Professional Documents

Culture Documents

FM16 - 15 - 15 Ternium

FM16 - 15 - 15 Ternium

Uploaded by

Martín Elias Plaza VegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM16 - 15 - 15 Ternium

FM16 - 15 - 15 Ternium

Uploaded by

Martín Elias Plaza VegaCopyright:

Available Formats

TECHNICAL PROTOCOL - FM016/15 - REV 15

CUSTOMER/USER: TERNIUM

COUNTRY: COLÔMBIA

SUPPLIER: GERDAU OURO BRANCO

DATE OF COMING INTO FORCE: AUGUST/ 2023

APPROVAL BY

__________________________________________

TERNIUM

_________________________________________

THAYENE OLIVEIRA SILOTTI

PROCESS AND PRODUCTS TECHNOLOGY MANAGER

Remarks:

• In order to comply with the GERDAU OURO BRANCO Quality System (ISO 9001), we are considering September/ 2023

as the final date for the approval of this Technical Protocol.

• It is considered as approval evidence the customer signature or no objection from the customer within this period.

• Signatures sent by electronic means (scanned and sent by e-mail or by Docusign), will be considered as original

signatures.

Issued by:

___________________________

Erika Beatriz Fernandes Diniz

Process and Product Engineering

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete - 36420-000 - Ouro Branco - MG - Fone: (31) 3749-2749 - Fax (31) 3749-2233

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:2/11

REVISIONS CONTROL

NUMBEROF

DESCRIPTION DATE

REVISION

00 • Approved by Gerdau Ouro Branco. 09/2015

01 • It was modified tensile strength range of items 6 and 8. 11/2015

02 • It was included 1070KN 11,00 mm (item 6) and SAE 1060 6,50 mm (item 9). 02/2016

• It was included 1012M 11,00 mm (item 12).

03 • It was excluded 1080CAM (item 7). 03/2016

• It was modified the application description (EXHIBIT 1).

• It was included EXHIBIT 5 – METALLURGICAL PROPERTIES.

04 • The modifications are highlighted. 07/2016

05 • The steel grades 1070KI (item 13) and 1022M (item 14) were included. 09/2016

06 • It was included to item 2 (1015FE) diameters 8.0 and 9.0 mm. 11/2016

• It was included to item 2 (1015FE) diameter 7.0mm;

07 12/2016

• It was included to item 8 (SAE 1045) diameter 16.0mm.

08 • It was included wire rod diameters at EXHIBIT 4. 02/2017

09 • It was modified residual elements. 05/2017

• It was included item 1080CAM (item 15), end use commercial quality, according

10 08/2017

EXHIBIT 1 described on the Application column.

11 • It was included new diameters to item 1080CAM (Item 15) 05/2018

• It was included item 16 (1009L), diameters 7.0 and 8.0 mm.

12 08/2020

• The modifications are highlighted.

• It was included diameter 12mm for item 6 (1070KN) and modified Tensile Strength

13 min for diameters 8mm to 12mm; 01/2023

• The modifications are highlighted.

• It was included item 17 (1010X);

14 01/2023

• The modifications are highlighted.

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:3/11

NUMBEROF

DESCRIPTION DATE

REVISION

• It was modified tensile strength of item 12 (1012M);

• It was modified min Mn of item 12 (1012M);

• It was modified tensile strength of item 8 (1045);

15 • It was modified tensile strength of item 16 (1009L); 08/2023

• It were modified residual elements of item 3 (1018AKFG CHQ);

• It was included upper limit for Cu+Ni+Mo+Cr of item 3 (1018 AKFG CHQ);

• The modifications are highlighted.

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:4/11

1 - MATERIAL DESCRIPTION, PROCESSING

1.1 - Introduction

Through this document the technical specifications of wire rods are established for supplying to TERNIUM by GERDAU

OURO BRANCO.

1.2 - Manufacturing Process

• L.D. Process;

• Continuous casting;

• Wire rod mill.

2 - STEEL SPECIFICATIONS

• According to exhibit 1.

3 - DIMENSIONS, SHAPE AND TOLERANCE

• According to exhibit 2.

4 - SURFACE QUALITY

• According to exhibit 3.

5- MECHANICAL PROPERTIES

• According to exhibit 4.

6- MARKING AND PACKAGING

• According to exhibit 5.

7- RADIATION

• According to exhibit 6.

8 - WEIGHT

• The GERDAU OURO BRANCO products will be delivered by actual weight.

• The weight tolerances between GERDAU OURO BRANCO weighting scale and customer weighting scale will be

0.5% max. per each shipment.

9 - MILL SHEET CERTIFICATE

Mill Sheet Certificate shall contain:

• Steel specification;

• Nominal dimensions;

• Chemical analysis (ladle analysis) per heat;

• Mechanical properties (average) per heat.

10 - CLAIM

10.1 - Claim Procedure

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:5/11

GERDAU OURO BRANCO makes a commitment of analyzing and giving a technical diagnosis and a commercial

solution for all claims/complaints, presented by customers since they are submitted within the following period:

Weight claim: Within 6 months from the shipping date.

Others Technical claim: Within 01 year from the shipping date.

10.2 - It is not guaranteed by GERDAU OURO BRANCO any other final end use than the specific one established in

EXHIBIT 1 .

10.3 - Customer may indicate, at his own expenses, inspection by adequate institution, without prejudice GERDAU

OURO BRANCO production schedules.

11 - TRIAL ORDER

The technical negotiation is nominated trial order relative to new Customer, quality, processing, application, specific

restriction, etc. The main purpose is to obtain as soon as possible, expected results for both companies, and

minimize problems due to poor quality performance.

Production under trial order conditions means very close relationship during process at both companies. The

quantity shall be a minimum number of heats required to fulfill the quality performance per different final

application. As a general rule, a new order shall be completed only after final results are approved by Customer and

submitted to GERDAU OURO BRANCO.

12 - OTHERS

This document can be changed by mutual agreement.

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:6/11

EXHIBIT 1 – STEEL SPECIFICATIONS

Chemical Composition – (Ladle Analysis) %

Steel Killing

Item Application

Grade Practice Element C Mn Si P S Cu Ni Cr Mo Sn V AlT Cu+Ni+Mo+Cr

Lower 0.05 0.40 - - - - - - - - - - -

1 1006 LC Welding Electrode

Si or Upper 0.10 0.60 0.10 0.030 0.035 0.10 0.10 0.10 0.03 0.03 0.02 0.060

-

Al/Si Lower 0.13 0.40 - - - - - - - - - - -

2 1015 FE Mesh

Upper 0.18 0.60 0.15 0.030 0.050 0.10 0.10 0.10 0.05 0.03 0.02 0.070 -

Lower 0.15 0.60 0.15 - - - - - - - - 0.020 -

3 1018 AKFG Al/Si Screw

CHQ Upper 0.20 0.90 0.35 0.030 0.045 0.02 0.02 0.05 0.02 0.02 0.04 0.060 0,12

Lower 0.15 0.70 0.10 - - - - - - - - - -

Si or

4 1018 FE - Mesh

Al/Si Upper 0.20 0.90 0.25 0.030 0.050 0.10 0.10 0.10 0.05 0.03 0.02 0.070 -

Lower 0.65 0.70 0.15 - - - - - - - - -

5 1065 FE Springs

Upper 0.70 0.90 0.35 0.030 0.050 0.10 0.10 0.10 0.05 0.03 0.02 0.060 -

Si

Lower 0.70 0.60 0.15 - - - - - - - - - Springs commercial

6 1070 KN quality / Cables /

Upper 0.75 0.80 0.35 0.030 0.030 0.10 0.10 0.10 0.02 0.02 0.02 0.050 -

Galvanized Wire /

Lower 0.43 0.60 0.15 - - - - - - - - - - Industrial wire

8 SAE 1045 Al/Si

Upper 0.50 0.80 0.25 0.030 0.030 0.10 0.10 0.10 0.03 0.02 0.02 0.060 - Springs commercial

quality / Commercial

Lower 0.60 0.60 0.15 - - - - - - - - - - quality wire

9 SAE 1060 Si

Upper 0.65 0.80 0.25 0.030 0.030 0.10 0.10 0.10 0.03 0.02 0.02 0.060 -

Lower - 0.30 - - - - - - - - - - -

10 SAE 1008

Upper 0.10 0.50 0.15 0.030 0.030 0.10 0.10 0.10 0.05 0.02 0.02 0.070 -

Si or Lower - 0.25 - - - - - - - - - - -

11 SAE 1006 Mesh

Al/si Upper 0.08 0.40 0.15 0.030 0.030 0.10 0.10 0.10 0.05 0.02 0.02 0.070 -

Lower 0.10 0.40 0.10 - - - - - - - - - -

12 1012M

Upper 0.15 0.75 0.25 0.030 0.030 0.10 0.10 0.10 0.05 0.02 0.02 0.070 -

Lower 0.67 0.60 0.15 - - - - - - - - - - Springs commercial

13 1070KI Si quality / Commercial

Upper 0.73 0.80 0.35 0.030 0.030 0.10 0.10 0.10 0.02 0.02 0.02 - - quality wire

Lower 0.18 0.60 0.15 - - - - - - - - - - Grounding rod / Cold

Si or

14 1022M drawn bar

Al/si Upper 0.23 0.90 0.35 0.030 0.030 0.10 0.10 0.10 0.02 0.02 0.02 - - commercial quality

Wire rope,

Lower 0.80 0.55 0.15 - - - - - - - - -

Aluminum

15 1080CAM Si Conductor Steel

Upper 0.85 0.75 0.35 0.030 0.030 0.10 0.10 0.10 0.02 0.02 0.02 0.050 - Reinforced (ACSR),

commercial quality.

Lower 0.07 0.70 0.05 0.040 0.010 - - - - - - - -

16 1009L Si Steel wool

Upper 0.11 0.90 0.20 0.090 0.030 0.10 0.10 0.10 0.10 0.02 0.02 0.005 -

Lower 0.08 0.30 - - - - - - - - - 0.015 -

17 1010X Al CHQ

Upper 0.13 0.60 0.10 0.030 0.030 0.10 0.10 0.10 0.05 0.02 0.04 0.070 -

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:7/11

REMARKS:

(1) Gerdau Ouro Branco produces steel through BOF converter. Thus, residuals elements are very low. Normal values: Ni:

0.01%; Cr: 0.01% and Cu: 0.01%.

(2) Tolerances according to SAE-J-409 will be guaranteed for all elements.

(3) Suitable for mechanical descaling process.

(4) Al T = Total aluminium = Aluminum soluble + insoluble.

(5) Gerdau guarantees chemical composition, mechanical properties and general characteristics for the described end

use. It is not allowed the use for safety parts for automotive industry, except when clearly described on the

application column.

EXHIBIT 2 – DIMENSIONS, SHAPE AND TOLERANCE

Wire rod:

Wire rod diameter TOLERANCES (mm)

Item Steel Grade

(mm) DIAMETER OUT OF ROUND (max.)

5.5 to 15.5 ± 0.30 0.40

All All

16.0 to 22.0 ± 0.40 0.50

(*) Available diameters: 5.5 / 6.5 / 7.0 / 8.0 / 9.0 / 9.5 / 10.0 / 11.0 / 12.0 / 13.0 / 14.0 /14.5 / 16.0 / 17.5 / 19.0 / 20.5 /

22.0 mm

Coil:

Coil dimensions and weight

Inner diameter (mm) 850 – 950

Outer diameter (mm) 1,200 – 1,250

5.5 to 15.5 1,500 max.

Height (mm)

16.0 to 22.0 1,700 max.

94% 1,800 – 2,100

Weight (kg)

6% 1,500 – 1,799

EXHIBIT 3 – SURFACE QUALITY

Item: Surface Quality (QS 21): The rolled wire rod shall be supplied free of any harmful surface defects which can affect

All the surface quality of the final products (defect deeper < 2% of diameter).

The rust level is according internal standards at Gerdau Ouro Branco:

Item Rust level

2,4,10,11,12,14 3 max.

1,3,5,6,8,9,13, 15, 16, 17 2 max.

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:8/11

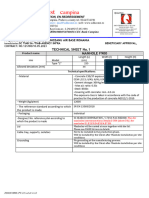

Fig.1 - NÍVEL 1 Fig.2 - NÍVEL 1 (detalhe da Fig.1)

Fig.2 - LEVEL 2 Fig.3 (Detail of Fig.2) - LEVEL 2

Fig.4 - LEVEL 3 Fig.5 (Detail of Fig.4) - LEVEL 3

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:9/11

EXHIBIT 4 – MECHANICAL PROPERTIES

Tensile Strength (MPa) Reduction of

Item Steel Grade Wire rod diameter (mm) (*) Area minimum

Min Max (%)

1 1006 LC 5.5 to 22.0 - 460 40

5.5 to 9.0 440 - 40

2 1015 FE 10.0 to 14.5 420 - 30

16.0 to 22.0 400 - 20

1018 AKFG 40

3 5.5 to 22.0 370 540

CHQ

5.5 to 7.0 440 540 40

4 1018 FE 8.0 to 10.0 440 520

40

11.0 to 22.0 440 520

5 1065 FE 5.5 / 6.5 985 1075 30

5.5 / 6.5 / 7.0 1,000 1,120 30

6 1070 KN

8.0 / 9.0 / 10.0 / 11.0 / 12.0 985 1,110 30

5.5 to 7.0 760 880

8 SAE 1045 35

8 to 19.0 720 880

9 SAE 1060 5.5 to 8.0 850 1050 30

10 SAE 1008 5.5 to 22.0 - 450 40

11 SAE 1006 5.5 to 22.0 - 420 40

12 1012M 5.5 to 22.0 400 480 60

13 1070KI 5.5 to 8.0 990 1,100 30

14 1022M All - 550 -

15 1080CAM 5.5 to 11.0 1,060 1,230 30

16 1009L 7.0 and 8.0 420 520 65

17 1010X All 360 460 60

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:10/11

EXHIBIT 5 – METALLURGICAL PROPERTIES

All tests must be performed in wire rod samples.

Item Steel Grade Characteristic Level

Decarburization total: Is not acceptable.

Decarburization (According to

Decarburization partial: is not deeper than 2% for all

DIN EN ISO 16120) diameter.

Microstructure (According to - Fine perlite: 85% mínimo.

6 1070KN Gerdau standard) - Coarse perlite: 15% máximo.

Carbon Segregation (According to Maximum Class 2 (10 % of the samples tested can be Class 3)

DIN EN ISO 16120) – Class 4 is not allowed.

Cleanliness (ASTM E45) According to Table 1.

Table 1 – Inclusions

Inclusion type

Series A B C D

Maximum average value (Valor médio Thin 2,0 2,0 2,0 2,0

máximo admissível) Heavy 1,5 1,5 2,0 1,5

Maximum isolated field of view (Valor Thin 2,5 2,5 2,5 2,5

máximo campo isolado) Heavy 2,0 2,0 2,0 2,0

EXHIBIT 6 – MARKING AND PACKAGING

Item Wire rod diameter Number

Tag material Information printed on tag

(mm) Ties/coil Tags/coil

Customer Name, product, size, steel quality,

All All 4 2 PVC

weight, Heat number

Remarks:

• Uncoiling:

• direction: clockwise

• side: opposite to the seal (tail)

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

TECHNICAL PROTOCOL - FM016/15 - REV 15

Page.:11/11

EXHIBIT 7 – RADIATION

Gerdau Ouro Branco certifies that all wire rod supplied to Ternium contains no radioactivity. The supplied steel is not

knowingly exposed to radioactivity while processed at Gerdau Ouro Branco or any heat produced until the present date

has come in direct contact with radioactivity. We use 100 % of internally generated scrap made mainly from plain C steel;

we do not use purchased scrap in the process.

Usina: Rodovia MG 443, Km 7 - Fazenda do Cadete – 36497-899 - Ouro Branco - MG

www.gerdau.com.br

This content is Internal.

You might also like

- Equipment Calibration Record ChartDocument3 pagesEquipment Calibration Record ChartNatarajan MurugesanNo ratings yet

- Caracteristici BST 500Document2 pagesCaracteristici BST 500Rosu GabrielNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Assignment 1 ECN3112Document4 pagesAssignment 1 ECN3112Surenraj SubramaniamNo ratings yet

- Causes of High School DropoutsDocument2 pagesCauses of High School DropoutsLauriLeighQuevadaZumárragaNo ratings yet

- Eng SM Tan 020 - 03Document20 pagesEng SM Tan 020 - 03Валерий ШостакNo ratings yet

- Technical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemDocument17 pagesTechnical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemsaikatNo ratings yet

- Expansion ProcedureDocument13 pagesExpansion ProcedureMani Tamil100% (1)

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- 2.1. FT MANHOLE D400.ro - enDocument5 pages2.1. FT MANHOLE D400.ro - enVerde GriNo ratings yet

- Project Profile On Hard Chromium PlatingDocument13 pagesProject Profile On Hard Chromium PlatingKishora BhatNo ratings yet

- Cylinder Liner Quality SpecificationDocument11 pagesCylinder Liner Quality Specificationwinda100% (1)

- Diamant Technical Data Sheet DWH 310 FLDocument4 pagesDiamant Technical Data Sheet DWH 310 FLhoriaNo ratings yet

- Pressure Vessel and ExchangerDocument17 pagesPressure Vessel and ExchangerJose FedeNo ratings yet

- Nawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesDocument18 pagesNawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesWalid KhelfaNo ratings yet

- Corotap® T200 and T300: Optimized For Iso P Steel ApplicationsDocument2 pagesCorotap® T200 and T300: Optimized For Iso P Steel ApplicationsolivaresjhonNo ratings yet

- Corotap® T200 and T300: Optimized For Iso P Steel ApplicationsDocument2 pagesCorotap® T200 and T300: Optimized For Iso P Steel ApplicationsHồng HoàngNo ratings yet

- 1.1. FT MANHOLE F900.ro - enDocument4 pages1.1. FT MANHOLE F900.ro - enVerde GriNo ratings yet

- d601000258 Man 001Document24 pagesd601000258 Man 001Oswaldo VillarroelNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IRDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IRDadaso Baburao JamdarNo ratings yet

- Minimess KatalogDocument39 pagesMinimess Kataloganeesh awasthiNo ratings yet

- TDC 6 388Document3 pagesTDC 6 388sonnu151No ratings yet

- DNV GL CertificateDocument3 pagesDNV GL CertificatemikeNo ratings yet

- MC 10136126 9999Document3 pagesMC 10136126 9999Erti HariziNo ratings yet

- HD 80W-90 en FR Motul 35500 20210713Document2 pagesHD 80W-90 en FR Motul 35500 20210713Marcelo Santo AndréNo ratings yet

- 88 PagesDocument87 pages88 PagesOdutayo AdemilolaNo ratings yet

- BQM1102 040Document2 pagesBQM1102 040yavorvnNo ratings yet

- Minimess CouplingDocument39 pagesMinimess Couplingani_datNo ratings yet

- 0280K00849 702 1Document16 pages0280K00849 702 1sinasayedanaNo ratings yet

- Triveni GearsDocument8 pagesTriveni Gearsnilesh121219No ratings yet

- Albany Profile (GT) RevDocument48 pagesAlbany Profile (GT) RevHeri SetyantoNo ratings yet

- Daily Report-018 (Su Jinlong)Document8 pagesDaily Report-018 (Su Jinlong)sujinlongNo ratings yet

- Alsons PresentationDocument19 pagesAlsons PresentationAditya VuthaNo ratings yet

- DBR Mechanical REV02Document34 pagesDBR Mechanical REV02abdellah faqdaniNo ratings yet

- CHL 1187-SCL 17 0173-F0Document20 pagesCHL 1187-SCL 17 0173-F0alex0% (1)

- Oil & Gas Development Company Limited: TENDER ENQUIRY NO. PROC-FD/CB/DO-0565/2012 Hiring of Coring ServicesDocument8 pagesOil & Gas Development Company Limited: TENDER ENQUIRY NO. PROC-FD/CB/DO-0565/2012 Hiring of Coring ServicesLeonardo Octavio Olarte SánchezNo ratings yet

- GK Profile-2016Document7 pagesGK Profile-2016Prakash viswanathanNo ratings yet

- Quotation: M/S Dalhia Energy Service LTDDocument3 pagesQuotation: M/S Dalhia Energy Service LTDPawan MouryaNo ratings yet

- C03-001-Structural Steel CalculationsDocument86 pagesC03-001-Structural Steel CalculationsNguyễnBìnhPhươngNo ratings yet

- Detail Engineering Services For Engen Tank X368 RebuildDocument9 pagesDetail Engineering Services For Engen Tank X368 RebuildpavanNo ratings yet

- Larsen & Toubro Limited, Construction.: WOM Bill Annexure - EC578BIL0000026 DT:09 Apr 2020Document4 pagesLarsen & Toubro Limited, Construction.: WOM Bill Annexure - EC578BIL0000026 DT:09 Apr 2020Kannan GnanaprakasamNo ratings yet

- BRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Document21 pagesBRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Minh TruongNo ratings yet

- MR-HEN-363-S15-P03-007 SOW - Rehab Machine Workshop Project - Engineering Procurement InstallationDocument9 pagesMR-HEN-363-S15-P03-007 SOW - Rehab Machine Workshop Project - Engineering Procurement InstallationDavidNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- Accordion Wall PartitionDocument8 pagesAccordion Wall Partitionmoytabura96No ratings yet

- Cpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Document3 pagesCpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Gaurav KumarNo ratings yet

- Saftey Materials and Precasted Concretes - IWWN TENDER DOCUMENTSDocument14 pagesSaftey Materials and Precasted Concretes - IWWN TENDER DOCUMENTSyasseenNo ratings yet

- Revamping of The 80 T MRP-L Converter at Aperam Timoteo : ISSN 1982-9345Document10 pagesRevamping of The 80 T MRP-L Converter at Aperam Timoteo : ISSN 1982-9345AYUSH RAYNo ratings yet

- Torgy Insulation BlocksDocument3 pagesTorgy Insulation Blockskanchanabalaji100% (1)

- Quality Review Meeting 1 - 10.03.08Document93 pagesQuality Review Meeting 1 - 10.03.08bvdasNo ratings yet

- Hamaca Crude Upgrader Project Epc Buildings: Electrical Descriptive MemoryDocument8 pagesHamaca Crude Upgrader Project Epc Buildings: Electrical Descriptive MemoryJose Antonio Salazar HidalgoNo ratings yet

- 11C043F0300-5330 - 2 Calculation Carbon FilterDocument120 pages11C043F0300-5330 - 2 Calculation Carbon FilterLorenzoNo ratings yet

- UM 80-10 Cover at Rotary Joint eDocument5 pagesUM 80-10 Cover at Rotary Joint eremydejongrsrNo ratings yet

- Trunkline ReplacementDocument5 pagesTrunkline ReplacementahmedrkhissNo ratings yet

- Vol 01Document153 pagesVol 01chandrasingh4564No ratings yet

- P445 - Technical Proposal Rev.0Document37 pagesP445 - Technical Proposal Rev.0ArtG.EnziNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Arguments For and Against Animal CrueltyDocument11 pagesArguments For and Against Animal CrueltyAbraham SaucedoNo ratings yet

- Surface Treatment of Aluminum and Aluminum Alloys2Document6 pagesSurface Treatment of Aluminum and Aluminum Alloys2bnolascoNo ratings yet

- Rules and Regulations For The Classification of Ships Using Gases or oDocument128 pagesRules and Regulations For The Classification of Ships Using Gases or ocell bboy100% (1)

- Visitor Management System Design and Implementation During The Covid-19 PandemicDocument9 pagesVisitor Management System Design and Implementation During The Covid-19 PandemicozNo ratings yet

- Warren Baker ResumeDocument1 pageWarren Baker Resumeapi-378066787No ratings yet

- Sturtevant Classifier MillDocument6 pagesSturtevant Classifier MillPieter geert BremanNo ratings yet

- Food Additives PDFDocument2 pagesFood Additives PDFNafeeza AlmyraNo ratings yet

- Beginner's Course Instruction BookletDocument39 pagesBeginner's Course Instruction BookletDaniel VeigaNo ratings yet

- Did It Work? Reflections and Five Humble Questions To Guide AssessmentDocument4 pagesDid It Work? Reflections and Five Humble Questions To Guide AssessmentJennaNo ratings yet

- Universitas Muhammadiyah Ponorogo Health Sciences JournalDocument5 pagesUniversitas Muhammadiyah Ponorogo Health Sciences JournalAndriz LallendiNo ratings yet

- Henry Sy Success StoryDocument6 pagesHenry Sy Success StoryRho Vince Caño MalagueñoNo ratings yet

- Eggshell With Flour and Mango Seed As Media For Chalk ProductionDocument11 pagesEggshell With Flour and Mango Seed As Media For Chalk ProductionAbigail Faith PretestoNo ratings yet

- EsclatorDocument24 pagesEsclatorRohit JainNo ratings yet

- Unit 1 TestDocument10 pagesUnit 1 TestAustin HopkinsNo ratings yet

- What Is A Neuron? The Parts of A Neuron: - ! Cell Body or Soma! - ! - !Document7 pagesWhat Is A Neuron? The Parts of A Neuron: - ! Cell Body or Soma! - ! - !Bernadine SaladoNo ratings yet

- Tes Psikotes BUMN - 9 - Bahasa InggrisDocument17 pagesTes Psikotes BUMN - 9 - Bahasa InggrisPrsty 12No ratings yet

- Report On CSR Activities Done by WiproDocument17 pagesReport On CSR Activities Done by WiproShravani RajaNo ratings yet

- Gue Gub Junction BoxesDocument5 pagesGue Gub Junction BoxesAlexis Michel Cabrera AntonioNo ratings yet

- Transport of Water in PlantsDocument27 pagesTransport of Water in PlantssaketgolyanNo ratings yet

- List Unit Dan Roster DriverDocument16 pagesList Unit Dan Roster DriverMarcoNo ratings yet

- Agri Bayanihan - Enterprise - Coffee - TABUK CITYDocument4 pagesAgri Bayanihan - Enterprise - Coffee - TABUK CITYRheyJun Paguinto AnchetaNo ratings yet

- 1SDA066561R1 A3n 400 TMF 400 4000 3p F FDocument3 pages1SDA066561R1 A3n 400 TMF 400 4000 3p F FJessika duperly rueda vasquezNo ratings yet

- Manual Geo PDFDocument242 pagesManual Geo PDFGustavo HuertasNo ratings yet

- ILS SB2 U07 Test ScriptDocument2 pagesILS SB2 U07 Test ScriptLâm DuyNo ratings yet

- Booking Report 12-1-2021Document3 pagesBooking Report 12-1-2021WCTV Digital Team0% (1)

- Qoutation For The Furbishment of ERN GROTTO Mining Site in ChimanimaniDocument2 pagesQoutation For The Furbishment of ERN GROTTO Mining Site in ChimanimaniDarrylNo ratings yet

- Monfardini-Manual of Adult and Paediatric Medical OncologyDocument409 pagesMonfardini-Manual of Adult and Paediatric Medical OncologyganmarifNo ratings yet

- Scholarship OmnibusDocument52 pagesScholarship OmnibusKay Ann TorreNo ratings yet