Professional Documents

Culture Documents

Capa 8D

Uploaded by

Vinod Kumar SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capa 8D

Uploaded by

Vinod Kumar SharmaCopyright:

Available Formats

Rev. no./Date.

PIPL Corrective and Preventive Action Report ( 8D REPORT) Document

No:F/QC/05 00/00

PYROCAST INDIA PVT. LTD

1.Concern title Dimensional NG in Foot Peg Rider Open Date: 24.5.23

Customer Name: Premier Plasmotec pvt.ltd

Machine Name: VMC Lot Qty,- 1620 sets

Part Name Foot peg rider Rejected Qty. 4 nos.

Part No.: VX111020/30 2) Problem Description (Definition):

Team Members Title Telephone Number 1. Dim.19.2+0.2 observed 19.6

Vinod Sharma Quality 8053203378 2. Dia 8.2+0.2 observed 8.1

Ombir Production 3. Dim.5.3 ±0.2 observed 4.89~5.34

Parveen Quality 8708271751

Randhir Programmer/Setter 9643369402

Champion : Vinod Sharma 8053203378

3) Containment WIP stock check immediately &

segregated if rejected if any. Man

Action(s)

choosed Machine

semi

skilled

4) What are the Root operator

Cause(s)? Part not VMC

clamped programm

WHY-1 VMC programme error properly before

m/cing e error

WHY-2 Part not clamped properly before machining Causing Dimensional

error

WHY-3 choose semiskilled person for machining

WHY-4 Wrong tool selection

Material

Method

WHY-5 Setting pcs mixed with ok qty Wrong tool selection

5) Choose and Verify Permanent Corrective Action(s): 5) Implementation Date: 5) Verification: 5) Verification Date:

1.Not allowed semiskilled person for VMC operation immediately Done 27.5.23

2.check setting pcs immediately after m/c set up and sent to red tag

area to avoid mixation,there should be no delay for this work. immediately Done 27.5.23

3.check each part properly by inspector if ever power B/D immediately Done 27.5.232

4.Provide training to operators and inspectors 27.5.23 done 27.5.23

Verification By:

Implementation responsibility 6) Implementation Date:

6) Implemented Permanent Corrective Action(s)

1.Not allowed semiskilled person for VMC operation Head VMC Deptt. Plant head immediately

2.check setting pcs immediately after m/c set up and sent to red tag

area to avoid mixation,there should be no delay for this work. QC Deptt immediately

Plant head

3.Check each part properly by inspector if ever power B/D QC Deptt Plant head immediately

4.Provided training to operators and inspectors QA Deptt. Plant head 27.5.23

Implementation responsibility

7) Action(s) to Prevent Recurrence : 7) Implementation Date:

4.Make gauges immediately to check all dimensions of foot rest Rider

QA 27.5.23

for line inspection and final inspection stage. Plant Head

8) Congratulate the Team!!

Close Date: Reported By: VINOD SHARMA

27.5.232 (AUTHORIZED SIGNATORY)

Format No.- F/HRD/05

PYROCAST INDIA

PVT LTD TRAINING SHEET Rev. No.- 00

Eff. Dt.- 20.10.2017

TRAINING SUBJECT :- Dimensional NG Date:27.5.2023

FACULTY/ TRAINER:- Vinod Sharma

VENUE:- Conference room

Cusomer complaint received for Part name: Foot Rest Rider, Customer

Training Agenda

Name: Premier plastomotec Pvt.Ltd.

OBJECTIVE OF THE TRAINING IS :- Zero Rejection at the customer end

S.NO TRAINING /INSTRUCTION DETAILS REMARKS

Not allowed semiskilled person for VMC operation

1

check each part properly by inspector if ever power B/D

2

Every operator needs that if any part is found defective, do not give it the next

3 operation and put it in the rework or rejected bin.or give to supervisor.

4 Every person strictly use red bin/yellow bin and blue bin as per requirement

5 Rejected parts immediately move to red Tag Area for further action,Do not delay at any

cost, because by this mistake of ours the part can go further to the customer.So be careful

6

Each packer needs aware while packing, no one rejected piece be pack

.check setting pcs immediately after m/c set up and sent to red tag

7 area to avoid mixation,there should be no delay for this work.

8 Use Gauges at all operation on VMC machine.

Trainees Name and Designation

EVALUATIO

NAME DEPARTMENT Designation

N RESULT

1 Naveen Quality Engineer OK

2 Parveen Quality Engineer OK

3 Sonu Quality Engineer OK

4 Ankit Final inspection Viewer OK

5 Divya Final inspection Viewer OK

6 Kiran Final inspection Viewer OK

7 Ombir Production M/C shop Prod.Engineer OK

8 Arun Production VMC Operator OK

9 Sanjay Production VMC Operator OK

10 Sunny Production VMC Operator OK

11 Sohan Production VMC Operator OK

12 sarvan Packing VMC Operator OK

13 Veeru Packing VMC Operator OK

14 Jagdish Packing VMC Operator OK

Prepared By: Approved By:

You might also like

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- Trimming Machine WiDocument2 pagesTrimming Machine WiraghbirNo ratings yet

- Cm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- Cm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)Document3 pagesCm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)ali morisyNo ratings yet

- Cm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)Document2 pagesCm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)ali morisyNo ratings yet

- Problem Solving Report Tata Motors LTD Pantnagar Works: % EffectDocument2 pagesProblem Solving Report Tata Motors LTD Pantnagar Works: % EffectAbhinashNo ratings yet

- Anant SPG MOM 7-08-18Document4 pagesAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- Tag No.: Asset Id: Machine Name: Area: TanggalDocument8 pagesTag No.: Asset Id: Machine Name: Area: TanggaldioNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- CAPA Incomplete Part MixDocument16 pagesCAPA Incomplete Part MixRohtash fastnerNo ratings yet

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- BHT - Technical Publications 1 MDocument1 pageBHT - Technical Publications 1 Mmarcelo juniorNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Cm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- S200 Acifm MNT 30 RPT XXXXXXX 04126Document3 pagesS200 Acifm MNT 30 RPT XXXXXXX 04126fayasibrahimkuttyNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- FORM-HSE-001-028 Checklist Forklift - Id.enDocument6 pagesFORM-HSE-001-028 Checklist Forklift - Id.enroni jasonNo ratings yet

- S200-ACIFM-MNT-30-RPT-XXXXXXX-01975 ## RevisedDocument4 pagesS200-ACIFM-MNT-30-RPT-XXXXXXX-01975 ## RevisedfayasibrahimkuttyNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- Cm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)Document1 pageCm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)ali morisyNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- Pto - Threading Machine Rev 2Document3 pagesPto - Threading Machine Rev 2grantNo ratings yet

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- BEMS-MP-06 OHS Monitoring and Measurement PlanDocument13 pagesBEMS-MP-06 OHS Monitoring and Measurement PlanrememberNo ratings yet

- Wi Opr-E020 Sub-Station System Works (Edit 2)Document13 pagesWi Opr-E020 Sub-Station System Works (Edit 2)Yusuf AlfathonyNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- S200 Acifm MNT 30 RPT XXXXXXX 04132Document3 pagesS200 Acifm MNT 30 RPT XXXXXXX 04132fayasibrahimkuttyNo ratings yet

- DAPA FormatDocument13 pagesDAPA FormatTezender singhNo ratings yet

- Nternet Protocol Based CCTV CameraDocument1 pageNternet Protocol Based CCTV CameraJason SalazarNo ratings yet

- Cm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)Document1 pageCm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)ali morisyNo ratings yet

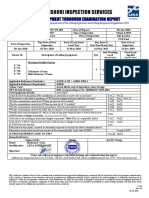

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

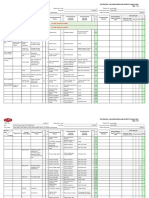

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- Vendor System Audit Check SheetDocument6 pagesVendor System Audit Check SheetOm Prakash - AIPL(QC)No ratings yet

- Semi-Annual Report Jul-Dec 2009Document6 pagesSemi-Annual Report Jul-Dec 2009Robert Ulatan93% (45)

- EMR Installing PV-380-R3 - AHDocument3 pagesEMR Installing PV-380-R3 - AHahmed nourNo ratings yet

- Taws Recieving SotreDocument5 pagesTaws Recieving SotresahilNo ratings yet

- Application For Waiver of Pressure Test: Appendix 2Document1 pageApplication For Waiver of Pressure Test: Appendix 2Natarajan MurugesanNo ratings yet

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNo ratings yet

- 9 - Maintain Load TestDocument1 page9 - Maintain Load TestRafee Pie100% (1)

- Cm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)Document1 pageCm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)ali morisyNo ratings yet

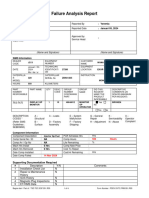

- Failure Analysis Report format-RKU-28.05.20Document3 pagesFailure Analysis Report format-RKU-28.05.20Asim GhoshNo ratings yet

- 63204b31518a9 WEB 3.0 CASE CHAIN ROUND 2Document14 pages63204b31518a9 WEB 3.0 CASE CHAIN ROUND 2Shinde Chaitanya Sharad C-DOT 5688No ratings yet

- Console Upper at LHD Wrong MarkingDocument4 pagesConsole Upper at LHD Wrong MarkingubraghuNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocument4 pagesEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNo ratings yet

- Control Plan Ingersol RandDocument2 pagesControl Plan Ingersol Randrgrao85No ratings yet

- Transformer 3Document77 pagesTransformer 3Abhinav TewariNo ratings yet

- Field Service GEN-SETSDocument6 pagesField Service GEN-SETSJoeNo ratings yet

- Supplier Problem Response Report Unpressed IssueDocument1 pageSupplier Problem Response Report Unpressed IssueKuldeep SinghNo ratings yet

- Specification: Commissioning - Transitioning Assets Into OperationDocument77 pagesSpecification: Commissioning - Transitioning Assets Into OperationAmda AmdaNo ratings yet

- Hazard Study 4 - Compress AirDocument12 pagesHazard Study 4 - Compress AirSaran rasayaNo ratings yet

- Semi Annual Report Jul Dec 2009Document5 pagesSemi Annual Report Jul Dec 2009Mykka ArtillagaNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Project Planner of Dalog Monitoring SystemDocument42 pagesProject Planner of Dalog Monitoring SystemSUNIL TVNo ratings yet

- Name of The Factory: Quality ControlDocument4 pagesName of The Factory: Quality ControlTutunNo ratings yet

- Technical Service Bulletin: Troubleshooting Other Service Job Knowledge Sharing SubjectDocument3 pagesTechnical Service Bulletin: Troubleshooting Other Service Job Knowledge Sharing SubjectKhincho ayeNo ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- 003 Arch3Document1 page003 Arch3kingjam dimacaling2019No ratings yet

- Ee3tr4 Lab 3Document3 pagesEe3tr4 Lab 3RezaNo ratings yet

- Homotopy Analysis Laplace Transform Method For Analytical Solution of Porous Medium EquationDocument6 pagesHomotopy Analysis Laplace Transform Method For Analytical Solution of Porous Medium EquationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- PrintUnit 2 ThroughputLogDocument2 pagesPrintUnit 2 ThroughputLogErick GómezNo ratings yet

- En 2Document558 pagesEn 2suhaasNo ratings yet

- Precalculus Note Sequence SeriesDocument4 pagesPrecalculus Note Sequence Series01bourgeoisie 040104No ratings yet

- AvntDocument5 pagesAvntDeekshith YennamNo ratings yet

- BEST OF ATD at 75Document39 pagesBEST OF ATD at 75VMIN PARKIMNo ratings yet

- Service Manual: Part No. 780005 (Rev. E)Document16 pagesService Manual: Part No. 780005 (Rev. E)Tony KututoNo ratings yet

- Stair Case PressurizationDocument2 pagesStair Case PressurizationMohammed Hassan Mohiuddin Khan100% (2)

- Prachi Patil SAP-Azure ArchitectDocument2 pagesPrachi Patil SAP-Azure ArchitectprachiNo ratings yet

- GDC 800H Handset Eng User GuideDocument35 pagesGDC 800H Handset Eng User Guideadyta_roNo ratings yet

- Lea-Self-Reflection-Tool 1Document15 pagesLea-Self-Reflection-Tool 1api-302339207No ratings yet

- Computer Link 4 Las Quarter 2 Week 1Document11 pagesComputer Link 4 Las Quarter 2 Week 1MARJUN BARTOLONo ratings yet

- Manual ING SHJ 7005Document59 pagesManual ING SHJ 7005ricardo assaf marchetiNo ratings yet

- Redken Shades EQ Color Chart 02 PDFDocument28 pagesRedken Shades EQ Color Chart 02 PDFHailey MarieNo ratings yet

- Catalogue of ShunliDocument18 pagesCatalogue of Shunliange_cNo ratings yet

- ACI Remote Leaf Fabric Discovery v1.0 PDFDocument24 pagesACI Remote Leaf Fabric Discovery v1.0 PDFdelplayNo ratings yet

- PDF 20221018 001855 0000Document12 pagesPDF 20221018 001855 0000Tanvi JainNo ratings yet

- Electrical Power and Energy Systems: Browh Serge Tekpeti, Xiaoning Kang, Xinghua HuangDocument14 pagesElectrical Power and Energy Systems: Browh Serge Tekpeti, Xiaoning Kang, Xinghua HuangashishNo ratings yet

- Bachelor Thesis Ideas Computer ScienceDocument6 pagesBachelor Thesis Ideas Computer Sciencedwt65fcw100% (2)

- Bizmanualz AS9100 Rev C Policies and Procedures SampleDocument8 pagesBizmanualz AS9100 Rev C Policies and Procedures SampleHoang TanNo ratings yet

- Architectural 3D Modeling in Historical PDFDocument10 pagesArchitectural 3D Modeling in Historical PDFThoraya SajidNo ratings yet

- N9000B CXA X-Series Signal Analyzer, Multi-TouchDocument16 pagesN9000B CXA X-Series Signal Analyzer, Multi-TouchhungntNo ratings yet

- Pronunciation NEWDocument7 pagesPronunciation NEWTrần Minh ThànhNo ratings yet

- Chapter 5 - The Expenditure Cycle Purchasing To Cash DisbursementsDocument3 pagesChapter 5 - The Expenditure Cycle Purchasing To Cash DisbursementsHads LunaNo ratings yet

- Topic Wise Bundle PDF Course 2022 - Quantitative Aptitude Ages Set-1Document5 pagesTopic Wise Bundle PDF Course 2022 - Quantitative Aptitude Ages Set-1bala15876No ratings yet

- Comparison of Noise Calculation Methods of Air ConDocument8 pagesComparison of Noise Calculation Methods of Air ConweporNo ratings yet

- Write An Essay (At Least 300 Words) About Your Experiences and Learnings in Math 100Document2 pagesWrite An Essay (At Least 300 Words) About Your Experiences and Learnings in Math 100Christian Shane BejeranoNo ratings yet

- Cambridge O Level: Second Language Urdu 3248/01Document8 pagesCambridge O Level: Second Language Urdu 3248/01cima2k15No ratings yet