Professional Documents

Culture Documents

4. JSA for Cold Cutting^J Hot Cutting^J Loading and Unloading-Rev-00

4. JSA for Cold Cutting^J Hot Cutting^J Loading and Unloading-Rev-00

Uploaded by

DLPS HSECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4. JSA for Cold Cutting^J Hot Cutting^J Loading and Unloading-Rev-00

4. JSA for Cold Cutting^J Hot Cutting^J Loading and Unloading-Rev-00

Uploaded by

DLPS HSECopyright:

Available Formats

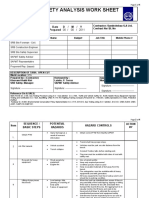

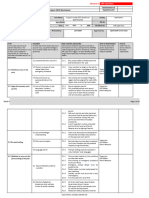

JOB SAFETY ANALYSIS WORK SHEET

Contractor: DIVERSIFIED LINES

JSA# 02 Revision- 00 Date 29/02/2024 PETROLEUM SERVICES

JSA Function Name Badge # Job Title Mobile Phone #

Contractor Field Supervisor/Foreman Supervisor

Contractor Safety Damodaran Nair 8452789 Safety Manager 0538035986

Proponent Rep. (Ops) (Optional)

DESCRIPTION OF TASK: Cold Cutting, Hot Cutting, Loading and Unloading of Pipe line

Work Location: RAS TANURA AREA QRT-1 & QRT-3 - PIPELINE

Prepared By: (Contractor Safety Checked By: (Contractor’s Reviewed By: Approved By:

Manager) Supervisor)

Name: Damodaran Nair Name: Name: Hosam basaffar Name:Mortadha Al-Obidi

Mobile #0538035986 Mobile # Mobile # Mobile # 0504810382

REQUIRED SAFETY EQUIPMENT & MATERIAL: Hard Hats, FRC Clothing, Environmental Protection, Safety Glass/Goggles/, Hand

Gloves, Safety Shoes, Fire Extinguishers, Safety Warning Signs and Barricades, Pipe cutter, Gas cutting set and Hand tools, Welfare

Facilities

REFERENCES: GI 7.029, Rigging Hardware Requirements

SAUDI ARAMCO General Instruction GI 7.030, Inspection and Testing Requirements for Elevating/Lifting Equipment

GI 7.031, Heavy Equipment Services

G.I. 2.100 Work permit system SA CSM 5th Ed.

G.I. 6.030, Traffic and Vehicle Safety Safety hand book

GI 6.030, Traffic and Vehicle Safety .

GI 7.025, Heavy Equipment Operator Testing and Certification

GI 7.026, Crane and Heavy Equipment Incident Reporting Procedures

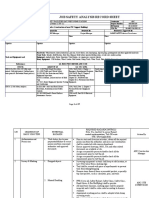

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

Sequence of Basic

No Potential Hazards Required Hazard Controls

Job steps Actions by

1- Obtain Work Permit Unsafe working Obtain a work permit (as per GI. 2 .100) before start work. Work Permit

condition Permit Issuer and Receiver to conduct joint site inspection to Receiver

discuss the hazards and precautions required for conducting

Site

the job safely.

Supervisor

Ensure no work is conducted in the area until signed permits to

work are in place.

Toolbox meeting shall be conducted to the entire work force

before commencing job.

Pre-job safety meeting shall be conducted on a daily basis to

the entire work force.

JSA shall be reviewed with the entire work force and with all

concern parties before commencing job to control the hazards.

Provide detail information on the work permit by specifying the

work to be done, the equipment to be used, and the location of

the work.

2- Secure the area Struck by vehicle Install barricade &safety warning signboard as per GI 1021 at Site

against traffic Struck by trailers & reasonable distance. Supervisor

Block all entrances heading to pipe stringing area. (follow-up)

side boom

Install berms at both directions at a distance of 1 meter away.

3- Mobilization of Traffic hazards. Prepare the area / clear of obstructions prior mobilizing of Work Permit

equipment to Property damage. equipment’s and pipes. Receiver Site

worksite Ensure tools / equipment are pre-inspected before Supervisor

mobilization. (follow-up)

DLPS-JSA For Demolition Page 2 of 9

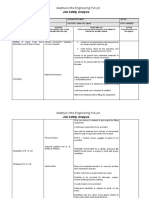

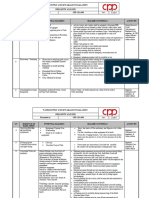

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

Unattended Ensure all equipment’s / tools / pipes are properly secured on

reversing/maneuveri trailers. Pre-journey Inspection to be conducted.

ng Lifting devices & tools to be color coded.

Vehicle. Offload equipment’s in a secured location / away from moving

Overhead Power line equipment /

Edge of excavations.

Secure the area with barricade and signboards at reasonable

distance.

Trained banks man equipped with safety vest and flag that will

guide vehicle drivers and control the traffic.

Install goal post to warn the operators of the hazard of

overhead power line.

4. Cold cutting of Miss-Communication Coordinate and obtain approval from Saudi Aramco operations Work Permit

existing Pipeline / Understanding and Work Permit Issuer prior to start of work Receiver Site

(using Hinge Pipe Improper Perform regular gas testing / gas Monitoring on the work area Supervisor

Cutters) coordination by competent/qualified personnel.

Inaccurate reading Ensure to follow correct procedure in existing line cutting.

and computation of Ensure all workers are aware the procedure for emergency

pressure and flow response, the method statement and the correct PPE to be

requirements used.

Pipe rupture Assign skilled, competent and trained workers for the task.

Explosion appropriate PPE shall be worn.

Exposure to Appropriate and adequate fire fighting equipment to be

Hazardous Gases positioned at the jobsite.

and Liquids Assigned trained fire watch and stand by man to monitor

closely the activity

Stay at Up-Wind direction while performing the cold cutting

DLPS-JSA For Demolition Page 3 of 9

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

STOP WORK TRIGGER:

If no Competent operator, equipment is not in safe condition

5. Hot cutting of Fire / Sparks / Molten Task appropriate PPE Work Permit

pipeline slug. Use welding mask Receiver Site

Flying objects ventilate the area Supervisor

Glare Use welding gloves or welders out fit

Smoke Ear plug / ear muff

Burn / nicks / cuts / STOP WORK TRIGGER:

hot object If no available Fire watchman/Fire extinguishers, hand

Noise pollution tools/power tools are not in safe condition, poor

housekeeping, damaged welding cables, or not wearing

appropriate PPE

6. Loading of Material Unauthorized Only trained and Aramco certified operator shall be permitted Work Permit

using Clamp loader operator to operate the Equipment. Receiver Site

Lack of knowledge/ The equipment shall not be operated without valid third party Supervisor

awareness on the certification including Clamp and daily inspection checklist duly

equipment safety signed.

operation Ensure safety operations understand by the operator.

Certified rigger/flagman are allowed to give signal to the

operator during loading/unloading or maneuvering the

equipment

STOP WORK TRIGGER:

If no Certified & Competent operator, equipment is not in safe

condition.

DLPS-JSA For Demolition Page 4 of 9

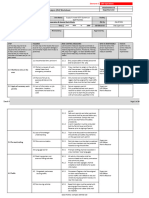

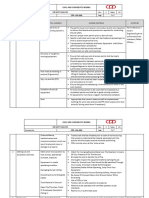

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

7. Loading of Material Unstable base Crane shall be set up correctly on firm ground, level, outrigger Work Permit

using Crane condition fully extend. Receiver Site

Unknown weight / Weight shall be determined prior to lift Supervisor

Overloading Know the capacity of the operating radius of the Crane

Overhead hazard Ensure area is barricaded and no unauthorized personnel

Fall of load inside the working area.

Incompetent rigger No Personnel shall stay under suspended load.

Struck by rotating Ensure lifting tackle is inspected and colour code.

equipment Ensure load are secured

Pinch Point No personnel shall stay beside the Crane while in motion

Injury Aramco Certified rigger shall in do the job.

Slips, trips, Fall No personnel shall stay beside the Boom while in motion

Failure of lifting Task appropriate PPE

equipment Ensure lifting equipment should have valid third party

Miss communication certification and daily inspection is carried out

Area should be barricaded and signage “LIFING IN

PROGRES”

Stop lifting if does not understand the lifting signal or not

confident about safe lifting operation and seek supervisor

assistance.

Insure good communication between rigger and operator

STOP WORK TRIGGER:

If no licensed or certified operator, equipment is not in safe

condition, and weather condition worst

8- Loading and Mechanical Failure Drivers shall check vehicles daily for serviceability of such Work Permit

removal of Materials basic equipment as tires, brakes, lights, fluid level, glass, Receiver,

mirrors, etc. and shall be corrected immediately.

DLPS-JSA For Demolition Page 5 of 9

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

and equipment from Injury due to lack of Driver shall in position of valid license Site

location awareness in the Conduct pre start briefing on daily basis. Supervisor

work/ activity Task supervisor to explain JSA to all employees

Truck could be Wear proper Personal Protective Equipment’s.

unleveled and cause Park truck on firm level ground. Check area for obstructions

load to shift when and power lines. Where driver vision is limited spotters must

chained. Could be be used.

close to power lines. Wheel chocks are required on all trucks and trailers loads and

Driver may have deliveries once the trailer has been spotted for unloading.

limited vision Use open hand to latch binders. Stand back from binder when

opening. Be aware of loads that may have shifted during transit

Chain binders could Use proper lifting techniques and stay below 50lb per person

snap open. Load limit

could shift

Daily inspection of equipment shall be carried out by the

Manual Lifting operator.

(Strains)

Operator

Lift Failure

STOP WORK TRIGGER:

If no licensed or certified operator, equipment is not in safe

condition

Unloading of Pipe Injury to personnel Work Permit

spools and Injury due to lack of Wear appropriate personal protective equipment (Hand gloves, Receiver, Site

9- equipment from awareness in the Hardhat, Safety shoes, Safety glass, FR clothing, etc.). Supervisor

trailer work/ activity Un-authorized personnel are not allowed to enter in the area

DLPS-JSA For Demolition Page 6 of 9

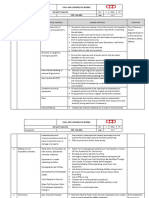

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

Truck could be Park truck on firm level ground. Check area for obstructions

unleveled and cause and power lines. Where driver vision is limited spotters must

load to shift when be used

unchained. Could be Wheel chocks are required on all trucks and trailers loads and

close to power lines. deliveries once the trailer has been spotted for unloading

Driver may have

limited vision

Truck could roll or STOP WORK TRIGGER:

suddenly move If no licensed or certified operator, equipment is not in safe

forward/backwards condition

Weather Condition Extreme weather No work shall be stop in extreme weather condition. Work Permit

condition (Fog, rain, rest shelter with Receiver Site

sand storm, strong follow heat stress management procedure. Supervisor

wind, heat stress) proper work/rest cycle shall be followed

Cold Drinking water shall be provide at all time

STOP WORK TRIGGER:

10 If weather is not in safe condition

“Emergency Evacuation Plan”

No BASIC STEPS POTENTIAL HAZARDS CONTROL MEASURE ACTION BY

DLPS-JSA For Demolition Page 7 of 9

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

1. Emergency NO PREPARATION OR All work is stopped at once. Permit

Evacuation Plan PLANNING OF Shut down all equipment Receiver

PERSONNEL Evacuate personnel to emergency assembly area.

IN CASE OF A roll call is taken and every personnel are accounted for.

EMERGENCY No one will be allowed to return to work until notification has

been received from SA Representative that the area is now

safe for workers.

All work permits shall be revalidated prior to commencing

work.

Emergency situation shall be reported by calling Southern

Area emergency contact number through mobile phone #

013-572- 0911.

Saudi Aramco representative shall be immediately informed

about the emergency situation (serious personal injuries, fire,

critical damage to equipment etc.)

Give clear information when calling in an emergency:

Training of all personnel will be conducted before entry to

plant areas.

Evacuation Drill will be conducted regularly.

DLPS-JSA For Demolition Page 8 of 9

JOB SAFETY ANALYSIS (JSA)

PIPE REMOVAL AND SALES

DLPS-JSA For Demolition Page 9 of 9

You might also like

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 pagesHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiNo ratings yet

- S/N Sequence of Basic Steps Potential Hazards Hazards Control Action byDocument7 pagesS/N Sequence of Basic Steps Potential Hazards Hazards Control Action byjavithNo ratings yet

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- 1991 GMC Topkick Repair Manual: Click Here To DownloadDocument2 pages1991 GMC Topkick Repair Manual: Click Here To DownloadOscar Molina Hernandez0% (4)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- 10.26.2020 20-029 Drilling Activity Using Drill MachineDocument4 pages10.26.2020 20-029 Drilling Activity Using Drill MachinePangky AbasoloNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Aramco Heat IndexDocument1 pageAramco Heat IndexDLPS HSE0% (1)

- 08 Yamaha Raider SVC ManualDocument494 pages08 Yamaha Raider SVC Manualbartoleone100% (2)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- ARK JSA 0 Rev 00 Crane LiftingDocument6 pagesARK JSA 0 Rev 00 Crane LiftingREMYANo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- ARK-JSA-08 Manual Tie-In Welding Rev-3Document9 pagesARK-JSA-08 Manual Tie-In Welding Rev-3REMYANo ratings yet

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- JSA Road ConstructionDocument17 pagesJSA Road ConstructionMohammad Al Masa'dehNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- Job Safety Analysis Work SheetDocument7 pagesJob Safety Analysis Work SheetTomNo ratings yet

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- ARK-JSA - Installation of Form Works, Rebars & Concrete PouringDocument7 pagesARK-JSA - Installation of Form Works, Rebars & Concrete PouringREMYA100% (3)

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationREMYA50% (2)

- Job Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityDocument7 pagesJob Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityMuhammad TariqNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- 12 Euro III Engine-N900 Series JMCDocument91 pages12 Euro III Engine-N900 Series JMCRusonegroNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- Car Rental AgreementDocument2 pagesCar Rental AgreementRon Yhayan72% (32)

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Document10 pagesJSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Barkat UllahNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Yammar 4TNV88 2.2L 8VDocument4 pagesYammar 4TNV88 2.2L 8Vferran_alfonsoNo ratings yet

- 360WALKAROUNDDocument20 pages360WALKAROUNDquang the captain50% (2)

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- JSA Asphalt PavingDocument10 pagesJSA Asphalt PavingMohammad Al Masa'dehNo ratings yet

- JSA - ELLECTRICAL AINDAR LAYING TERMINATION - CompressedDocument8 pagesJSA - ELLECTRICAL AINDAR LAYING TERMINATION - Compressedmalikshoaib8528No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Up Dated Job Safety Analysis Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis Gypsum Plastering WorksshahbazchafekarNo ratings yet

- Red Tile Placing JSADocument5 pagesRed Tile Placing JSAShahid BhattiNo ratings yet

- JHSA Water Supply and Sewer InstallationDocument4 pagesJHSA Water Supply and Sewer InstallationAnna JisabaNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Erection of Tower Structure-132KV-TL: Method StatementDocument14 pagesErection of Tower Structure-132KV-TL: Method StatementBanolka NobNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- Incident Id 6645139Document1 pageIncident Id 6645139DLPS HSENo ratings yet

- Aramco HSE ExamDocument66 pagesAramco HSE ExamDLPS HSENo ratings yet

- Attachment J - Rakkah Camp 7 - Feb-2021Document72 pagesAttachment J - Rakkah Camp 7 - Feb-2021DLPS HSENo ratings yet

- 1.21 Safety Observation & Nearmiss ReportingDocument2 pages1.21 Safety Observation & Nearmiss ReportingDLPS HSENo ratings yet

- Dlps-Ompp Heat Stress Response TeamDocument1 pageDlps-Ompp Heat Stress Response TeamDLPS HSENo ratings yet

- Dlps Equipment Inspection StickerDocument1 pageDlps Equipment Inspection StickerDLPS HSENo ratings yet

- 5s ArabicDocument1 page5s ArabicDLPS HSENo ratings yet

- Caution Acetylene CylinderDocument1 pageCaution Acetylene CylinderDLPS HSENo ratings yet

- Extranet User Access Request Form (SA 8205-5)Document2 pagesExtranet User Access Request Form (SA 8205-5)DLPS HSENo ratings yet

- Waste Manifest - DLPS-OMPPDocument2 pagesWaste Manifest - DLPS-OMPPDLPS HSENo ratings yet

- Safety Gap Analysis Report ExampleDocument142 pagesSafety Gap Analysis Report ExampleDLPS HSENo ratings yet

- Lifesaving Rules BookletDocument20 pagesLifesaving Rules BookletDLPS HSENo ratings yet

- 14 Near Miss Reporting ProcessDocument8 pages14 Near Miss Reporting ProcessDLPS HSENo ratings yet

- Chemical Storage & Handling SafetyDocument2 pagesChemical Storage & Handling SafetyDLPS HSENo ratings yet

- Blaster Medical ReportDocument2 pagesBlaster Medical ReportDLPS HSENo ratings yet

- PMRF 012020Document2 pagesPMRF 012020DLPS HSENo ratings yet

- HE Daily Inspection ExistingDocument1 pageHE Daily Inspection ExistingDLPS HSENo ratings yet

- Heavy Equipment Pre Insp (EctionDocument1 pageHeavy Equipment Pre Insp (EctionDLPS HSENo ratings yet

- Internal Permit FormsDocument6 pagesInternal Permit FormsDLPS HSENo ratings yet

- Orientation CardDocument1 pageOrientation CardDLPS HSENo ratings yet

- AssemblyDocument1 pageAssemblyDLPS HSENo ratings yet

- (CH-4) Fuel PropertiesDocument35 pages(CH-4) Fuel Propertiesxan pitchuNo ratings yet

- M44 Combo Vibraphone: 5 3/4" Dia. (18.06" Long)Document3 pagesM44 Combo Vibraphone: 5 3/4" Dia. (18.06" Long)fabianNo ratings yet

- Automine For Trucks Brochure EnglishDocument4 pagesAutomine For Trucks Brochure EnglishJH Miguel AngelNo ratings yet

- Product Recommendation Eaton Fuller Heavy-Duty Transmissions 13 - 18 Speed RT-6613Document2 pagesProduct Recommendation Eaton Fuller Heavy-Duty Transmissions 13 - 18 Speed RT-6613DavidNo ratings yet

- PavementDocument24 pagesPavementfarhan khanNo ratings yet

- LDP Series Actuator - DEMBLADocument4 pagesLDP Series Actuator - DEMBLAKamitkumar PatelNo ratings yet

- New Leadership Named at Comau in Preparation For Its Future As A Publicly Listed CompanyDocument2 pagesNew Leadership Named at Comau in Preparation For Its Future As A Publicly Listed CompanyAllan Bruno RosaNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA Repair-5Document5 pagesEngine Controls (Powertrain Management) - ALLDATA Repair-5HervinNo ratings yet

- Montero Sport 2016Document3 pagesMontero Sport 2016Sis E. NegNo ratings yet

- Manual Operacion y Mantenimiento CUMMINS EngineDocument288 pagesManual Operacion y Mantenimiento CUMMINS EngineKevin GuoNo ratings yet

- Toyota - Hilux - ANCAP SafetyDocument8 pagesToyota - Hilux - ANCAP SafetyValmir AndradeNo ratings yet

- DTC Headlamp Range Adj - ALLDocument3 pagesDTC Headlamp Range Adj - ALLletgoeverythingyoufeartoloseNo ratings yet

- 310E 310SE and 315SE Backhoe Loaders IntroductionDocument5 pages310E 310SE and 315SE Backhoe Loaders Introductionasesores consultoresNo ratings yet

- Dexter Specifications T-30 COMERCIALDocument2 pagesDexter Specifications T-30 COMERCIALmairimsp2003No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Sheer Driving PleasureDocument25 pagesSheer Driving Pleasuremst317No ratings yet

- GM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesDocument55 pagesGM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesBrian NormanNo ratings yet

- Gas Operated ValveDocument2 pagesGas Operated Valvesunflower co-operative housing society ltdNo ratings yet

- SO20669 (Parts Catalogue) : 6CTA8.3-G1Document12 pagesSO20669 (Parts Catalogue) : 6CTA8.3-G1Phyo Aung Kyaw0% (1)

- Adding Turbo To VR6 3.2 QA #3Document10 pagesAdding Turbo To VR6 3.2 QA #3LucasPalombaNo ratings yet

- Description: Rc60F / Rc61F Manual Transmission / Transaxle Manual Transmission System Diagnosis SystemDocument2 pagesDescription: Rc60F / Rc61F Manual Transmission / Transaxle Manual Transmission System Diagnosis SystemEnrique Arevalo LeyvaNo ratings yet

- 920-18 Truck & Trailer Feed Mixer: Assembly, Operation and Parts ManualDocument97 pages920-18 Truck & Trailer Feed Mixer: Assembly, Operation and Parts ManualRoger ObregonNo ratings yet

- Texto 2Document46 pagesTexto 2Erick Gamboa JimenezNo ratings yet

- Rental Catalog: Quality Rental Tools and Equipment - Well Serviced, Priced RightDocument36 pagesRental Catalog: Quality Rental Tools and Equipment - Well Serviced, Priced RightShamshidNo ratings yet