, transparent system. management, supplier quality, etc.)

with whom we strategically collaborate to achieve our goals Transactions with suppliers are based on the three values

through the promotion of consistent procurement activities that the Alliance regards as important: trust (work fairly,

on a global scale. impartially, and professionally), respect (honor commitments,

We aim to achieve sustainable growth built on a foundation liabilities, and responsibilities) and transparency (be open,

of mutual trust with our business partners. We listen closely frank, and clear).

to and work with our suppliers as equal partners, developing Nissan and Renault have produced a booklet, The Renault-

and maintaining cooperative and competitive relations that Nissan Purchasing Way*1, outlining the values and processes

enable us to implement best practices. the Alliance sees as important when doing business. This

booklet has been shared with tier-1 Renault and Nissan

To optimize purchasing activities, the Alliance partners suppliers since 2006. In Japan, we also adhere to the proper

established a common purchasing company, the Renault- trading guidelines issued by the Ministry of Economy, Trade

Nissan Purchasing Organization (RNPO), in 2001 and have and Industry for the automotive industry.

steadily increased the scope of its activities in the years

since then. Its name was changed to the Alliance Supply Processes from supplier selection to mass production

Chain Management Purchasing Organization (APO) in Choice of

Design

Selection of Prototype production Mass

April 2018, after Mitsubishi Motors joined the Alliance. supplier Sourcing

suppliers Evaluation for mass production

candidates

The new organization aims to help each company in the production

Alliance achieve sustainable performance through the

steady development of the Alliance as well as through the

Performance monitoring

advantage of economies of scale.

*1 Click here for more information on The Renault-Nissan Purchasing Way. https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/ASSETS/PDF/Renault_Nissan_Purchasing_Way_English.pdf

ESG data book 2023 097

Nissan Motor Corporation

Contents Corporate direction Environmental Social Governance Data

Social policies Diversity, equity Product safety Supply chain Human resource Employees’ health Community

Human rights Traffic safety Labor practices

and philosophy and inclusion and quality management development and safety engagement

Supply chain management policies investigating, and formulating corrective measures. In the addition to Japanese and English language booklets, we also

case of a noncompliance incident, we will take firm action publish Chinese language versions as appropriate.

and philosophy based on our regulations and do everything necessary to Additionally, in Japan, we have provided opportunities with a

prevent a recurrence. series of dialogues to deepen mutual understanding on the

Initiatives with suppliers

The Renault-Nissan CSR Guidelines for Suppliers importance of activities and the future direction regarding

To build a sustainable supply chain, Nissan is committed Supplementary Handbook for Nissan Suppliers (2022) is human rights. We plan to establish an whistleblowing system

to conducting business in an ethically, socially, and aimed at promoting an understanding and further clarifying for suppliers to report human rights violations by Nissan and

environmentally responsible manner at every stage of its important issues that must be taken into consideration its employees during fiscal 2023 to further promote respect

global supply chain. and addressed regarding compliance and social issues for human rights throughout the supply chain.

In addition to the values the Alliance should respect as represented by human rights and labor.

set forth in The Renault-Nissan Purchasing Way (2006)*1, When issuing each policy, we distributed booklets that were In fiscal 2022, no human rights violations, such as

which is the procurement policy of the Alliance, Nissan explained at supplier meetings to ensure that suppliers and discrimination, occurred, and no supplier was found to be at

aims to build a sustainable supply chain and realize business partners were fully aware of these policies. In serious risk of forced labor or child labor.

responsible procurement of all parts and raw materials. To

this end, Nissan established the Nissan Green Purchasing

Guidelines (2008)*2 , the Renault-Nissan CSR Guidelines Supply chain management policies and philosophy

for Suppliers (first published in 2010, revised in 2015)*3 , and

Supplementary Handbook for Nissan Suppliers (2022)*4 Supply chain management policies and philosophy

The Renault-Nissan Purchasing Way Shared values with suppliers (trust, respect, transparency)

defining the initiatives expected of suppliers. We request our Supplier sourcing process

Basic Alliance principles for purchasing

suppliers and their business partners be aware of, manage, Support for suppliers

and practice these policies.

Renault-Nissan CSR Guidelines for Suppliers aspects

The Renault-Nissan CSR Guidelines for Suppliers (revised Five Areas and 26 Categories of Expected Initiatives Under The Renault-Nissan Supplier CSR Guidelines

in 2015) explain expected initiatives in 26 categories across “Renault-Nissan CSR Guidelines for Suppliers”

■ Compliance Compliance with laws and regulations, compliance with the Competition Law, ensure anti-corruption, management

Supplementary Handbook for Nissan Suppliers

five areas with the aim of encouraging suppliers to review and protection of confidential information, export trade controls, and protection of intellectual property, in

accordance with Japanese government guidelines and ordinances, elimination of anti-social forces in Japan, and Additional detailed explanation regarding compliance,

their corporate activities from a sustainability perspective responsible mineral procurement human rights and labor issues aspects

■ Safety and Quality Provide products and services meeting customer needs, ensure the safety of products and services, as well as the

and implement CSR initiatives.(Refer to the table in right) quality of products and services

Nissan Green Purchasing Guidelines

We require suppliers to undergo assessments by third-party ■ Human Rights and Labor Prevent discrimination, respect human rights, prohibit child labor, prohibit forced labor, ensure wages, working Compliance with regulations and Nissan’s basic

hours, conduct dialogues and consultations with employees, ensuring a safe and healthy working environment environmental principles

organizations and provide a written commitment ensuring Establishment of management system

■ Environment Environmental management, reduction of greenhouse gas emissions, prevention of air, water, soil and other

Management of chemical substances

that suppliers and their business partners will maintain the environmental pollution, resource conservation, waste reduction, chemical substance management, protection of

ecosystems Activities to reduce environmental load

Completion of surveys on CO2 emissions, water

same levels of management. Further, if suppliers are found ■ Information Disclosure Open and fair communication with stakeholders usage, other environmental factors

to be in a state of non-compliance, the guidelines prescribe

required responses, such as filing a report immediately,

Nissan Human Rights Policy *5

*1 Click here for more information on The Renault-Nissan Purchasing Way(PDF). https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/ASSETS/PDF/Renault_Nissan_Purchasing_Way_English.pdf

*2 Click here for more information on collaborations with suppliers within Strengthening Our Business Foundations to Address Environmental Issues. >>> P064

*3 Click here for more information on the Renault-Nissan CSR Guidelines for Suppliers . https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/SUPPLIERS2015/

*4 Click here for more information on the Renault-Nissan CSR Guidelines for Suppliers Supplementary Handbook for Nissan Suppliers. https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/SUPPLIERS_SH/index.html

*5 Click here for more information on Nissan human rights policies and initiatives. >>> P068

ESG data book 2023 098

Nissan Motor Corporation

Contents Corporate direction Environmental Social Governance Data

Social policies Diversity, equity Product safety Supply chain Human resource Employees’ health Community

Human rights Traffic safety Labor practices

and philosophy and inclusion and quality management development and safety engagement

Supply chain management and implement; (1) confirming supply risks under normal Promotion of Monozukuri activities with

circumstances; (2) following up annually on quality, cost,

suppliers

Evaluation, monitoring, and auditing of delivery, development, management, sustainability, and risk

We work to continually improve the competitiveness of

suppliers sustainability practices (QCDDMSR) performance; and (3) working with suppliers

to craft response plans for natural disasters to ensure our products through the Monozukuri Activities program,

Nissan has been confirming suppliers commitment of the production continuity or early restoration of capacity. a collaboration between suppliers and Nissan that was

Renault-Nissan CSR Guidelines for Suppliers and check their We monitor compliance from the perspective of supplier launched in 2008. Since 2009, these activities have

environmental management systems and their willingness management, constantly assessing the situation at each expanded through the joint THANKS Activities initiative,

to advance environmental activities with us at the time of supplier based on a range of factors. When high risk is which emphasizes trust and cooperation between Nissan

supplier selection. Among newly selected suppliers in fiscal identified, we work with the supplier to rapidly draft and and its suppliers. With the goal of working with suppliers

2022, 100% of them met both Nissan s social standards and implement countermeasures. to become cost leaders under today s challenging market

basic environmental principles. In fiscal 2022, there were no suppliers whose compliance conditions, we strive to improve product quality, reduce costs,

In 2016 the Renault-Nissan Alliance began third-party was problematic, and no supplier contract was terminated for and rationalize manufacturing through measures that include

assessment of suppliers sustainability activities to raise such a reason. *3 increasing production volume per part, promoting localization,

standards through mutual confirmation. When results do and improving logistics.

not meet Alliance standards, suppliers are requested to In fiscal 2013, we introduced the Total Delivered Cost (TdC)

draw up plans for improvement. We then monitor their Challenge, aiming to optimize all fluctuating costs, including

implementation. We held a seminar for suppliers, where a for specifications, materials, exchange rates, and logistics.

rating organization spoke to them directly how to answer Our various functional departments, together with suppliers,

assessment questions and formulate improvement plans. are continuously working to proactively promote the TdC

By now, more than 90% of Nissan s purchase demands are Challenge and improve both quality and supply.

covered by a third-party assessment.

We also conduct sustainability training in our purchasing

department to ensure that employees conduct checks

of suppliers sustainability activities in their daily work. In

addition, Nissan requires all employees to attend e-Learning

courses on the Subcontractors Act*1 and the Anti-Monopoly

Act*2 as mandatory training every year in order to maintain

fair and impartial relationships with suppliers.

If there are issues with the supply of parts and materials,

they may lead to problems not only for Nissan s production

but also the supply chain as a whole. We therefore position

the following measures as part of sustainability activities

*1 Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors

*2 Act on Prohibition of Private Monopolization and Maintenance of Fair Trade

*3 Click here for more information on the detail of Nissan Human Rights management and its structure. >>> P070

ESG data book 2023 099

Nissan Motor Corporation

Contents Corporate direction Environmental Social Governance Data

Social policies Diversity, equity Product safety Supply chain Human resource Employees’ health Community

Human rights Traffic safety Labor practices

and philosophy and inclusion and quality management development and safety engagement

Engagement with suppliers Recognizing supplier contributions

Providing suppliers with timely and accurate information worldwide

is a key task for Nissan. Suppliers meetings are held in Each year we recognize the contributions of our suppliers

Japan and overseas to spread understanding of Nissan s to the development of our business and improvement of our

purchasing policy for the fiscal year, midterm business plan, performance with awards presented at the global level as

and other matters. In Japan, we hold monthly meetings and well as in each of the regions where we operate.

directly inform suppliers of our production plans, activities, The purpose of this awards program is to ensure that

and requirements. Nissan s concept of balanced management in terms of social

The meetings are also an opportunity for Nissan to respond and environmental*1 considerations as well as quality*2, cost

to supplier questions and requests. reduction, technological development, and other economic

activities, permeates the entire supply chain on a global level.

At the Nissan Global Supplier Awards, we present

Global Quality Awards to suppliers showing exceptional

performance in quality for the year, and Global Innovation

Awards to suppliers whose innovative initiatives improved

Nissan s brand and product power. Global Quality Award

recipients are selected by Nissan s purchasing, quality and

other divisions using standard criteria applied worldwide.

Global Innovation Award recipients are selected from

suppliers nominated by Nissan s production, development,

and other divisions in two categories: product technology and

process management.

In fiscal 2022, five companies received Global Quality

Awards, while Global Innovation Awards went to 13 projects

and 15 companies.

*1 Click here for more information on collaborations with suppliers within Strengthening Our Business Foundations to Address Environmental Issues. >>> P095

*2 Click here for more information on initiatives with suppliers within Product Safety and Quality. >>> P064

ESG data book 2023 100

Nissan Motor Corporation

Contents Corporate direction Environmental Social Governance Data

Social policies Diversity, equity Product safety Supply chain Human resource Employees’ health Community

Human rights Traffic safety Labor practices

and philosophy and inclusion and quality management development and safety engagement

Responsible minerals sourcing Responsible minerals sourcing management In fiscal 2022 we conducted surveys in nine markets Japan,

the U.S., Mexico, Europe, China, Thailand, India, South Africa

Referring to the OECD Due Diligence Guidance for

Minerals sourcing policy and Brazil. No suppliers were found to be using minerals

Responsible Supply Chains of Minerals from Conflict and

from smelters / refineries believed to be connected to armed

In 2013, Nissan moved quickly to establish a policy High-Risk Areas, Nissan carries out due diligence on high-

groups.

against use of conflict minerals and published the policy risk minerals sourced from conflict and high-risk areas,

Going forward, we plan to make our surveys more effective

on its website. Following this, in July 2020 it formulated including 3TGs (tin, tungsten, tantalum, and gold) and cobalt.

by improving its methodology in conjunction with the

and published its new Global Minerals Sourcing Policy Since 2021, the Renault-Nissan-Mitsubishi Alliance has

member companies of the Japan Automobile Manufacturers

Statement*1 and expanded the scope from the conflict joined the RMI*2 to assess risks together with suppliers and

Association, Inc., and the Japan Auto Parts Industries

minerals known as 3TGs (tin, tungsten, tantalum, and gold) further strengthen activities to correct problems when they

Association. We will also continue to seek responses from

to all minerals including cobalt from conflict-affected and are identified.

suppliers that did not reply to the survey.

high-risk areas. Nissan requests that suppliers ensure similar With regard to 3TGs, we began conducting conflict mineral

We are aware that cobalt poses geopolitical risks,

controls. surveys in our major areas of operation (Japan, North

environmental damage and human rights issues during

America, and Europe) in fiscal 2013. Starting in fiscal 2014,

mining. We have conducted interviews with lithium-ion

Nissan s goal is to conduct ethical, social, and we gradually expanded the scope of these surveys to other

battery suppliers, from the viewpoint of cobalt content, and

environmentally conscious business practices at every level areas. Surveys on a massive scale are required to grasp the

since 2018, we have been working to identify supply chains

of our global supply chain. We monitor our supply chain to status of minerals usage throughout the global supply chain.

and smelters and refiners. The results are disclosed annually

assess whether the mineral resources contained in materials We therefore collaborate with organizations including the

in our Actions for minerals sourcing report.*3

or components used to manufacture our products have Japan Automobile Manufacturers Association, Inc., the Japan

The head of the Purchasing Department is responsible for

any harmful social effect, such as on human rights or the Auto Parts Industries Association, and the Japan Electronics

conducting supply chain due diligence with the cooperation

environment. When there are concerns about the minerals and Information Technology Industries Association to

of the R&D Division, Sustainability Development Department,

being used, Nissan actively works to end that use. hold regular working group sessions to consider methods

and other related divisions, and reports the results to the

for investigation and analyzing the results of those

Global Sustainability Steering Committee. The results are

investigations.

also appropriately reported to the Executive Committee

The surveys track minerals back through the chain of

(EC), Nissan s highest decision-making body, for use in

suppliers using CMRT (Conflict Mineral Reporting Template)

determining future initiatives.

provided by the RMI. This enables Nissan to identify smelting

and refining companies that are not procuring minerals that

are a source of funds for armed groups in their regions.

We provide the suppliers we survey with manuals describing

how to fill in required forms and what tools to use to collate

results. In this way, we work to increase understanding of

conflict mineral issues throughout the supply chain.

*1 Click here for more information on the Global Minerals Sourcing Policy Statement. https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/ASSETS/PDF/Minerals_Sourcing_Policy_e.pdf

*2 RMI stands for Responsible Minerals Initiative, an organization with member companies and associations from the information and communications technology and other industries that works to improve global social and environmental awareness.

*3 Click here for more information on our Actions for minerals sourcing. https://www.nissan-global.com/EN/SUSTAINABILITY/LIBRARY/ASSETS/PDF/Minerals_e.pdf

ESG data book 2023 101

You might also like

- KLAS Report 2023 Best in Klas Awards Software and Professional Services FullDocument250 pagesKLAS Report 2023 Best in Klas Awards Software and Professional Services FullJakob EmersonNo ratings yet

- Introduction To Accounting: Fundamentals of Accountancy, Business and Management 1Document9 pagesIntroduction To Accounting: Fundamentals of Accountancy, Business and Management 1Marilyn Nelmida TamayoNo ratings yet

- 9001 Audit Checklist-Production SupportDocument7 pages9001 Audit Checklist-Production SupportAmer RahmahNo ratings yet

- Delivery Maturity IndexDocument33 pagesDelivery Maturity Indexcalio jr. joven Dumam-agNo ratings yet

- BR100 - AP - Application - Setup Ver 1.0Document35 pagesBR100 - AP - Application - Setup Ver 1.0Muhammad Naveed AshrafNo ratings yet

- Family NUrsing Care Plan FNCPDocument2 pagesFamily NUrsing Care Plan FNCPadrianwiz0781% (21)

- Servicenow Benchmarks: at A GlanceDocument2 pagesServicenow Benchmarks: at A Glancefali500No ratings yet

- Costa Coffee Marketing StartegyDocument15 pagesCosta Coffee Marketing Startegyarulit0495% (21)

- Focus: IntraDocument12 pagesFocus: IntraNguyen Thi Phuong DungNo ratings yet

- DI - TMT - Digital Transformation Series No. 13Document16 pagesDI - TMT - Digital Transformation Series No. 13Anh VuNo ratings yet

- @shingo Model HandbookDocument52 pages@shingo Model HandbookKao AkanaNo ratings yet

- Loan AgreementDocument5 pagesLoan AgreementAnthony MalungaNo ratings yet

- Sample CSHP (Safety&Health D.O.13 DOLE)Document1 pageSample CSHP (Safety&Health D.O.13 DOLE)Jemsel D. Valdez, Sr.No ratings yet

- Benchmarking Definition and HistoryDocument7 pagesBenchmarking Definition and HistoryMichelle Mc IntyreNo ratings yet

- Brochure AVEVA-Wonderware PartnerGuide 04-19Document31 pagesBrochure AVEVA-Wonderware PartnerGuide 04-19John SmithNo ratings yet

- Agile Leadership: A Leader’S Guide to Orchestrating Agile Strategy, Product Quality and It GovernanceFrom EverandAgile Leadership: A Leader’S Guide to Orchestrating Agile Strategy, Product Quality and It GovernanceNo ratings yet

- Benchmarking Research Paper PDFDocument8 pagesBenchmarking Research Paper PDFnachiappanmNo ratings yet

- Fiscal ManagementDocument28 pagesFiscal ManagementEdlyn NacionalNo ratings yet

- Shingo Model HandbookDocument52 pagesShingo Model Handbookhoracio4espinoza4calNo ratings yet

- Lean SystemTOCDocument93 pagesLean SystemTOCbullfinch2No ratings yet

- T R - N P W: HE Enault Issan Urchasing AYDocument12 pagesT R - N P W: HE Enault Issan Urchasing AYMehdi RostamiNo ratings yet

- Esgdb23 e P091-096Document6 pagesEsgdb23 e P091-096sushantNo ratings yet

- Synesgy - The ESG NetworkDocument4 pagesSynesgy - The ESG NetworkManish AwasthiNo ratings yet

- Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our DealersDocument5 pagesValue Chain: P. 70 Working With Our Suppliers P. 72 Working With Our DealersTaVoVelaNo ratings yet

- The SAC Higg IndexDocument40 pagesThe SAC Higg IndexRanjit SamalNo ratings yet

- Sdb2021e-Supply ChainDocument6 pagesSdb2021e-Supply Chainhameed hanifNo ratings yet

- Esgdb23 e P102-106Document5 pagesEsgdb23 e P102-106sushantNo ratings yet

- Literature Review Software Company Efficiency andDocument9 pagesLiterature Review Software Company Efficiency anddbNo ratings yet

- Shingo Model HandbookDocument52 pagesShingo Model Handbookfadhel ben fdhilaNo ratings yet

- Shingo Model HandbookDocument52 pagesShingo Model Handbookfadhel ben fdhilaNo ratings yet

- Procurement Strategy & Innovation (SCM457J - 2021) : Maturity AnalysisDocument9 pagesProcurement Strategy & Innovation (SCM457J - 2021) : Maturity AnalysisDheraviam ParivallalNo ratings yet

- SCM Project GuidelinesDocument6 pagesSCM Project GuidelinesAMAN GUPTA MBA 2019-21 (Delhi)No ratings yet

- Substantive Facets of Market SensingDocument27 pagesSubstantive Facets of Market SensingpostsibasisNo ratings yet

- Business Model StrategyDocument31 pagesBusiness Model Strategyboomrock400No ratings yet

- CSR Guideline For Suppliers 2019enDocument14 pagesCSR Guideline For Suppliers 2019enNAWINKUMAR RNo ratings yet

- NissanDocument4 pagesNissanfara_munawarNo ratings yet

- Index: Wipro Company AnalysisDocument20 pagesIndex: Wipro Company AnalysisRehan TyagiNo ratings yet

- Smart Buyer: A Bayesian Network Modelling Approach For Measuring and Improving Procurement Performance in OrganisationsDocument23 pagesSmart Buyer: A Bayesian Network Modelling Approach For Measuring and Improving Procurement Performance in OrganisationsHerjun WicaksonoNo ratings yet

- For ABE Use Only: Assignment Cover SheetDocument13 pagesFor ABE Use Only: Assignment Cover SheetHibernation PetersonNo ratings yet

- 2017 Bookmatter Risk-BasedMaintenanceForElectrDocument25 pages2017 Bookmatter Risk-BasedMaintenanceForElectrrodrigo_domNo ratings yet

- Pptforpom 140306074652 Phpapp01Document36 pagesPptforpom 140306074652 Phpapp01Sonal AgarwalNo ratings yet

- Responsible Procurement PraticesDocument8 pagesResponsible Procurement PraticesShilpi MehrotraNo ratings yet

- TATA Motors ValuechainDocument24 pagesTATA Motors ValuechainBhawana SinhaNo ratings yet

- 2023-03 Onboarding+PresentationDocument105 pages2023-03 Onboarding+Presentationducduydang36No ratings yet

- Value Chain: Watch The Video!Document8 pagesValue Chain: Watch The Video!Hans PeterNo ratings yet

- Supply Chain: Material IssuesDocument14 pagesSupply Chain: Material Issuesreach2ghoshNo ratings yet

- 04 Strategic ManagementDocument24 pages04 Strategic ManagementAditio Sadhi RaditoNo ratings yet

- Tata Motors ValuechainDocument24 pagesTata Motors ValuechainNithesh PawarNo ratings yet

- Value Chain Management: The Concept of Value Addition in Supply ChainsDocument23 pagesValue Chain Management: The Concept of Value Addition in Supply ChainsANo ratings yet

- Marketing: - Competitor Analysis - Competitive Factors - Competitive Advantage - Marketing InformationDocument19 pagesMarketing: - Competitor Analysis - Competitive Factors - Competitive Advantage - Marketing InformationSAGARNo ratings yet

- Unec 1696696515Document15 pagesUnec 1696696515nicatmamedov794No ratings yet

- CHP 3 Customer Relationship ManagementDocument47 pagesCHP 3 Customer Relationship ManagementKiran KumarNo ratings yet

- CUSTOMER INSIDE DigitalDocument68 pagesCUSTOMER INSIDE DigitalMNo ratings yet

- Yamaha Supply ChainDocument7 pagesYamaha Supply ChainkagneyNo ratings yet

- M.Refaat MISDocument26 pagesM.Refaat MIStarek.sayd.23d983No ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain Managementkamal1342No ratings yet

- 5 S - A Quality Improvement Tool For Sustainable PerformanceDocument46 pages5 S - A Quality Improvement Tool For Sustainable PerformanceDương NguyễnNo ratings yet

- Global Social Compliance Programme: Presentation & UpdateDocument11 pagesGlobal Social Compliance Programme: Presentation & Updatemayank ladNo ratings yet

- Rhino: Establishing A Competitive E-Commerce PlatformDocument1 pageRhino: Establishing A Competitive E-Commerce Platform7744405mmmNo ratings yet

- Abhijna Mukherjee DM21B02 PMSDocument25 pagesAbhijna Mukherjee DM21B02 PMSAbhijna MukherjeeNo ratings yet

- SCM Unit-4 WordDocument9 pagesSCM Unit-4 WordNeelam YadavNo ratings yet

- Chapters (4) Sangeetha Report SSSS San PDFDocument56 pagesChapters (4) Sangeetha Report SSSS San PDFMohan GNo ratings yet

- Ocd 4Document32 pagesOcd 4Lucky SharmaNo ratings yet

- Jurnal PenelitianDocument19 pagesJurnal PenelitianYORI ILHAM ALKINDINo ratings yet

- AFE Value Chain Analysis SEEP AGM 04Document15 pagesAFE Value Chain Analysis SEEP AGM 04kimlengtycoonNo ratings yet

- 04-Strategic ManagementDocument24 pages04-Strategic ManagementXI-IPS 3-29-Reisya Adelia Putri A. ANo ratings yet

- The BizDevOps Revolution: Unleashing Agile Synergy in Business, Development, and OperationsFrom EverandThe BizDevOps Revolution: Unleashing Agile Synergy in Business, Development, and OperationsNo ratings yet

- Financial Range Wise of No. of Projects 2006-07Document1 pageFinancial Range Wise of No. of Projects 2006-07sushantNo ratings yet

- Industry Group Wise No - of ProjectsDocument1 pageIndustry Group Wise No - of ProjectssushantNo ratings yet

- Esgdb23 e P163Document1 pageEsgdb23 e P163sushantNo ratings yet

- Year Wise Number of ProjectsDocument1 pageYear Wise Number of ProjectssushantNo ratings yet

- Loans For Village and Small IndustriesDocument1 pageLoans For Village and Small IndustriessushantNo ratings yet

- Dynamic CSRReportDocument25 pagesDynamic CSRReportsushantNo ratings yet

- Esgdb23 e P107-111Document5 pagesEsgdb23 e P107-111sushantNo ratings yet

- Dev Sector Wise ReportDocument3 pagesDev Sector Wise ReportsushantNo ratings yet

- Esgdb23 e P002Document1 pageEsgdb23 e P002sushantNo ratings yet

- Entities Included in The Organization's Sustainability ReportingDocument1 pageEntities Included in The Organization's Sustainability ReportingsushantNo ratings yet

- Esgdb23 e P058-059Document2 pagesEsgdb23 e P058-059sushantNo ratings yet

- Organizational DetailsDocument2 pagesOrganizational DetailssushantNo ratings yet

- Esgdb23 e P132-133Document2 pagesEsgdb23 e P132-133sushantNo ratings yet

- GLEN-2021 Extended Esg DataDocument51 pagesGLEN-2021 Extended Esg DatasushantNo ratings yet

- Cameco 2022 SASB IndexDocument3 pagesCameco 2022 SASB IndexsushantNo ratings yet

- Bank Indonesia Case StudyDocument13 pagesBank Indonesia Case StudysushantNo ratings yet

- XBRLor Customized XMLDocument12 pagesXBRLor Customized XMLsushantNo ratings yet

- XBRL International Membership ApplicationDocument2 pagesXBRL International Membership ApplicationsushantNo ratings yet

- Annual Action PlanDocument1 pageAnnual Action PlansushantNo ratings yet

- Brambles GRI Disclosure 2022Document88 pagesBrambles GRI Disclosure 2022sushantNo ratings yet

- Galiano Gold 2020 GRI Table October 2021Document99 pagesGaliano Gold 2020 GRI Table October 2021sushantNo ratings yet

- SICONFI Case Study Revised FinalDocument16 pagesSICONFI Case Study Revised FinalsushantNo ratings yet

- PFC SemiconductorsDocument10 pagesPFC SemiconductorssushantNo ratings yet

- N20-Nitric 2.1 0Document6 pagesN20-Nitric 2.1 0sushantNo ratings yet

- Report On Leak of Furnace Oil in The Premises of The Chandrapura Thermal Power Station (CTPS), Chandrapura, Jharkhand, 10 - 11 - 2020Document3 pagesReport On Leak of Furnace Oil in The Premises of The Chandrapura Thermal Power Station (CTPS), Chandrapura, Jharkhand, 10 - 11 - 2020sushantNo ratings yet

- Cory GRI Content Index 2020Document16 pagesCory GRI Content Index 2020sushantNo ratings yet

- ReunertG3 IndexDocument7 pagesReunertG3 IndexsushantNo ratings yet

- Calculating N2O Emissions From The Production of Nitric AcidDocument3 pagesCalculating N2O Emissions From The Production of Nitric AcidsushantNo ratings yet

- GHG Estimation-Tool-08-V3Document6 pagesGHG Estimation-Tool-08-V3sushantNo ratings yet

- Environmental Gri Indicators Abb csr19Document2 pagesEnvironmental Gri Indicators Abb csr19sushantNo ratings yet

- Hello SURESHA, Here's Your Tax Invoice: Original For RecipientDocument1 pageHello SURESHA, Here's Your Tax Invoice: Original For RecipientSuresh CANo ratings yet

- Cipla Ar 2020 21 Single PageDocument442 pagesCipla Ar 2020 21 Single PageMichelle CastelinoNo ratings yet

- Justice Failure: Efficiency and Equality in Business EthicsDocument19 pagesJustice Failure: Efficiency and Equality in Business Ethicsmapri doniNo ratings yet

- In Partnership With: Jack Appleby - 07494479242 - John Walpole - 07938219903Document12 pagesIn Partnership With: Jack Appleby - 07494479242 - John Walpole - 07938219903Jack BradNo ratings yet

- For SainsburyDocument5 pagesFor Sainsburysusmit dasNo ratings yet

- The Intrapreneurship Formula: How To Drive Corporate Entrepreneurship Through Employee EmpowermentDocument41 pagesThe Intrapreneurship Formula: How To Drive Corporate Entrepreneurship Through Employee EmpowermentCharlene KronstedtNo ratings yet

- In The Books of M/S. Vikas Trading Co.: Date Particulars Debit Credit CGST SGST IgstDocument12 pagesIn The Books of M/S. Vikas Trading Co.: Date Particulars Debit Credit CGST SGST IgstBlossom KaurNo ratings yet

- ScriptDocument5 pagesScriptKat DegNo ratings yet

- AKUNTANSI-LEMBAR KERJA-BUKU BESAR PT. PrimaDocument24 pagesAKUNTANSI-LEMBAR KERJA-BUKU BESAR PT. PrimaWendelyn ShieNo ratings yet

- Annual Report 2023 24Document228 pagesAnnual Report 2023 24abdulmunayeem3986No ratings yet

- Professor Kremepuff Has Written A New Highly Simplified Economics TextDocument2 pagesProfessor Kremepuff Has Written A New Highly Simplified Economics Texttrilocksp SinghNo ratings yet

- Executive Master of Public Administration: Tackle Tomorrow's Leadership ChallengesDocument7 pagesExecutive Master of Public Administration: Tackle Tomorrow's Leadership Challengesbani1uk932No ratings yet

- Marketing Strategic Vs TacticalDocument4 pagesMarketing Strategic Vs TacticalShaneNo ratings yet

- TLE Sir Paras PresentationDocument21 pagesTLE Sir Paras PresentationGAYLY ANN TOLENTINONo ratings yet

- Capital Asset Pricing ModelDocument17 pagesCapital Asset Pricing ModelChrisna Joyce MisaNo ratings yet

- A Defence Against The Next Convexity CrunchDocument6 pagesA Defence Against The Next Convexity CrunchkevNo ratings yet

- Company Secretary Training With Exemption Registration EtcDocument7 pagesCompany Secretary Training With Exemption Registration EtcVikram SekherNo ratings yet

- Berk/Demarzo, Corporate Finance Chapter 18 Tables and ExamplesDocument3 pagesBerk/Demarzo, Corporate Finance Chapter 18 Tables and ExamplesPourisotNo ratings yet

- How To Fill The Guarantor FormDocument22 pagesHow To Fill The Guarantor FormDavid magicianNo ratings yet

- Account For MaterialDocument25 pagesAccount For Materialshrestha.aryxnNo ratings yet

- HRM - HeartbreakDocument3 pagesHRM - Heartbreak23321gauravNo ratings yet

- MBA II CV FormatDocument2 pagesMBA II CV FormatnomanNo ratings yet