Professional Documents

Culture Documents

Quality Control Three Stages

Quality Control Three Stages

Uploaded by

fouad elferdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Control Three Stages

Quality Control Three Stages

Uploaded by

fouad elferdiCopyright:

Available Formats

Fałkowo 11.12.

2018

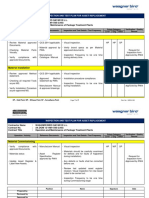

EDER 3 Step Quality Control Process

Supplier

OC/drawing Customer order

confirmation 1

Supplied material

2

New Passed

Complaint

Visual control and

tensile test

1st step of QC -

and return

3 Incoming

Preparation on Quality Control

technical

documentation

Inspection of raw and component

materials from suppliers upon

4 Rejected Passed arrival to make sure your product

Applying quality will not be affected, among

changes others using our Zwick Z010 TN

Documentation check

ProLine testing machine, together

with documentation check.

Utilization/recycling

or assigned for

other application

Rejected Passed

Material and documentation are given

to production

5

Production phase

Final documentation 6

check

produkcja zleconego

wyrobu

2nd step of QC

7

- In-Process

Rejected Passed

kontrola Quality Control

najważniejszych

parametrów podczas IPQC refers to the quality control

produkcji during the production process. It

is very important because you

can detect and handle the

problem that occurs ahead of

time.

Utilization/

Rejected Passed

recycling

Transfer of pre-production and

production documentation to the

product Quality Control department.

8 9

3rd step of QC -

Final control by

Outgoing

Out for

Rejected Quality Control team

member

Passed

delivery Quality

Assurance

OQA is the inspection of products

before shipping. It's a crucial step

in ensuring the shipment is

defect-free.

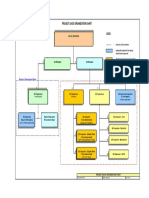

Departments responsible for the individual stages:

1 and 2. Logistics + Sales + Quality control

3 and 4. Quality control

5. Quality control

6 and 7. Production + Quality Control

8. Quality control

9. Logistics

Opracował: Tomasz Kołaczkowski i Mateusz Grzybowski

You might also like

- Process Validation An Essential Process in Pharmaceutical IndustryDocument4 pagesProcess Validation An Essential Process in Pharmaceutical Industryedgar palominoNo ratings yet

- Itp FormatDocument8 pagesItp FormatAhmed KassemNo ratings yet

- QAQC Organization ChartDocument1 pageQAQC Organization Chartteto100% (1)

- Process Validation FDADocument12 pagesProcess Validation FDAkamran alamNo ratings yet

- INSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFDocument3 pagesINSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFmustafaNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Iqoqpq RMG PDFDocument11 pagesIqoqpq RMG PDFsrinivas rNo ratings yet

- 13 Procedure For QADocument8 pages13 Procedure For QASasi Kss100% (1)

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Guiding Principles For Plant Quality - 20140708Document4 pagesGuiding Principles For Plant Quality - 20140708didik dadtNo ratings yet

- Flow Chart of Receiving Operation ProcessDocument1 pageFlow Chart of Receiving Operation ProcessKhawarizmi SuraniNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- As-QMS-014 in Process InspectionDocument8 pagesAs-QMS-014 in Process Inspectiondehamanez100% (1)

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- Process Flow Chart ForDocument9 pagesProcess Flow Chart ForKHUSHBUNo ratings yet

- OBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Document4 pagesOBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Andy RojasNo ratings yet

- Validation and VerificationDocument14 pagesValidation and VerificationpadungekNo ratings yet

- Master Sheet Process Audit Check SheetDocument11 pagesMaster Sheet Process Audit Check SheetRakesh S100% (1)

- 560-S27 QUALITY CONTROL PROGRAM Rev.4Document27 pages560-S27 QUALITY CONTROL PROGRAM Rev.4AbdelmuneimNo ratings yet

- Engineering Process FlowDocument2 pagesEngineering Process FlowNavneesh bansal100% (1)

- Interaction of ProcessesDocument1 pageInteraction of ProcessesBharath100% (1)

- My Turtle DiagramDocument8 pagesMy Turtle DiagramSathyaprakash HsNo ratings yet

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- Process Interaction DiagramDocument1 pageProcess Interaction DiagramPooja SankhlaNo ratings yet

- Prerequisite Validation WorksheetDocument2 pagesPrerequisite Validation WorksheetDulce Zarate100% (3)

- SAP QM Introduction DeckDocument22 pagesSAP QM Introduction DeckVikash RanjanNo ratings yet

- Itp For Site Preparation & Earth WorksDocument17 pagesItp For Site Preparation & Earth WorksDaniel Martinez50% (2)

- Isaca'S Cobit Assessment Programme (Based On COBIT 5)Document33 pagesIsaca'S Cobit Assessment Programme (Based On COBIT 5)Yasmi AfrizalNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Flow Process Chart For Stage InspectionDocument1 pageFlow Process Chart For Stage InspectionEngr Saeed AnwarNo ratings yet

- Halonix Technologies Private Limited Supplier Audit Check SheetDocument1 pageHalonix Technologies Private Limited Supplier Audit Check Sheetatul sachanNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- Flowchart QC-QCDocument13 pagesFlowchart QC-QCDevid Peri Sonefel100% (1)

- Saej 1587 V 003Document225 pagesSaej 1587 V 003JhonnyVillarroelMendietaNo ratings yet

- PreTest ETechDocument3 pagesPreTest ETechAngela D. De LeonNo ratings yet

- Arens Chapter17Document44 pagesArens Chapter17dilla100% (1)

- Strategic Agility in A Changing World 20190418Document12 pagesStrategic Agility in A Changing World 20190418Naveen NirajNo ratings yet

- Introduction To GRAPH DatabaseDocument18 pagesIntroduction To GRAPH DatabaseSantanu GhoshNo ratings yet

- QAQC Monthly Report (April 2022)Document10 pagesQAQC Monthly Report (April 2022)Mohamed FaroukiNo ratings yet

- Fatema Maam PosterDocument1 pageFatema Maam PosterMD Fahad MiajiNo ratings yet

- 836 Flow ChartDocument1 page836 Flow ChartChithralekha AnanthNo ratings yet

- Itp R2Document3 pagesItp R2NIMISHNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- Receiving Inspection: Your Logo HereDocument3 pagesReceiving Inspection: Your Logo Herejohn bothaNo ratings yet

- SOP SRC QC 04 - Material InspectionDocument5 pagesSOP SRC QC 04 - Material InspectionDHANEESH VELLILAPULLINo ratings yet

- PBU PPVC MAS Flowchart New Application RenewalDocument1 pagePBU PPVC MAS Flowchart New Application RenewalNicky LimNo ratings yet

- Quality Control Process Flow: Prepared By: Emmanuel N. DakayDocument9 pagesQuality Control Process Flow: Prepared By: Emmanuel N. DakayEmmanuel DakayNo ratings yet

- QP 74301 Rev 08 Incoming Inspection Procedure ReferenceDocument10 pagesQP 74301 Rev 08 Incoming Inspection Procedure ReferencevinayNo ratings yet

- Pharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Document4 pagesPharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Rona MalagambaNo ratings yet

- SOP-SRC-QC-02 - Calibration of Equipments and Measuring InstrumentsDocument5 pagesSOP-SRC-QC-02 - Calibration of Equipments and Measuring InstrumentsDHANEESH VELLILAPULLINo ratings yet

- A Review On Pharmaceutical ValidationDocument5 pagesA Review On Pharmaceutical Validationabdul335139No ratings yet

- Inspection and Test Plan For Asset ReplacementDocument2 pagesInspection and Test Plan For Asset Replacementshujad77No ratings yet

- Guide How To Test Your Metal Detector enDocument12 pagesGuide How To Test Your Metal Detector enRukhayati RukhaNo ratings yet

- Flow Chart Progress Claim 2Document2 pagesFlow Chart Progress Claim 2Marshall BoazyunusNo ratings yet

- Authorizations: HMIQP-1012 - Product TraceabilityDocument2 pagesAuthorizations: HMIQP-1012 - Product TraceabilityAKNo ratings yet

- Lecture 8 Quality ControlDocument21 pagesLecture 8 Quality Controllight fragranceNo ratings yet

- Incoming Inspection ProceduresDocument9 pagesIncoming Inspection ProceduresvinayNo ratings yet

- ITP ProcedureDocument35 pagesITP ProcedureArif Sameer KhanNo ratings yet

- Contoh Proses Bisnis: Management ProcessDocument2 pagesContoh Proses Bisnis: Management ProcessSilvi KhoNo ratings yet

- Qp-I&t R05 - OkDocument5 pagesQp-I&t R05 - OkFatin NajehahNo ratings yet

- QC слайды по качеству к индонезии вариант 20.07.2012 вечер - engDocument10 pagesQC слайды по качеству к индонезии вариант 20.07.2012 вечер - engAbdul Rapiq PaneNo ratings yet

- Inspection and Test Plan For HVAC SystemDocument14 pagesInspection and Test Plan For HVAC SystemKarthick BellanNo ratings yet

- ProcedureDocument1 pageProcedureSiti SarahNo ratings yet

- Continuous & Continued Process Verification: Presented by Eoin Hanley 4 July, 2016Document39 pagesContinuous & Continued Process Verification: Presented by Eoin Hanley 4 July, 2016surafelNo ratings yet

- Api Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCDocument2 pagesApi Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCRavi TyagiNo ratings yet

- Wipo Ip WK Nbo 16 T 4Document16 pagesWipo Ip WK Nbo 16 T 4fouad elferdiNo ratings yet

- The Quality Control Tools Used ForDocument6 pagesThe Quality Control Tools Used Forfouad elferdiNo ratings yet

- عناصر الاجابةDocument2 pagesعناصر الاجابةfouad elferdiNo ratings yet

- Altrkiz Oalmhalil Alilktrolitia Tshih Slsla Altmarin 2Document7 pagesAltrkiz Oalmhalil Alilktrolitia Tshih Slsla Altmarin 2fouad elferdiNo ratings yet

- Lab 3: Fourier Transform Infrared Spectroscopy (FTIR) : GoalsDocument12 pagesLab 3: Fourier Transform Infrared Spectroscopy (FTIR) : Goalsfouad elferdiNo ratings yet

- Micelles and BilayersDocument3 pagesMicelles and Bilayersfouad elferdiNo ratings yet

- Soap Making - Fact Sheet - 2014 08 22 - enDocument9 pagesSoap Making - Fact Sheet - 2014 08 22 - enfouad elferdiNo ratings yet

- Structure Determination:: Proton 1.00728 U Neutron 1.00866 U Electron 0.00055 UDocument12 pagesStructure Determination:: Proton 1.00728 U Neutron 1.00866 U Electron 0.00055 Ufouad elferdiNo ratings yet

- 3.09 InterpretationDocument10 pages3.09 Interpretationfouad elferdiNo ratings yet

- Manuscript Preparation Checklist: GeneralDocument3 pagesManuscript Preparation Checklist: GeneralALAKOUKONo ratings yet

- Procurement Process Analysis Using Process Mining in Cement Manufacturing Company (Case Study PT. Semen Indonesia Persero, TBK)Document6 pagesProcurement Process Analysis Using Process Mining in Cement Manufacturing Company (Case Study PT. Semen Indonesia Persero, TBK)alma millaniaNo ratings yet

- COMPANY: Jordanian Electric Power Company: Mut'ah University Engineering School Electrical Engineering DepartmentDocument15 pagesCOMPANY: Jordanian Electric Power Company: Mut'ah University Engineering School Electrical Engineering DepartmentAbood QaissyNo ratings yet

- 8 Free Market Research Tools & Resources (2022 Guide) - CrayonDocument20 pages8 Free Market Research Tools & Resources (2022 Guide) - CrayonAamer MohammadNo ratings yet

- HP Indigo 7600 Digital PressDocument4 pagesHP Indigo 7600 Digital PressAlejandro SotoNo ratings yet

- Engineering and Natural Gas (Listening Comprehension)Document4 pagesEngineering and Natural Gas (Listening Comprehension)JUAN ANDRES URBIÑEZ GOMEZNo ratings yet

- STI International Model TargetMaster .45 AutoDocument3 pagesSTI International Model TargetMaster .45 AutoLeonardo CamposNo ratings yet

- Chain and Belt DrivesDocument44 pagesChain and Belt DrivesmanilycanNo ratings yet

- Felices PLC Module ActivityDocument22 pagesFelices PLC Module ActivityRessie FelicesNo ratings yet

- Prospera Tor Database Arhitect DeveloperDocument4 pagesProspera Tor Database Arhitect DeveloperJawaraNo ratings yet

- JSP Lecture NotesDocument12 pagesJSP Lecture NotesminniNo ratings yet

- Elsewedy EgyptDocument7 pagesElsewedy EgyptshenshNo ratings yet

- Designing Controls For The Process Industries 1st Seames Solution ManualDocument6 pagesDesigning Controls For The Process Industries 1st Seames Solution ManualElizabethVancejodf100% (43)

- DSD Lab 8 HandoutDocument9 pagesDSD Lab 8 HandoutMuhammad AnasNo ratings yet

- 53 Rakesh PatilDocument15 pages53 Rakesh PatilRakesh PatilNo ratings yet

- Dmpa - 12 - Unidad Iii - Tercero - Inlges B NS - 2021Document6 pagesDmpa - 12 - Unidad Iii - Tercero - Inlges B NS - 2021Udad ManchegoNo ratings yet

- Lab-1 Web Server Controls and Validation ControlsDocument5 pagesLab-1 Web Server Controls and Validation Controlsshreeya joshiNo ratings yet

- Departemen Obstetri Dan Ginekologi: Fakultas Kedokteran Universitas Sumatera UtaraDocument9 pagesDepartemen Obstetri Dan Ginekologi: Fakultas Kedokteran Universitas Sumatera UtaraYarman War officialNo ratings yet

- Borang Claim Thesis JpaDocument7 pagesBorang Claim Thesis Jpamichelledavisvirginiabeach100% (2)

- General AssignmentDocument2 pagesGeneral AssignmentVishwajeet SatavNo ratings yet

- Esp32 s2 Mini 1 - Esp32 s2 Mini 1u - Datasheet - enDocument30 pagesEsp32 s2 Mini 1 - Esp32 s2 Mini 1u - Datasheet - enAnonymous XgX8kTNo ratings yet

- Introduction To Neuromorphic Computing NewDocument3 pagesIntroduction To Neuromorphic Computing NewTCOC54 Sarthak kakadeNo ratings yet

- AI (FSM, Behavior Tree, GOAP, Utility AI) - Nez Framework DocumentationDocument3 pagesAI (FSM, Behavior Tree, GOAP, Utility AI) - Nez Framework DocumentationAnna J BischoffNo ratings yet

- JX-300XP System OverviewDocument53 pagesJX-300XP System OverviewJehangir Phone0% (1)