Professional Documents

Culture Documents

20) Process For Machine Maintenance.

20) Process For Machine Maintenance.

Uploaded by

Sagar DaundOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20) Process For Machine Maintenance.

20) Process For Machine Maintenance.

Uploaded by

Sagar DaundCopyright:

Available Formats

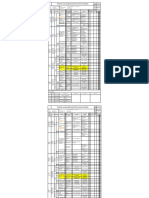

Doc. No.

: REPL/QAP/MNT/01

Process Mapping Orig. Date : 16.01.2015

Rev. No. / Date : 05 / 31.01.2024

Documented Process For Plant Maintainence Page No. 01 of 04

Purpose :- The purpose of this Documented Process is to establish a system for define the method and criteria for Plant Maintenance.

Scope:- To define the method used to maintain production equipments and utilities to achieve the required

out put.

Process Owner :- The overall responsibility of maintaining the effectiveness and implementation of this Documented Process lies

with Maintinance Head

Reference :- IATF Clause No. - 8.5.1 & VSA Clause No. - 10

Document /

Input Reference Activity Flow Output Resp. Control Point

Formats

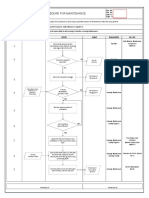

BREAKDOWN MAINTENANCE START Breakdown

Intimation:

Machine Owner ;

Breakdown Receipt of Breakdown Immediately on Machine

Breakdown

Machine Breakdown Intimation Slip REPL/F/MNT/01 Intimation Slip:

Intimation from Receipt of Breakdown slip from concerned department Intimation Slip Breakdown

(REPL/F/MNT/01) Maintenace

Concerned Supervisor

Department

Decision for

Machine Breakdown Ask the operator for machine behaviour before break down Maintenance head,

Inhouse or

Breakdown Intimation Slip REPL/F/MNT/01 Supervisor Within 2 hours

Machine Manual (REPL/F/MNT/01) and Investigation of machine Breakdown Outsorced

Maintenance

Yes

Can be solved in-house?

No

Out sourced Out sourced Outsourced

Call 3rd Party for Breakdown Repair Maintenance Maintenance Maintenance head,

Maintenance Maintenance Agency Within 24 hours

List Agency Agreement Supervisor

Agency List

Breakdown Intimation Maintenance head, In-house Maintenance:

Break Down REPL/F/MNT/02

Machine Manual Slip Supervisor Within 24 hours ;

Skilled Technician List of Spare Parts Analysis the problem Analysis Sheet. Outsourced

Machine spares Machine Manual Maintenance: Within 3

days (max)

Corrective Action

Take Corrective Action in Breakdown Maintenance head,

Root Cause & Hand over Machine to Concerned department Intimation Slip Supervisor

REPL/F/MNT/01

Analysis

Machine Spare Machine Manual In-house Maintenance:

Machine Manual Machine Within 24 hours ;

Breakdown REPL/F/MNT/03 Outsourced

Skilled Technician

Update breakdown details in machine breakdown register Register Maintenance: Within 3

days (max)

Breakdown Slip Breakdown Slip Update the machine history Card & Preventive maintenance Updated Machine REPL/F/MNT/04

Preventive History Card / Maintenance head,

Preventive checksheet if required Revised Preventive

Maintenance Maintenance Check Maintenance Check REPL/F/MNT/05, Supervisor

Check Sheet Sheet 05A, 05B….. Etc. Same of Machine

Sheet

Handover

Monitor Machine Breakdown hours, Calculate MTTR & MTBF

Machine as per Target assigned by Top Management. Action plan to be MTBF/MTTR REPL/F/MNT/06 Maintenance Head 1. M/C Breakdown hrs of

Breakdowns, Machine History Card available hours

Breakdown

Machine Breakdown taken if target not achieved. 2. MTBF

Register

Targets 3. MTTR

Line wise pareto

Machine Breakdown Intimation Do Breakdown Analysis (Pareto Analysis) of repeated & Monthly Root Repeatative

Maintenance Head

Breakdowns Slip Monthly for top 3 Breakdowns area wise of month upto 10th cause Analysis & Breakdowns

of next month and major breakdowns defined in Annexure-A corrective &

REPL/F/MNT/02

at same time. Horizontal diployment of action after 3 months preventive actions

effectiveness check.

Breakdown

intimation: Immediately on Machine

Analysis Report Machine Owner ; Breakdown

Corrective Action Receipt of Breakdown

Update Preventive Maintenance Check sheet on basis slip:

Machine Manual Maintenace Head

of past breakdowns in every 3 months and all

breakdowns to be incorporate &

Aware all Supervisor / Machine operators.

Revised Preventive

REPL/F/MNT/05,

Maintenance

05A, 05B….. Etc.

Corrective actions Monthly MRM Review Check Sheet Maintenance Head Every Month

Review in Monthly MIS

BREAKDOWN MAINTENANCE END

Prepared By - Checked By - Approved By -

Doc. No. : REPL/QAP/MNT/01

Process Mapping Orig. Date : 16.01.2015

Rev. No. / Date : 05 / 31.01.2024

Documented Process For Plant Maintainence Page No. : 02 of 04

Input Reference Activity Flow Output Document / Resp. Control Point

Formats

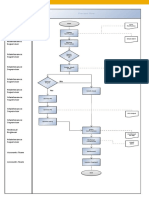

PREVENTIVE MAINTENANCE

START

Criteria to Update Master list :

1. New Machine Acquisition

2. Obsolete Machinery

Machine/ Master List of Removal

Maintain a Master List of Machines / Utility /Equipment & will REPL/F/MNT/07 Maintenance Head

Equipment/ Utility Machines 3. Compliance with

be review on Quaterly basis or any change. Regulations

Check all machines as per check points in daily start Daily Maintenance REPL/F/MNT/08 Maintenance Head Daily

Machine List Machine List

check sheet. Check Sheet

Machine List, Preventive Every 3rd week of Dec. for

Machine List, Prepare Annual Preventive Maintenance Plan. REPL/F/MNT/09 Maintenance Head

Previous year

Previous Year Maintenance next year

Breadowns

Breakdown Trend

Frequency and check points to be as per Machine maker

Annual Plan

(Machine wise) maintenance manual

Maintenance Head

Daily machine Every month 3rd week for

Preventive REPL/F/MNT/09A

maintenance: next month

Preventive Preventive Prepare Monthly Preventive Maintenance Schedule & Maintenance Machine operator

Maintenance Plan Maintenance Plan Circulate to concern Dept. Monthly Schedule

Preventive Conduct Preventive Maintenance based upon PM Check REPL/F/MNT/05, Maintenance Head,

Maintenance Preventive PM Check sheet

Sheet (Machine Wise) 05A, 05B….. Etc. Maint. Supervisor

Schedule Maintenance

Spare Parts List Schedule-

Skilled Technician Spare Parts List-

Skilled Technician

Maintenance Head

Record in PM check sheet Daily machine

Updated PM Check REPL/F/MNT/05, maintenance:

PM Check sheet PM Check sheet (Note condition before and after of PM) Sheet 05A, 05B….. Etc. Machine operator

Preventive Preventive No Preventive

Maintenance Maintenance Abnormlity found ? Request for release of

Maintenance Check REPL/F/MNT/05, Maintenance Head,

Schedule Schedule- Machine one day in

Spare Parts List Spare Parts List- sheet (Machine 05A, 05B….. Etc. Technician

advance

Skilled Technician Skilled Technician Wise)

Plan for correction ( Internal/External)

Updated Machine

History Sheet /

Revised Preventive

Correct the Fault Maintenance Check

Sheet & Machine

breakdown summary

report

Updated Monthly &

Annual

Preventive Preventive Update Preventive Maintenance Schedule & Preventive REPL/F/MNT/09

Maintenance Maintenance Plan Maintenance Maintenance Head Same Day of Actual PM

Schedule Schedule REPL/F/MNT/09A

Schedule

Updated Preventive Updated Preventive

Maintenance Maintenance

Schedule Schedule Update Machine History Card REPL/F/MNT/04

Updated Machine Maintenance Head,

Machine History Machine History Supervisor Same Day of Actual PM

Card Card History Card

Updated Monthly &

Annual

In case PM is not carried out as per Schedule, REPL/F/MNT/09 Maintenance Head,

Preventive

record reason, re-plan & carry out PM. REPL/F/MNT/09A

Machine History Maintenance

Machine History

Card

Card Schedule

Breakdown Trend

PREVENTIVE MAINTENANCE

END

Prepared By - Checked By - Approved By -

Doc. No. : REPL/QAP/MNT/01

Process Mapping Orig. Date : 16.01.2015

Rev. No. / Date : 05 / 31.01.2024

Documented Process For Plant Maintainence Page No. : 03 of 04

Machine List PREDICTIVE MAINTENANCE START

Machine List

Annual Predictive Every 3rd week of Dec.

Previous year REPL/F/MNT/10 Maintenance Head

Previous Year Maintenance Plan for next year

Breakdowns

Breakdown Trend

(Machine wise)

Prepare Annual Predictive Maintenance Plan & Circulate

to all Department Heads

Machine List

Machine List Predictive

Machine Manual

Machine Manual Maintenance Check REPL/F/MNT/11 Maintenance Head, Every 3rd week of Dec.

Previous year

Previous Year sheet (Machine Technician for next year

Breadowns

Breakdown Trend Wise)

(Machine wise)

Prepare or Review Final Predictive Maintenance Check

Sheet (Machine Wise)

Predictive

Predictive

Maintenance Predictive

Maintenance Request for release of

Schedule Maintenance Check REPL/F/MNT/11 Maintenance Head,

Schedule Machine one day in

/ Spare Parts sheet (Machine Supervisor

Spare Parts List advance

List / Skill Wise)

Skilled Technician

Techinican

Updated Monthly &

Predictive Predictive

Request for realeasing Machine one day in advance & Annual

Maintenance Maintenance Carry Out Predictive Maintenance Predictive

REPL/F/MNT/10 Maintenance Head Same Day of Actual PM

REPL/F/MNT/10A

Schedule Schedule Maintenance

Schedule

Updated Monthly Updated Monthly

& Annual & Annual Update Monthly & Annual

Predictive Predictive Predictive Maintenance Schedule

Updated Machine REPL/F/MNT/04 Maintenance Head, Same Day of Actual PM

Maintenance Maintenance

History Card Supervisor

Schedule Schedule

Machine History Machine History

Card Card

Machine History

Machine History Predictive REPL/F/MNT/10A Maintenance Head,

Card

Card maintenance plan Supervisor

Breakdown Trend Update Machine History Card

Minutes of

As per MRM review

MRM Agenda MRM Management REPL/F/QMS/07 Maintenance Head

frequency

Review Meeting

Incase PM is not carried out as per Schedule, record

reason, re-plan & carry out PM.

Review in Monthly MIS/MRM

PREDICTIVE MAINTENANCE END

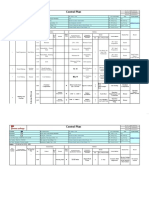

SPARE MANAGEMENT

Machine History List of Key Criteria to define

Machine History

Card

Card Identify Critical Machine Available ? Equipment & REPL/F/MNT/12 Maintenance Head minimum Critical

Breakdown Trend spares Requirement and Critical Spare. Spares :

define min. and max. level. 1. Machine Criticality

2. Failure Frequency

3. Lead time for spare

Procurement

4. Impact of Downtime

5. Supplier REliability

Prepare Indent & send

Issue From Store to purchase

Update in Spare List & Receive Spares & verify Qty

Maintain Min Stock of Sapre & size as per Invoice

Prepared By - Checked By - Approved By -

Doc. No. : REPL/QAP/MNT/01

Process Mapping Orig. Date : 16.01.2015

Rev. No. / Date : 05 / 31.01.2024

Documented Process For Plant Maintainence Page No. : 04 of 04

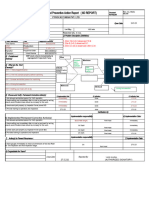

ANNEXURE-A

CRITERIA FOR 5 WHY ANALYSIS OF BREAKDOWNS:

MTTR / Breakdown MTBF/

S.NO Machine description RESP.

Time Repeated.

1 Liebherr Hobbing & Gear Grinding Machine 7 Hours 30 Days Head Maint.

2 ID / OD Grinding machine 5 Hours 30 Days Head Maint.

3 All Shapping,Shaving,Turring Machine 4 Hours 30 Days Head Maint.

4 All Machine Shop 2 Hours 30 Days Head Maint.

5 Utility 3 Hours 30 Days Head Maint.

Documents :-

Sr. No. Document No. Document Name Prepared By Approved By

1 REPL/F/MNT/07 Master List of Machines Machine Maint. (Engineer) HOD Machine Maint.

2 REPL/F/MNT/09 Preventive Maint. Plan for Machine Maint. (Engineer) HOD Machine Maint.

Machines

3 REPL/F/MNT/10A Predictive Maint. Plan Machine Maint. (Engineer) HOD Machine Maint.

Records :-

Sr. No. Record No. Record Name Retention Period

1 REPL/F/MNT/01 Machine Breakdown Slip 2 years

2 REPL/F/MNT/08 Daily Machine Check Sheet 2 years

3 REPL/F/MNT/03 Machine Breakdown Register 2 years

4 REPL/F/MNT/04 Machine History Card Till machine exist plus one calender year

REPL/F/MNT/05,

6 05A,05B,05C,05D,05E,05F,05 Preventive Maint. Check sheet 2 years

G,05H,05I,05J & 05K .. Etc.

7 REPL/F/MNT/06 MTTR & MTBF Sheet 2 years

8 REPL/F/MNT/13

List of Key Equipment & Critical Updated Machine History Sheet / Revised Preventive Maintenance Check Sheet & Machine breakdown

Spare summary report

6 REPL/F/MNT/11 Predictive Maint. Check sheet 2 years

9 REPL/F/MNT/02

Breakdown Analysis Sheet For 2 years

Machines

Rev. No. Revision details Section Rev. Date

0 Initial release - 16.01.2015

1 Updated to incorporate IATF16949:2016 requirement - 26.12.2017

2 Specification & method of checking with responsibility 5.1 07.01.2023

3 Lesson learnt by the personnel during breakdown analysis is added in the preventive

5.1 10.03.2023

maintenance check sheet.

4 Improve Effectiveness of Maintenace & Document Control No. Change - 12.12.2023

5 Criteria to be Master List of Machine and Critical Spare list defined - 31.01.2024

Prepared By - Checked By - Approved By -

You might also like

- Roadside Design Guide 4th Edition PDFDocument345 pagesRoadside Design Guide 4th Edition PDFbrunoelageNo ratings yet

- Sap PMDocument48 pagesSap PMRehan KhanNo ratings yet

- Abnormality Handling - R2Document4 pagesAbnormality Handling - R2Sagar Daund100% (5)

- Standard Operating ProceduresDocument25 pagesStandard Operating ProceduresgupsseeNo ratings yet

- Standard Operating Procedure For Engineering Breakdown MaintenanceDocument2 pagesStandard Operating Procedure For Engineering Breakdown MaintenanceMdrahaman Mithu100% (2)

- 022-SOP For Emergency Repair and MaintenanceDocument3 pages022-SOP For Emergency Repair and MaintenanceNoorzaman Afridi NoorNo ratings yet

- C++ Interview Questions All Together by CMKDocument176 pagesC++ Interview Questions All Together by CMKMohan Krishna100% (1)

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceAnmol ChetriNo ratings yet

- Repair and Maintenance ProcedureDocument5 pagesRepair and Maintenance Proceduremacky PanuelosNo ratings yet

- SOP - MT - 01 MaintenanceDocument2 pagesSOP - MT - 01 MaintenanceHarits As SiddiqNo ratings yet

- Punyam Manufacturing INC: EngineeringDocument4 pagesPunyam Manufacturing INC: EngineeringMAYMODERN STEELNo ratings yet

- General Maintenance: Who Will Do? Process FlowDocument7 pagesGeneral Maintenance: Who Will Do? Process FlowSameer BagalkotNo ratings yet

- Breakdown Analysis SystemDocument13 pagesBreakdown Analysis Systemsherif mahmoudNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Ntegrated Ean Igma: Maintenance ConceptsDocument26 pagesNtegrated Ean Igma: Maintenance Conceptsjeanfelipesantos100% (1)

- 1.1 SMP For Mechanical Maintance of AirtubeDocument2 pages1.1 SMP For Mechanical Maintance of AirtubePRANAV KUMAR GAUTAMNo ratings yet

- Checkpont of Tyre Building ORPDocument3 pagesCheckpont of Tyre Building ORPDilnesa EjiguNo ratings yet

- PPC Types of MaintenanceDocument4 pagesPPC Types of MaintenanceRajesh RoutrayNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- Inspection at 150 Flight HoursDocument4 pagesInspection at 150 Flight HoursSiswadiNo ratings yet

- Self Assessment Sheet by VendorDocument60 pagesSelf Assessment Sheet by VendorAjayNo ratings yet

- QP MNT 01 Maintanance of Plant & Machinery NewDocument5 pagesQP MNT 01 Maintanance of Plant & Machinery NewMASU BRAKE PADS QANo ratings yet

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatNo ratings yet

- (F-PR-10) Contingency PlanDocument3 pages(F-PR-10) Contingency PlanshalinmishraNo ratings yet

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Standard Operating Procedure MaintenanceDocument6 pagesStandard Operating Procedure MaintenancePADCL100% (1)

- R&D - Oi - 01 - Fmea P1Document7 pagesR&D - Oi - 01 - Fmea P1Abhinav SinghNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Cm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)Document3 pagesCm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)ali morisyNo ratings yet

- Why Plant Maintenance (Also Known As EAM)Document12 pagesWhy Plant Maintenance (Also Known As EAM)RobinReddy100% (1)

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatNo ratings yet

- Job Description: StellenbeschreibungDocument5 pagesJob Description: StellenbeschreibungMireya RochaNo ratings yet

- Standard Operating Procedure: Record of RevisionDocument6 pagesStandard Operating Procedure: Record of RevisionEldhose PaulNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging UnitDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging Unitjp mishraNo ratings yet

- Centurion Power Cables (P) LTD.: MaintenanceDocument3 pagesCenturion Power Cables (P) LTD.: MaintenancetriveshNo ratings yet

- Maintenance Order FormDocument2 pagesMaintenance Order FormErBikasKumarPathakNo ratings yet

- MR 08 Contingency PlanDocument11 pagesMR 08 Contingency PlanManoj KaushikNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Total Productive Maintenance (TPM)Document14 pagesTotal Productive Maintenance (TPM)Muhammad IrfanNo ratings yet

- Whousekeeping SOPDocument3 pagesWhousekeeping SOPMohamed SelimNo ratings yet

- Cm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)Document1 pageCm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)ali morisyNo ratings yet

- FRM - 004 - WIMS - Machine Guarding Survey (Approved)Document14 pagesFRM - 004 - WIMS - Machine Guarding Survey (Approved)heikal hajazieNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- PM F 13 OvefDocument1 pagePM F 13 Ovefjp mishraNo ratings yet

- Work Instruction For Handling Abnormal Situations: Impact On Product Impact-ProcessDocument1 pageWork Instruction For Handling Abnormal Situations: Impact On Product Impact-Processhow2belive100% (2)

- 1.0 Breakdown Analysis SummaryDocument7 pages1.0 Breakdown Analysis Summarysherif mahmoudNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- Cm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)Document1 pageCm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)ali morisyNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil SystemDocument2 pagesChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil Systemjp mishraNo ratings yet

- Abnormal Handling RuleDocument1 pageAbnormal Handling RuleSuraj RawatNo ratings yet

- Check Point For MixerDocument1 pageCheck Point For MixerDilnesa EjiguNo ratings yet

- Procedure System of Safe Lifting For Material, Plant and EquipmentDocument57 pagesProcedure System of Safe Lifting For Material, Plant and EquipmentImtiyaz AkhtarNo ratings yet

- Part One (1&2) Introduction & Damages-1Document93 pagesPart One (1&2) Introduction & Damages-1leakebelaysmNo ratings yet

- FMEA Template - Road To ReliabilityDocument27 pagesFMEA Template - Road To ReliabilityVinicius Ucelli100% (2)

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- ACI PRMIO PLASTIC Maintenance Dept Presentation On Performance Meeting-April21Document38 pagesACI PRMIO PLASTIC Maintenance Dept Presentation On Performance Meeting-April21Samir Ahmed ShimulNo ratings yet

- Cm-Elec - (01 To 01) - Send To MGPS at (01-01-2021)Document1 pageCm-Elec - (01 To 01) - Send To MGPS at (01-01-2021)Ali AlmorisyNo ratings yet

- Iso 9001Document27 pagesIso 9001Sagar DaundNo ratings yet

- Documented Process For Customer Complaints HandlingDocument2 pagesDocumented Process For Customer Complaints HandlingSagar DaundNo ratings yet

- A) Social and Psychological Work EnvironmentDocument4 pagesA) Social and Psychological Work EnvironmentSagar DaundNo ratings yet

- Safety: A) Machine Safety SystemDocument5 pagesSafety: A) Machine Safety SystemSagar DaundNo ratings yet

- Breakdown and Preventive MaintainanceDocument3 pagesBreakdown and Preventive MaintainanceSagar DaundNo ratings yet

- Management ReviewDocument2 pagesManagement ReviewSagar Daund100% (1)

- Internal AuditDocument3 pagesInternal AuditSagar DaundNo ratings yet

- Product Sheet AnchorsDocument2 pagesProduct Sheet AnchorsRobert FlateråsNo ratings yet

- Atlanna FinalDocument3 pagesAtlanna FinalprojectmasternigNo ratings yet

- 1990 ECM WiringDocument8 pages1990 ECM WiringHenry Garro MoraNo ratings yet

- D&D Hardware-Door Closer UL-R40717Document2 pagesD&D Hardware-Door Closer UL-R40717FernandoSanfigNo ratings yet

- Detection of Seepage Patterns Direction in The Bajulmati Dam, Banyuwangi, Indonesia Using Geoelectrical Method, Schlumberger and Dipole Dipole ConfigurationDocument4 pagesDetection of Seepage Patterns Direction in The Bajulmati Dam, Banyuwangi, Indonesia Using Geoelectrical Method, Schlumberger and Dipole Dipole ConfigurationAgim DjuhaepaNo ratings yet

- SAP SOlution ManagerDocument67 pagesSAP SOlution ManagervyomakeshNo ratings yet

- EDALAT NOBARZAD Amir KeyvanDocument149 pagesEDALAT NOBARZAD Amir KeyvanGaetanoD'AloiaNo ratings yet

- Hyponic Full Catalog WEBDocument144 pagesHyponic Full Catalog WEBIsidro Pale CordobaNo ratings yet

- Sample Java Interview QuestionsDocument433 pagesSample Java Interview QuestionstyredofNo ratings yet

- Bucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPDocument10 pagesBucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPFuad JahićNo ratings yet

- Jet Ø160mm TC-0005-BLA: Downlight IP54 Jet Ø160mm LED 17.8W 4000K Blanco 1667lmDocument16 pagesJet Ø160mm TC-0005-BLA: Downlight IP54 Jet Ø160mm LED 17.8W 4000K Blanco 1667lmPatricia AscaNo ratings yet

- Chemistryproject On Alloy Extraction Class 12Document17 pagesChemistryproject On Alloy Extraction Class 12Shobhit VarshneyNo ratings yet

- Science Reviewer: Concepts of Motion - An Object Is Said in Motion If It ChangesDocument3 pagesScience Reviewer: Concepts of Motion - An Object Is Said in Motion If It ChangesDark3126 Tower1008No ratings yet

- PB Series-V2 - NoDocument20 pagesPB Series-V2 - Nonegar adelniaNo ratings yet

- SadfsdafDocument5 pagesSadfsdafAjeet RajpootNo ratings yet

- 13behavior of Soils Strengthened by Plastic Waste MaterialsDocument13 pages13behavior of Soils Strengthened by Plastic Waste MaterialsasdfghjkNo ratings yet

- 2 - SNG Group Equip & ServicesDocument16 pages2 - SNG Group Equip & Servicesadeelsiddiquepso100% (1)

- TS PGECET Environmental Management Syllabus & Exam PatternDocument1 pageTS PGECET Environmental Management Syllabus & Exam PatternpavaniNo ratings yet

- Injection Cheat Sheet Non SQLDocument1 pageInjection Cheat Sheet Non SQLKahJin MartinezNo ratings yet

- Cbrplus Safety Data SheetDocument4 pagesCbrplus Safety Data SheetbzanahNo ratings yet

- Chapter 05Document49 pagesChapter 05HassanKMNo ratings yet

- Project: Location: By: Date: Chk. By: Date: Clear Data Entry CellsDocument1 pageProject: Location: By: Date: Chk. By: Date: Clear Data Entry Cellsblackk7No ratings yet

- A Scalable Verification Solution For BlockchainsDocument50 pagesA Scalable Verification Solution For BlockchainsJosé IgnacioNo ratings yet

- Drainage Calculations - MaDocument17 pagesDrainage Calculations - MaMarianaNo ratings yet

- DP Operation and DP ModesDocument13 pagesDP Operation and DP Modesnancy domimguez moralesNo ratings yet

- Determination of Seismic Bearing Capacity of Shallow Strip Footings On SlopesDocument10 pagesDetermination of Seismic Bearing Capacity of Shallow Strip Footings On SlopesboyzesNo ratings yet