Professional Documents

Culture Documents

Interfacings and Edge Finishes

Uploaded by

tertianerima1010 ratings0% found this document useful (0 votes)

2 views6 pagesFashion and Textiles

Original Title

INTERFACINGS AND EDGE FINISHES

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFashion and Textiles

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views6 pagesInterfacings and Edge Finishes

Uploaded by

tertianerima101Fashion and Textiles

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

INTERFACINGS AND EDGE FINISHES

INTERFACINGS

It is an under fabric used to stiffen areas in garment. They

are special fabrics used to strengthen or stiffen specific

parts of a garment ie collars, pockets tops, facings.

PURPOSES OF INTERFACINGS

i. It helps to maintain shapes of areas such as the

collars, the belts, and open edges.

ii. It helps to add body and crispness without bulk

iii. It strengthens and prevents stretching of fabric and

garment.

Types of interfacings

1. Woven interfacing eg lawn, calico

2. Iron-on interfacing- used with great care once

ironed on some do not stay permanently in place

unless stitched to the fabric. It decreases stiffness

as they detach. Advantage used on large areas as

they are designed for small portions. However, you

must check whether it can be washed or dry cleaned.

3. Non-woven interfacing: these usually carry the

manufacturer’s recommendation for use and

combination of fabrics. It is made for specific

fibres the right type and weight of the fabric. It is

used on large areas.

OUTSIDE FABRIC CORRECT INTERFACING

Dress weight Pre-shrunk treated lawn

Cotton, linen, wool Iron –on non-woven

interfacing as

recommended by the

manufacturer

Skirt weight Treated cotton

interfacing such as bleach

Cotton, linen, wool

calico.

Iron on woven interfacing

as recommended by the

manufacturer.

Man-made fabrics Non-woven interfacing for

very light fabrics lawn,

voile etc

Pure silk organza

Soft organdie / pure silk

organza

EDGE FINISHES

These are neatening made on straight or curved edges of

materials to hide the hanging threads and give a smart look.

Neatening can be at the neckline, arm hole, waist of skirts

and shorts, lower edge of skirts, dresses and blouses and

the boarder of tablecloth. Sometimes these finishes apart

from being functional they are decorative. The edge

finishes include binding, facing, scalloping, hemming,

lacing, frills, shell edging.

BINDING RAW EDGES

These serves two purposes. They may be for decoration or

for neatening or both at once. Binding is useful for

neatening the edges of arm holes, sleeves. It is often

better to use a softer fabric for neatening sleeves rather

than garment material.

ATTACHING BINDING:

1. Cut a cross way strip twice the required finished width

and twice the turning allowance wide and as strong as

it’s necessary.

2. Place the right side of the strip to the right side of

the garment raw edges together tack and stitch.

3. Turn under the raw edges on the free edge of the

binding strip.

4. Fold the edge over the raw edges to the wrong side of

the garment tuck just above the machining line and

hem into position.

CROSS WAY STRIP

A bias is cut on the diagonal that runs a cross both the

lengthwise and the crosswise grain of the fabric. Bias strips

or cross way strips are narrow strips cut on diagonal, used

for neatening, and decorating. Strips stretch sufficiently.

Cross way strips are usually cut from the irregular shaped

pieces left over after cutting out the garment sections.

HOW TO CUT A CROSS WAY STRIP

I. Fold the fabric over at the corner so that the

crosswise grain runs parallel to the selvedge. A 45 0 angle

is formed when this is done.

II. Crease the fold line.

III. Using a ruler as a guide, mark lines parallel to the fold

line. The distance between the lines is the required

width of the strip.

IV. Cut along the marked line

JOINING A CROSS WAY STRIP

a) Lay out the strips side by side, right sides upper

most. Cut the ends parallel to the fold line. The

distance between the lines is required width of the

strip.

b) Cut ends parallel to the selvedge edges.

c) Place the selvedge edge together, right sides facing

corners overlapping corners.

d) Remove tacking and press turning out flat.

e) Snip off the protruding corners

HEMMING

Hems are made by turning the edge of the material

twice to the wrong side of the garment. The first

turning is usually narrower to reduce bulk on hems are

made on edges of skirts, shirts, sleeves, and pockets.

The width of the hem varies according to the garment.

It is narrow in circular skirts, wide on children’s

dresses and it can be let down when babies grow. There

are three types of hems:

STRAIGHT HEMS:

Are made on straight edges eg pockets, blouses, trousers

etc

- Mark hem line with pins/ straight line of tackings

- Mark 1 cm 1st turning along the length of hem

- Mark a 2nd turning with fold on marked hemline.

- Pin and tack at edge of first fold.

- Hem with hemming stitches, slip hemming or machine.

TRASPARENT HEM

Hemming on transparent material. The width of both

turning should be equal so that one line is visible on the

right side for curved edges, the hem is very narrow and

rolled.

Method

- Mark level of hem

- Divided hem into equal parts

- Fold material on 2nd marked line and then the first

line.

CURVED HEMS

They are made more difficult to create as the fullness

(extra material) must be disposed off to make the hem flat.

Method

- Mark hem line.

- Fold hem to the wrong side of garment and near

fold(match seam lines )

- Distribute fullness by making small dart pins and hem

small darts down a single layer of material.

- Fold in 5mm

- Tack around the hem and press. The hem should be

flat, slip hem the fold.

You might also like

- Identifying The Type of Knit.: Side Interlock Rib Knit JerseyDocument7 pagesIdentifying The Type of Knit.: Side Interlock Rib Knit JerseyNitesh LuthraNo ratings yet

- Common Fabrics for Sewing: Pocket Guide: A Glossary of Fabrics and How to Use Them for Sewing ProjectsFrom EverandCommon Fabrics for Sewing: Pocket Guide: A Glossary of Fabrics and How to Use Them for Sewing ProjectsNo ratings yet

- Preparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricDocument13 pagesPreparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricNaasonNo ratings yet

- Construction MethodDocument34 pagesConstruction MethodSajid Rehman0% (1)

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerFrom EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerRating: 4 out of 5 stars4/5 (3)

- Review MaterialsDocument35 pagesReview MaterialsTrisha Costo SaysonNo ratings yet

- Sewing Supplies Handy Pocket Guide: 65+ Tips & Facts for Tools, Notions & MaterialsFrom EverandSewing Supplies Handy Pocket Guide: 65+ Tips & Facts for Tools, Notions & MaterialsNo ratings yet

- Types of Knit FabricDocument10 pagesTypes of Knit Fabrictextile028No ratings yet

- UntitledDocument32 pagesUntitledShweta ChauhanNo ratings yet

- Knitted Fabrics and TypesDocument10 pagesKnitted Fabrics and TypesMostafizur Rahman100% (1)

- Gar 8Document32 pagesGar 8ShoaibNo ratings yet

- Gar8 PDFDocument32 pagesGar8 PDFAfih CfptiNo ratings yet

- Types of Knit 14th Feb 2019Document9 pagesTypes of Knit 14th Feb 2019Sumon MonNo ratings yet

- Primary Base Weft Knitted StructuresDocument5 pagesPrimary Base Weft Knitted StructuresShantnu MittalNo ratings yet

- CT MMB 183Document6 pagesCT MMB 183Yetana WubnehNo ratings yet

- Fabrics-store-Churchill - Linen Dog Bed Pattern-1Document9 pagesFabrics-store-Churchill - Linen Dog Bed Pattern-1KiwiNo ratings yet

- Pin TucksDocument16 pagesPin Tucksvidhinisar100% (1)

- 4 104 Preparing To Sew PDFDocument2 pages4 104 Preparing To Sew PDFEnamul HaqueNo ratings yet

- Fabric Fundamentals Knitted FabricsDocument6 pagesFabric Fundamentals Knitted FabricsShreyaNo ratings yet

- Line Garments: How To Achieve Smooth, Comfortable Looks That Still Move With YouDocument6 pagesLine Garments: How To Achieve Smooth, Comfortable Looks That Still Move With YouamelieNo ratings yet

- KnittingDocument50 pagesKnittingSanghamitra KalitaNo ratings yet

- Basic Techniques in SewingDocument32 pagesBasic Techniques in SewingNiko EscuetaNo ratings yet

- Unit 5 FabricDocument22 pagesUnit 5 Fabricina gastadorNo ratings yet

- Terminology & Definitions A.: Sewing Room Terms & DefinitionsDocument9 pagesTerminology & Definitions A.: Sewing Room Terms & DefinitionsAbdur Rauf Khan100% (1)

- Lesson13 Clothing ConstructionDocument3 pagesLesson13 Clothing ConstructionEmerson John RoseteNo ratings yet

- FabricDocument7 pagesFabricSujita BaruahNo ratings yet

- FA 311 Module 2Document7 pagesFA 311 Module 2Jorita ManayonNo ratings yet

- Group 1 Seam and Hem FinishesDocument69 pagesGroup 1 Seam and Hem FinishesAnnieCastilloSampayan100% (1)

- DrapingDocument27 pagesDrapingDivya SinglaNo ratings yet

- FMMQ Assignment2Document9 pagesFMMQ Assignment2Shailendra GendleNo ratings yet

- Textile Material Knowledge SeriesDocument9 pagesTextile Material Knowledge SeriesSamy DagneNo ratings yet

- Dartspleats and TucksDocument34 pagesDartspleats and TucksArcade W MiguelNo ratings yet

- Seam, Classification of Seam, Features of Seam, Uses of SeamDocument13 pagesSeam, Classification of Seam, Features of Seam, Uses of SeamJahidul IslamNo ratings yet

- Fabrics Store Churchill Dog Bed Sewing PatternDocument10 pagesFabrics Store Churchill Dog Bed Sewing Patterndafemsta_05No ratings yet

- Garment TrimmingsDocument60 pagesGarment Trimmingspats escanilla75% (4)

- Difference Types FabricDocument22 pagesDifference Types FabricHasanuzzaman Sumon100% (1)

- Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion ADocument4 pagesFashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion A Fashion AamelieNo ratings yet

- Compare The Warp and Weft Knitted StructuresDocument5 pagesCompare The Warp and Weft Knitted StructuresMuhammad Farooq Kokab100% (1)

- Basic Sewing Terms - (FreeCourseWeb - Com)Document5 pagesBasic Sewing Terms - (FreeCourseWeb - Com)Viorel GrigorescuNo ratings yet

- Glossary of Sewing TermsDocument7 pagesGlossary of Sewing TermsFrances PlattsNo ratings yet

- Interlining in ApparelsDocument13 pagesInterlining in ApparelssmitharaoNo ratings yet

- Apparel Industry Construction MethodsDocument42 pagesApparel Industry Construction MethodsSachin Roy0% (1)

- Fashion REDUCING FULLNESS (Reduce Size)Document5 pagesFashion REDUCING FULLNESS (Reduce Size)Caphas Kaptain100% (1)

- EM Tote To Go Bag Sewing Pattern Instructions - CompressedDocument31 pagesEM Tote To Go Bag Sewing Pattern Instructions - CompressedWestwickateNo ratings yet

- Module 1 Lesson 3Document6 pagesModule 1 Lesson 3Trisha Marie Nalla TallodarNo ratings yet

- Sewing Glossary PDFDocument5 pagesSewing Glossary PDFSubramanya RaoNo ratings yet

- Diff. Types of Seams PDFDocument2 pagesDiff. Types of Seams PDFRAIZEN LANIPA OBODNo ratings yet

- Trainnig Material.Document32 pagesTrainnig Material.siraj kataleNo ratings yet

- Knitting: - Ms. Amrit Uppal - Asst. Prof. FD Dept. - Khalsa College For WomenDocument15 pagesKnitting: - Ms. Amrit Uppal - Asst. Prof. FD Dept. - Khalsa College For WomenRosh's CreativeBizNo ratings yet

- Seam Finishes 2Document8 pagesSeam Finishes 2riteshbansal23No ratings yet

- Type of WeavesDocument5 pagesType of WeavesSanket PatilNo ratings yet

- Artisan Presentation FinalDocument46 pagesArtisan Presentation Finalchrislyn llevadoNo ratings yet

- 12fabric ConstructionDocument3 pages12fabric ConstructionRoderick Viloria MiloNo ratings yet

- Seams and Seams FinishingDocument14 pagesSeams and Seams FinishingShivamNo ratings yet

- Kniting FabricDocument40 pagesKniting FabricNguyễn Công ThoạiNo ratings yet

- Clothing PresentationDocument14 pagesClothing PresentationChichi VevoNo ratings yet

- ISE1500 Be A Sewing Super HeroDocument67 pagesISE1500 Be A Sewing Super HeroamyNo ratings yet

- Tailoring Women's JacketsDocument32 pagesTailoring Women's JacketsAnna Anna86% (7)

- Cambridge Assessment International Education: Fashion and Textiles 6130/01 October/November 2018Document28 pagesCambridge Assessment International Education: Fashion and Textiles 6130/01 October/November 2018tertianerima101No ratings yet

- Fabric FinishesDocument15 pagesFabric Finishestertianerima101No ratings yet

- Bonding - Structuce 3 QPDocument14 pagesBonding - Structuce 3 QPtertianerima101No ratings yet

- Cambridge O Level: Fashion & Textiles 6130/01Document20 pagesCambridge O Level: Fashion & Textiles 6130/01tertianerima101No ratings yet

- Cambridge O Level: Fashion and Textiles 6130/01 May/June 2021Document25 pagesCambridge O Level: Fashion and Textiles 6130/01 May/June 2021tertianerima101No ratings yet

- Cambridge O Level: Fashion & Textiles 6130/01Document24 pagesCambridge O Level: Fashion & Textiles 6130/01tertianerima101No ratings yet

- Fashion and TextilesDocument1 pageFashion and Textilestertianerima101No ratings yet

- Controll of Fullness 2Document13 pagesControll of Fullness 2tertianerima101No ratings yet

- Collars, Sleeves, CuffDocument19 pagesCollars, Sleeves, Cufftertianerima101No ratings yet

- Fashion and TextilesDocument1 pageFashion and Textilestertianerima101No ratings yet

- The Face of VirtueDocument8 pagesThe Face of VirtueCarl Gabriel Calpe Culvera100% (1)

- Empower B2 Upper Intermediate StudentbooDocument179 pagesEmpower B2 Upper Intermediate StudentbooRicardo AyalaNo ratings yet

- 3D Cisco Icon Library v3.1Document27 pages3D Cisco Icon Library v3.1Karl KugelhagelNo ratings yet

- V 8 e Bridge Details SetDocument25 pagesV 8 e Bridge Details SetJuan Gutier CcNo ratings yet

- Weight Watchers Life Hacks For Busy People - Updated 2020Document6 pagesWeight Watchers Life Hacks For Busy People - Updated 2020Ona Černiauskienė100% (1)

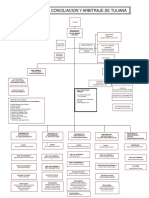

- Organigrama Jlca 2018Document1 pageOrganigrama Jlca 2018Yoscelin CervantesNo ratings yet

- Philips Accent LightingDocument37 pagesPhilips Accent LightingCecila Torrez BenitezNo ratings yet

- Toxic BiohazardDocument16 pagesToxic BiohazardDj-XienefMixNo ratings yet

- Nursery Rhyme Readers Humpty Dumpty 054526720XDocument14 pagesNursery Rhyme Readers Humpty Dumpty 054526720XamyloumNo ratings yet

- Steps in English 3 Units 1-2 Progress Test BDocument3 pagesSteps in English 3 Units 1-2 Progress Test BKasia FelkaNo ratings yet

- Soal Materi 1 KLS X IntroductionDocument2 pagesSoal Materi 1 KLS X IntroductionFira AnandaNo ratings yet

- Marc Guitar - More Slow Blues Licks in C7Document3 pagesMarc Guitar - More Slow Blues Licks in C7andreas papandreouNo ratings yet

- XMH-2 Fallen of SharnDocument42 pagesXMH-2 Fallen of Sharnmike_mckeown_3100% (2)

- Top Online CasinosDocument1 pageTop Online Casinosnepalfield83No ratings yet

- Henry IV AnalysisDocument29 pagesHenry IV AnalysisWilliam Bahls de CastilhoNo ratings yet

- CBN DirectNet APT Price List (IRON)Document1 pageCBN DirectNet APT Price List (IRON)AldellaPutraAtmadjaNo ratings yet

- Ejercicios: Some or Any?Document5 pagesEjercicios: Some or Any?pauli_nina747No ratings yet

- Jyothi Engineering College: Lab ManualDocument11 pagesJyothi Engineering College: Lab Manualtmsbharadwaj100% (1)

- Marcelo Bielsa's Murderball - What It Is and What Leeds United Players Say About It - Leeds LiveDocument9 pagesMarcelo Bielsa's Murderball - What It Is and What Leeds United Players Say About It - Leeds LiveToday BetterNo ratings yet

- A Rationale For Reading ASPDocument4 pagesA Rationale For Reading ASPAnonymous 4WBHTP6TNo ratings yet

- YesudasDocument13 pagesYesudasRamyaKrishnanNo ratings yet

- Writing ActivityDocument3 pagesWriting ActivityDANIEL EDUARDO TORRES VEGANo ratings yet

- M-Commerce 621 NotesDocument3 pagesM-Commerce 621 NotesVHUHWAVHO TSHIKHUDONo ratings yet

- Music of Your LifeDocument7 pagesMusic of Your LiferietracolNo ratings yet

- Pre-Production Planning: Storyboarding, Visual Planning, Location Reece/ Search, Risk Assessment, Call Sheet..Document19 pagesPre-Production Planning: Storyboarding, Visual Planning, Location Reece/ Search, Risk Assessment, Call Sheet..faith kellyNo ratings yet

- Data Sheet - Series 7000 Meter DSDocument6 pagesData Sheet - Series 7000 Meter DSJesus DavalosNo ratings yet

- Lab Comm6Document6 pagesLab Comm6Karmel AlameerNo ratings yet

- Chinh Doan-Resume Experience - Aug 2018 FinalDocument2 pagesChinh Doan-Resume Experience - Aug 2018 Finalapi-150823485No ratings yet

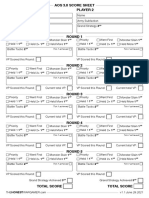

- AoS 3 Score Sheet v1.1Document1 pageAoS 3 Score Sheet v1.1Марко Видаковић - ДарвинNo ratings yet

- Sport ReportDocument4 pagesSport ReportWz OngNo ratings yet

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Amigurumi for Every Occasion: 21 Easy Projects to Celebrate Life's Happy MomentsFrom EverandCrochet Amigurumi for Every Occasion: 21 Easy Projects to Celebrate Life's Happy MomentsNo ratings yet

- Crochet Amigurumis Patterns: A walk through the countrysideFrom EverandCrochet Amigurumis Patterns: A walk through the countrysideRating: 5 out of 5 stars5/5 (1)

- Art Journals & Creative Healing: Restoring the Spirit through Self-ExpressionFrom EverandArt Journals & Creative Healing: Restoring the Spirit through Self-ExpressionRating: 3 out of 5 stars3/5 (7)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Geek Chic Crochet: 35 retro-inspired projects that are off the hookFrom EverandGeek Chic Crochet: 35 retro-inspired projects that are off the hookRating: 3 out of 5 stars3/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesFrom Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo ratings yet

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsFrom EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo ratings yet

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeFrom EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeRating: 5 out of 5 stars5/5 (2)

- Chain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsFrom EverandChain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsNo ratings yet

- More than a Granny: 20 Versatile Crochet Square Patterns UK VersionFrom EverandMore than a Granny: 20 Versatile Crochet Square Patterns UK VersionRating: 5 out of 5 stars5/5 (5)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesFrom EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesRating: 5 out of 5 stars5/5 (3)