Professional Documents

Culture Documents

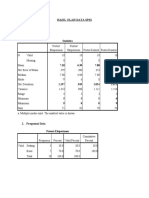

TABLE 1 Precision of Test On Residue

Uploaded by

JOSE CANTEROOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TABLE 1 Precision of Test On Residue

Uploaded by

JOSE CANTEROCopyright:

Available Formats

D 1754 – 97 (2002)

fluid condition if necessary. Complete the tests on residue by a high percentage of volatile components will usually exhibit a mass loss.

appropriate ASTM test methods within 72 h of performing this

test. 9. Precision and Bias

NOTE 6—Care should be taken if the sample is reheated more than 9.1 Criteria for judging the acceptability of the viscosity at

once, since excessive reheating can affect the apparent severity of the test. 60°C (140°F) and 135°C (275°F), viscosity ratio at 60°C

(140°F), change in penetration at 25°C (77°F), and mass

8. Report change test results obtained by this method are given in Table

8.1 Report the values of the original asphalt properties 1. The figures given in Column 2 are the standard deviations

measured in 6.2 and the residue property values as measured in that have been found to be appropriate for the materials and

7.5. Viscosity change may also be expressed as the ratio of the conditions of test described in Column 1. The figures given in

residual asphalt viscosity to the original asphalt viscosity. Column 3 are the limits that should not be exceeded by the

Penetration change is evaluated as the penetration of the difference between the results of two properly conducted tests.

residue expressed as the percentage of the original penetration. The figures given in Column 4 are the coefficients of variation

8.2 Report ductility or other test results in accordance with that have been found to be appropriate for the materials and

the appropriate ASTM test methods. conditions of test described in Column 1. The figures given in

8.3 When determined, report the average mass change of the Column 5 are the limits that should not be exceeded by the

material in all containers as mass percent of the original difference between the results of two properly conducted tests

material. A mass loss shall be reported as a negative number, expressed as a percent of their mean.

while a mass gain shall be reported as a positive number. 9.2 Criteria for judging the acceptability of ductility data at

NOTE 7—This test can result in either a mass loss or a mass gain. 15.6°C (60°F) are given in Table 1. Each test result is the

During the test, volatile components evaporate (causing a decrease in average of three ductility measurements.

mass), while oxygen reacts with the sample (causing an increase in mass).

The combined effect determines whether the sample has an overall mass 10. Keywords

gain or an overall mass loss. Samples with a very low percentage of

volatile components will usually exhibit a mass gain, while samples with 10.1 aging; asphalt cement; Thin-Film Oven Test (TFOT)

TABLE 1 Precision of Test on Residue

Standard Coefficient of Variation Acceptable Range of

Acceptable Range of

Material and Type Index Deviation (percent of Two Results (percent

Two Results (d2s)

(1s) mean) (1s%) of mean) (d2s%)

Percentage of retained penetration 1.43 4.0 ... ...

Change in mass percentage:

Not more than 0.4 % (max) 0.014 0.04 ... ...

Greater than 0.4 % ... ... 2.9 8.0

Viscosity at 60°C (140°F) ... ... 3.3 9.3

Viscosity at 135°C (275°F) ... ... 2.0 5.7

60° 140° ... ... 5.6 16.0

:

60° 140°

Ductility at 15.6°C (60°F), cm 7 20

Percentage of retained penetration 2.90 8.0 ... ...

Change in mass percentage:

Not more than 0.4 % (max) 0.055 0.16 ... ...

Greater than 0.4 % ... ... 14.0 40.0

Viscosity at 60°C (140°F) ... ... 11.6 33.0

Viscosity at 135°C (275°F) ... ... 6.4 18.0

Ratio: ... ... 9.1 26.0

60° 140°

60° 140°

Ductility at 15.6°C (60°F), cm 12 34

This is based on the analysis of data resulting from tests by 60 laboratories on four asphalts with average ductilities ranging from 20 to 40 cm.

Multilaboratory precision applicable to asphalt cements having viscosity ratios lower than 3.0. Precision for ratios greater than 3.0 have not been established.

You might also like

- Thermodynamics 1Document84 pagesThermodynamics 1Nick Decillo90% (145)

- D4402Document2 pagesD4402borisov2009No ratings yet

- ASTM D2669-06 Apparent Viscosity of Petroleum Waxes Compounded PDFDocument5 pagesASTM D2669-06 Apparent Viscosity of Petroleum Waxes Compounded PDFLluís FontNo ratings yet

- Experiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFDocument6 pagesExperiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFsaifNo ratings yet

- KeRRA Report - Week 8 & 9Document12 pagesKeRRA Report - Week 8 & 9Muthomi MunyuaNo ratings yet

- TGGuideline 114 Viscosity of LiquidsDocument7 pagesTGGuideline 114 Viscosity of LiquidsDonig FermanianNo ratings yet

- Experiment No. 4 Sieve Analysis of Aggregates: Referenced Standard: ASTM C 136-84a AASHTO T 27-93Document8 pagesExperiment No. 4 Sieve Analysis of Aggregates: Referenced Standard: ASTM C 136-84a AASHTO T 27-93Meriann May Sacayan DivinagraciaNo ratings yet

- Assignment 2Document4 pagesAssignment 2Syed Faisal Mohiuddin SharfiNo ratings yet

- VDOTGearOil TAE 2006Document1 pageVDOTGearOil TAE 2006zinbobo htetNo ratings yet

- Ch6A-Lab Manual Asphalt BinderDocument8 pagesCh6A-Lab Manual Asphalt BinderRicky GargNo ratings yet

- Quality EngineeringDocument2 pagesQuality Engineeringbrahma2deen2chaudharNo ratings yet

- Calibration of Bitumen Sprayers Part 6: Viscosity of Test OilDocument3 pagesCalibration of Bitumen Sprayers Part 6: Viscosity of Test Oilतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Test On Aggregates - 2Document7 pagesTest On Aggregates - 2SupreethNo ratings yet

- Reynolds Experiment ENSC3003Document6 pagesReynolds Experiment ENSC3003Jodi LynchNo ratings yet

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 pagesPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharNo ratings yet

- Asphalt Technology: LaboratorDocument10 pagesAsphalt Technology: LaboratorOmar BokhareNo ratings yet

- Lecture 2 - Introductory StatisticsDocument55 pagesLecture 2 - Introductory Statisticscheta21No ratings yet

- Name: Dana Isabelle R. Villan Locker Number: 40H Experiment 1: Density of Beverages Date: 09/18/18Document6 pagesName: Dana Isabelle R. Villan Locker Number: 40H Experiment 1: Density of Beverages Date: 09/18/18Dana VillanNo ratings yet

- Highway Materials Lab PDFDocument40 pagesHighway Materials Lab PDFAbdulaziz BarhomehNo ratings yet

- Norma Do BetuminosoDocument9 pagesNorma Do BetuminosoAna PinhoNo ratings yet

- Asphalt Mix Design, WadriboDocument85 pagesAsphalt Mix Design, WadriboAbuBakerNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument4 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestTemur LomidzeNo ratings yet

- Marshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Document11 pagesMarshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Bernard Kitosi100% (1)

- 25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Document3 pages25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Mithun RaulNo ratings yet

- MS 02 Asphalt Mix Design, 7th Edition, 2014Document2 pagesMS 02 Asphalt Mix Design, 7th Edition, 2014Shafiqullah GowharyNo ratings yet

- ASHRAE 52-2 ExplainedDocument2 pagesASHRAE 52-2 ExplainedVenkatesan RamalingamNo ratings yet

- Gradation and Fineness Modulus of Fine AggregateDocument7 pagesGradation and Fineness Modulus of Fine AggregateAlbert JanssenNo ratings yet

- Density, Relative Density and API Gravity: According To IP559 and ASTM D7777Document1 pageDensity, Relative Density and API Gravity: According To IP559 and ASTM D7777AdikoDenzeyAnonhNo ratings yet

- Baterie YTZ12S-BSDocument1 pageBaterie YTZ12S-BSHoratiu SichitiuNo ratings yet

- 1986 - Prediction of Properties of Petroleum Mixtures - Improvement in Reliability and Validity of Tuned ParametersDocument8 pages1986 - Prediction of Properties of Petroleum Mixtures - Improvement in Reliability and Validity of Tuned ParametersRosendo Monroy LoperenaNo ratings yet

- Li 2017 IOP Conf. Ser. Mater. Sci. Eng. 280 012017Document6 pagesLi 2017 IOP Conf. Ser. Mater. Sci. Eng. 280 012017mohamedNo ratings yet

- Viscosity of Asphalts by Vacuum Capillary Viscometer: Standard Test Method ForDocument8 pagesViscosity of Asphalts by Vacuum Capillary Viscometer: Standard Test Method ForMohamed Maamoun T.No ratings yet

- Specialty Chemcials Lab FinalDocument9 pagesSpecialty Chemcials Lab FinalSharath BalachandraNo ratings yet

- VTC401 TDS DefDocument6 pagesVTC401 TDS DefRGFENo ratings yet

- Lampiran Hasil Analisa StatistikDocument7 pagesLampiran Hasil Analisa StatistikFariza AndriyawanNo ratings yet

- Lampiran Hasil Analisa StatistikDocument7 pagesLampiran Hasil Analisa StatistikFariza AndriyawanNo ratings yet

- Experiment No. 2 Sieve Analysis of Aggregates: Reference Standard: ASTM C 136-84a AASHTO T27-93Document17 pagesExperiment No. 2 Sieve Analysis of Aggregates: Reference Standard: ASTM C 136-84a AASHTO T27-93AJ DuhaylungsodNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- FrequencyDocument2 pagesFrequencyAnak LangitNo ratings yet

- Overview of Materials For Thermoset Polyurethane Foam, UnreinforcedDocument4 pagesOverview of Materials For Thermoset Polyurethane Foam, Unreinforcedvaratharajan g rNo ratings yet

- Uk-C: Marshall Mix Design Method (Astm D 1559 or JKR Method)Document5 pagesUk-C: Marshall Mix Design Method (Astm D 1559 or JKR Method)AiniHazwaniNo ratings yet

- Qualitative Examination: Table 1Document1 pageQualitative Examination: Table 1VimalNo ratings yet

- StatistikDocument5 pagesStatistikElvisa FitriNo ratings yet

- Studies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesDocument27 pagesStudies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesKis KhisbiahNo ratings yet

- Overview of Materials For Polypropylene With 20% Glass Fiber FillerDocument4 pagesOverview of Materials For Polypropylene With 20% Glass Fiber FillerbiroutiNo ratings yet

- Viscosity-Graded Asphalt Cement: Standard Specification ForDocument4 pagesViscosity-Graded Asphalt Cement: Standard Specification Formohammed karasnehNo ratings yet

- Water Repellency: Spray TestDocument3 pagesWater Repellency: Spray TestVickyNo ratings yet

- TABEL ANSAR Kelompok 13Document51 pagesTABEL ANSAR Kelompok 13Muhammad Dewangga RamadanNo ratings yet

- Miller-Et Al - PARIODocument1 pageMiller-Et Al - PARIOMarvin Ubaldo SantiagoNo ratings yet

- 094 Anggraini Kinasih TP6B Latian SPSS RALDocument5 pages094 Anggraini Kinasih TP6B Latian SPSS RALAnggraini KinasihNo ratings yet

- Experiment No. 2: Marshall Stability Test For Bitumen Mix DesignDocument12 pagesExperiment No. 2: Marshall Stability Test For Bitumen Mix DesignKanishka SarkarNo ratings yet

- 6501 Climomaster DatasheetDocument2 pages6501 Climomaster DatasheetDedi KartiwaNo ratings yet

- Calibration of InstrumentsDocument32 pagesCalibration of InstrumentsEsha Naveed100% (2)

- Bituminous Mix DesignDocument62 pagesBituminous Mix DesignShaim RehanNo ratings yet

- Experiment No. 1: "Sieve Analysis of Coarse and Fine Aggregates"Document5 pagesExperiment No. 1: "Sieve Analysis of Coarse and Fine Aggregates"Jhon Russel Cruz AntonioNo ratings yet

- Instrument Performance Evaluation, Comparing ISO 10723 and NORSOK I-106Document37 pagesInstrument Performance Evaluation, Comparing ISO 10723 and NORSOK I-106MohitNo ratings yet

- Summary Test Result of Mix For: Ac - BC: No Test Description Unit Trial Lab SpecDocument35 pagesSummary Test Result of Mix For: Ac - BC: No Test Description Unit Trial Lab SpecAris Atma WijayaNo ratings yet

- Standard Method of Test For: 1. ScopeDocument4 pagesStandard Method of Test For: 1. ScopeSalma AlzwayNo ratings yet

- (Spring - 2013 - CVEN350) Environmental Engineering: Experiment #6 Coagulation and FlocculationDocument6 pages(Spring - 2013 - CVEN350) Environmental Engineering: Experiment #6 Coagulation and FlocculationConstantinTudoseNo ratings yet

- Membrane Separations Technology: Single-Stage, Multistage, and Differential PermeationFrom EverandMembrane Separations Technology: Single-Stage, Multistage, and Differential PermeationNo ratings yet

- Qte4mi9bmtgytq 2Document1 pageQte4mi9bmtgytq 2JOSE CANTERONo ratings yet

- FIG. X1.2 Recommended TFOT Shelf With Four PansDocument1 pageFIG. X1.2 Recommended TFOT Shelf With Four PansJOSE CANTERONo ratings yet

- Qte4mi9bmtgytq 4Document1 pageQte4mi9bmtgytq 4JOSE CANTERONo ratings yet

- Qte4mi9bmtgytq 3Document1 pageQte4mi9bmtgytq 3JOSE CANTERONo ratings yet

- Qte4mi9bmtgytq 1Document1 pageQte4mi9bmtgytq 1JOSE CANTERONo ratings yet

- Qte4mi9bmtgytq 5Document1 pageQte4mi9bmtgytq 5JOSE CANTERONo ratings yet

- Qte1oq 5Document1 pageQte1oq 5JOSE CANTERONo ratings yet

- D3822 2Document2 pagesD3822 2JOSE CANTERONo ratings yet

- D3822 5Document2 pagesD3822 5JOSE CANTERONo ratings yet

- D3822 4Document2 pagesD3822 4JOSE CANTERONo ratings yet

- D3822 3Document2 pagesD3822 3JOSE CANTERONo ratings yet

- D3822 1Document2 pagesD3822 1JOSE CANTERONo ratings yet

- Hardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)Document3 pagesHardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)JOSE CANTERONo ratings yet

- Chapter 8 16 PDFDocument1 pageChapter 8 16 PDFAlwin WanNo ratings yet

- Walpole Probability & Statistics For Engineers & Scientists-Pearson (2017) - 747-752Document6 pagesWalpole Probability & Statistics For Engineers & Scientists-Pearson (2017) - 747-752Juan Francisco Padilla MartinezNo ratings yet

- 1-Towards Digital Design of Gas TurbinesDocument12 pages1-Towards Digital Design of Gas TurbinesSajjad KheirandishNo ratings yet

- CE8395-Strength of Materials For Mechanical EngineersDocument19 pagesCE8395-Strength of Materials For Mechanical Engineers26 MaheshkannanNo ratings yet

- Células de Carga - FH5399gb - PWSDocument2 pagesCélulas de Carga - FH5399gb - PWSVinícius OliveiraNo ratings yet

- Design of Absorption Column 160127152306Document33 pagesDesign of Absorption Column 160127152306Dũng LêNo ratings yet

- Dungeons and Dragons Science Spell BookDocument34 pagesDungeons and Dragons Science Spell BookHerea Isidor100% (1)

- 10 26701-Ems 644733-1070465Document6 pages10 26701-Ems 644733-1070465Boubacar FofanaNo ratings yet

- Chapter 1 - Electric Charges and FieldsDocument97 pagesChapter 1 - Electric Charges and FieldsPriyaNo ratings yet

- Simultaneous Diagonalization: John E. MitchellDocument24 pagesSimultaneous Diagonalization: John E. MitchellMalika BehroozrazeghNo ratings yet

- Generalpaper On Power Shift of Hydraulic ExcavatorDocument7 pagesGeneralpaper On Power Shift of Hydraulic ExcavatorShankar yadavNo ratings yet

- 2.17 Conditional Distributions: Intro / DefinitionDocument19 pages2.17 Conditional Distributions: Intro / Definition6688558855No ratings yet

- Molasses Tank 18092020Document31 pagesMolasses Tank 18092020Keshav GopaulNo ratings yet

- Pre-Calculus Q2 Module 9Document7 pagesPre-Calculus Q2 Module 9Prince Reinier JonNo ratings yet

- Steel GirderDocument42 pagesSteel GirderPutri PuttNo ratings yet

- LAS Week 4 5 AnswerSheetsDocument4 pagesLAS Week 4 5 AnswerSheetsLyanna Nina CabralNo ratings yet

- 4 Esthetics in DentistryDocument81 pages4 Esthetics in DentistryAME DENTAL COLLEGE RAICHUR, KARNATAKANo ratings yet

- Valves. Valves and Fittings Pressure Drop CoefficientsDocument270 pagesValves. Valves and Fittings Pressure Drop CoefficientsJSN1790% (1)

- 3.2 Logarithmic Functions & Their GraphsDocument16 pages3.2 Logarithmic Functions & Their GraphsGaming With the BoysNo ratings yet

- DCC50222 - Assignment 1SII22223-1Document3 pagesDCC50222 - Assignment 1SII22223-1Fauzan PojanNo ratings yet

- 01.07.2023 - Jr.C-IPL - JEE MAINS - WTM-2 Q.PAPERDocument18 pages01.07.2023 - Jr.C-IPL - JEE MAINS - WTM-2 Q.PAPERGowri ShankarNo ratings yet

- Investigating Newton's Law of CoolingDocument9 pagesInvestigating Newton's Law of CoolingsuhaasNo ratings yet

- MIT8 01F16 Pset3Document8 pagesMIT8 01F16 Pset3joshuapwallenNo ratings yet

- Science Le - Thirdquarter - HeattransferDocument4 pagesScience Le - Thirdquarter - HeattransferFatima Abacan Reyes100% (3)

- DesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingDocument10 pagesDesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingMEEN201101002 KFUEITNo ratings yet

- Klausmeier 1999Document3 pagesKlausmeier 1999Emmanuel kpegloNo ratings yet

- ks2 Science 2012 Test BDocument20 pagesks2 Science 2012 Test BZane soh100% (1)

- Operation Manual R-Series EthernetIP 551283 enDocument39 pagesOperation Manual R-Series EthernetIP 551283 enBryan AndradeNo ratings yet

- ISRO RAC Conference RTST Brochure and Guidelines 1Document5 pagesISRO RAC Conference RTST Brochure and Guidelines 1manavhazarika36No ratings yet